Table of Contents

Advertisement

Quick Links

This manual contains reserved and proprietary information. All rights are reserved. It may

not be copied, disclosed or used for any purposes not expressly authorized by PrimoPal

Motor.

PrimoPal Motor reserves the right to make changes without further notice to any products

for improving reliability, function or design.

This manual is intended for skilled technical staff. In case the arguments, the terms and the

concepts should not be clear you can contact PrimoPal Motor. It is forbidden to use the

products herein described without being sure to have understood characteristics, installation

and use procedures.

Even though products described have been designed with extreme care, they are not

intended or authorized for use as components in applications intended to support or sustain

life and in application where the failure of the product could create a situation where physical

injury may occur to lives.

PrimoPal Motor will not be liable for any direct or indirect damages coming from the use of

its products.

The content in this manual has been carefully checked and is believed to be accurate, but

no responsibility is assumed for inaccuracies. Any suggestion to improve it will be highly

appreciated.

PST5056

Stepper Motor Drive

User's Manual

Version 1.0

Advertisement

Table of Contents

Summary of Contents for PrimoPal PST5056

- Page 1 PrimoPal Motor will not be liable for any direct or indirect damages coming from the use of its products.

- Page 2 Table of Contents Table of Contents Table of Contents 8. Wiring Notes......................10 9. Typical Connections ....................11 1. Introduction, Features and Applications ..............1 10. Sequence Chart of Control Signals ................ 11 1.1 Introduction ..................... 1 11.

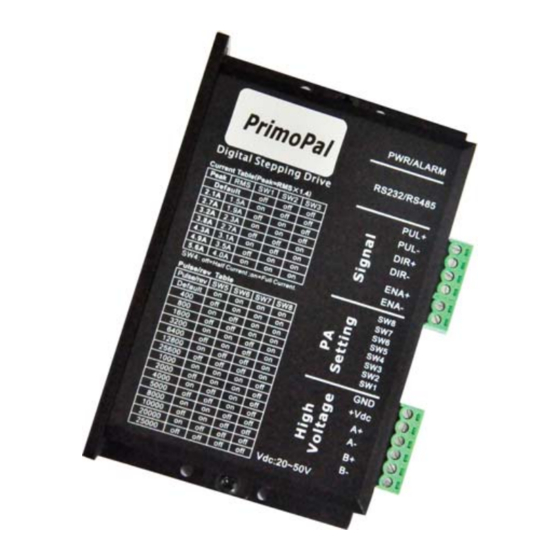

- Page 3 2. Specifications 1.1 Introduction 2.1 Electrical Specifications (T 25°C) The PST5056 is a versatility fully digital stepping driver based on a DSP with advanced PST5056 Parameters control algorithm. The PST5056 is the next generation of digital stepping motor controls. It...

-

Page 4: Pin Assignment And Description

PST5056 User Manual 2.3 Operating Environment and other Specifications 3.2 Selecting Active Pulse Edge and Control Signal Mode The PST5056 supports PUL/DIR and CW/CCW modes and pulse actives at rising or falling Cooling Natural Cooling or Forced cooling edge. See more information about these settings in Section 10. Default setting is PUL/DIR... -

Page 5: Connecting The Motor

This configuration is also referred to as full copper. In full The stepper drive PST5056 can drive any 2-pahse and 4-pahse hybrid stepping motors. coil mode, the motors should be run at only 70% of their rated current to prevent overheating. -

Page 6: Power Supply Selection

Figure 8: 8-lead motor parallel connections 6. Power Supply Selection The stepper drive PST5056 can match medium and small size stepping motors (from NEMA 7.1 Microstep Resolution Selection size 17 to 34). To achieve good driving performances, it is important to select supply voltage and output current properly. -

Page 7: Wiring Notes

25000 the last pulse. Theoretically, this will reduce motor heating to 36% (due to P=I *R) of the original value. If the application needs a different standstill current, please contact PrimoPal. 7.2 Current Settings 8. Wiring Notes For a given motor, higher driver current will make the motor to output more torque, but at the ... -

Page 8: Typical Connections

(pulse generator). A typical connection is shown as figure 9. 11. Protection Functions To improve reliability, the driver incorporates some built-in protection functions. The PST5056 uses one RED LED to indicate what protection has been activated. The periodic time of RED is 3 s (seconds), and how many times the RED turns on indicates what protection has been activated. -

Page 9: Protection Indications

Motor phases may be connected in reverse direction In the event that your stepper drive PST5056 doesn’t operate properly, the first step is to DIP switch current setting is wrong identify whether the problem is electrical or mechanical in nature. The next step is to isolate The driver in fault the system component that is causing the problem. -

Page 10: Warranty

PrimoPal Motor Co., Ltd. warrants its products against defects in materials and workmanship for a period of 12 months from shipment out of factory. During the warranty period, PrimoPal Motor will either, at its option, repair or replace products which proved to be defective.

Need help?

Do you have a question about the PST5056 and is the answer not in the manual?

Questions and answers