Table of Contents

Advertisement

Quick Links

Chip & swarf management system

Original instruction manual

EN

INSTRUCTION MANUAL

Translation of original instruction manual

DA

BETJENINGSVEJLEDNING

DE

BEDIENUNGSANLEITUNG

ES

MANUAL DE INSTRUCCIONES

IT

MANUALE DI ISTRUZIONI

PL

INSTRUKCJA UŻYTKOWANIA

SV

ANVÄNDARMANUAL

2016-12-12

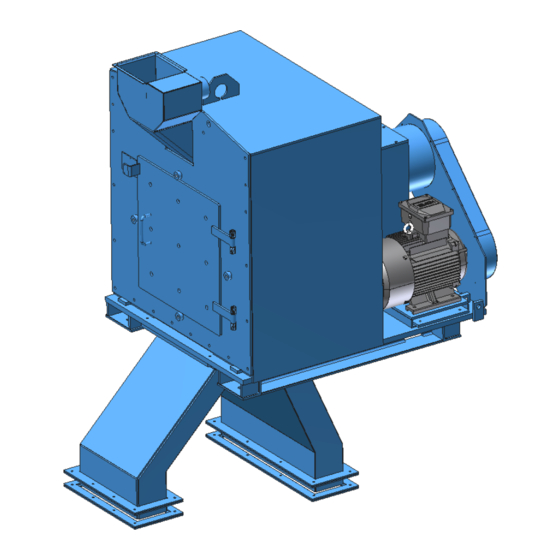

Horizontal centrifuge

Instruction manual

HD82

QMM001(02)

Advertisement

Table of Contents

Summary of Contents for Nederman HD82

- Page 1 Instruction manual Chip & swarf management system Horizontal centrifuge HD82 Original instruction manual INSTRUCTION MANUAL Translation of original instruction manual BETJENINGSVEJLEDNING BEDIENUNGSANLEITUNG MANUAL DE INSTRUCCIONES MANUALE DI ISTRUZIONI INSTRUKCJA UŻYTKOWANIA ANVÄNDARMANUAL 2016-12-12 QMM001(02)

- Page 2 HD82 QMM001(02)

- Page 3 HD82 Figures ..................... 4 English ..................... 9 QMM001(02)

-

Page 4: Figures

HD82 Figures QMM001(02) - Page 5 <Product name> HD82 QMM001(02)

- Page 6 HD82 QMM001(02)

- Page 7 <Product name> HD82 QMM001(02)

- Page 8 HD82 <Product name> <Product name> QMM001(02)

-

Page 9: Table Of Contents

HD82 English Instruction manual Chip and swarf management system Horizontal centrifuge HD82 Table of contents Figures ................................. 1 Declaration of conformity ...................... 2 Preface ..............................2.1 Foreword ............................2.2 Guarantee ............................. 3 Notices ..............................4 Safety ................................. 5 Description ............................ - Page 10 HD82 QMM001(02)

-

Page 11: Declaration Of Conformity

To maintain this status, all installation, repair and maintenance work for this product is to be carried out by qualified personnel using only original spare parts. Contact the nearest authorized distributor or Nederman for advice on technical service and obtaining spare parts. -

Page 12: Guarantee

HD82 Guarantee All products from NEDERMAN are guaranteed free from any fault in material and labour usually during a period of one year. One year consists of 365 calendar days or 1800 hours which ever occurs first. The guarantee period for our products starts the day the equipment is sent to the client and continues during one year as earlier described. -

Page 13: Safety

• Materials able to centrifuge are different qualities of steel swarf as well as brass and cast iron swarf, if any other material please ask Nederman. • The data sheet from the coolant supplier must be studied as parts from coolant can cause allergic reactions. -

Page 14: Technical Data

Accessories The screen opening is delivered as a standard 0.7 mm if not otherwise specified in the order. Other screen openings may be fitted. The accessories for HD82: • Support stand. • Inductive sensor for shaft monitoring (without control). • Wear Parts Stainless Steel / Hardox. -

Page 15: Before Installation

Lifting fixtures should be available in view of the fact that several of the parts which need to be replaced weigh over 125 kg. NEDERMAN Swarf Centrifuge is delivered fully fitted. Observe care during installation and always use the lifting hooks which it is equipped with. The mountings should be level and sufficiently secure to support a load of about 1700 kg (incl. -

Page 16: Operation

6. Supplementary adjustment: NEDERMAN Swarf Centrifuge is on delivery adjusted to cope with the majority of chip types unless otherwise specified. If a chip type should be run subsequently to installation which was unknown to us on the occasion of installation then a supplementary adjustment may be made. -

Page 17: Lubrication

The service intervals in this chapter are based on the unit being professionally maintained. NEDERMAN Swarf Centrifuge is very robust in design but should like every other production machine be regularly checked and maintained. Daily checks should be made at the start of operations until a permanent maintenance schedule can be established. -

Page 18: Recycling

The product has been designed for component materials to be recycled. Its different material types must be handled according to relevant local regulations. Contact the distributor or Nederman if uncertainties arise when scrapping the product at the end of its service life. -

Page 19: Troubleshooting

• different materials should be recycled in accordance with current regulations for each variety. Troubleshooting If the trouble shooting guide in ‘Table 12-1: Trouble shooting guide’ does not solve the problem, contact your nearest authorized distributor or Nederman service center for technical advice. Table 12-1: Trouble shooting guide. Problem... - Page 20 HD82 NEDERMAN Manufacturing Poland Sp. z o. o. 05-270 Marki, Poland ul. Okólna 45 A Tel.: 048 227616000 Fax: 048 227616099 www.nederman.com QMM001(02)

- Page 22 www.nederman.com...

Need help?

Do you have a question about the HD82 and is the answer not in the manual?

Questions and answers