Table of Contents

Advertisement

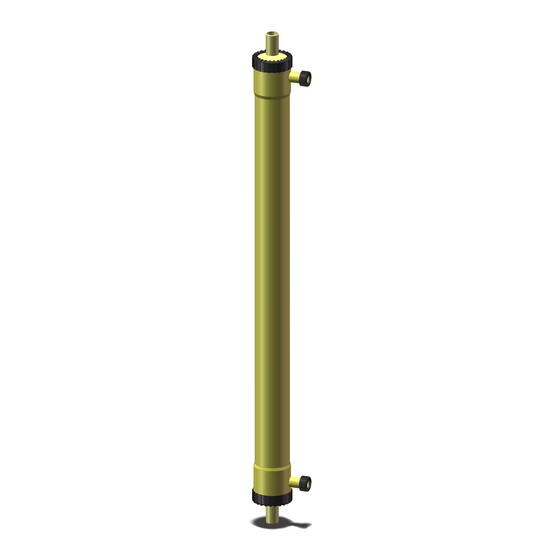

Water Treatment Membrane Module

TM

MICROZA

UNA Series

OPERATING INSTRUCTIONS

Caution

To ensure safe and proper use of the module, carefully read these Operating Instructions and

adhere to all of the safety instructions herein.

Keep the Operating Instructions in a convenient location for consultation.

Asahi Kasei agrees not to assert its own right under its patented invention about method for

use of the membrane module(s) against the end-user of membrane module(s) manufactured by

Asahi Kasei only to the extent necessary to use such module(s).

18Z03K

Advertisement

Table of Contents

Summary of Contents for AsahiKASEI MICROZA UNA Series

- Page 1 Water Treatment Membrane Module MICROZA UNA Series OPERATING INSTRUCTIONS Caution To ensure safe and proper use of the module, carefully read these Operating Instructions and adhere to all of the safety instructions herein. Keep the Operating Instructions in a convenient location for consultation. Asahi Kasei agrees not to assert its own right under its patented invention about method for use of the membrane module(s) against the end-user of membrane module(s) manufactured by Asahi Kasei only to the extent necessary to use such module(s).

- Page 2 PREFACE Allow us to begin by expressing our appreciation for your adoption of our Microza UNA series module. These Operating Instructions explain the installation of the module and discuss the treatment and operation precautions to be observed. To ensure safe and proper use of the module, carefully read and adhere to all of the safety instructions therein.

-

Page 3: Table Of Contents

CONTENTS 1. SAFETY INSTRUCTIONS ........................4 2. Spec ............................... 7 2.1 Module Standard Specification ..................... 7 2.2 Module and Parts Shipped as Standard ..................8 2.3 Module Connection ........................9 2.3.1 List of Module Connection Parts ..................9 2.3.2 Module Connection Types and Required Parts .............. 10 2.3.3 Connection of Module Upper Part ................... - Page 4 7.2.1 Pretreatment ........................47 7.2.2 Filtration Process ......................47 7.2.3 Pressure on the Permeate (Treated Water) Side............49 7.2.4 Simultaneous Air Scrubbing/Reverse Filtration (AS/BW) ..........50 8. MEMBRANE INTEGRITY TEST AND REPAIR ................... 54 8.1 Pressure Hold Test (PDT) ......................55 8.2 Air Leak Test ..........................

-

Page 5: Safety Instructions

1. SAFETY INSTRUCTIONS Adhere to the Notes in these Operating Instructions when using the module to ensure correct and safe operation. Asahi Kasei shall not be held liable for injuries, losses, or consequential damages caused by non-adherence to these Operating Instructions. The Safety Notes and warning labels in these instructions are classified as follows. - Page 6 Safety Symbol Legend There are three types of signals in these Operating Instructions. WARNING or CAUTION. NO or DO NOT. MUST DO.

- Page 7 Safety Guidelines Warning When handling hazardous chemicals, always wear protectors such as safety goggles and rubber gloves. The chemicals include, but are not limited to, sodium hypochlorite and sodium hydroxide. If the solution comes in contact with eyes or skin, immediately rinse thoroughly with water.

-

Page 8: Spec

2. Spec 2.1 Module Standard Specification Item UNA-600A UNA-660A UNA-620A Membrane Material High-bonding network structured polyvinylidene fluoride Effective membrane area (outer surface (m Performance Nominal pore size (micro meter) Use Conditions Max. feed pressure (kPa) 300 * 300 * 300 * Max. -

Page 9: Module And Parts Shipped As Standard

2.2 Module and Parts Shipped as Standard Permeate Outlet Discharge Outlet Label indicating retentate outlet Label Module Housing Alarming Label (Japanese) (English) Label indicating feed water inlet Feed Water Inlet Description Qty. Blind cap Gasket End cap Protection cap... -

Page 10: Module Connection

2.3 Module Connection The UNA series modules are connected online at three sections: 1) permeate outlet on top of the module, 2) feed inlet at the bottom of the module, and 3) discharge outlet side nozzle. The permeate outlet on top of the module is connected through of a combination of End cap B and an expansion joint. -

Page 11: Module Connection Types And Required Parts

2.3.2 Module Connection Types and Required Parts The following are the parts to connect the module. The estimated replacement period is based on operation with a 30-minute filtration cycle. This estimated period depends on the use condition, so that the period is not guaranteed. Cap B connection Parts O-ring... -

Page 12: Connection Of Module Upper Part

2.3.3 Connection of Module Upper Part The permeate outlet on top of the module is connected to a rack permeate pipe through a combination of End cap B and an expansion joint. Parts Qty. Remark O-ring Sold separately End cap B Sold separately Sold separately Expansion joint... -

Page 13: Connection Of Module Lower Part, Using Cap A

2.3.4 Connection of Module Lower Part, Using Cap A The feed water inlet at the bottom of the module is connected to a rack feed pipe through a combination of End cap A, a ferrule, and a clamp. Parts Qty. Remark O-ring Sold separately... -

Page 14: Connection Of Module Lower Part, Using Cap B

2.3.5 Connection of Module Lower Part, Using Cap B The feed water inlet at the bottom of the module is connected to a rack feed pipe through a combination of End cap B and an expansion joint. Parts Qty. Remark O-ring Sold separately End cap B... -

Page 15: Connection Of Module Side Nozzles

2.3.6 Connection of Module Side Nozzles The discharge nozzle on the side of the module is connected to a rack discharge pipe through a union socket. Parts Qty. Remark Cap nut Sold separately Gasket Standard attachment Union socket Sold separately... -

Page 16: Rack Specifications

2.4 Rack Specifications The following figure illustrates a type of rack for which the feed inlet at the bottom of the module is connected to a rack feed pipe through an expansion joint: Permeate Collection Effluent Collection Header Pipe Header Pipe Toppling Prevention Chain... -

Page 17: Module Precautions

3.MODULE PRECAUTIONS 3.1 Notes on Solvents and Chemical Agents As notice on solvents, Asahi Kasei affixes the following warning label to resin module housings: Chemical resistance characteristics of the ABS housing are as follows: Precautions Do not come to contact with the following solvents and/or chemicals or vapors of them to prevent stress cracking of module housing: Classification Typical Examples... - Page 18 Other Notices Do not contact module with rubber sheet that contains ester plasticizer or with soft PVC hose. Trace plasticizer or solvent may cause crack on module housing Do not wipe off module with solvent wet cloth, or paste PVC tape or gum tape. Do not mark on the module housing with a felt pen.

-

Page 19: Notes On Feed Water To The Module

3.2 Notes on Feed Water to the Module Note the following precautions on feed water for stable operation: 3.2.1 Raw Water to the Module Raw water to modules refers to a liquid that is pretreated by sand filtration, coagulating sedimentation, or with activated carbon as required before being passed through strainers installed upstream of modules. -

Page 20: Module Precautions

4.MODULE PRECAUTIONS Carefully adhere to the Operating Instructions for proper and safe use of the module. 4.1 Module Use Sequence Operational steps from system commissioning to module replacement is shown graphically below. System Water Rinsing Chemical Module Installation Operation Cleaning Cleaning Module Removal for Replacement... -

Page 21: Preservative Solution

Preservative Solution The module is shipped, filled with an aqueous preservative solution of 30% calcium chloride. Adhere to the precaution below when handling the module. Also, if these preservative solutions are subject to regulations on chemical substances in your country, take appropriate procedures on your own initiative. - Page 22 Rinsing Procedure Rinsing can be performed one of the following two ways: Batch Method (1) Install the modules in the unit. (2) Feed rinse water to the raw water tank. ・ Use clean water for the rinse water. ・...

- Page 23 Method to Supply Rinse Water Continually (1) Install the modules in the unit. (2) Feed rinse water to the raw water tank. ・ Use clean water for the rinse water. ・ Use raw water if clean water is not readily available. (3) As illustrated in Fig.2, continuously feed rinse water to the modules with the water being discharged from the retentate and permeate outlets.

- Page 24 Relationship between Ca Concentration/Hardness and Electric Conductivity Typical River Water Conductivity Ca Concentration (mg/l) Figure 3 Relationship between Ca Concentration and Electric Conductivity 1000 平均的な河川水の電気伝導度 Typical River Water Conductivity Ca Concentration (as CaCO C a硬度 (as CaCO mg/l) mg/l) Figure 4 Relationship between Ca Concentration and Electric Conductivity ...

- Page 25 Rinse example Figures 5 and 6 show rinse test results for a single UNA series module. <Rinse conditions> Rinse water flow rate on permeate side: 0.5m Rinse water flow rate on discharge side: 0.5m <Rinse results> Rinse Volume (L) Figure 5 Relationship between Rinse Volume and Ca Concentration Rinse Volume (L) Fig.6...

-

Page 26: Storage & Transportation

4.3 Storage & Transportation Transportation Precautions When only several modules are transported, they are packaged in cardboard boxes individually. When many modules are transported, they are placed on dunnage. (See the photo below.) Use a forklift to carry the dunnage. ... -

Page 27: Protect From Freezing

Protect from Freezing Although the module must be stored in a dark and cool location, ensure that the membrane is not allowed to freeze, as freezing may damage the membrane due to water/ice expansion. Avoid UV Light and High Temperature Exposure Store the module under an ambient temperature of below 40°C. - Page 28 Case 1 Storing the Module off the System For a short period less than one month (1) After removing the module from the system, plug the feed inlet such as with a blind plate. If no blind plate can be used for a structure or a contour reason, the feed inlet may be plugged with a plastic sheet and tape * Example of Blind Plate ブラインドプレート取付け例...

- Page 29 (2) Feed sodium hypochlorite solution of about 50mg/l from the discharge side and fill the module with it. Fig.7 shows the module sections relating to solution filling. Nozzle to feed solution Plug the feed inlet with a blind plate. Figure 7 Example of Filling the Module with Sodium Hypochlorite Solution (3) When the module is filled with the solution, remove the blind plate of the feed inlet (bottom of the module) to discharge all the solution.

- Page 30 For a storage period more than one month Method 1: Use of sodium hypochlorite solution Follow the procedure for "For a short period less than one month" Repeat the same procedure every other month for solution displacement thereafter. Method 2: Use of calcium chloride solution Solution displacement is unnecessary if the module is filled with a solution of 30% calcium chloride concentration for wetting.

-

Page 31: Module Disposal

4.4 Module Disposal Modules are to be disposed of in accordance with applicable local ordinances and adhering to applicable regulatory requirements. Note Dispose of the module as industrial wastes and adhere to applicable regulatory requirements. Ensure that proper measures are taken when there is possibility of remaining hazardous material in the module. -

Page 32: Module Installation

5.MODULE INSTALLATION Follow the below installation procedure for modules (or dummy modules). When old modules (or dummy modules) are to be removed, follow the procedure in the MODULE REMOVAL section. The module is shipped as shown in 2.2. A separate order is required for parts shown in 2.3. ... -

Page 33: End Cap B Attachment

5.1.1 End Cap B Attachment Step Work Description Attach an O-ring to End cap B. Note: Check that the O-ring is snugly placed in the groove without any displacement. Align End cap B with the module end face on the permeate side. Note: Check that the O-ring is snugly placed in the groove without any... - Page 34 Tighten the cap with a torque wrench until the torque wrench clicks. Note Pay attention to the direction in which to rotate the torque wrench. Note that a different tightening torque is used for dummy module. (For dummy modules: 200N-m)

-

Page 35: End Cap A Attachment

5.1.2 End Cap A Attachment Step Work Description Attach an O-ring to End cap A. Note: Check that the O-ring is snugly placed in the groove without any displacement. Align End cap A with the module end face on the feed side. Note: Check that the O-ring is snugly placed in the groove without any... - Page 36 Tighten the cap with a torque wrench until the torque wrench clicks. Note: Pay attention to the direction in which to rotate the torque wrench. Note that a different tightening torque is used for dummy module. (For dummy modules: 200N-m)

-

Page 37: Connecting Modules Online

5.2 Connecting Modules Online This section explains two ways of module installation to racks: 1) Use of End cap A at the bottom of the module; and 2) Use of End cap B at both the top and bottom of the module. ... - Page 38 Expansion Joint Assembly Order The expansion joint consists of nuts, sleeves, gaskets, and a main body. Sleeve Gasket Main body Packing Sleeve Nut Put a gasket on the Put a gasket on one Put a nut on the Put a sleeve on the other end face of the end face of the main sleeve and lightly...

-

Page 39: Use Of End Cap A For The Feed Water Inlet

5.2.1 Use of End Cap A for the Feed Water Inlet Step Work Description 1) Place a sanitary gasket on the feed water pipe ferrule and then place End cap A of the module on End cap A the ferrule. 2) Position the discharge nozzle of the module in line with the discharge pipe. - Page 40 1) Loosen the expansion joint nut on the permeate side, insert the expansion joint onto a permeate pipe of the rack, and lightly tighten the nut so that the expansion joint does not fall. 2) Set the module in place, loosen the expansion joint nuts, slide the entire joint downward onto the End cap B nozzle, and lightly...

-

Page 41: Use Of End Cap B At Both Ends

5.2.2 Use of End cap B at Both Ends Step Work Description Attach a nut, a sleeve, and a gasket of the expansion joint to End Cap B. Attach a nut, a sleeve, a gasket and End cap B the body pipe of the expansion joint to the feed pipe. - Page 42 1) Attach a gasket to the discharge nozzle of the module. Align the nozzle with the discharge pipe and fasten the cap nut. 2) Connect the discharge nozzle to the discharge pipe of the rack. Note: Ensure that the gasket is not Cap Nut misaligned.

- Page 43 1) Loosen the expansion joint nuts, slide the entire joint upward onto the End cap B nozzle, and tighten the nuts by hand. 2) Operate the system and run water through the expansion joint to check for leakage. Precaution on the connection of End cap B through an expansion joint As illustrated in Figure 8, there must be space between the end cap and the expansion joint.

-

Page 44: Module Removal

6.MODULE REMOVAL Follow the below procedure to remove modules (or dummy modules). Displace the liquid in the piping and the modules (or dummy modules) with water. Drain the water in the piping and module with the drain valve. Manually loosen the cap nut of the discharge nozzle at the upper part of the module, and disengage the discharge pipe from the nozzle. -

Page 45: Standard Operating Parameters For The Una Series

7.STANDARD OPERATING PARAMETERS FOR THE UNA SERIES Observe the following operating parameters when using the UNA series: Outside-in filtration mode Ensure that the modules are installed appropriately with the label on the housing indicating 'feed inlet' located downward (on the bottom). Installing the module upside down (with the label "Feed Inlet"... - Page 46 Backwash Pressure: 300 kPa or less Note Avoid any pressure increase during backwash. Extended operation with sudden pressure increases during backwash may cause degradation of the membrane's physical properties and result in failure of the resin at the permeate outlet end of the module.

-

Page 47: Standard Operating Parameters

7.1 Standard Operating Parameters Standard Operation Mode Filtration Simultaneous air scrubbing and reverse filtration (AS/BW) Flushing (FL) Standard Operating Parameters Requirement/Standard Item Note Value Filters or strainers (500 Do not use slit screens as they let film-like substances μm or less, or 200 μm Pretreatment pass through but use perforated strainers. -

Page 48: Operation Processes

7.2 Operation Processes UNA series operation consists of the following processes performed in this order as one filtration cycle: Pretreatment Filtration process Simultaneous Air scrubbing/Backwash (AS/RF) Flushing (FL) Each process is explained below. 7.2.1 Pretreatment If foreign substances such as chips generated during piping installation, sands, and activated carbon enter the module, they may damage hollow fibers and cause leaks from those hollow fibers. - Page 49 AV-4 Permeat Circulated Water AV-2 AV-5 AV-3 AS/BW NaCl EFM/CIP AV-1 AV-7 Raw Water Auto Strainer Tank Air Compressor Figure 9 Filtration Process Flow Diagram Timing Chart (Reference) Filtration Cycle 30-min (1,800 seconds) Cycle Valve Valve Valve Process Filtration AS/BW Flushing Opening/Closing Opening/Closing...

-

Page 50: Pressure On The Permeate (Treated Water) Side

7.2.3 Pressure on the Permeate (Treated Water) Side The pressure on the permeate side fluctuates depending on factors such as the diameter of the pipe through which permeate flows, the distance to a permeate storing tank, and module and rack heights. -

Page 51: Simultaneous Air Scrubbing/Reverse Filtration (As/Bw)

7.2.4 Simultaneous Air Scrubbing/Reverse Filtration (AS/BW) Upon completion of filtration, AS/BW starts. Permeate is used as backwash (BW) water in order to preclude possible contamination of the system permeate side. The following outlines equipment operation: The backwash valve AV-4, AS/BW drain valve AV-5, and air supply valve AV-6 open. Then the backwash pump P-2 and sodium hypochlorite adding pump start simultaneously. - Page 52 (Permeate flux × Filtration time) - (Backwash flow rate × Backwash time) Water 水回収率 = recovery × 100 (%) rate (Permeate flux × Filtration time) + (Flushing flow rate × Flushing time) Sodium Hypochlorite Concentration Sodium hypochlorite is added to backwash water until its concentration in the backwash water is 1 to 5 mg/L.

- Page 53 ・ Regulator Should an air receiver tank be also used to supply air to air valves for their operation, an additional regulator (adjustable to 400 to 500kPa) is necessary for the valves ・ Air flowmeter Flowmeter capable of measuring air flow rates under a pressure set and for one entire rack. ・...

- Page 54 Flushing Process Contaminants removed from the membrane in AS/BW process are discharged from the upper module nozzle. However, this discharge is insufficient to discharge the liquid remaining in the lower part of the module. Flushing is implemented to discharge this dirty water from the modules with raw water. The following outlines equipment operation at this time: (1) Raw water feed valve AV-1 and AS/BW drain valve AV-5 open.

-

Page 55: Membrane Integrity Test And Repair

8. MEMBRANE INTEGRITY TEST AND REPAIR Module is to be tested for integrity when: A new module is deployed Leakage is suspected Precautions Module leak testing utilizes pressurized air which could result in filtration performance degradation due to membrane drying and/or from contamination from dirty air. Follow the below precautions when checking the integrity of modules. -

Page 56: Pressure Hold Test (Pdt)

8.1 Pressure Hold Test (PDT) In addition to a permeate water quality monitoring system, the Asahi Kasei membrane systems are designed with capability for conducting both pressure hold test and air leak tests in order to establish the integrity of the membranes. See below test protocol flow chart. Start air leak test Pressure Decay Test (PDT) Pressure decay (kPa/min) measurement... - Page 57 The following is the leak test procedure: ● Step 1 (1) Open drain valve AV-5. (2) Open the air supply valve for leak testing (AV-11) to pressurize the module's permeate side with air. (3) The water in the permeate side of the module will be displaced by the air. When all the water is displaced, PIA (permeate pressure gauge) should read the set pressure (180 to below 200 kPa).

- Page 58 ● Step 2 (5) Once the pressure reading of PIA has stabilized, close the air supply valve for leak testing (AV-11). (6) Hold the pressure for 3 minutes and check for pressure decay. (7) Pressure decrease of 15 kPa (5 kPa/min) or more: leak present Pressure decrease of less than 15 kPa (5 kPa/min): no leak (8) If there is a leak, an air leak test is conducted to identify the modules that have a leak.

- Page 59 ● Step 3 (9) Upon completion of testing, open the air bleeding valve AV-12 to release the pressure. To avoid sudden pressure release, open and close AV-12 alternately at intervals of one second until the pressure (PIA) drops to about 10 kPa. AV-4 Feed Tank AV-9...

- Page 60 ● Step 4 (1) Filtration process resumes after the air pressure drops below 10 kPa (reading of PIA). AV-4 Feed Tank AV-9 AV-5 AV-10 Chemical Tank AV-2 Permeate Tank AV-3 BW Pump AV-12 Air Vent AV-8 Chemical Pump AV-11 AV-7 AV-1 Filtration Pump PICA...

-

Page 61: Air Leak Test

8.2 Air Leak Test An air leak test may be performed by an operator as required or in cases such as where air pressure drops at a higher rate than the reference rate during a pressure hold test and a module(s) is judged to have a leak. - Page 62 The following is the leak test procedure: ● Step 1 (1) Open the filtrate valve AV-2. (2) Open air supply valve AV-7 to pressurize the module feed side with air. (3) The raw water in the module is filtered out of it. (4) When all the raw water has been filtered, check that the pressure gauge (PICA) on the feed side reads 200kPa.

- Page 63 ● Step 2 (8) Close the air supply valve AV-7 to stop air supply. (9) Close the filtrate valve AV-2. (10) Open the drain valve AV-5 to bleed compressed air. To avoid a sudden release of a large amount of air, open and close drain valve AV-5 alternately at intervals of about one second until the applied pressure decreases to below 10 kPa.

- Page 64 Precautions Fill the feed and permeate sides with water for integrity testing. Pressurizing the feed side causes the water on the feed side to be filtered, pushing the air inside the hollow fibers out. If air bubbles remain on the permeate side, it is difficult to determine whether or not air bubbles are from a leaking section.

-

Page 65: Membrane Leak Repair Method For The Una Series

8.3 Membrane Leak Repair Method for the UNA Series Use the SUS nail exclusively for membrane leak repair. Shown below is the membrane leak repair procedure. Inspection Procedure Step Work Description Remove the module from the system and remove the end cap only on the permeate side. - Page 66 Fit an O-Ring onto the module end face on the permeate side. Pour clean water (e.g., permeate) permeate end of the module until water completely covers the surface. 1) Gradually pressurize the module using the air scrubbing unit. 2) Observe for a continuous stream of bubbles that would...

- Page 67 Cut off the nail 2 to 3 mm above the module's end surface. Feed air again and raise the air pressure to 180 to 200 kPa (the maximum allowed) for the final check and observe. Note To ensure safety, do not observe the module end face from directly above when pressurizing.

-

Page 68: Chemical Cleaning And Sterilization Of Una Series

9.CHEMICAL CLEANING AND STERILIZATION OF UNA SERIES Use the following procedures should there be a decline in membrane permeate flux caused by contaminants (organic or inorganic) or when it proves necessary to clean and/or sterilize the system. Perform chemical cleaning when the transmembrane pressure (TMP) has reached around 200 kPa. -

Page 69: Acid Selection

9.1.2 Acid Selection Acids to remove inorganic substances should be selected from various points of view such as cleansing effect, waste chemical solution treatment, toxicity, corrosive nature, and costs. Classification of acid cleaning solutions Substance Corrosive Chemicals Difficult to Effluent Treatment Toxicity Nature Remove... -

Page 70: Types Of Chemical Cleaning (Efm, Ceb, And Cip)

9.2 Types of Chemical Cleaning (EFM, CEB, and CIP) There are two kinds of chemical cleaning: 1) light cleaning performed with chemical solution of low concentration for a short time at frequent intervals; and 2) heavy cleaning performed in an opposite manner to 1) to completely clean membrane for higher flux recovery. - Page 71 As illustrated in Figure 24, chemical cleaning can be performed in one of two ways: 1) CEB in which chemical solution is infused directly into a backwash pipe; and 2) EFM in which chemicals are prepared in a chemical tank and chemical solution is fed from the feed side. Also, EFM can be implemented either by circulating chemical solution through modules and a chemical tank or by holding chemical solution stationary in modules for membrane soaking.

-

Page 72: Chemical Cleaning Sequences Of Efm, Ceb, And Cip

Example of method selections Chemical solution Chemical solution Raw Water Type discharged from discharge discharged from Stationary port and permeate outlet discharge port to soaking to chemical tank chemical tank Natural water Sewage secondary effluent ▲ ▲ ▲ Seawater ▲: Contact Asahi Kasei. 9.3 Chemical Cleaning Sequences of EFM, CEB, and CIP Adhere to the below sequences for EFM, CEB, and CIP. - Page 73 AV-4 Permeate Effluent AV-2 AV-5 AV-3 AS/BW NaClO AV-1 AV-7 AV-6 Feed Tank Auto Strainer Air Compressor Figure 25 CEB Process Flow Diagram Reference) CEB Timing Chart (* Valve open/close duration excluded) CEB Process 60 min at a time Chemical Rinse Process AS/BW...

- Page 74 Reference) CIP (CEB method) Timing Chart (* Valve open/close duration excluded) CIP Process 480 min (8 hr) at a time Chemical Rinse Chemical Rinse Process AS/BW Drain Soaking Drain AS/BW FL Drain Soaking Drain AS/BW Supply (BW) Supply (BW) Duration (min) Raw water feed AV-1 valve...

- Page 75 EFM (chemical solution returned from both discharge port and permeate outlet) AV-2 Permeate AV-4 Effluent AV-5 AV-10 AV-9 AV-3 AS/BW NaClO NaNCl Chemical AV-8 Tank AV-1 AV-7 AV-6 Feed Tank Auto Strainer Air Compressor Figure 26 EFM Process Flow Diagram...

- Page 76 Reference) EFM Timing Chart (* Valve open/close duration excluded) EFM Process 60 min at a time Chemical Rinse Process AS/BW Drain Drain AS/BW Supply (BW/FL) Duration (min) Raw water feed AV-1 valve AV-2 Filtrate valve AV-3 Backwash valve AV-4 Return valve AS/BW drain AV-5 valve...

- Page 77 Reference) CIP (EFM method) Timing Chart (* Valve open/close duration excluded) EFM Process 480 min (8 hrs) at a time Chemical Rinse Chemical Rinse Process AS/BW Drain Drain AS/BW FL Drain Drain AS/BW Supply (BW/FL) Supply (BW/FL) Duration (min) Raw water feed AV-1 valve AV-2...

-

Page 78: Cleaning Protocol

Precautions Measure permeate flux before and after each EFM, CEB, alkali CIP, and acid CIP to allow for a check of flux recoverability (effect of cleaning). Ensure sufficient rinsing between chemical cleaning steps when employing more than one chemical. Mixing sodium hypochlorite and acid generates chlorine gas. - Page 79 Chemical cleaning protocol Item Protocol The following are examples of chemical solution volumes required, based on the total volumes of module holdup volumes + piping volumes: Item UNA-600A UNA-660A UNA-620A Chemical Solution Module Holdup Volume Volume Reference Chemical Solution 40 - 50 60 - 70 Volume Unit: L/module...

- Page 80 Standard protocol Cleaning Chemical Concentration Cleaning Step Type Used Duration (hr) NaClO 0.25% Alkali NaOH 1.00% CIP Protocol Acid Citric Acid 1.00% (heavy cleaning) Acid cleaning: Acids such as oxalic acid, citric acid, and nitric acid can be used. These are standard protocols and depend on permeate flux recovery rates achieved.

-

Page 81: Assessing Post Cleaning Permeate Flux Recovery

When only sterilizing, use a sodium hypochlorite solution with an effective chloride concentration of ≤ 100 mg/l. Thoroughly rinse the modules using clean water after sanitization. Thoroughly wash off any chemical solution adhering to the outer surfaces of module housings. Warning When handling hazardous chemicals, always wear protectors such as safety goggles and rubber gloves. - Page 82 Calculation Using the measured values, calculate permeate flux at 100 kPa and 25°C at the start of operation and before and after cleaning. Permeate flux at 100 kPa and 25°C = Permeate flux × 100 / TMP × Temperature conversion factor * Average filtration pressure (TMP) = (Mod.

- Page 83 Temperature conversion coefficient table ℃ 2.013 2.006 1.999 1.992 1.985 1.978 1.972 1.965 1.958 1.951 1.945 1.938 1.932 1.925 1.919 1.912 1.906 1.899 1.893 1.887 1.881 1.874 1.868 1.862 1.856 1.850 1.844 1.837 1.831 1.825 1.820 1.814 1.808 1.802 1.796 1.790 1.784 1.779...

- Page 84 Contact Asahi Kasei: If the specified filtration rate is not achieved Difficulty with integrity test assessment If the intended application is not specifically noted in these Instructions or a change of the originally intended application Module storage requirements exceeding one (1) year ...

Need help?

Do you have a question about the MICROZA UNA Series and is the answer not in the manual?

Questions and answers