Table of Contents

Advertisement

Quick Links

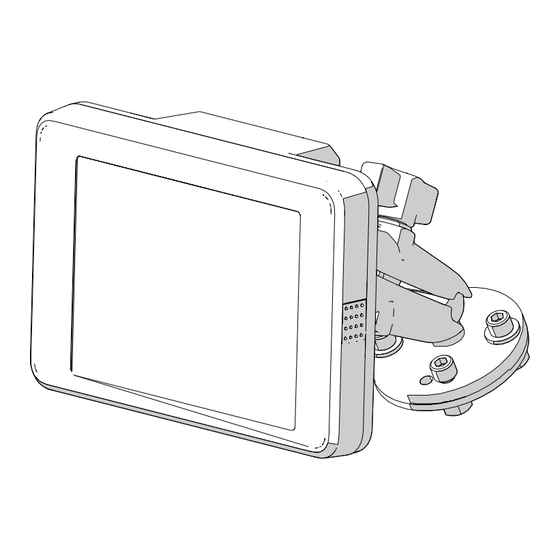

TIREBOSS 2

®

Tire Pressure Control

TB2 Service Manual

Version 2.0 | Current as of August, 2022

This is a working document that is

subject to change without notice

Contact TPC International with any inquries at;

15803-121A Ave., Edmonton, Alberta, Canada T5V 1B1

Toll Free Phone: North America 1-888-338-3587

|

New Zealand 1-800-443-971

Australia 1-800-148-694

|

Phone: (780) 451-4894

Fax: (780) 452-6786

Email: info@tirepressurecontrol.com

TECHNICAL - documents | DOCUMENTS | SERVICE MANUAL | Service Manual - V 2._

Advertisement

Table of Contents

Need help?

Do you have a question about the TIREBOSS 2 and is the answer not in the manual?

Questions and answers