Summary of Contents for Anatol VOLT

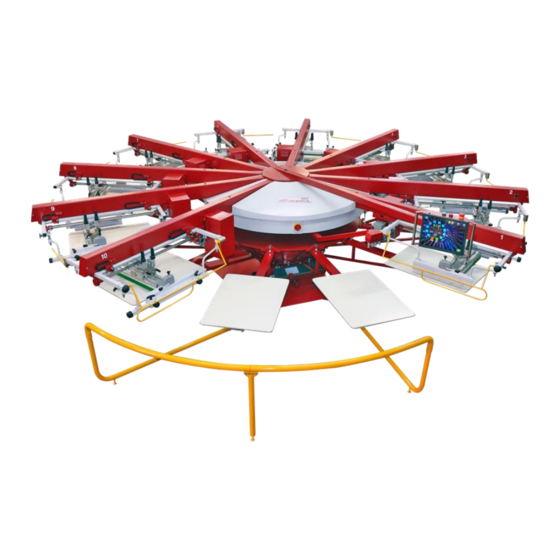

- Page 1 OPERATOR’S MANUAL VOLT ANATOL EQUIPMENT MANUFACTURING CO. 919 SHERWOOD DR. LAKE BLUFF, IL 60044 USA PHONE: 847-582-1825 FAX: 847-582-1854 anatol.com 2018...

- Page 2 We at Anatol welcome you to our family and look forward to a long relationship, allowing us to serve your needs now and in the future.

-

Page 3: Table Of Contents

1.7 Micro Registration 1.8 Operator Safety Guarding 1.9 Lubrication & Maintenance II. Operating Console 2.1 Emergency Stop 2.2 Main Screen Descriptions 2.2.1 Lower Menu 2.2.2 Easy Setup 2.2.3 Upper Menu 2.2.4 Virtual Carousel anatol.com 2.2.5 Machine Setup and Indexing Window... -

Page 4: Machine Setup & Operation

VOLT SECTION I Machine Setup & Operation anatol.com... -

Page 5: Safety Precautions

(pressed in). 1.2 Installation Requirements Installation of any VOLT will be done ONLY be a factory-trained technician and/or by persons approved by Anatol Equipment Manufacturing Company. We will furnish one (or more) factory technician(s) to assist and supervise equipment installation. - Page 6 1.2 Installation Requirements A) Remove the VOLT indexer from the skid and all wrapping/packaging material. Remove all blocking, screws, nails and/or strapping materials from any components that were fastened or secured for shipment. B) A forklift with 6-8’ extended forks capable of lifting 5000 lbs. will be required to unload the truck and remove the base from its skid.

- Page 7 1.2 Installation Requirements D) The installing technician will assemble and level the rest of the machine. Some additional labor will be required during the installation assembly, most likely some lifting when installing the print heads. anatol.com...

-

Page 8: Preliminary Information

1.3 Preliminary Information Thank you for choosing our Anatol product. In order to ensure the quality of the machine, please carefully read the instruction manual. 1. When opening the package, please carefully check the machine along with the documents. If a problem occurs, please contact our company immediately. -

Page 9: Specifications

1.4 Specifications VOLT L 20”x20” Print Area ALL ELECTRIC SCREEN PRINTING ITEM STATIONS/COLORS MAX IMAGE SIZE MAX SCREEN SIZE PALLET SIZE VOLT-0604-2020 20”x20” 26”x36” 16”x22” VOLT-0605-2020 20”x20” 26”x36” 16”x22” VOLT-0806-2020 20”x20” 26”x36” 16”x22” VOLT-0807-2020 20”x20” 26”x36” 16”x22” VOLT-1008-2020 10/8 20”x20”... - Page 10 1.4 Specifications VOLT L 20”x20” Print Area ALL ELECTRIC SCREEN PRINTING ITEM STATIONS/COLORS DIAMETER ELECTRICAL REQUIREMENTS phase, 208 VAC, 18A VOLT-0604-2020 11’4” 3 phase, 208 VAC, 11A phase, 208 VAC, 19A VOLT-0605-2020 11’4” 3 phase, 208 VAC, 12A phase, 208 VAC, 20A VOLT-0806-2020 12’2”...

-

Page 11: Machine Start-Up Procedure

“ON” position. You will hear an audible beep and the computer will scan for connected devices (indexer, print heads, flashes) Check that all the safety bars are in the correct (closed) position. The machine will not operate with a safety bar being open. (see photo) anatol.com... - Page 12 Pressing the “START” button will start the machine after a short (programmable time duration) warning chime. To stop the machine normally, press the CYCLE STOP button. The machine will stop when the index/print cycle is completed. anatol.com...

-

Page 13: Pallet Placement

1.6 Pallet Placement There are currently 2 different styles of mounting for pallets on the VOLT. Both require the pallets to be locked in place before running the press. Also, attention must be given to the orientation of the long end of the pallet on “ANATOL STYLE”... -

Page 14: Micro Registration

5) Micro adjustment Knob 3 – moves the bottom of the screen left to right B. When the adjustments are completed, lock both the front and rear micro locks. C. Lock the left side micro locks. D. Repeat these steps for each print head. anatol.com... -

Page 15: Operator Safety Guarding

1.9 Lubrication & Maintenance The VOLT machine and its motors are fully electric. Be sure to check the oil levels in the servo indexer as described below and if necessary, supplement or replace the missing oil with new oil of the same type. -

Page 16: Operating Console

VOLT SECTION II Operating Console anatol.com... -

Page 17: Emergency Stop

To restart the machine, refer to the standard start-up procedure. Once the E-Stop button has been depressed, to release: Turn the button counter- clockwise to release and perform the reset procedure. anatol.com... -

Page 18: Main Screen Descriptions

Virtual carousel – illustrates the current condition of pallets and machine heads. Troubleshooting – pressing the button will open the Troubleshooting window Maintenance reminders – pressing the button will open the Maintenance Reminders window. More information for each section can be found in the following menu subsections of this manual. anatol.com... -

Page 19: Lower Menu

Home – pressing this button will start homing all servos. This is necessary every time the press is started and if any malfunction or emergency occurs. Lock – pressing this button closes the indexer. Be sure to set the right bearing on the arm for the fork. anatol.com... - Page 20 (in item 2 above). Easy Setup – pressing this button will switch the machine to Easy Setup. For more details on this mode, see Easy Setup. anatol.com...

- Page 21 There was a break in communication with the machine controller. This is one of the errors that will require restarting the machine, and if this does not fix the problem, contact Anatol service. Empty lower menu – means that the machine is in a single move. Wait until the traffic is complete and the buttons in the lower menu appear.

-

Page 22: Easy Setup

(more details in the section titled Error: No referrer source found). 5. When the machine is operating in any of the printing modes (manual, automatic or test mode), the off-contact (4) returns to the preset level displayed in the main window. anatol.com... -

Page 23: Upper Menu

Counters – access the counter settings menu Warming – access the heating settings menu Setup - Access to the settings and configurations. Lists of windows and codes are available in the section titled List of Windows and Setup Codes. anatol.com... -

Page 24: Virtual Carousel

After clearing the screens, press the button again to return the pallets to their positions below the heads. Clear Info – delete all shirt icons. Head set access buttons – pressing this button will open the print head settings window. anatol.com... - Page 25 Load button before loading the last item to switch to last print or print finish (one shirt will appear on the button) and end the job (stop loading shirts). The machine will turn off each successive print head under which an empty pallet appears. After printing the last shirt, the machine will stop. anatol.com...

- Page 26 A colored light indicates that the indexer lock is not closed (locked). A flashing light indicates that the lock is closing or opening. A colored light indicates that the table is raised up. A colored light indicates that the pallets are in the half index or clear screen position. anatol.com...

-

Page 27: Machine Setup And Indexing Window

A colored light indicates that the safety bar is open. A colored light indicates that the E-STOP safety button is pressed. A colored light indicates a machine error. The error code is displayed above. Call Anatol service if assistance is needed. - Page 28 Last On/Off – when printing with the Work Counter, if the status of the button is Last On, it means that a function is enabled that stops the machine when the last shirt is to be printed. If the button is in the Last Off state, the function is off. anatol.com...

- Page 29 This time is calculated from the end of the indexer movement. (Not recommended for Volt machines) 16. Look – pressing this button will open a dialog where you can change the theme of the background, icon set and language.

- Page 30 2.2 Main Screen Descriptions 2.2.6 Lift Setup WARNING! Before you make any changes, please contact the Anatol service department. Take a picture for your records before making any changes. You can access the lift settings by clicking on the Settings button located in the top menu of the main window.

- Page 31 Turning on Cycle Mode automatically shuts down the Step Back function if Step Back was enabled. Activate/Deactivate Counters With the / button, you can enable or disable the counter for skipped t-shirts that is displayed on the screen in the main window. anatol.com...

- Page 32 If you use your own ink colors, select Pantone format. This will allow you to create your own ink color by adding to the ink color list. 4. Now you can set the appropriate colors used on each print head. See: How to set the ink color anatol.com...

- Page 33 Print Head selection – to switch to Print Head, click the corresponding print head icon. After changing the head mode, the Print icon will light up. On Volt machines, pressing the button will not work if the head is currently set to Quartz, because you have to disconnect the flash from the print head.

- Page 34 Front Speed icon – set the print carriage speed in the forward direction (away from the machine’s center column). Range Limit 1 and Range Limit 2 – this feature is only available on Volt machines with servo/servo print heads. The Range Limit 1 and Range Limit 2 parameters determine the range in which the print carriage travels.

- Page 35 Used to set the pressure of the squeegee on the screen. 12. Hold On/Off button This function is only available on Volt machines with servo/servo print heads for head setup. 12.1 When the Hold On button is pressed in the head settings window, the message displayed on the button changes to Hold Off, which means the carriage can be manually reset.

- Page 36 A shirt must be on the pallet on which you want to perform test printing. 14.2 Select the value of head parameters 14.3 Perform test printing. If the test is okay, you can proceed to full production. anatol.com...

- Page 37 2.3.1 Rapid Wave Quartz Flash Settings Window Flash Sockets The flash sockets on the Volt machines are located on the heads. Insert the plug in the socket and then tighten it. Be sure to protect electrical wires so that they do not come into contact with any moving parts of the machine.

- Page 38 It is therefore advisable to set the flash master power to 100% (extreme right of the knob). To change the curing power, press the Heat Intensity icon. Then a numeric keypad will open where you can enter a power value (0-100%). anatol.com...

- Page 39 Cure Time – the drying time for which the set temperature is maintained. Press the icon and a numeric keypad will open where you can enter the desired time in seconds. Standby Power – recharge power Standby Time – warm up time anatol.com...

- Page 40 Test Function Test cycle – pressing the Test button will raise the table upwards and turn the flash on for a pre-set curing time. After the programmed time has elapsed, the table will lower and the flash will shut off. anatol.com...

- Page 41 To change the warm-up time, press the Flash Time icon. Then the numeric keypad will open where you can enter the desired time. On each flash you can independently activate the function and set the time-independent recharge. When the function is activated, the following message appears on screen: anatol.com...

- Page 42 When the Warm Pallets window is open, the machine switches to the “Ready to warm pallets” mode. The head settings buttons are inactive. The print heads remain disabled and the flash enabled, to ensure that when warming the pallets there is no work done on any print head. anatol.com...

- Page 43 Note the readings from the sensor on the head nearest the flashing station. -In cycle control mode, the machine will execute the set number of turns. One full rotation means that the machine heated each pallet once. anatol.com...

- Page 44 NOTE: Only one time setting can be active at a time. The currently selected time is marked with a symbol. To change the curing time, press the Cure Time icon on the Head Setup screen. A numeric keypad will open where you can enter the desired time. anatol.com...

- Page 45 When you press the Test icon, the pallet with the shirt will table up to the flash curing position for the preset time. After the programmed time has elapsed, the table will drop down and the flash will turn off. anatol.com...

- Page 46 Touch the buttons to enter the desired value and confirm with the Enter button. Alphanumeric Press the buttons indicating the desired name or number and press the Enter key to confirm. anatol.com...

- Page 47 Press the ON/OFF button to turn on individual sequences (green=on, grey=off). In the middle of the window there is a Reset button. It is used to reset the current print status, allowing you to start printing from the beginning. anatol.com...

- Page 48 Continue printing on new shirts – press the green loading station icon until it is empty and press the Start button so the machine finishes printing the remaining shirts. When the first series of shirts is finished, a new series can be printed. anatol.com...

- Page 49 Select Ink Color dialog box. 3.4 The Color Selection window will close by clicking anywhere outside the menu area. Is your ink a Pantone color? See: How to add ink colors to the list anatol.com...

- Page 50 4. Exit search. This button is not visible unless the search option is in use. 5. The plus sign icon opens a space to add a new color. 6. The arrow down icon switches to the next page of the list. anatol.com...

- Page 51 5. Confirm with the OK button. The newly added color will be immediately assigned to the ink color on the head. If you do not want to add a color to the list, you can click outside of the open area at any time by closing the alphanumeric keypad and Color Selection windows. anatol.com...

- Page 52 If the list is empty, no items in the list meet the search criteria. Close the keypad by clicking anywhere outside the open windows. Cancel the search session by pressing the Exit Search button (3). The full list of color names will display. anatol.com...

- Page 53 When the head is inactive, an will display next to that head in the Head Activation window. An will also display in the main window instead of the button that opens the Head Setup window. 5. The Head Activation window will close by clicking anywhere outside the menu area. anatol.com...

- Page 54 Here is a situation that can happen when saving the machine’s operating parameters. Situation: After pressing Enter, a box pops up with a warning and the parameters will not save. Solution: A file with the given name already exists. Please enter a different name for the job or delete it. anatol.com...

- Page 55 Load the selected work. This button is inactive if no item is selected. Search Exit search. This button is inactive if the search option is used. Delete the job. This button is inactive if no item is selected. Switch to the next page of the list. anatol.com...

- Page 56 Solution: If the message “RS232 timeout” is displayed, then Load Job Parameters has failed. The most likely cause is failed communication between the machine driver and the monitor. In that case, turn the machine off and turn it back on again, and then try to load the job again. anatol.com...

- Page 57 The saved job is compatible and may be run on this machine. A message that indicates the size of the machine, for which work has been saved. Information about the type of the head (print/flash) and whether it is enabled (ON) or disabled (OFF). anatol.com...

- Page 58 If a head was a print head in a saved job and is now a flash head, disconnect the flash from that head. 6. The OK button. Pressing this button will load the saved parameters. 7. The Cancel button. Pressing this button will cancel the loading job parameters. anatol.com...

- Page 59 VOLT SECTION III Maintenance anatol.com...

- Page 60 When complete, open the Maintenance window and press the button to the right of the maintenance task you performed. This will reset the countdown and the icon will return to green. Do not ignore these notifications. Perform them as directed to ensure your machine’s operation. anatol.com...

- Page 61 The application may be operated in full screen mode. To enable the mode, use the control in the upper right corner of the screen (1). Another control is used to disable full screen mode (2). anatol.com...

- Page 62 Grease is an extreme pressure, high temperature, water, rust and corrosion resistant grease. It is produced by Century Lubricants Co., Kansas City, KS 66111 3.4 Recommended Maintenance Other than checking the scheduled lubrication, cleaning is the only maintenance required. anatol.com...

- Page 63 VOLT SECTION IV Support Documentation anatol.com...

- Page 64 4. 1 Print Head Carriage 4.1.1 Print Head Control Box 4.1.2 Print Head Carriage anatol.com...

- Page 65 VOLT SECTION V Warranty & Limitation of Liability anatol.com...

- Page 66 1. This warranty covers the installation of equipment by an Anatol Equipment technician or Anatol Equipment Certified Technicians. 2. Repair or replacement of parts found by Anatol Equipment to have a defect in materials, workmanship, or factory preparation within the terms of the Warranty and subject to the terms laid out in “Limitations of Warranty”.

- Page 67 14. Shipping costs for replacement parts are non-refundable to the Customer or distributor. 15. All defective parts must be returned back to Anatol Equipment within 30 days to receive credit. Credit will be determined after parts are inspected and found defective by Anatol technicians.

- Page 68 Notes...

Need help?

Do you have a question about the VOLT and is the answer not in the manual?

Questions and answers