Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Walter systemtechnik WIF-BA-10

- Page 1 Inline Filter Operating Manual Version Rev -...

- Page 2 Walther Systemtechnik GmbH Hockenheimer Straße 3 D 76726 Germersheim Phone: +49 (0)7274-7022-0 Fax: +49 (0)7274-7022-91 info@walther-systemtechnik.com http://www.walther-systemtechnik.com Operating Manual Inline Filter WIF-BA-10 Page 2 of 18...

-

Page 3: Table Of Contents

Routine Tasks ........................... 15 Troubleshooting ..........................15 Customer Service / Support ......................15 Taking out of Service ..................... 16 Long-term Interruption ........................16 Shutdown of Device .......................... 16 Spare Parts / Accessories ....................17 Operating Manual Inline Filter WIF-BA-10 Page 3 of 18... -

Page 4: Introduction

It describes the following phases of the produce life cycle: • Transport • Description of the product • Start of operation • Service and maintenance • Taking out of service • Spare parts / accessories Operating Manual Inline Filter WIF-BA-10 Page 4 of 18... -

Page 5: Warranty And Liability

The use of wrong media can lead to personal or material damages. IMPORTANT Indicates tips for usage and other particularly useful information. No dangerous situation. Operating Manual Inline Filter WIF-BA-10 Page 5 of 18... -

Page 6: Ordering Key

Plug-in connection 6/4 Outlet Plug-in connection 6/4 Mesh width [µm] [µm] [µm] [µm] Ordering key example: WIF-S64-S64-084 Standard Types Article Number Ordering Key 50008385 WIF-S64-S64-084 50008389 WIF-S64-S64-150 50008390 WIF-S64-S64-320 50008391 WIF-S64-S64-510 Operating Manual Inline Filter WIF-BA-10 Page 6 of 18... -

Page 7: Safety Instructions

Immediately correct failures which can adversely affect safety and security. WARNING Hazard from hydraulic energy Hydraulic energy can cause serious injuries. When individual parts are damaged, medium can be discharged under high pressure, causing injuries and material damages!! Operating Manual Inline Filter WIF-BA-10 Page 7 of 18... -

Page 8: Correct Use

• Using the device in explosive areas, according to directive 2014/34/EU. • Any other than the designated use, system changes or manipulation will lead to a loss of warranty/liability and the CE conformity. Operating Manual Inline Filter WIF-BA-10 Page 8 of 18... -

Page 9: Required Qualification Of Personnel And Protective Equipment

Personnel with Specialist personnel technical Task qualification Packaging and transport Installation and start of operation Operation Service, maintenance and troubleshooting Taking out of service and disposal Table 1 – Required qualification Operating Manual Inline Filter WIF-BA-10 Page 9 of 18... -

Page 10: Transport

The device will be aligned and leveled by appropriate fastening elements. The following will be observed when the receiving checks reveal damages in transport: • Contact the carrier (carrier, train etc.) • Write a protocol of damages • Contact the supplier Operating Manual Inline Filter WIF-BA-10 Page 10 of 18... -

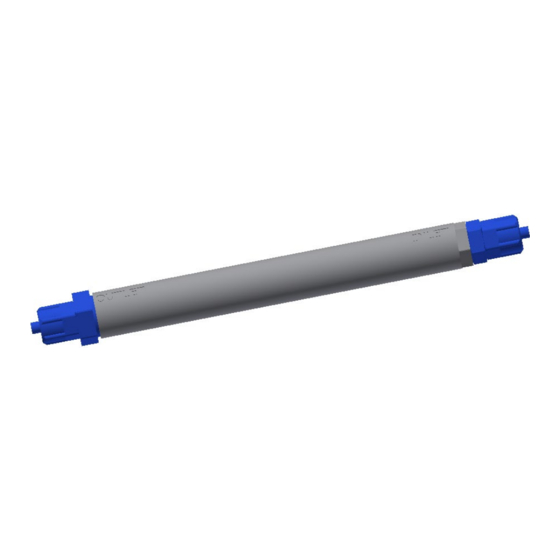

Page 11: Description Of Product

Housing (stainless steel) Inlet: plug-in connection 6/4 Hose screw-joint (plastic) Flow direction medium (fluid) Double nipple Filter cartridge Housing: stainless steel Sealing ring (PVC hard) Pressure spring Figure 2 – Construction „Inline Filter“ Operating Manual Inline Filter WIF-BA-10 Page 11 of 18... -

Page 12: Performance Characteristics

When you install an Inline Filter, make sure that the line is not in use and that no pressure is applied. Now you can properly install the Inline Filter. Pay attention to the flow direction – orientation of arrow. Figure 3 – Flow direction Operating Manual Inline Filter WIF-BA-10 Page 12 of 18... - Page 13 Once installed, the Inline Filter can be immediately used. Prior to any operation, please check again: • All connections are tightly fastened and do not leak. • Make a tightness test. Operating Manual Inline Filter WIF-BA-10 Page 13 of 18...

-

Page 14: Service And Maintenance

Short (colored) end of filter cartridge will point towards INLET. Properly insert new filter cartridge. Close filter housing: Put on blue screw joint and screw in the opposite direction until fastened. Operating Manual Inline Filter WIF-BA-10 Page 14 of 18... -

Page 15: Routine Tasks

In case of serious problems that cannot be resolved, please contact the Walther Systemtechnik GmbH customer service. Customer Service / Support Walther Systemtechnik GmbH Hockenheimer Straße 3 D-76726 Germersheim Phone: +49 (0)7274-7022-0 Fax: +49 (0)7274-7022-91 E-Mail: info@walther-systemtechnik.com Web: www.walther-systemtechnik.com Operating Manual Inline Filter WIF-BA-10 Page 15 of 18... -

Page 16: Taking Out Of Service

For a shutdown, take the following steps: • Remove all pressure from the system • Remove pressure from material supply lines • Properly dispose of medium • Properly dispose of filter cartridge Operating Manual Inline Filter WIF-BA-10 Page 16 of 18... -

Page 17: Spare Parts / Accessories

Filter cartridge 320 [µm] mesh width Ø 10 x 120 mm 50008733 WIF-FK-150 Filter cartridge 150 [µm] mesh width 50008732 WIF-FK-084 Filter cartridge 84 [µm] mesh width Table 4 – Spare part list Operating Manual Inline Filter WIF-BA-10 Page 17 of 18... - Page 18 WST-Key: WIF-BA-10 Article Number: 50012614...

Need help?

Do you have a question about the WIF-BA-10 and is the answer not in the manual?

Questions and answers