Summary of Contents for airBee HOME

- Page 1 AIR AND SURFACE SANITIZING DEVICE HOME USE AND MAINTENANCE MANUAL Dott. Ing. Luigi Palcone 22/12/2020 1.2.1 287-CE-RFA-2020 (Editing) (Date) (Version) (Project)

- Page 2 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Pag. 2 di 88...

-

Page 3: Table Of Contents

Drawings, diagrams, descriptions and explanations necessary for the use, maintenance and repair of the machine and to verify its correct functioning Fig.5.1 – Home elevation view Fig.5.2 – Home power supply and motherboard Fig.5.3 – Air flow into the device Fig.5.4 – Initial filtration Fig.5.5 –... - Page 4 Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.5.6 – Sensor for detecting pollutants Fig.5.7 – Elevation view of the device base Identification of main components Fig.5.1.2 – Home wiring diagram Fig.5.1.3 – Ballast 4.1.1 Control system Fig.5.1.1.1 – LED board Recognition of left and right side of the machine: Fig.5.2.1 –...

-

Page 5: Company Name, Address Of The Manufacturer And Introduction

AIR – BEE S.r.l. Via Colico, 10 - 20158 – MILANO - P.IVA 10755150967 This document represents the use and maintenance manual of the HOME device, used to sanitize the air through a photocatalysis process that prevents microorganisms such as viruses, molds and / or particles of "dirt"... -

Page 6: Update Of The User's Manual

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Read this use and maintenance manual carefully before using it and / or for any work or routine / extraordinary maintenance. Carefully observe the labels, pictograms and indications affixed to the machine, as well as plates or cards showing the technical and / or performance characteristics of the machine. - Page 7 Via Colico, 10 – 20158 – Milano P.IVA 10755150967 The definition of the warranty terms for AIRBEE devices is determined according to the general conditions of supply. The warranty does not cover items that have been repaired, modified (even partially) or replaced by non-original and / or unauthorized spare parts.

-

Page 8: Summary Of Symbols And Terminology Used In This Manual

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 The transfer of the machine to another user also includes the delivery of the manual. Failing that, not being able to acquire information on the correct use of the device, all liability on the part of the manufacturer, including any warranty, will be void. - Page 9 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 occur. WARNING Alerts the reader to a dangerous situation that could cause minor injuries. MACHINE OPERATOR OR DRIVER Identifies qualified and professionally trained personnel who, in compliance with the legislation in force in the country where the operation is performed, are authorized to carry out only switching on, using, setting up (obligatorily with the protections enabled and the machine off) and switching off...

- Page 10 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 interventions exclusively on electrical devices to carry out adjustments and maintenance in absolute compliance with the instructions contained in this manual. Equipped with the required personal protective equipment (PPE). OBLIGATION TO READ THE MANUAL Obligation to read the Safety Prescriptions and in particular the entire use and maintenance manual.

- Page 11 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Cut resistant safety gloves / Insulating gloves. There are many types of this product on the market. Regardless of the brand chosen, it is essential that they are equipped with CE marking and that they perform the characteristics of insulation and protection from any punctures, cuts and abrasions to hands.

-

Page 12: Definitions

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 2.2 DEFINITIONS Definizione Descrizione Characteristic of metal products that expresses sheet resistance to thinning Anisotropy during deformation. Materials used to isolate the device from the support structures so that the mechanical vibrations do not propagate, but are absorbed by these supports Anti vibration (anti-vibration) in the shortest possible time. - Page 13 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 for its management. The person (s) in charge of installing, operating, adjusting, cleaning, repairing and moving or maintaining a machine The person (s) in charge of installing, operating, adjusting, cleaning, repairing and moving or maintaining a machine.

-

Page 14: Intended Use Of The Machine

It also allows the microbial and viral load to be brought back within optimal hygiene standards. With the AirBee devices, sanitization is conceived as an ordinary activity because although we do not notice it, the air we breathe every day in the rooms is... - Page 15 (UV lamp + titanium dioxide photocatalyst) shown in Fig.1.5 .2. The AirBee air device is especially effective inside small and medium-sized rooms (for large spaces it is possible to connect multiple devices, connected to each other, thus increasing their range of action), with high probability presence of polluting loads such as: Pag.

- Page 16 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.1.5.1 – Air intake into the device ● Small, medium and large homes (network of multiple devices); ● Emergency Rooms; ● Medical and / or dental offices; ●...

- Page 17 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 The following slide shows the direction of the air flow which, once it enters the device, will be sanitized and reintroduced into the environment without the volatile substances harmful to the human body.

-

Page 18: Education / Training Of Maintenance Workers

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.1.5.2 – Air Sanitization Circuit 2.4 Education / training of maintenance workers The main purpose of this document is to bring the user of the device closer, in a simple and gradual manner, to the legislation for the prevention of accidents and to those rules of conduct that are the basis for a correct and safe use of the device (Essential requirements for safety required by the applicable directives and harmonized standards). - Page 19 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 In this regard, the safety information and requirements contained in this use and maintenance manual must always be respected as they are absolutely binding for the correct use of the machine. All CE marked devices are accompanied by the declaration of conformity (a copy is given in Chapter 3) with which the manufacturer guarantees the compliance of the device with the essential safety requirements.

-

Page 20: Model

(see Chapter 17) that uniquely identifies it, with the serial number. The facsimile of the CE plate is shown in the last chapter (Chap.17). The machines, produced by AirBee, are carried out adequate tests and inspections, designed during the prototype construction phase, in order to intercept any construction defects, malfunctions or other types of problems associated with the construction and safety of the machine and / or its users. - Page 21 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 ● Transformer IN 220VAC - OUT 12VCC 24VAC; ● # 1 Suction fan (Fig.1.5.1) for introducing air into the air sanitization circuit; ● Frame in wood and steel; ●...

- Page 22 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.2.2 shows the image of the antibacterial filter, a strip of mesh covered with catalyzing material (titanium dioxide TiO2), to increase the air purification capacity of the device. Pag.

-

Page 23: Ec Declaration Of Conformity (Facsimile)

Via Colico, 10 20158 Milano P.IVA 10755150967 The person in charge of setting up the technical file and its detention are Messrs Pasquale Sannini and Gatti Luca, as legal representatives of AirBee S.r. Declares that the machine Type Model HOME... -

Page 24: General Description Of The Machine And Technical Specifications

The device has been created, with different models, to best meet the air sanitization needs for the environments in which it has to operate. The HOME model has been studied and designed to be used in medical environments where the required performance level is high. - Page 25 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 of innovative technology without causing damage to the health of users. Fig.4.1 shows the image of the narrow-mesh HEPA filter with high filtration performance characteristics for fine dust.

-

Page 26: Operation Via App

Fig.4.2 – Scheme of the photocatalysis process AirBee devices for air sanitization, through the PCO (Photocatalytic Oxidation) / photocatalysis process, destroy the molecular structure of bacteria, viruses and molds. This completely innovative photocatalysis process produces extraordinary results without having... -

Page 27: Manual Operation

Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Thanks to the simple and functional "AIR BEE Home" APP, which runs on both Android and iOS systems, the user can also receive information from their smartphone as well as set the different operating modes that the platform provides. -

Page 28: Factory Default

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 SLEEP. UV lamp on, minimum fan speed, visual communication LEDs off and the front ones off; AUTO. UV lamp on, automatic fan speed, visual communication LEDs on; OFF. -

Page 29: Detail Of Visual Signaling Led

Via Colico, 10 – 20158 – Milano P.IVA 10755150967 At the rear, as shown in Fig.1.5.2, the HOME device has a hole of about 1mm in diameter. Using a thin tip like that of a toothpick, it is possible to lightly press the button located inside this hole (Fig.4.3.1). - Page 30 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 On the front and at the bottom, as shown in Fig.1.5.2, there are LEDs designed for visual signaling, in compliance with the requirements of directive 93/42 / EEC. The possible combinations of lights are described below so that the user can have an immediate understanding of the meaning of the different light combinations that are emitted by the device:...

-

Page 31: Scope Of Use Of The Machine

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 signaling, the system restarts to attempt a new connection, therefore the Initialization OK signal reappears; ● To check if the device is connected in ACCESS POINT mode, the LEDs in fig. 4.4.1 will be colored red. -

Page 32: Technical Specifications

In this way it is possible, at any time, to determine the life cycle of the product from its creation to delivery to the end user. The HOME technical sheet follows Typology... -

Page 33: External Application Operation

UART mode, PCB antenna 3.7 External application operation The AIR-BEE devices (Home, Wall, ... etc.), created to perform the innovative function of natural sanitization through the photocatalysis process, can optionally be equipped with a centralized software system. Its peculiar function is, thanks to specific probes / sensors, to "smell"... - Page 34 Via Colico, 10 – 20158 – Milano P.IVA 10755150967 there are no problems using it within your home network. Fig. 4.7.1.1 shows the initial page where you can LOGIN and enter your credentials, username and password. If the user is at his first access, it is necessary to proceed with the registration (Fig. 4.7.1.2) where little information will be entered including the password which, for security reasons, must have a minimum length of 8 characters.

- Page 35 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.4.7.1.1 – Login Fig.4.7.1.2 - Registration Fig. 4.7.1.3 shows the interface that is used for adding devices to the network, created through the device used that performs the task of access point for other devices and connection to a remote server, using the MQTT protocol.

- Page 36 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.4.7.1.3 – Information GPS must be activated in order to receive Weather information as well as to record the location of the device during registration. Pag. 36 di 88...

- Page 37 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.4.7.1.4 – Reading of values obtained from internal sensors In Fig. 4.7.1.4 you can see how easily it is possible to read the features managed by the APP.

-

Page 38: New Device Registration

● IP address for device registration. Necessary the first time when communicating in local WI-FI mode with the device; ● Option that indicates whether the device is already configured on the home WI-FI network (connected to the line provided by the ISP) and then connected to the MQTT server;... - Page 39 Operation Lamp hours Percentage of filter wear. To be changed every 1000h (One thousand hours); Device control buttons. They vary by device. In the HOME version there will be speed, auto, sleep and shutdown control buttons; Remote device status: detected only for the home device;...

- Page 40 Via Colico, 10 – 20158 – Milano P.IVA 10755150967 The layout of a Home device is shown in Fig. 4.7.2.2, and the information read by the sensors, present within the network, is shown in Fig. 4.7.2.3. Fig.4.7.2.1 – New device registration Once the device has been inserted into the network, it is possible, as described above, to check its status and the information read in real time.

- Page 41 ● Remote device status: detected only for the home device; ● Indicators of gas and particle parameters detected. The layout of a Home device is shown in Fig. 4.7.2.2, and the information read by the sensors, present within the network, is shown in Fig. 4.7.2.3.

- Page 42 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.4.7.2.2– Home data Pag. 42 di 88...

- Page 43 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.4.7.2.3 – Sensor reading Fig.4.7.2.4 – Description of the MQTT connection Pag. 43 di 88...

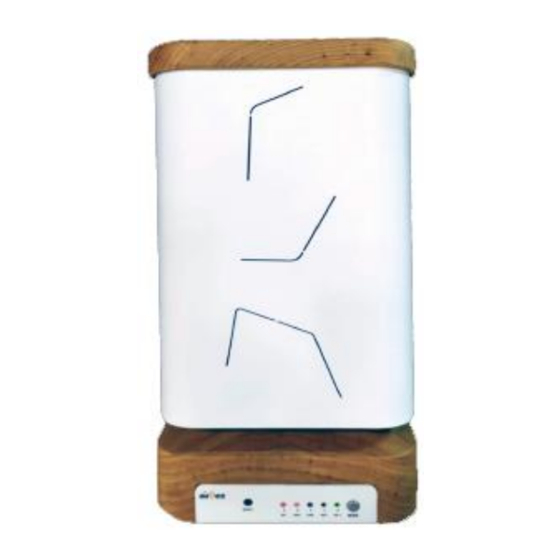

- Page 44 The next paragraphs will provide information on the device necessary for the use, maintenance and repair of the AirBee sanitizer. Fig.5.1 – Home elevation view Fig.5.1 shows the elevation view of the device showing the dimensions of the device components.

- Page 45 Wi-Fi Module FTR-F3CA005E Fig.5.2 – Home power supply and motherboard Fig.5.3 shows the diagram of the direction of the incoming air flow. As can be seen from this drawing, the air is introduced into the sanitation chamber through the suction of the fan presented in Fig.1.5.1.

- Page 46 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 found in the upper part of Fig.5.3 obtained by the passage of air from the large mesh filter, hit by UV light. Most of the sanitized air is extracted from the upper part of the device, as shown in the following drawing, but the slits, placed on the side of the frame, allow a first exit of filtered and sanitized air, as shown in Fig.

- Page 47 Fig.5.4 – Initial filtration Fig.5.5 shows the base where the ballast is present, for powering the UV lamp, and the transformer. On the perimeter of the base there are LEDs to provide lighting for visual signaling of HOME operation. LED Board BALLAST...

- Page 48 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.5.5 – Base of the device Viti di fissaggio Sensore intercettazione inquinanti Fig.5.6 – Sensor for detecting pollutants Fig.5.7 shows the elevation of the base from which it is possible to see the indicator lights for activating the device functions.

-

Page 49: Identification Of Main Components

7. UV lamp; Warning: danger of electrocution. Never open the device case wihen the power plug is inserted. pericolo di folgorazione. The following slide shows the wiring diagram of the components responsible for the operation of the HOME. Pag. 49 di 88... -

Page 50: Control System

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Fig.5.1.2 – Home wiring diagram The following image (Fig.5.1.3) shows the ballast, namely the power supply of the UV lamp (s) inside the device. Fig.5.1.3 – Ballast 4.1.1 Control system... -

Page 51: Recognition Of Left And Right Side Of The Machine

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 visual communication ones make a gradual transition from green to red and vice versa, while the LEDs on the front panel turn on and off progressively, until the final completion of the ignition. -

Page 52: Instructions For Assembly And Disassembly

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Left side Right Side Sanitized air outlet Air inlet to be sanitized Fig.5.2.1 – Front elevation It follows that the front is the one where the power button is shown, while the rear is where the mains power input connector (230V) is located. - Page 53 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 3. Make sure that the machine is in a perfect horizontal position with respect to the surface (horizontal or vertical) on which it is fixed; 4. Before starting the machine, check that the frame has been securely closed to avoid potential risk of electrocution.

-

Page 54: Adjustments

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 For disassembly, the operations to be carried out are the same as for assembly, but clearly in reverse.. First of all, disconnecting from the central electrical network and after waiting a few seconds, start with the disassembly operations. -

Page 55: Requirements For Operating And Maintenance Personnel

4.6 Requirements for operating and maintenance personnel The personnel assigned to the use (assembly and disassembly) and maintenance of the device in the event that they are not authorized and recognized by AirBee, must have adequate skills in mechanics, electronics and electrical engineering. These peculiar characteristics, together with the consultation of this instruction manual, make it possible to obtain the maximum possible result from the device in question. - Page 56 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 electrical circuits can lead to a potential fire risk. Check for any worn, deformed or rusting parts (art.7 DPR 164/56). The Visiva presence of at least one of the three conditions must be immediately resolved through an immediate revision of the device.

-

Page 57: Warnings For Safe Use

In the event of a fuse or other electrical and / or electronic components breaking, do not attempt to repair the product, contact the manufacturer and / or the technical assistance of AirBee or one of its partner centers. In the event that the external device is somehow contaminated / soiled, it is recommended to clean it carefully with a damp cloth, taking care to remove the mains power supply. - Page 58 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 network. Quelli che sono descritti di seguito rappresentano i pittogrammi e/o la segnaletica di pericolo che deve essere predisposta in prossimità o a bordo della macchina. WARNING. Risk of electrocution WARNING.

-

Page 59: Periodic Maintenance And Checks

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 5 Periodic maintenance and checks According to the provisions of Art. 71, paragraph 4, point 2 and paragraph 8, point 2 of Legislative Decree 81/08 maintenance interventions must be carried out at regular intervals. From the norm it is clear that maintenance activities are an essential condition for the optimal maintenance of the machine. -

Page 60: Cleaning

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 the most trivial safety measures, such as disconnecting the device from the network during maintenance activities. 5.1 Cleaning The machine must be periodically cleaned to clean it of any residual dust and / or dirt that may have deposited during the operation of the machine. -

Page 61: Filters Cleaning

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Filters cleaning 5.1.1 Routine maintenance of the machine involves cleaning the filters and the fan in order to remove any dust deposits that may have settled during the machine's operating cycle. Filters play an important role within the air sanitization cycle. - Page 62 Cleaning the fan The AirBee's air sanitizer fan is the only mobile component capable of producing vibrations, directly proportional to the rotation speed of the blades. In this regard, it is important that it is periodically cleaned thoroughly, by carrying out the following procedure: Pag.

-

Page 63: Fan Cleaning

P.IVA 10755150967 5.1.2 Fan cleaning The AirBee's air sanitizer fan is the only mobile component capable of producing vibrations, directly proportional to the rotation speed of the blades. In this regard, it is important that it is periodically cleaned thoroughly, by carrying out the following procedure: The AirBee's air sanitizer fan is the only mobile component capable of producing vibrations, directly proportional to the rotation speed of the blades. -

Page 64: Screw Tightness Check

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 For the maintenance of the electrical system (Fig.5.1.2) it is absolutely necessary that you have sufficient skills and technical knowledge or, if not, contact the manufacturer. An incorrect intervention could compromise the integrity, operation, and safety of the machine. -

Page 65: Component Replacement

/ or by authorized workshops with specific experience and knowledge of the machine. The use of components not supplied by AirBee voids the warranty of the machine, and / or any liability attributable of the manufacturer. Before carrying out any replacement, the machine must be placed in STOP condition and the power supply must be completely disconnected from the mains. - Page 66 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Any removed and / or replaced component must not be left inside the frame for any reason, it must be removed and disposed of in accordance with current legislation.

- Page 67 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 CAUTION. Exposure to UV rays is dangerous for the eyes and skin. It is recommended to NEVER use the lamp outside the safe place in the device or without the foreseen protections.

-

Page 68: Example Photos Of The Safety Devices

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 6 Example photos of the safety devices During the design and construction phase, all the potential risk conditions associated with the use of the machine were resolved. The external case or frame, without edges and rough parts, represents the main guard of the air sanitizer and has been designed to be placed on a horizontal plane. - Page 69 Due to mechanical risks, in all AirBee devices, there are no sharp parts and the only moving parts are the fans, which in any case are protected.

-

Page 70: Description Of The Workplaces

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 been designed provide a valid prevention tool but an inappropriate use could pose serious risks to the health of the users. 7 Description of the workplaces Although there are no "traditional" workplaces, maintenance for this type of machine can only be entrusted to personnel with adequate training and experience, or to operators who have read this use and maintenance manual and have read all potential and residual risks of the machine. -

Page 71: Prohibitions

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 ● ● General visual check of the whole machine (evident deformations or breakages of the structure, protections, etc.), check of the conditions of the power supply cable, cable glands, etc .;... - Page 72 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 No part of the machine must be removed or tampered with Do not remove or render ineffective the guards Do not make any modifications to the machine unless expressly authorized by the manufacturer Do not dispose of removed and / or replaced parts into the environment Do not carry out maintenance activities on the machine unless you have made...

- Page 73 In case of incompatibility between the plug of one appliance and the wall socket it is preferable to replace the second. Never let the AirBee sanitizing device be left unattended in the hands of children, especially when it is in operation (and connected to the mains).

-

Page 74: Description Of The Intended Use Of The Machine

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 8 Description of the intended use of the machine The devices, subject of this use and maintenance manual, have been designed and manufactured to carry out an air sanitization process through a photocatalysis process. Our devices, as already described above, are particularly effective for: ●... -

Page 75: Reasonably Foreseeaable Misuse

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 ● It is not allowed to modify or replace parts of the machine without the prior authorization of the manufacturer; ● Use original spare parts and, if necessary, always consult the manufacturer in advance in case of doubts and / or uncertainties;... -

Page 76: Instructions For Installation And Assembly Aimed At Reducing Noise And Vibrations Produced

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 9 Instructions for installation and assembly aimed at reducing noise and vibrations produced The machine must be installed, adjusted and maintained in the manner described above. In particular, the filters must be cleaned regularly according to its use and / or the type of environment to be sanitized. -

Page 77: Residual Risks

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Periodically check the condition of the fan, manually checking that the blades rotate without any impediment. Carry out this check in conjunction with the periodic cleaning activities. 10 Residual risks During the design phase, an analysis of all possible risks was carried out, for which technical solutions were identified that eliminated or reduced them. - Page 78 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 The rotating and moving parts of the machine have Entanglement in rotating or been adequately protected. However, it is necessary moving parts; not to wear: fluttering clothes, scarves or any garments that could get caught The machine is equipped with external covers, do not allow the machine to operate during maintenance...

-

Page 79: Risks To Health

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 10.2 Risks to health This type of risk is the one that relates to human-work environment interaction. We talk about hygienic-environmental risks. Residual risk Protective measures to be taken Where there is a total absence of ventilation / air recycling, it is necessary to suspend the activity of the machine to resume Microclimate... -

Page 80: Method To Be Followed In The Event Of An Accident Or Breakdown

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 operating instructions to the workers who deal with the maintenance of the machine 11 Method to be followed in the event of an accident or breakdown The basic legislation of the guidelines is constituted, in order, by the laws of the State already in force that give the knowledge for the prevention of accidents and occupational hygiene, as well as by the European directives implemented and transformed into laws that apply to the field of machines and in general working environments with particular regard to industry,... - Page 81 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Before administering any type of medicine, the existence of personal impediments must be verified, such as allergy to particular drugs or molecules. Before any direct rescue operation, medical assistance must be immediately alerted by calling 118 and / or the doctors on call in case of accidents at work.

-

Page 82: Transport - Storage

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 12 Transport – Storage The machine is shipped using packaging capable of withstanding the normal treatment undergone during transport. Once received, the unit must be inspected to detect any damage that may have occurred during shipment due to incorrect handling. - Page 83 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 Pag. 83 di 88...

-

Page 84: Recovery After A Period Of Inactivity

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 13 Recovery after a period of inactivity After a period of no-use of the machine it is necessary: ⮚ Carry out a general visual check to make sure there are no damages to the structure; ⮚... -

Page 85: Safety Signs On The Machine

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 14 Safety signs on the machine In order to complete the series of actions aimed at making the machine safe, specific signs have been applied to the same which, with the relative pictograms, indicate where the risks are present. -

Page 86: Instructions For Decommissioning And Disposal Of The Machine

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 15 Instructions for decommissioning and disposal of the machine 15.1 Disposal of components and materials When the machine should be scrapped, its parts must be disposed of separately, taking into account the different nature of the same (eg: metals, plastic and rubber, etc.) by appointing, in this regard, specialized and authorized companies, in compliance with the provisions of the law in force regarding the disposal of industrial waste. - Page 87 AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 ● Insufficient tightening of screws or bolts; ● A possible impact may have deformed some Excessive machine vibration elements (e.g. fan); ● Uneven wear of the fan. In this case it will have to be repaired.

-

Page 88: Ce Plate

AIR – BEE S.r.l. Via Colico, 10 – 20158 – Milano P.IVA 10755150967 16 CE PLATE Pag. 88 di 88...

Need help?

Do you have a question about the HOME and is the answer not in the manual?

Questions and answers