Table of Contents

Advertisement

Quick Links

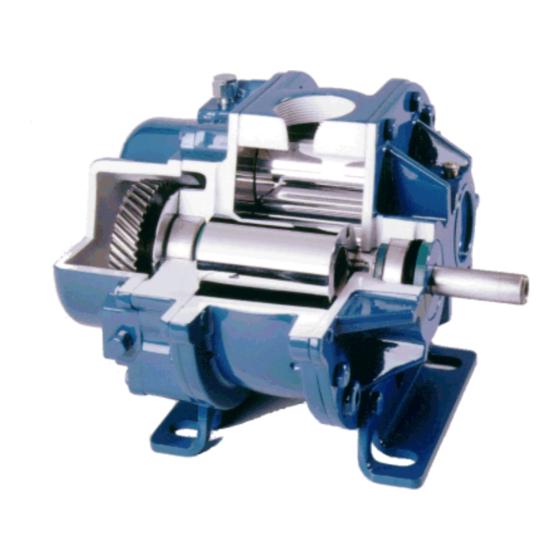

Rotary Positive Blowers

COMPETITOR PLUS rotary blowers are designed to be

interchangeable with equivalent sizes of Roots Universal

®

RAI

, and many Sutorbilt

™

Series L and P blowers. COMPETITOR PLUS

Legend

models are rated up to 15 PSIG discharge pressure or 16" Hg

dry vacuum.

In addition to interchangeability, M-D has improved on

existing designs with the following superior features ordinarily

found only on premium blowers:

Helical Gearing

OMPETITOR PLUS blowers are timed with hardened,

C

precision helical gears, keyed to the rotor shafts, not taper fit

spur gears offered by other manufacturers which have greater

backlash, and can slip and lose timing. Helical gears are also

quieter, reducing mechanical noise.

Stronger Bearings

COMPETITOR PLUS blowers include double row ball

bearings at the gear end, stronger than single row ball

bearings offered by other manufacturers. Drive shaft bearing

is cylindrical roller type for additional strength against side

loading from V-belt drives. As a result of this superior design,

COMPETITOR PLUS blowers offer an average design

bearing life of up to 50% greater than models offered by other

manufacturers.

Rotors with Integral Shafts

COMPETITOR PLUS blowers include precision machined

ductile iron rotors with large, integrally cast shafts, not press

fit and/or pinned shafts offered by other manufacturers, which

can loosen over time and cause rotor clash. All rotors are

dynamically balanced for vibration-free rotation.

Positive End Clearances

End clearances are positively established at the blower gear

end, eliminating the risk of shifting end clearances when

installing or removing drive components. This also eliminates

the need for those special fork and saddle tools required by

other brands to reset end clearances.

Polished Sealing Surfaces

All shaft surfaces in contact with sealing members are

polished to reduce seal wear and risk of leakage.

Individually Tested

Every COMPETITOR PLUS blower is factory tested to assure

you of the highest quality. While some manufacturers perform

only sample testing, M-D goes the distance to insure that your

blower meets our rigid ISO 9001 registered quality standards.

®

California Series B and F, and

ISO 9001 Registration

COMPETITOR PLUS blowers are manufactured under M-D's

ISO 9001 registered quality assurance program, the first

American manufacturer of rotary blowers to gain such

international recognition.

Warranty

Every COMPETITOR PLUS blower is backed by M-D's limited

warranty for a period of 18 months after installation or 2 years

after original blower shipment, whichever occurs first.

Versatility

COMPETITOR PLUS blowers can be field converted from

horizontal to vertical flow, or vice versa, without any special

tools or additional components.

Metric Availability

All COMPETITOR PLUS blowers are available with metric drive

shaft and process connections.

Worldwide Sales and Service

With sales offices and service facilities located on six continents,

you can be assured of availability and service for your

COMPETITOR PLUS blowers.

Material Specifications:

Housing: Cast iron

End Plates: Cast iron

End Cover: Cast iron

Rotors: Ductile iron

Shafts: Ductile iron cast integrally with rotors

Bearings: Gear end - Double row ball, both rotors

Drive end - Cylindrical roller on drive rotor

Single row ball on driven rotor

Drive Shaft: Ductile iron, cast integrally with drive rotor

Gears: Heat treated alloy steel, helical cut

Seals: Lip seals on rotor shafts and drive shaft

Lubrication: Oil splash on gear end, grease on drive end

Model

Max.

Max.

Size

Press.

Vac.

PSI

(in. Hg)

2002

12

16

2004

7

14

3003

12

15

3006

7

12

4002

15

16

4005

10

14

4007

7

14

5003

15

16

5006

10

15

5009

7

14

6005

15

16

6008

12

16

6015

6

12

LEADING THE SEARCH FOR NEW SOLUTIONS

4840 West Kearney Street, P. O. Box 2877

Springfield, Missouri USA 65801-2877

Tel 417 865-8715 800 825-6937 Fax 417 865-2950

www.mdpneumatics.com

Nominal Min.

Nominal Max.

RPM @ Max.

RPM @ Max.

Disch. Press.

Disch. Press.

2940

5275

1480

5275

2080

3600

1150

3600

1820

3600

1300

3600

1000

3600

1900

2850

980

2850

700

2850

1240

2350

890

2350

600

2350

Displ.

CFR

.016

.032

.0616

.102

.061

.121

.160

.132

.221

.323

.246

.395

.740

Advertisement

Table of Contents

Summary of Contents for M-D Pneumatics COMPETITOR PLUS 2002

- Page 1 ISO 9001 Registration COMPETITOR PLUS blowers are manufactured under M-D’s ISO 9001 registered quality assurance program, the first American manufacturer of rotary blowers to gain such international recognition. Warranty Every COMPETITOR PLUS blower is backed by M-D’s limited warranty for a period of 18 months after installation or 2 years after original blower shipment, whichever occurs first.

- Page 2 Performance Blower SPEED 2 PSIG 4 PSIG 6 PSIG 7 PSIG 10 PSIG 12 PSIG 15 PSIG Max. Vacuum Pressure performance is based on inlet conditions Model (RPM) CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP “ Hg CFM BHP of 14.70 PSIA and 70 1170 Vacuum performance is based on inlet temperature...

- Page 3 Tuthill Pneumatics Rotary Positive Displacement Air Blower Models 2002 3003 4002 5003 6005 2004 3006 4005 5006 6008 4007 5009 6015 INSTALLATION OPERATION MAINTENANCE REPAIR WARNING DO NOT OPERATE BEFORE READING MANUAL. LEADING THE SEARCH FOR NEW SOLUTIONS 4840 West Kearney Street, P. O. Box 2877 Springfield, Missouri USA 65801-2877 Tel 417 865-8715 800 825-6937 Fax 417 865-2950 E-mail: mdpneumatics@tuthill.com...

- Page 4 SAFETY INSTRUCTIONS 1. Do not operate before reading the enclosed instruction manual. 2. Use adequate protection, warning and safety equipment necessary to protect against hazards involved in installation and operation of this equipment. WARNING WARNING WARNING Keep body and Hearing Do not operate clothing away from Protection...

-

Page 5: Table Of Contents

TABLE OF CONTENTS SECTION PAGE INTRODUCTION OPERATING DATA INSTALLATION LUBRICATION PREVENTATIVE MAINTENANCE STARTUP CHECKLIST TROUBLESHOOTING RECOMMENDED SHUTDOWN PROCEDURE DISASSEMBLY AND INSPECTION BLOWER DISASSEMBLY BLOWER ASSEMBLY MAINTENANCE AND SERVICE SPECIFICATIONS SHEET SPECIAL TOOL DRAWINGS CUTAWAY VIEW AND PARTS LIST WARRANTY STATEMENT SAFETY PRECAUTIONS For equipment covered specifically or indirectly in this instruction book, it is important that all personnel observe safety precautions to minimize the chances of injury. -

Page 6: Introduction

INTRODUCTION CONGRATULATIONS on your purchase of a new Tuthill Pneumatics COMPETITOR PLUS Rotary Positive ™ Displacement Blower from Tuthill Pneumatics Group. Please examine the blower for shipping damage, and if any are found, report it immediately to the carrier. If the blower is to be installed at a later date make sure it is stored in a clean, dry location and rotated regularly. -

Page 7: Installation

INSTALLATION WARNING: Customers are cautioned to provide adequate protection, warning and safety equipment necessary to protect personnel against hazards involved in the installation and operation of this equipment in the system or facility. Do not use air blowers on explosive or hazardous gases. Casing pressure must not exceed 25 PSIG (1.72 bar g). Each size blower has limits on pressure differential, running speed, and discharge temperature, which must not be exceeded. -

Page 8: Lubrication

LUBRICATION The bearings at the drive shaft end of the blower are grease lubricated. The timing gears and bearings at the other end are lubricated by the lower timing gear (when in the horizontal flow configuration) acting as a oil slinger, carrying oil to the upper timing gear and providing splash lubrication for the bearings. -

Page 9: Preventative Maintenance

PREVENTATIVE MAINTENANCE A good maintenance program will add years of service to your blower. A newly installed blower should be checked frequently during the first month of operation, especially lubrication. Check oil level in the gear housing and add oil as needed. Complete oil changes are recommended every 1000 operating hours, or more frequently depending on the type of oil and oil operating temperature. -

Page 10: Troubleshooting

TROUBLESHOOTING Although COMPETITOR PLUS blowers are well designed and manufactured, problems may occur due to normal ™ wear and the need for readjustment. The chart below lists symptoms that may occur along with probable causes and remedies. SYMPTOM PROBABLE CAUSE REMEDIES Loss of oil. -

Page 11: Recommended Shutdown Procedure

RECOMMENDED SHUTDOWN PROCEDURE TO MINIMIZE RISK OF FREEZING OR CORROSION When high humidity or moisture is present in an air piping system, condensation of water can occur after the blower is shut down and the blower begins to cool. This creates an environment favorable to corrosion of the iron internal surfaces, or in cold weather, the formation of ice. -

Page 12: Disassembly And Inspection

DISASSEMBLY & INSPECTION With proper maintenance and lubrication, normal life expectancy for gears, bearings, and seals can be achieved. However, over a period of time these parts must be repaired or replaced to maintain the efficiency of your blower. This section is written in a way that will allow you to completely disassemble your blower. The inspection of certain repairable or replaceable parts is referred to at the point of disassembly where these parts are exposed. - Page 13 Press rotors out of end plate in press if available. If Using a tube or round bar of a slightly smaller diameter press is not available, support end plate and rotors in than the shaft clearance holes in the end plates, tap the the housing.

-

Page 14: Blower Assembly

BLOWER ASSEMBLY Place end plate [Item 4] on rotors. After thorough cleaning of the seal and bearing bores of both end plates apply a thin coat of sealant on the Apply a thin coat of lubricant on the rotor shafts and the outside diameter of the new seals and press them into inner race of the bearings. - Page 15 ADJUSTING ROTOR INTERLOBE CLEARANCE If clearances check OK, put a spacer [28] and a shim Using feeler gauges take interlobe readings and record [30] on each shaft. Timing shims that were removed on each side of housing as indicated in Figure A5 below. should be put back on the shaft from which they were By removing or adding shim behind the helical gear, it removed.

-

Page 16: Maintenance And Service Specifications Sheet

MAINTENANCE AND SERVICE SPECIFICATIONS SHEET ASSEMBLY CLEARANCES Metric values (mm) are shown in parentheses ( ) All other values are in inches LOBES TO END PLATES LOBE TO CASING INTERLOBE MODEL TOTAL DRIVE END GEAR END MINIMUM MAXIMUM MININUM (MIN./MAX.) (MINIMUM) (MINIMUM) 2002, 2004... -

Page 17: Special Tool Drawings

SPECIAL TOOL DRAWINGS All dimensions shown are in inches. MODEL PART NUMBER 2000 2200718B 1.560± 1.27± .98± .70± 1.10± 3.50± 3.00± .001 .005 .005 .005 .005 .005 .005 3000 3300718B 2.035± 1.70± 1.335± 1.015± 1.415± 3.75± 3.00± .001 .005 .005 .005 .005 .005... -

Page 18: Cutaway View And Parts List

CUTAWAY VIEW AND PARTS LIST ITEM DESCRIPTION ITEM DESCRIPTION Housing Screw, Hex Head Mounting Foot Screw, Hex Head 8 ** Drive End Plate Screw, Hex Head Gear End Plate Plug, Oil Gear Cover Relief Fitting Drive Rotor Grease Fitting Driven Rotor Bearing Retainer Timing Gear Lip Seal, Drive Shaft... -

Page 19: Warranty Statement

WARRANTY Subject to the terms and conditions hereinafter set forth and set forth in General Terms of Sale, Tuthill Pneumatics Group (the seller) warrants products and parts of its manufacture, when shipped, and its work (including installation and start-up) when performed, will be of good quality and will be free from defects in material and workmanship. - Page 20 NOTES...

Need help?

Do you have a question about the COMPETITOR PLUS 2002 and is the answer not in the manual?

Questions and answers