Table of Contents

Advertisement

Quick Links

Operations & Repair Manual

Product Type

:

Model

:

Manufacturer

:

Model Number

:

Manual Number :

Release Date

:

Project Number :

Serial Number(s) :

Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA

Phone

Fax

Internet E-Mail

Web Site

Tank Cleaning Machine

Rotating Jet-Head

LT

Butterworth®, Inc.

________________________

132.2008.01.03

Pending

________________________

:

281.821.7300

:

281.821.5550

:

eng@butterworth.com

:

www.butterworth.com

Page 1 of 36

TRH©2007

Advertisement

Table of Contents

Summary of Contents for Butterworth LT6Z33NO

- Page 1 ________________________ Manual Number : 132.2008.01.03 Release Date Pending Project Number : ________________________ Serial Number(s) : Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 1 of 36 Phone 281.821.7300 TRH©2007 281.821.5550 Internet E-Mail eng@butterworth.com Web Site...

-

Page 2: Table Of Contents

HOW TO ORDER SPARE PARTS AND WARRANTY CLAIM PROCEDURE .......................... 36 Ordering Spare Parts ............................................36 Warranty Claim Procedure ............................................ 36 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 2 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com... -

Page 3: Introduction

INTRODUCTION This manual has been prepared as a guide for the persons who will be operating and maintaining your Butterworth® tank cleaning machine. The key to long life for your tank cleaning machine will always be a system of carefully planned maintenance. Tank cleaning machines are expected to perform various types of cleaning jobs. -

Page 4: General Description

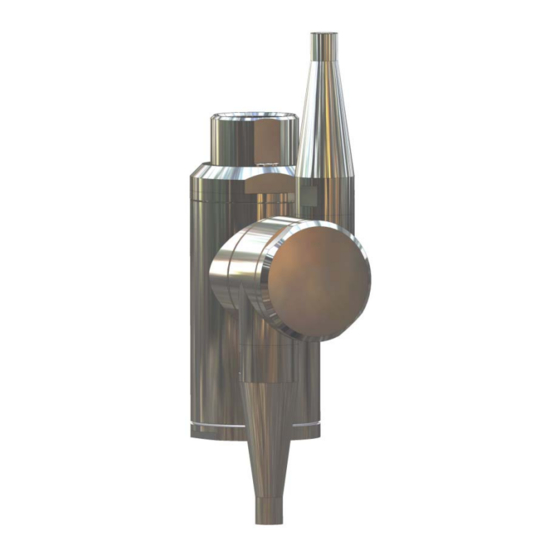

: Pending GENERAL DESCRIPTION The Butterworth® LT is a sealed gearbox tank cleaning machine that uses lubricant (see page 35 for lubricant specifications). How It Works The flow of the cleaning fluid into the tank cleaning machine passes through a turbine, which is set into rotation. The turbine rotation is through a gearbox transformed into a combined horizontal rotation of the body and a vertical rotation of the nozzles. -

Page 5: Standard Configurations

(Note: Optional configurations are available as non-standard products by contacting your nearest agent or distributor.) Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 5 of 36 Phone 281.821.7300... -

Page 6: Installation Instructions

51168: Food Grade Anti-Seize; 8 oz. brush top 51170: Food Grade Anti-Seize; 2 lb. can 51171: Food Grade Anti-Seize; 40 lb. pail Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 6 of 36 Phone 281.821.7300... -

Page 7: Technical Data

300° F (95° C) Standard Configuration Materials Of Construction See exploded view drawing (page 32 ) Principal dimensions in inches and [mm]: Figure 5 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 7 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com... -

Page 8: Performance Curves - Pressure & Flow

To achieve the performance indicated in the curves, allowance must be made for pressure drop in the supply lines between pump and machine. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 8 of 36 Phone 281.821.7300... -

Page 9: Performance Curves - Pattern Time

Note: The pattern time related in these curves is the time required to make 65 axial revolutions. Pattern time is not indicative of the time required to perform the required cleaning. Depending upon the application, the number of pattern completions will vary for the relative cleaning application. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 9 of 36 Phone 281.821.7300... -

Page 10: Performance Curves - Jet Length

Maximum jet-length on this curve is measured at static conditions and where the last droplet falls. The effective range is subjective to the cleaning requirement. However in this curve effective is at the point of arc deviation. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 10 of 36 Phone 281.821.7300... -

Page 11: Installation And Normal Operation

General Installation Instructions The Butterworth® tank cleaning machine should be installed in vertical position (upright or inverted). It is recommended to install a filter in the supply line in order to avoid large particles lodging inside the machine. Before connecting the machine into the system, all supply lines and valves should be flushed to remove foreign matter. -

Page 12: Maintenance And Repair

PREVENTIVE MAINTENANCE In order to keep your Butterworth® tank cleaning machine servicing you as an efficient tool in your tank cleaning operations, it is essential to maintain its high performance by following a simple preventive maintenance program, which will always keep your tank cleaning machine in good condition. -

Page 13: Top Assembly

32.3 and 32.5 as well as pos. 32.4. This is illustrated in Figure 10. It is advised to include the use of Anti-Seize as described on page 6 when connecting position 1 to position 12.4. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 13 of 36 Phone 281.821.7300... -

Page 14: Top Assembly - Exploded View Drawing

Release Date : Pending MAINTENANCE AND REPAIR Top Assembly - Exploded View Drawing Figure 9 Figure 10 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 14 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site www.butterworth.com... -

Page 15: Impeller Housing Sub-Assembly

On completion of step 5 above remove positions 12.6 from 12.1 along with removing positions 12.1, 12.2, and 12.3. These items should be removable by hand or with a small regular screwdriver. Reassembly Reverse the above procedure in the steps mentioned. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 15 of 36 Phone 281.821.7300 281.821.5550... -

Page 16: Impeller Housing Sub-Assembly - Drawing

NCE AND R REPAIR mpeller housing g sub-assembly y - Drawing gure 13 Figure gure 12 Butterworth®, Inc. – 1 16737 West Hardy St treet – Houston, TX 7 77060 - USA Page 1 16 of 36 Phone .821.7300 .821.5550 nternet E-Mail g@butterworth.com... -

Page 17: Bottom Assembly

Figure 14 41.3 to position 15. Figure 20 for gear alignment instructions when placing position 37 back into position 32.3. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 17 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com... -

Page 18: Bottom Assembly - Exploded View Drawing

View Drawing Figur re 14 Note: This is a lef ft-hand thread Figu re 15 Figure 16 Butterworth®, Inc. – 1 16737 West Hardy St treet – Houston, TX 7 77060 - USA Page 1 18 of 36 Phone .821.7300 .821.5550... -

Page 19: Hub Subassembly

Loctite Product Numbers: 24205: Threadlocker 242 Removable, 0.5ml capsule 24221: Threadlocker 242 Removable, 10ml bottle 24231: Threadlocker 242 Removable, 50 ml bottle Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 19 of 36 Phone 281.821.7300 281.821.5550... -

Page 20: Hub Subassembly - Drawing

Nozzle Ca Right Han Threads Figure 18 Counter clockw wise to loosen nozzle cap. Figure 17 Butterworth®, Inc. – 1 16737 West Hardy St treet – Houston, TX 7 77060 - USA Page 2 20 of 36 Phone .821.7300 .821.5550 nternet E-Mail g@butterworth.com... -

Page 21: Gearbox Subassembly

Figure 20 Fill the gearbox cavity with lubricant; see page 35 for details on the lubricant specification. Gearbox Cavity Figure 19 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 21 of 36 Phone 281.821.7300 281.821.5550... -

Page 22: Gearbox Subassembly - Drawing

Figure 21 Planet gears should be aligned to the dots on the gears as indicated below on the red line. Figure 20 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 22 of 36 Phone 281.821.7300 281.821.5550... -

Page 23: Tool Listing

Figure 28 3. 1 each 1772 253 Main stem m insertion tool; not shown Butterworth®, Inc. – 1 16737 West Hardy St treet – Houston, TX 7 77060 - USA Page 2 2 3 of 36 Phone .821.7300... -

Page 24: Tools

: Pending TOOLS Figure 25 Figure 26 Figure 23 Figure 24 Figure 27 Figure 22 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 24 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site... - Page 25 Release Date : Pending TOOLS Figure 28 Figure 29 Figure 30 Figure 32 Figure 31 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 25 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site...

-

Page 26: Trouble Shooting Guide

Rotation should be smooth and consistent. If that is not the case then parts replacement is most probably required. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 26 of 36 Phone 281.821.7300... -

Page 27: Reference List Of Parts

8663-02 Impeller shaft assembly; type 1; ver. 02 See individual parts See individual parts Non standard None Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 27 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site www.butterworth.com... - Page 28 Non standard Yes None Nozzle bevel gear √ 177008-01 17‐4ph SS ASTM A747‐CCB7CU‐1 Yes Standard None Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 28 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site www.butterworth.com...

- Page 29 Elgiloy,Mineral filled PTFE Contact Butterworth Non standard None 177039-02 Elgiloy,UHMW Contact Butterworth Non standard None Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 29 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site www.butterworth.com...

- Page 30 ASTM A351-CF8M Standard None ASTM A747-CCB7CU- √ 377101 Drive Gear 17-4ph SS Standard None Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 30 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site www.butterworth.com...

- Page 31 ASTM F562 Standard None 47.2 √ 370807-01 End Plate 316 SS ASTM A351-CF8M Standard None Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 31 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site www.butterworth.com...

-

Page 32: Exploded View Drawing

Operators Manual Model : LT Manual No. :132.2008.01.03 Release Date : Pending EXPLODED VIEW DRAWING Figure 33 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 32 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site... -

Page 33: Crossectional Drawing

Operators Manual Model : LT Manual No. :132.2008.01.03 Release Date : Pending CROSSECTIONAL DRAWING Figure 34 Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 33 of 36 Phone 281.821.7300 281.821.5550 Internet E-Mail eng@butterworth.com Web Site... -

Page 34: Standard Spare Part Kit

It is suggested that you possess the correct tools before performing repairs on the LT machine. For a list of tools and tool kit part number see page 24. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 34 of 36 Phone 281.821.7300... -

Page 35: Lubricant Specification

Equivalents are optional; as long as they meet the required specifications. Deviations from this equivalent could serve to invalidate the warranty period. For a complete data sheet and MSDS on Mobilgrease® FM102; contact Butterworth. Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA... -

Page 36: How To Order Spare Parts And Warranty Claim Procedure

Error! Bookmark not defined.. To send in a unit for warranty review, you will need to call the Butterworth® Sales Desk and advise the associate that you wish to return a machine(s) for warranty review. They will issue a Returned Goods Number for tracking your equipment once received by our company.

Need help?

Do you have a question about the LT6Z33NO and is the answer not in the manual?

Questions and answers