Table of Contents

Advertisement

Quick Links

User Manual Swissdrive 400

Version with Removable Brushes (P./N. 035.4039)

Content

1. Description and Intended Purpose

2. Performance Data

5.

1. Description and Intended Purpose

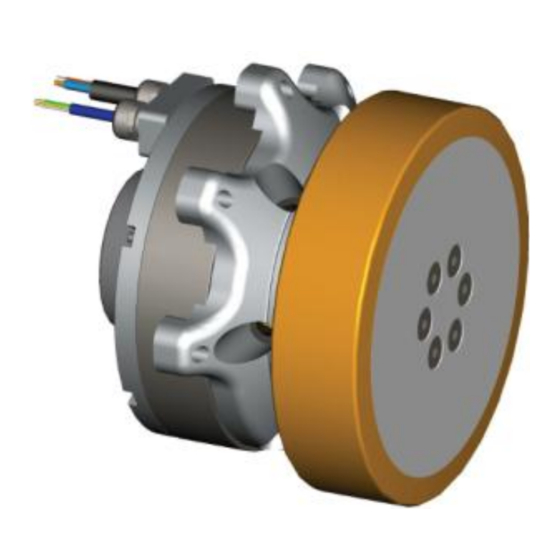

The motor Swissdrive 400 (type RNH 175/20) is a permanent-excited DC motor with brushes. It

contents a planetary gear with the ratio 1:8.8, a Vulkollan coated drive wheel, an internal thermo

switch and an electrically released brake. The brake has been designed as a parking brake, its use as

a main brake is limited. Emergency stops with high load and / or at high speed cause increased wear

of the brake components. Therefore after 5'000 emergency stops shall be provided maintenance of

the brake. In case of increased requirements to running smoothness or positioning accuracy there

can be installed an encoder, type EM1 or HEDS 9100 or similar, with hub wheel hole diameter 4mm.

The brushes can be removed from outside of the motor (see point 6). On request the drive wheel can

be delivered with different coatings or diameters on request.

The Swissdrive 400 motor was designed as a vehicular drive with a maximum wheel load of 500kg for

use in enclosed rooms, e.g. for an industrial truck.

2. Performance Data

Voltage: 24VDC

Power: 350W

Current Consumption: 32A

Ins. Class: F

Class of Protection: IP 43

Gear Ratio: 1:8.8

Speed Rating: 120/min

Brake Torque: 45Nm (at drive wheel)

Permitted Wheel Load: 500kg

Fig. 1: Swissdrive 400

Page 1 von 7

Advertisement

Table of Contents

Summary of Contents for micromotor Swissdrive 400

- Page 1 The brushes can be removed from outside of the motor (see point 6). On request the drive wheel can be delivered with different coatings or diameters on request. The Swissdrive 400 motor was designed as a vehicular drive with a maximum wheel load of 500kg for use in enclosed rooms, e.g. for an industrial truck.

- Page 2 3. Safety Instructions In this user manual there will be used safety instructions with the following icons: Danger! Warning about risk of injury or accident. Attention! Warning about risk of technical damage. Note! Operating instructions. Note! Read first the user manual before operating. 4.

- Page 3 Fig. 2: Mounting Dimensions The cable outlet is placed at the side facing away from the wheel. Fig. 3: Connecting cables The motor may only be connected to a supply voltage of 24VDC. The motor cables shall be rated for a nominal current of 32A and be installed shielded from damage.

- Page 4 The wire arrangement is shown in the following tables: Power Supply Brake +24VDC 4.0mm white +24VDC 0.25mm blue ground 4.0mm brown ground 0.25mm Encoder Thermo Switch orange 0.14mm green 0.25mm green channel A 0.14mm yellow 0.25mm yellow channel B 0.14mm blue ground 0.14mm...

- Page 5 Untighten the cross head screws of the cover with a cross head screwdriver size 1 and remove the cover. Place the hub wheel (hole diameter 4mm) at the motor shaft end. Untighten the cylinder screws with a slotted screw driver size 1, place the encoder instead of the plastic sleeves (throw the plastic sleeves away) together with the distance sleeves at the motor and fix it with the cylinder screws.

- Page 6 Fig. 6: Assembling of Drive Wheel 6.2. Change of Brushes In case of need remove the drive wheel or the whole motor for a better accessibility of the brushes. First remove all six brushes: Untighten the tubular covers with a slotted screwdriver size 4 and remove the old brushes.

- Page 7 7. Spare and Wear Parts Part P./N. S./P. W./P. Notice Motor complete 035.4039 Drive wheel 600.1874 Counter sunk screw M8x20 Torx (6 St) 100.4380 for drive wheel Set: brushes with tubular cover 913.1755 1 set for motor Cover 600.1886 Counter sunk screw M3x30 cross recess (2 St) 103.1036 for cover Sticker “Swissdrive”...

Need help?

Do you have a question about the Swissdrive 400 and is the answer not in the manual?

Questions and answers