Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Zigler Z-2323

- Page 1 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Type: Z-2323 Signature: A0310.02.2323.905.1.EN TRANSLATION OF THE ORIGINAL INSTRUCTIONS. 2018. No part of this document may be reprinted or copied by any means, without the written permission of ZIGLER POLSKA...

-

Page 2: Table Of Contents

TABLE OF CONTENTS EQUIPMENT MANUFACTURER ......................4 1. General information .........................5 The purpose of a Z-2323 Semi-automatic BOV Filling Machine ............5 Technical data ..........................5 2. Safety manual of a Z-2323 ......................7 General information concerning operation of the machine ............. 7 Personnel authorized to operate the machine ................ - Page 3 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 7. Maintenance of Z-2323 ......................26 Conditions of the functional reliability and life of pneumatic control systems ....... 26 General rules applicable for replacing worn out parts ..............27 Maintenance operations schedule ....................27 Cleaning instructions ........................

-

Page 4: Equipment Manufacturer

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 EQUIPMENT MANUFACTURER A0310.02.2323.905.1.EN Page 4/39... -

Page 5: General Information

1. General information The purpose of a Z-2323 Semi-automatic BOV Filling Machine A Z-2323 Semi-automatic BOV Filling Machine is a device serving for filling aerosol containers with liquid product through valves crimped on the aerosol container. The amount of the dosed product is regulated in the range 0 ÷... - Page 6 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Fig. 1. Overall dimensions of Z-2323 A0310.02.2323.905.1.EN Page 6/39...

-

Page 7: Safety Manual Of A Z-2323

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 2. Safety manual of a Z-2323 General information concerning operation of the machine This machine should be operated according to this operation and maintenance manual, which is a condition of safe and trouble-free functioning. A user is responsible for their own and other people’s safety, has to be familiar with the rules of the device use provided below and follow them. -

Page 8: Personnel Authorized To Operate The Machine

ZIGLER POLSKA company, persons who have been sufficiently trained and prepared by the user to operate the device. -

Page 9: Conditions Of Operating The Machine Safely

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Conditions of operating the machine safely 1. Order at a work station should be maintained. Disorder at a work station may easily result in an accident. 2. Work-stations should be properly lit. 3. It is not advisable that any unauthorized persons stay near the machine while it is being operated. -

Page 10: Safety Rules During Repairs And Maintenance

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Safety rules during repairs and maintenance It is forbidden to perform any cleaning and ordering works, nor to remove defects while the device is being operated. Compressed air, active substance and product supply, and in case of electric appliances, power supply should be cut off first. -

Page 11: Transport, Installation And Storage Of Z-2323

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 3. Transport, installation and storage of Z-2323 Transport Before transporting the machine, disconnect the compressed air supply. The machine can be transported in one block and does not require disassembly. For transport, the height of the Filling head should be set at the lowest possible level (using the height adjustment mechanism of the stand). -

Page 12: Storage

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 In order to obtain normal working conditions, pressure in order of 0.8 – 1.2 MPa (8 - 12 bar) is required. Attention should be paid to ensuring, whether compressed air is not polluted. In order to eliminate water from the installation, install an air drier at the lowest point of the supply hose. -

Page 13: Construction Of Z-2323 Semi-Automatic Bov Filling Machine

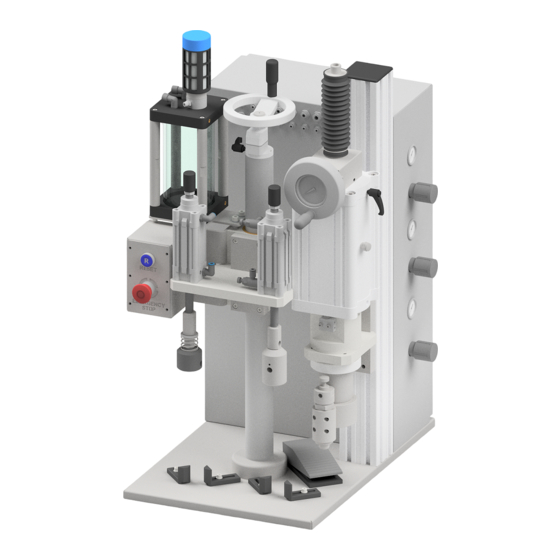

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 4. Construction of Z-2323 Semi-automatic BOV Filling Machine In construction of Z-2323 following elements can be distinguished [Fig. 3]: 1. Footing; 11. Filling head lowering actuator; 2. Adjustable support stand; 12. Cleaning head lowering actuator;... - Page 14 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 The Manufacturer reserves the right to change the design of the produced machine. 1. Dose regulation wheel 2. Dose indicator 3. Air cylinder 4. Product cylinder 5. Cylinders connector 6. Product non-return valve 7.

-

Page 15: Air Preparation Unit

Compressed air provided to the device must be preliminarily cleaned. Achieving quality of supply air class 4 (according to ISO 8573-1 norm), required to power pneumatic devices produced by ZIGLER POLSKA company, is obtained using an air preparation unit. Implemented air preparation unit consist of following elements [Fig. 5]: Cut-off valve [pos. - Page 16 The above description relates to the air preparation unit manufactured by FESTO. In manufactured by ZIGLER POLSKA products there are air preparation units from the following producers: FESTO, CAMOZZI, SMC, CKD, METALWORK. Principle of operation and construction of all types of units conforms to the previously given description.

-

Page 17: Operation Manual Of Z-2323

Semi-automatic BOV Filling Machine Z-2323 5. Operation manual of Z-2323 Steps before starting the machine Before starting Z-2323, make sure that following steps were taken: The device is properly installed, compressed air supply and product supply is connected in accordance with chapter 3.2.;... -

Page 18: Stopping The Machine. Emergency Stop

Fig. 7. Drain tank with drain valve Stopping the machine. Emergency Stop Stopping of a Z-2323 takes place in a manner analogous to the run – you need to switch the manual cut-off valve to closed position. Additionally, the device was equipped with emergency stop button [Fig. 3, pos. 5], causing an immediate lift of working heads in case of emergency. -

Page 19: Adjustment Of Operating Parameters Of Z-2323

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 6. Adjustment of operating parameters of Z-2323 Adjustment of operating pressure Following description applies to all pressure regulating valves installed in the device. To increase the pressure on regulation valve, first enable the air supply by switching manual cut-off valve located at the air preparation unit to the open position, then [Fig. -

Page 20: Dose Adjustment

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Dose adjustment Setting the dose of product is performed by limiting the piston stroke with the use of the regulation wheel. While adjusting, the product cylinder should be emptied of product. Also, the piston in the air cylinder cannot be under the pressure of compressed air since it will not be possible to turn the regulation wheel then. - Page 21 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Fig. 11. Adjusting product dose Enable compressed air supply by moving the slide valve up to opened position. Open the inflow of the product to the product cylinder by unscrewing the knurled screw and gently tighten the securing nut on check-valve.

-

Page 22: Setting The Height Of Filling And Cleaning Head

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Setting the height of filling and cleaning head Crimped containers may be of 65 ÷ 320 mm height. The height adjustment should always be performed on initial state of the machine – when the compressed air supply is enabled and working heads are in upper position. -

Page 23: Setting The Container Limiters Position

Semi-automatic BOV Filling Machine Z-2323 Setting the container limiters position The Filling Machine Z-2323 is adapted for filling the aerosol cans of diameter φ35 ÷ φ66 mm. Position of the container on the footing of the Filling machine is defined by the limiters. The regulation of the location of limiters consists in ensuring the axial setting of the container and the Filling head. -

Page 24: Regulation Of Proximity Sensors Placement On Actuators

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Regulation of proximity sensors placement on actuators Magnetic proximity sensors are responsible for detecting actuators limit position, what is important to maintain correctness of algorithm controlling the machine. Magnet is built in actuator piston and sensor, after detecting it, is generating signal used to control other modules of the device. -

Page 25: Regulation Of Flow Control/Throttling Valves

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Regulation of flow control/throttling valves Flow control valves can be used to adjust speed of actuators (if installed on its outlets – e. g. GRLA type valve type - Fig. 17) or to adjust time delays (when installed on signal cables of control valves –... -

Page 26: Maintenance Of Z-2323

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 7. Maintenance of Z-2323 Conditions of the functional reliability and life of pneumatic control systems Work safety and life of the pneumatic system to a substantial degree depend on the preparation of compressed air. Polluting compressed air with e.g. scale, rust, dust, as well as liquid ingredients in the air such as condensed steam, may cause a lot of damage to pneumatic devices. -

Page 27: General Rules Applicable For Replacing Worn Out Parts

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Tab. 3. Division into the quality classes according to the ISO 8573-1 norm 1. SOLID PARTICLES 2. WATER CONTENT 3. OIL CONTENT Class maximum maximum particle maximum pressure maximum viscosity (mg/m saturation point ( concentration (mg/m particle size (µm) -

Page 28: Cleaning Instructions

The machine should be cleaned after each production cycle which is a condition for proper and safe operation of all machine components. Z-2323 is made of steel and other materials resistant to the effects of most common detergents. The machine should be cleaned manually using soft fabric or paper with cleaning and disinfecting products. -

Page 29: Quality Of The Pneumatic Oil

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Quality of the pneumatic oil Satisfying work of mini-head lubricating nipples and the effective result of lubrication depend on the proper choice of pneumatic oil. Majority of oils for lubrication, optimally possessing good qualities in terms of resistance to corrosion and oxidation, are suitable in case of compatibility with the classification below. -

Page 30: Replacing The Lip Sealing On Products Piston

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Replacing the lip sealing on products piston If in the rear part of the connector there is a product leak, it means that the seal on the piston in the product cylinder is worn out. The seals are replaced as follows: 1. - Page 31 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Sealing 9003.42.001.0/VS1 19 mm Ring 9003.42.001.0/GR1 Fig. 19. Replacing product piston lip sealing Fig. 20. Adjustable caliper pin face spanner (similar to DIN 3116A) A0310.02.2323.905.1.EN Page 31/39...

-

Page 32: Replacing The Lip Seal In The Filling Head

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Replacing the lip seal in the filling head The lip sealing mounted in filling head is a dynamic seal, therefore it is exposed to wear. Its condition should be checked whenever symptoms of head leakage are occurring. In order to replace the sealing perform following operations: 1. - Page 33 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Gasket 9003.34.650.0 22 mm Spring 9003.34.005.1/SG2 17 mm Sealing sleeve 9003.34.651.1 17 mm Brass sleeve 9003.34.612.0 Adapter Service key 9003.46.001.2 Sealing 9003.34.000.2/VS1 9003.34.636.0 Fig. 22. Replacing product head lip sealing A0310.02.2323.905.1.EN Page 33/39...

-

Page 34: Replacing Flat Gasket Of Filling Head

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Replacing flat gasket of filling head Condition of this sealing should be checked whenever symptoms of head leakage are occurring. Flat sealing of product head is replaced as follows: 1. Close the inlet of the product to the cylinder by tightening the knurled screw [Fig. 9, pos. 1] of the product cylinder non-return valve after loosening the securing nut [Fig. - Page 35 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Gasket 9003.34.650.0 22 mm Spring 9003.34.005.1/SG2 17 mm Sealing sleeve 9003.34.651.1 17 mm Flat gasket 9003.34.607.0 Service key 9003.46.001.2 Fig. 23. Replacing the flat gasket in filling head A0310.02.2323.905.1.EN Page 35/39...

-

Page 36: Replacing The Closing Teflon Cone Of Filling Head

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Replacing the closing Teflon cone of filling head 1. Close the inlet of the product to the cylinder by tightening the knurled screw [Fig. 9, pos. 1] of the product cylinder non-return valve after loosening the securing nut [Fig. 9, pos. 2]. - Page 37 INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Gasket 9003.34.650.0 22 mm Spring 9003.34.005.1/SG2 17 mm Sealing sleeve 9003.34.651.1 5 mm 9003.34.634.1 Spring 9003.34.000.2/SG1 Teflon cone 9003.34.002.0 Fig. 24. Replacing filling head Teflon cone A0310.02.2323.905.1.EN Page 37/39...

-

Page 38: Replacing O-Ring Seal In Filling Head Adapter

INSTRUCTION MANUAL Semi-automatic BOV Filling Machine Z-2323 Replacing o-ring seal in filling head adapter 1. Close the inlet of the product to the cylinder by tightening the knurled screw [Fig. 9, pos. 1] of the product cylinder non-return valve after loosening the securing nut [Fig. 9, pos. 2]. -

Page 39: Warranty Terms - Technical Inspections Schedule

The prerequisite for maintaining the machine's warranty during its validity period is, among others, to respect the schedule of technical inspections of machinery performed by Zigler Polska service personnel. During the base warranty period of 24 months, according to the general terms, at least... - Page 41 § 6. Any defective components or parts after replacement shall become the property of the PRINCIPAL. § 7. This guarantee shall apply only to the equipment manufactured and supplied by ZIGLER POLSKA. §8. The operation of the equipment, used in accordance with the operating and maintenance conditions as described in the maintenance and operating manual, is guaranteed.

- Page 42 PNEUMATIC DIAGRAMS...

- Page 43 Page name: Page No: 2018-08-31 A0310 Complete diagram Designed by: Device name: Artur Jedziniak Semi-automatic BOV Filling Machine Document No: ZIGLER Polska Sp. z o.o. Draw by: Dawid Mroczek A0310. 2323 .902.1. ul. Braci Gutmanów 7 Subtype: Device type: sR.SZp...

- Page 44 SPARE PARTS LIST WITH TECHNICAL DRAWINGS...

- Page 45 2323.00.601.1 2323.00.002.0/OR1 NOTE: When ordering spare parts, make sure to use drawing number as well as exact symbol/marking of particular part. Only complete information will allow to identify the part and properly process your order. Designed by: P.Horbaczewski 2017-05-18 Material Title Weight/piece 0,824...

- Page 46 A-A ( 1 : 2 ) 9003.41.616.0 9003.41.614.0 9003.41.001.2/RC 1 9003.41.615.0 9003.41.612.0 9003.41.617.1 9003.41.001.2/BG 1 9003.41.623.0 9003.41.625.0 9003.41.619.0 9003.41.050.0 9003.41.613.1 9003.41.618.1 9003.41.001.2/GI 1 (188ml) 9003.41.609.1 9003.41.001.2/GI 2 (294ml) 9003.41.608.0 9003.41.001.2/GI 3 (420ml) 9003.41.602.1 9003.41.000.1 9003.41.600.0 9003.41.001.2/GR 1 9003.41.001.2/LS 1 9003.41.001.2/LS 1 9003.41.620.0 9003.41.604.0 9003.41.001.2/OR 1...

- Page 47 9003.42.612.1 ( 40, 188 ml) 9003.42.611.1 ( 50, 294 ml) 9003.42.613.1 ( 60, 420 ml) 9003.42.600.1 9003.42.001.0/GR 1 ( 40, 188 ml) 9003.42.001.0/GR 2 ( 50, 294 ml) 9003.42.001.0/GR 3 ( 60, 420 ml) 9003.42.001.0/VS 1 ( 40, 188 ml) 9003.42.001.0/VS 2 ( 50, 294 ml) 9003.42.001.0/VS 3 ( 60, 420 ml) 9003.42.610.2 ( 40, 188 ml)

- Page 48 A-A ( 1 : 1 ) 9019.05.613.0 9019.00.002.1/HW1 9019.01.602.0 9019.00.600.0 9019.00.002.1/AH1 9019.05.613.0 9019.01.602.0 9019.05.615.0 9019.05.617.1 9019.01.050.0 NOTE: When ordering spare parts, make sure to use drawing number as well as exact symbol/marking of particular part. Only complete information will allow to identify the part and properly process your order.

- Page 49 9026.00.610.0 9026.00.609.0 9026.00.613.0 9026.00.001.0/OR5 9026.00.001.0/OR1 9026.00.607.2 9026.00.001.0/LS1 9026.00.612.1 9026.00.001.0/SG1 9026.00.001.0/OR3 9026.00.001.0/OR2 9026.00.001.0/RR1 9026.00.001.0/VS1 9026.00.618.0 9026.00.615.0 9026.00.611.0 9026.00.001.0/BL1 9026.00.616.0 9025.00.605.2 9026.00.001.0/OR4 NOTE: When ordering spare parts, make sure to use drawing number as well as exact symbol/marking of particular part. Only complete information will allow to identify the part and properly process your order.

- Page 50 9003.34.000.2/OR1 9003.34.634.1 9003.34.633.0 9003.34.005.1/SG2 9003.34.000.2/SG1 9003.34.002.0 9003.34.632.1 9003.34.000.2/OR2 9003.34.000.2/VS1 9003.34.651.1 9003.34.636.0 9003.34.639.0 9003.34.652.1 9003.34.654.0 9003.34.653.1 9323.34.000.0/OR3 9003.34.607.0 9003.34.628.0 (d2= 12) 9003.34.639.0 (d2= 14) NOTE: When ordering spare parts, make sure to use drawing number as well as exact symbol/marking of particular part.

Need help?

Do you have a question about the Z-2323 and is the answer not in the manual?

Questions and answers