Table of Contents

Advertisement

Quick Links

www.beltalignmenttool.com

DIGI-BELT XF-3000 BELT Tension Tester

Digital Measurement Tool Instructions

The Digi-Belt™ tension measurement tool is easy to use and gives repeatable belt

tension measurements. The following instructions for use define the procedure

for different belted applications. You must have the force deflection values for

the system you are working on. These values are readily available from your belt

and machine manufactures.

Model 3000-110 Maximum Deflection Force 110 lbs.

Model 3000-220 Maximum Deflection Force 220 lbs.

Section 1. Basic Single & Multi Belt Tensioning Procedure

Section 2. XF B.A.T. Green Laser Single & Multi Belt Tensioning Procedure

Section 3. Wide Belt Procedure Using Wide Belt Adapters

Section 4: Reference photos.

Section 5: BT 357D Operation and Specifications.

www.beltalignmenttool.com

800-997-4467

sales@beltalignmenttool.com

800-997-4467

sales@beltalignmenttool.com

Advertisement

Table of Contents

Summary of Contents for BELT ALIGNMENT TOOL DIGI-BELT XF-3000

- Page 1 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com DIGI-BELT XF-3000 BELT Tension Tester Digital Measurement Tool Instructions The Digi-Belt™ tension measurement tool is easy to use and gives repeatable belt tension measurements. The following instructions for use define the procedure for different belted applications. You must have the force deflection values for the system you are working on.

- Page 2 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com DIGI-BELT™ XF 3000 Kit Contents: a. 1-BT-357D: Digital Belt Tension Tester b. 1-BT-DSS-150: Deflection Span Scale c. 1-BT-ORS-25: Span Scale O-Ring d. 2-BT-357: B.A.T. Laser Magnetic Angle Brackets e. 2-BT-P24: Steel Magnet Adapter Plates 2-BT-357: B.A.T. Laser Magnetic Adapters g.

- Page 3 ZERO line (see picture 2) is even with the adjacent belt or even with the lasers. (B.A.T. Belt Alignment Tool Method as described in section 2) IF needed again Zero the BT-357D by pressing the ZERO button Apply a sufficient force to BT-357D to deflect the belt such that the O-ring is in-line with the other belts.

- Page 4 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com Diagram 2: Position O-Ring on Deflection Span Scale Diagram 3: Force Measurement Section 2 Digi-Belt™ XF B.A.T. Laser 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com...

- Page 5 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com Single & Multi Belt Tensioning Procedure 1. This cross-firing laser method is the easiest and most accurate way to measure belt tension. 2. Look up the recommended measurements and tension values from the belt manufacture and or the machine provider 3.

- Page 6 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com Diagram 4: B.A.T. Laser Span Deflection Method 7. Place the tip of the Span Deflection Scale on the belt, at the center of the span. 8. Loosen the brass lock nut, then adjust the position of the Deflection Span Scale up or down on the adjustment rod until the lasers are on the ZERO line (see picture 2 above) IF needed again Zero the BT-357D by pressing the ZERO button.

- Page 7 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com Section 3 Digi-Belt™ XF B.A.T. Laser Wide and Banded Belt Tensioning Procedure 1. Procedure for using the wide belt adapters for wide belts, banded belts, toothed belts, timing belts etc. 2. Select the Wide Belt Adapter bar the best suits the belt being tested. 3.

-

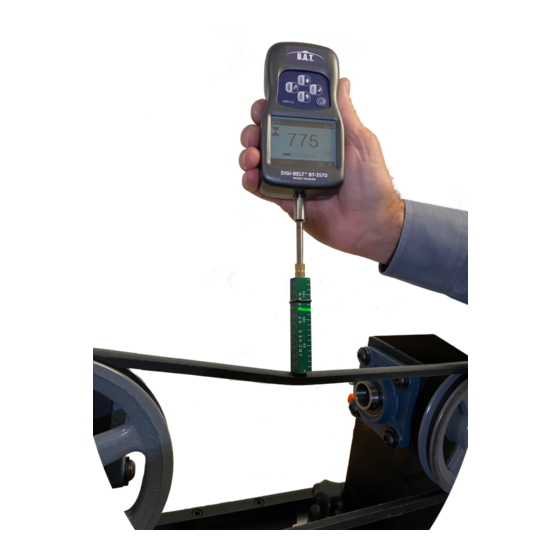

Page 8: Section 4 Reference Photos

800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com Section 4 Reference Photos Picture 4: Deflection Span Scale details Picture 5: BT-357D Details 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com... - Page 9 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com Section 5: BT 357D Operation and Specifications 800-997-4467 www.beltalignmenttool.com sales@beltalignmenttool.com...

- Page 10 DIGI-BELT BT-357D Digital Belt Tension Tester Operation Manual - Specifications Operators should wear protection such as a mask and gloves in case pieces or components break away from the unit under test. Whether the unit is ON or OFF, DO NOT exceed the capacity of the gauge.

- Page 11 1. OPERATION 1.1 Key Functions All keys are capacitive touch. ON/OFF: Push for 1 second to power On or Off During Measurement: Store data. In Menus: Back or quit. During Measurement: Enter the menus. In Menus: Select or Enter During Measurement: Track mode, tares weight of attachment.

-

Page 12: Saving The Measured Value

3.3 Select Test Mode 4.1 Memory The FG-3000 has 3 types of Test Modes. Track: The real time measuring mode. Under this mode, press the ZERO key to tare any initial reading being displayed. Peak: In Peak mode, the maximum force will be recorded and displayed. - Page 13 Fig. 4-3(a) Fig. 5-1(a) Reverse Obverse Fig. 4-3(b) Fig. 5-1(b) 4.4 Delete All 5.2 Auto Power All data points can be cleared from memory under the Delete all The FG-3000 has an automatic power off function. With Auto Pow- sub-menu (Fig. 4-4). A confirm window will appear asking you to er on, if there is no operation performed within five minutes it will confirm.

-

Page 14: Communication Port

5.6 Calibration Because of the sensor material performance or the influence of external factors, there may be errors of a certain level after a period of usage. It is recommended to send the force gauge to a specialized test- ing organization for calibration. Fig. -

Page 15: Troubleshooting

The RS232 serial port is used to connect the mini-printer to print 10. TROUBLESHOOTING the memory data stored on the gauge. According to the following table, review possilbe solutions for problems encountered. Do not disassemble the gauge by your- RS-232 Specifications: self or attempt to repair. -

Page 16: Capacity And Resolution

11. CAPACITY AND RESOLUTION Model Capacity 500.0 50.00 1800 110.0 3000-110 Resolution 0.01 Capacity 1000 100.0 3500 220.0 3000-220 Resolution...

Need help?

Do you have a question about the DIGI-BELT XF-3000 and is the answer not in the manual?

Questions and answers