Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for icopal Monarplan Series

- Page 1 Synthetic Membranes Monarplan ® Installation Manual...

-

Page 2: Table Of Contents

® Installation manual Contents Subject and range of application General Information on Flashings and Trims Icopal Synthetic Membranes – Product range at a glance 4 General Information on Substrates System Components Introduction Acceptable Substrates Packaging, delivery, storage and disposal of materials... -

Page 3: Subject And Range Of Application

The handling instructions and the manufacturer’s instructions and guidelines for roofers and notes on can labels and safety data sheets for Icopal adhesives construction site managers. They are the result of decades and accessory materials are to be observed. Drawings included in of practical experience in the laying of Icopal waterproofing these instructions are not true to scale and are schematic. -

Page 4: Icopal Synthetic Membranes Product Range At A Glance

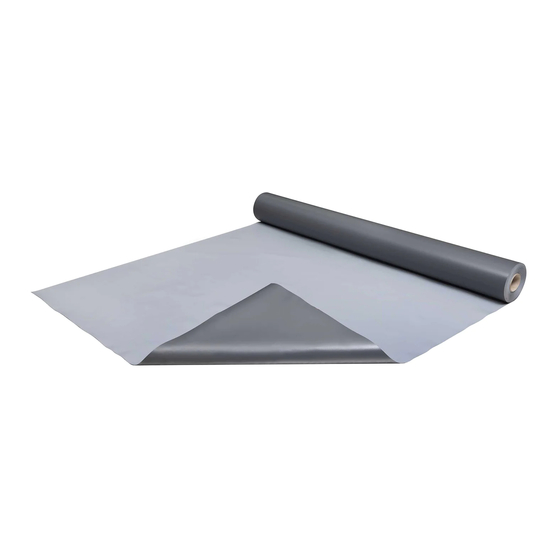

PVC membrane as Monarplan® G, but incorporating a polyester fleece backing. The factory PVC membranes from Icopal have been in use for over 50 years, laminated polyester backing allows the membrane to be covering roofs of all types and forms. Whether it’s domestic or applied in a part mechanically fixed/part adhered system or commercial, public or private;... - Page 5 Standard colour Accessories Monarplan® internal/external/ universal corners Monarplan® coated metal sheet Adhesives & other liquids Icopal Fleeceback Adhesive Partly Bonded (TK 400) Icopal Fleeceback Adhesive Fully Bonded (TK 3958) Monarplan® Contact Adhesive (TK 914) Monarplan® liquid PVC Monarplan® membrane cleaner...

- Page 6 Monarplan ® Installation manual 2.1.2 Accessories All Monarplan® single ply roof systems are complimented by a comprehensive range of ancilliary products to ensure maximum compatibility and single source responsibility for the roofing system. 1 Monarplan® Coated Metal sheet is a 0.6 mm hot dipped galvanised steel sheet coated with a layer of 0.6 mm non- reinforced PVC film for an overall thickness of 1.2 mm.

- Page 7 8 Icopal EPDM sealents can be combined with the Monarplan® outlet to construct a waterproof solution. 9 Icopal fixation bar is a 3 m galvanised steel bar with pre- drilled holes at specified centres to facilitate the mechanical restraint of Monarplan® membranes at the base of upstands or angle changes (Remark: Monarplan®...

- Page 8 The cured adhesive film has very good resistance to heat and hydrolysis, and is blue/ green in appearance. Icopal PVC Contact Adhesive: Terokal TK 914 is a high strength solvent based contact adhesive that allows the bonding of Monarplan® non-fleeceback membrane to various porous and non-porous substrates.

-

Page 9: Packaging, Delivery, Storage And Disposal Of Materials

Temporary storage on roofs should be in rolls and with an even effective and environmentally compatible collection and recycling spread over the roof deck, on lightweight steel decking only in of PVC roofing underlays. Icopal actively supports the pan- bearing areas. European program. -

Page 10: Roof Types

Monarplan ® Installation manual 4 Roof types General Method of Attachment There are generally three types of flat roof construction: The roof system must be secured to the roof structure to protect against wind uplift. The components of the roof system can be Warm Roof secured in a number of ways. -

Page 11: Choosing Of Membrane

Step 3: Method of Application Mechanically Fastened / partially or fully Adhered / Ballasted / Combination The following tables are intended to offer a simple summary. Please consult with Icopal Technical Services on project specific situations. Type of membrane Monarplan® FM Monarplan®... -

Page 12: Installation Principles

Monarplan ® Installation manual 5 Installation principles 5 cm 5 cm 11 cm Seam overlap Monarplan® waterproofing membranes are marked with several dashed lines along one longitudinal edge. These markings can be used as guiding lines for the corresponding lap width. 5 cm 11 cm 12 cm... -

Page 13: Position Of Butt Joints

Monarplan ® Installation manual min 150 mm Position of butt joints min. 20 mm At the end of the membrane, i. e. normally after 15 m, the backed Monarplan® GF waterproofing membranes can be butt-jointed or hot-air welded at an overlap of approx. 1 cm and covered with an unbacked strip of at least 15 cm width. -

Page 14: Formation Of Expansion Joints

Monarplan ® Installation manual Formation of expansion joints Expansion joints has especially to be planned by the architects and are project specific. Contact the Icopal technical service for guidance and advice. 062014V1... -

Page 15: Membrane Application

Monarplan® Tool Kit membrane. Icopal does not endorse or recommend any particular A typical tool kit should include the following: brand of equipment. • A 40 mm seam roller •... -

Page 16: Hot-Air Welding

Monarplan ® Installation manual Hot-Air Welding 6.2.2 Hot-air welding with welding machines 6.2.1 General Monarplan® roofing membranes are hot air welded to each other and the compatible range of PVC ancillaries in a homogeneous manner. The welding zone must be clean (free from dust) and dry. -

Page 17: Welding Of T-Joints

Monarplan ® Installation manual 6.2.3 Manual Hot-air welding nozzle always blows against already seal-welded areas of the seam. The weld must have a consistant width as possible and a minimum width of 20 mm. 6.3 Welding of T-joints T-joints are created when 3 membranes meet and must be formed very carefully, in order to prevent capillary action. - Page 18 Monarplan ® Installation manual min. 5 cm min. 5 cm 6.3.1 Butt joints of unbacked membranes Unbacked membranes are laid, analogue to the longitudinal edge, with an overlap of at least 5 cm at the end of the membrane. The top corner of the membrane must be rounded off! Before welding the T-joint, the respective inner (middle) membrane end must be chamfered over the whole lap width (min.

-

Page 19: Weld Tests

Monarplan ® Installation manual chamfered areas min. 15 cm with the membranes to be joined. Tack the strip in this position, in the middle, with hot air and seal it all around the perimeter. The longitudinal seam edges of the membranes to be joined, which min. -

Page 20: Sealing Of Seams

Monarplan ® Installation manual 6.4.2 Destructive weld test (Peel test) The peel test can also performed directly on the construction site Before starting work on site (morning and afternoon) and using an electrical tensiometer. The advantage is to determine whenever there has been a change in the weather conditions, the the welding strength and/or the peel force as well as the welding parameters have to be verified and adjusted accordingly corresponding elongation data. -

Page 21: Methods Of Application

Monarplan ® Installation manual 7 Methods of upstands application Introduction Monarplan® adhesive 3958 fleeceback is used in fully adhered systems. With today’s construction trends of highly intricate and complex Moisture-curing single-component PUR adhesive (Monarplan structures and the requirement for higher thermal insulation fleeceback adhesive TK 400), poured in lines (beads), are used in values, only membranes which aspire to the highest quality partly adhered systems. - Page 22 Icopal Fixation Bar The horizontal field membrane is secured at the foot of the upstand using an Icopal Fixation Bar fixed back to the more stable substrate, ie fixed vertically to the structural deck or horizontally to masonry or concrete upstands.

- Page 23 Monarplan ® Installation manual 7.2.2 Monarplan® Coated Metal 7.2.2.1 Complete profile solution Non-Fleecebacked membrane The perimeter of the Monarplan® G or FM reinforced membrane on the field area is welded continuously to the horizontal flange of a mechanically fastened 90° membrane-coated metal angle. Fleecebacked Membrane The perimeter of the Monarplan®...

-

Page 24: Membrane Termination

Depending on the method of installation and the type of termination bar used, the waterproofing membrane may first require mechanical restraint using the Icopal Fixation Bar. The termination bar is mechanically fastened to the wall at regular fixing centers. A suitable mastic sealant is applied behind the lip of the termination bar just prior to the final tightening of the fasteners. -

Page 25: Mechanically Fastened System

For confirmation of the appropriate size of washers and fasteners to use, refer to the Icopal Fastener product datasheet. Prior to application of the Monarplan® FM reinforced membrane, a wind uplift calculation must be carried out in accordance with EN 1991-1 to -4 or to the corresponding national regulations to determine the correct fixing centers specific to the project. - Page 26 Monarplan ® Installation manual End Laps 7.4.3 Fastening plan End laps should be a minimum of 50 mm and wherever possible If required, project-related individual calculations will be produced on request, as a service of the fastener manufacturer, including should be staggered to the adjacent sheet. installation instructions, material requirements and fastening plan.

-

Page 27: Ballasted System

Monarplan ® Installation manual Ballasted System • Concrete slabs / hollow grid tiles A loose laid protection layer e. g. rot-proof fleece, building- Membrane Used: Monarplan® G or GF protection mat (e.g. “Regupol” or similar), must be placed between the roof sealing and the concrete slabs or hollow grid tiles! Concrete slabs laid closely together, (e.g. - Page 28 Monarplan ® Installation manual • Paving Flags 7.5.2 Installation of loose-laid membranes with ballast Paving flags can be installed on paving slab supports, in an Protection against wind uplift with ballast is permissible only if underlayer of gravel or chalkfree grit, or in a bed of mortar (on the bearing capacity of the roof construction and, if necessary, the a drainage layer).

-

Page 29: Adhered System

In adhered systems the Monarplan® membrane is attached to the substrate using an adhesive. The adjacent sheets of membrane are then welded. Icopal offers four types of adhesives depending on the membrane used, and the type of substrate. The Monarplan® GF Fleeceback membranes are fully adhered using Icopal Single-ply Fleeceback adhesive, 3958 to the pre- secured insulation board. - Page 30 The fleeceback membrane has a fleece-free 7.6.4 Icopal Fleeceback Adhesive Fully Bonded: Terokal TK 3958 selvedge in the overlap area, to enable the side lap to be hot-air welded. Ensure no adhesive contaminates the weld zone.

- Page 31 Vigorously shake the can before use and then screw it onto the 25 mm medium nap roller. Application shall be continuous and Icopal foam gun. Icopal foam gun XL, equipped with a 60 cm lance, uniform avoiding globs or puddles.

- Page 32 Monarplan ® Installation manual 7.6.8 Methodology Side Laps Monarplan® GF Membranes are manufactured with a 70 mm fleece free selvage. Position the adjoining sheet allowing for a 50 mm side lap bond in place as above. The weld must have a compulsory minimum width of 20 mm.

-

Page 33: General Information On Flashings And Trims

Depending on the construction detail, the edge of the roof a strip of sealant. Consult Icopal’s standard drawings for further should be made air-tight. A strip of suitable sealant should information on www.icopal-synthetic.eu/download/cad-library. - Page 34 A strip of suitable sealant should a strip of sealant. Consult Icopal’s standard drawings for further be installed along the edge beneath the coated metal. If a information.

-

Page 35: General Information On Substrates

2 AA3004 H34. Reference should also be made to EN 1396 as The load bearing structure must comply with all associated appropriate. For mechanically fastened systems, refer to Icopal’s national standards and regulations, ensuring that the load bearing Technical Department for confirmation of suitability of fastener. -

Page 36: Fastener Withdrawal Resistance Criteria

• in field of the roof (with at least 2 tests conducted at the low tests were conducted and forwarded to Icopal for review. areas of the roof deck... -

Page 37: Roofing Details

For parapets up to 50 cm height, membranes can be loose laid without fixing on the wall. For parapets over 50 cm height, the membranes must be either fully bonded (Icopal® Contact Adhesive 914), or secured intermediately with Monarplan® coated metal sheets. -

Page 38: Corners

Monarplan ® Installation manual Corners The membranes must be laid so as to have as little covering layers lying on top of each other as possible at the parapet corners. Membranes laid parallel to the parapet are butt together at the corner areas or laid around corners. - Page 39 Monarplan ® Installation manual 9.4.2 External Corners • Cut the Monarplan® trim strip to size. • Weld all seams • Weld in external corner. • Upper trim of the parapet completed with prefabricated internal corner, reversed. • Check all seams and chamfer T- joints (blue circles on sketch) 062014V1...

-

Page 40: Materials From Other Manufacturers

• protection mats placed beneath roof plant & equipment, • mats of granulated rubber or • other anti-vibration materials. Prior to installation, the chemical compatibility must be proven and the product must be approved by Icopal or supplied by them. 062014V1... -

Page 41: Examples For System Components

PET aluminium foil. Icopal supplies a range of high performance polyethylene and Some examples: bituminous vapour control layers for use with its single-ply - Micoral SK has a blue SYNTAN resin upper surface allowing the roofing systems. -

Page 42: Insulation

As a fire protection layer, 120gr glass fleece on EPS is On metal decks, boards shall be laid with long edges at 90º to the advised (Icopal Glass Fleece deck troughs with end joints fully supported on the crowns. seperation layer). -

Page 43: Quality Assurance

® Installation manual 12 Quality Assurance Please note; the validity and the extent of the Icopal product warranty will only apply where Monarplan® membranes and accessories (or products made by others approved by Icopal prior to commencement of works) have been used. Any alterations to agreed system specifications shall render any warranty offer null and void. -

Page 44: Maintenance

Leaks Report leaks immediately to Icopal. Try to determine if it is a roof membrane leak or a wall, curb, skylight, metal ductwork or plumbing leak. A water leak may be indicated by soft or warped insulation or the presence of water under the membrane. - Page 45 Item Action Temporary Repairs Use a good grade sealant to make temporary repairs. Notify Icopal of this action in writing. Rooftop When it is necessary for workers to be on the roof to service rooftop equipment, e.g., HVAC units, antennas, Maintenance etc., workers should be cautioned to use walkways and to exercise care with their tools and equipment to avoid...

- Page 46 Icopal Ltd Barton Dock Road Stretford Manchester M32 0YL Tel: 0161 865 4444 Fax: 0161 864 2616 www.Icopal.co.uk 062014V1...

Need help?

Do you have a question about the Monarplan Series and is the answer not in the manual?

Questions and answers