Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for RONGDA VR-7625S

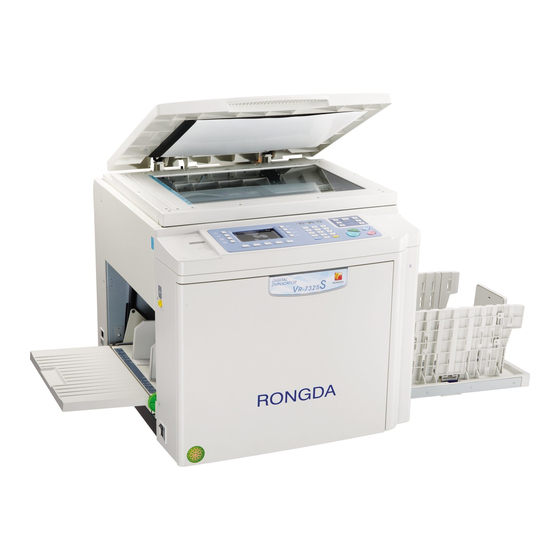

- Page 1 Operation Manual Digital Duplicator Appliable for the models VR-7625S / VR-7428S...

- Page 3 Perface First of all, thanks for purchasing our machine. The Manual records the operation method of machine and notices for use. To use the machine safely, easily and efficiently, please read the Operation Manual before using the machine. Description of symbols in Operation Manual Operation regardless of warning may lead to death or serious injury.

-

Page 4: Table Of Contents

Content Safety guides Please read this manual before working in order to operate machine in safe and correct way. Energy saving mode Setting of password On confirmation of total number of paper Notices mastered before use of machine ・ Installation environment and notices of the machine Before the machine is used, it is very important ・... - Page 5 Special printing function ・ Two-in-one function Two-in-one function, ink saving function ・ Master making of books and magazines seldom-used functions and functions ・ Ink saving mode unrelated to printing directly. ・ Quick ink outlet function ・ Running without load function Replacement of consumables (Ink and Master) Waste Master Treatment method Method of taking out and mounting drum...

- Page 6 Safe Use Manual ・ Power supply: use AC power supply/domestic power supply (AC 220V~240V). Do not use unregulated power supply. Use of unregulated power supply may lead to electric shock and fire hazard accidents. Prohibit ・ Please use independent socket. Do not share socket with high power appliances like duplicator/printer/microwave oven.

- Page 7 ・ Please do not drop sheetmetal (like clip and staple) and combustibles in the machine, or fire hazards and electric shock accidents will be caused. Prohibit ・ Please do not dismantle the outer cover of the machine. High-pressure, high-temperature, sharp and rotating members in the machine may lead to scratches and electric shock accidents.

- Page 8 ・ Do not use scratched and modified power cord. Furthermore, do not step on, press, hale and scratches power cord to avoid fire hazards and electric shock accidents. Prohibit ・ If the machine has abnormal high temperature, smoke and peculiar smell, fire hazards or electric shock accidents may be caused, please directly pull out the power supply in this case, and then contact with Supplier or After-sales Department.

- Page 9 ・ If the machine slides down and its outer cover is damaged, first turn off the switch, pull out the power supply, and then contact with the Supplier or the After-sales Department. If the machine is directly used without taking measures, it may lead to fire hazards and electric shock accidents.

- Page 10 ・ Please put the machine on hard horizontal plane, or the machine may drop to lead to personnel injury or influence its normal use. Prohibit ・ Please do not put the machine near the volatile combustible or in damp, dusty and easily-vibrated places, or fire hazards and electric shock accidents will be caused.

- Page 11 ・ Please do not put articles around the machine. If objects slide down, personnel injury and damage of machine may be caused, and furthermore, machine fault may be caused. ・ Please don’t touch the display board with heavy pressure to avoid the leakage of liquid , leading to the machine broken.

- Page 12 ・ Ink will be used when the machine is working. When the machine is failed, maintained and repaired, ink may make your clothes and skin dirty, please try to avoid such events. ・ Original table is made of glass. Please pay attention to the following matters in use: When originals are heavier like books and magazines, please put the originals on the original table gently.

- Page 13 - 8 -...

-

Page 14: Energy Saving Mode

Energy-saving Mode When the machine is not operated in a certain time after startup, it may enter energy-saving mode. There are two energy-saving modes: first, the display screen is black [1. Sleep mode] in the power-on state; second, the power supply is automatically cut off [2. - Page 15 ⅳ)Press【OK】 Key to complete the setting. ※ The machine will go back to the basic picture When the machine is under Sleep mode, there is only the Sleep indicator lamp is on. Press Sleep mode relief key to go back to the basic picture when the machine is under Sleep mode, 2.Auto Power-off If the machine starts automatic shutdown function and it is not operated for a certain time under...

- Page 16 ⅱ)Press [Auto Power-off] Key. ⅲ)Use numbric button to input the time you want. ※ If you want to set 20 min, then input [2][0] is ok. Press [C] key to cancel this function. Input the numbers correctly by turn. ⅳ) Press [OK] to confirm this set. ※...

- Page 17 When the auto-off time setting is not made and the setting time is [0], this function can not be workable even if this button is pressed. When the error message is displayed during printing, this function can not be workable even if the [SET] button is pressed.

- Page 18 ⅳ)Press【 # 】,the screen will show [Input the second password]. ⅴ)Use the numberic button to enter any 4 numbers ・ The numbers input showed as[*] Please record the password when the first and second are different. If both are the same, that is also workable.

- Page 19 ⅱ)Press【 # 】 key,go back to thte basic interface. Release the password setting ⅰ)Firstly, input password. Whichever you input in two passwords should be no problems. ⅱ)Press [Set] key on the operation panel when the machine is working. ⅲ)Press [Release the password] key, to show [Input the password]. - 14...

- Page 20 ⅳ) Input any password in two groups. ⅴ)Press【#】key,go back the basic interface and the password setting is released. If the password protection function is set, the machine will ask for a password when the main display is off or just turned on. (under opening machine/energy saving mode) Customers can’t release the password by his If the passwords are forget, please contact the dealer or agent.

- Page 21 Total count display function The total number of printing and the total number of plates can be determined from the machine after the completion of the installation of the workload, the workload can be used as a standard for machine maintenance, replacement of parts.

- Page 22 - 17 -...

- Page 23 Notices before use This part of the main description of the use of the machine environment, conditions, general precautions, the name of the various parts and functions and other important matters, please read the details before use. ・ The installation environment of the machine and precautions ・...

-

Page 24: Installation Environment And Notices Of The Machine

Installation environment and notices of the machine ・ In order to use the machine safely, please be sure that the machine kept on a horizontal place during operation, consumables replacement / maintenance of the machine. ・ There are safety hazards in the following environments and are trend to malfunction. -

Page 25: On Printing Paper

When the following originals are used, please rightly use pantograph function for adjustment. Originals bigger than 297mm × 420mm = zoom out Original smaller than 90mm × 140mm = enlarge Thicker originals Heavier originals Conventional original size ( Paper consumption ) 297mm ×... -

Page 26: On Paper Storage

On paper storage ・ Please do not use the following paper, because using of the following paper may lead to fault. ・ Store paper in dry environment. Dampness of paper is easy to cause [ Paper jam ], [ Poor printing ] and other problems. -

Page 27: Daily Management Of Machine

Daily management of machine ・ Please do not put weights on the machine, and do not impact the machine ・ Please do not put bottle and cup filled with water on the machine, once water enters the machine, the insulation effect of the machine will get worse. -

Page 28: Prohibit Copying/Printing

Prohibit copying / printing When the machine is used for copying and printing, contents to be copied and printed are limited. Even if matters to be copied and printed are reserved by us, the illegal contents are prohibited to be copied and printed. ・... - Page 29 - 24 -...

-

Page 30: Name And Functions Of Each Part

Name of each part and its functions Machine apprerance Name Functions 1 Make the original and scan cover contact well. Cover of scanning 2 Support the printing papers Paper feeding table 3 Press [ I ] side to make power on, press [ ○ ] side to make power off Power switch Pull the panel out at the depression with hand on 4... - Page 31 Drum unit Name Function 1 Drum To press the ink to the paper 2 Drum handle Take out the drum by this hand for safe operation 3 To use the specific ink 4 Ink bracket Install the specific ink container 5...

- Page 32 Paper feed tray assembly Name Function 1 Plug To get power 2 Paper feed tray To support the blank paper 3 Press [ I ] side to turn on the power,press [ ○ ] side to turn off . Power switch 4...

- Page 33 Paper feed tray in detail Name Function 1 Paper roller 2 pieces. Assist to feed the paper into the machine Pressure adjustment handle 2 3 levels. To adjust the paper feed pressure. for paper feed 3 Press blade 2 pieces on the left and right.,to decide the printing position. 4...

- Page 34 Paper receiving part Name Function 1 Disposal box To save the wast master paper 2 USB port Insert the USB disk for printing 3 Switch for disposal box Press this button to open the disposal box 4 Drum rotating button Press this button to rotate the drum during paper jam 5...

- Page 35 Disposal box Name Function 1 Air outlet Separate the printing paper from the drum. 2 Wasted master Throw it to waste box 3 Wasted paper plastic core To roll them up to the plastic core 4 Top cover of disposal box Cover the dispoal box 5...

- Page 36 Master-making part Name Function 1 Master installation handle Use it during installing the master 2 Cutter switch Used in installation of master 3 Cutter cover Protect the cutter 4 Cover of thermal head To push forward the stencil with this cover 5...

- Page 37 - 32 -...

-

Page 38: Name And Function Of Keys Of Operation Panel

Name and function of the button on operation panel There is [※] after key name, the same function key is existed on the right of the panel. Name Function 1 Confidential key Use it when the masters are compsulsory arranged to the drum 2... - Page 39 There is [※] after key name, the same function key is existed on the right of the panel. Name Function C key Cancel the setted number or account reset ※ Go to the operation screen. Press twice go back to basic interface. Set key ※...

-

Page 40: Operation Setting Picture

Operation setting screen Press the [ Setting ] button in the operation panel, the display will change to the operation setting screen (①~⑭) signs in the figure are only for explaination, it not existed in real machine. Name Function Page on Sign ①... - Page 41 Basic printing operation It mainly describes the pre-print preparation, the basic operating methods and operating sequence. Pre-print preparation ・ Installation method of power cord ・ Placement method of printing paper ・ Installation method of paper receiving tray ・ Installation method of originals Basic printing method - 36...

-

Page 42: Printing Preparation

Printing preparation Installation way of power line 1.Keep the switch power off ・ Power switch is on the left of the machine. Parts and functions of each part of the machine (Page 25 / 27) 2. Insert specific power cord of the machine ・... -

Page 43: Placement Method Of Printing Paper

Placement method of printing paper 1. Open the paper feeding table gently Parts and functions of each part of the machine (Page 25 / 27) On paper printing(Page 20) 2.Installation of printing paper ・ Put paper on paper feeding table, align the front end of paper with the front end of paper feeding bracket, adjust frisket finger according to paper size, and fix clipboard plate. - Page 44 4. Setting on pressure of the paper supply ・ Set the paper feed strength adjustment, adjust the paper feed force by the pressure adjustment handle. The feed pressure is not adjusted according to the paper, but is adjusted according to the paper feed condition.

- Page 45 The cases to weaken the paper pressure as follows: ・ Paper is wrinkled when the paper is fed, and the front of the paper is scratched ・ Paper feed is not smooth and is jammed The cases to strenthen the paper pressure as follows: ・...

-

Page 46: Installation Method Of Paper Receiving Tray

Installation method of paper receiving tray 1. Open the paper receiving table gently All the parts name and functions(Page 29) Do not release the table to avoid machine damage when opening. When the paper tray is fully open, it is slightly lower than the machine. Do not place items under the paper tray and open the paper tray completely. -

Page 47: Installation Method Of Originals

Installation method of originals 1. Open the cover of the scanning table 2. Put the printing sides of originals to be printed on the scanning table facedown 【▲】 ・ Align the original with the left end of the scanner on the glass. There is a sign in the middle of the left side of the glass plate to align the center of the front end of the document with this symbol. -

Page 48: Basic Printing Method

Basic printing method ※ Use new originals in master making~printing process 1. Power on ・ Power switch is on the left of the machine. When the button is pressed to [ I ], the power is on; when the button is pressed to [ O ], the power is off. Notices of power supply(Page 1/4)... - Page 49 4. Place originals ・ The machine can automatically recognize and display sizes of originals. On the original(Page 19~20) Setting method for the original(Page 42) On various settings of master making Change printing concentration Change scanning concentration(Page 57) Change master-making concentration(Page 56) Print color originals of pictures(Page 62)...

- Page 50 ・ After one trial… Increase proof printing(Page 68) Adjust printing position(Page 52) Change printing speed(Page 55) Adjust frisket finger of paper-out guidence and paper receiving support(Page 41) If problem happened during trial printing… Overall light / dark → Change master making concentration(Page 56) →...

- Page 51 Hints display in printing (Page 38) (Page 138 / 142) (Page 139 / 143) (Page 138 / 144) (Page 81) (Page 83) 8. Press [ Stop ] button to terminate printing ・ When the machine stops, remain number of paper will be displayed Please press [ Print ] button to continue printing Generally speaking, when input number of paper has been printed, number input place will tentatively...

- Page 52 Notices when one original is printed largely. Master used in printing is much thinner. When one original is largely printed, master paper will be damaged to influence printing quality. Therefore, in consideration of this factor, during printing, please make master again when one original is copied to about 2,000 pages.

-

Page 53: Input Of Printing Number

Various use functions Mainly record the application method of functions of input of printing number, printing speed,printing concentration and zooming. Input of printing number Printing position adjustment ・ Adjustment space of up/down direction ・ Left and right direction adjustment Printing speed adjustment Printing concentration adjustment ・... - Page 54 Input of printing numbers Input printing number by numeric key on operation panel. The maximum number which can be input once is [ 9999 ] pieces ( 4 digits ). If grouping times blend, a greater quantity of printing can be achieved. Input number will be displayed on display screen.

- Page 55 On group printing Manually start printing functions… After the input number of sheets is totally printed, the machine will continue to run, but stop feeding paper. In this period, printing paper on the paper-out table should be taken out or distinguishing objects should be placed, and then, when the machine needs to continue printing according to practical situation, printing button should be pressed to start next printing.

- Page 56 E.g.) 500 pcs in 3 groups / 1500 pcs in 1 group / 2000 pcs in 2 groups / complex grouping ( 7000pcs in total ) Group printing can be set to be 10 groups. Number input method ⅰ)Press【Group printing】Key. ⅱ)Use numberic button to input【5】...

-

Page 57: Printing Position Adjustment

Printing position adjustment Printing positions of printing paper can be up and down/ left and right. Up and down/left and right control buttons are different. 1. Adjustment of up / down direction ( Adjusting in printing ) Adjust through [ Print position ] button of operation part. No matter the machine is stopped or working, adjustment is based on center. -

Page 58: Left And Right Direction Adjustment

・ Adjust printing position to the center Press【Center reset】 key. 2. Left and right direction adjustment ( Forbidden in printing process ) Adjust the paper placement of the paper feeding table ・ When printing position is adjusted to left ( Operation side ) Rotate the knob to left, and move printing paper against operation side. - Page 59 The operation is forbidden in printing process. Be sure to adjust after terminating printing and lowering the paper feeding table. Lower printing table(Page 38~39) Excessive adjustment will lead to incomplete printing. After adjustment, please use proof printing function, and print after confirming printing state. When contents run over and need to be printed, edges or integrity of printing paper will be adhered back to back or during master making and printing, run-over contents are printed in new masters.

-

Page 60: Printing Speed Adjustment

Printing speed adjustment Adjust through [ Printing speed ] button on operation part.There are 5 classes in total. After setting, the selected level will be on the screen. Standard speed is [ 3 ]. [Speed 1] = 55pcs/minute [Speed 2] = 70pcs/minute ※... -

Page 61: Printing Concentration Adjustment

Printing concentration adjustment General printing concentration adjustment method: [ 1. Adjust master making concentration ]; [ 2. Adjust scanning concentration ]; [ 3. Adjust printing pressure ]. Adjustment of [ Master making concentration] or [ Printing pressure ] will change overall printing concentration, and adjustment of [ Scanning concentration ] will change color of originals. -

Page 62: Scanning Concentration Adjustment

ⅱ)Choose the concentraciton class. ・ Concentration is selected in 5 classes. [ Lightest ] [ Light ] [ Standard ] [ Dark ] [ Darkest ] ⅲ) The chosen class is displayed. Applicable to the following conditions: ・ When temperature is low and printing is light → Adjustdark concentration for master making ・... -

Page 63: Printing Pressure Adjustment

ⅱ)Choose the concentraciton class. ・ Concentration is selected in 5 classes. [ Lightest ] [ Light ] [ Standard ] [ Dark ] [ Darkest ] ⅲ)The chosen class is displayed. Applicable to the following conditions: ・ Original gets lighter integrally → Scanning concentration gets darker ・... - Page 64 ⅱ)Use [ Cursor key 【 】 【 】to set printing concentration. Except automatic setting, any setting is divided into 5 classes. [ 1 ] = Weakest; the same with speed 1 [ 2 ] = Weak; the same with speed 2 [ 3 ] = Medium;...

-

Page 65: Original Background Color Removal Function

Original background color removal function In case of directly making master when originals are older, have dirt and ground color, background color of original will be scanned to cause unclear printing paper. Under this condition, if [ Original background color removal function ] is used, the influence on original background color will be minimized. -

Page 66: Original Background Color Removal Function

ⅳ)Press [【OK】 button ] to complete setting. Display picture returns to basic picture. After setting is completed, even if the power supply is turned off or reset button is pressed, background color removal level will not return to standard [ 0 ]. According to the species and conditions of originals, there may be a certain impact on printing quality. - Page 67 Selection mode conforming to the original Setting before master making Select appropriate [ Image mode ] according to species of originals. There are 7 original setting modes. They respectively have their owncharacteristics. Factory setting is [ Text > Photo ] mode [ Text ] ・...

-

Page 68: Original Mode Selection

ⅱ)Choose the original mode. ⅲ)The chosen mode is on the screen. After setting, even if the machine is powered off or reset button is pressed, the machine will not return to [ Text > Photo ] mode. - 63 -... -

Page 69: Zooming Of Originals

Zooming of the originals Setting before master making Print after magnifying/zooming originals. When the edges of originals are not blank, please use [ 94% ] zooming function, and print after leaving a certain blank. On originals(Page 19) On page margin(Page 21) Original zooming is divided into [ Common ratio zooming ] and [ Free zoom ]. -

Page 70: Zooming Of Originals

ⅱ)Choose any ratio key ⅲ)Press [OK] to confirm the setting. Go to the basic screen The setted zoom ratio is displayed on the screen. When setting page margin (94%) When originals are zoomed out, the front center of the paper is based, printing is totally closer to the front end. - Page 71 Free zoom function In the range of 50% to 200%, the magnification ratio can be set by 1% increment。 Setting method ⅰ)Press 【zoom ratio】 ,turn to the screen. ⅱ)When you enter the number on the digital panel for zoom magnification, the entered values are showed as a percentage.

- Page 72 The operation way used for the paper sizes are different for o riginal and the copy. ⅰ)Firstly, place the original well. (Page12) ⅱ)The machine will check the paper size automatically. ⅲ)Choose[Copy Size]it will display the screen to choose the sizes of original and copy. ⅳ)Choose the actual size for copy Please revise the original size if checking mistakenly.

-

Page 73: Proof Printing Number Setting

Proof printing numbers setting When the machine starts master making and printing, there is a proof printing link after master making. After proof printing, the machine will stop. At this time, it is necessary to confirm printing position and printing quality. Proof printing button can be pressed for many times according to practical situation. - Page 74 ⅳ)Use numberic key to set the numbers. ・ It can set any from 1~9 ⅴ)Press [OK] to confirm the setting. After setting, even if the machine is powered off or reset button is pressed, proof printing number will not be reset to standard setting ( 1 pc ). During master making and proof printing, if printing paper is rolled on drum, the display screen will display [ Paper jam on center ].

-

Page 75: On Condenfiality Protect

On confidential protection operation At the end of the print, the stencil (original) used in the printing process remains on the drum. If you want to continue printing, you can enter the number of sheets to be added first, and then start printing again. When increasing the number of sheets is not too many, you can press Test key to increase the sheets. - Page 76 Special printing function Two in one master-making function The function is used when two same or different originals are printed on one piece of paper. 1pc of original 2pcs of original Operation method ⅰ)Put originals on original scanning table. Paper setting direction is different with general setting direction. ( Long sides of originals are put on the left, as the right figure ) ⅱ)Press [MODE] button ⅲ)Choose [2 in 1]...

-

Page 77: Special Printing Function

ⅳ)The chosen mastering mode will be showed on the screen. ⅴ)Flexibly use [ Original zooming ] and [ Original mode ] functions according to practical condition. Generally speaking, when the original size is a half of printing paper, 100% ratio of original is used. When large original is used, original zooming function is used, but the maximum original size should be no larger than A4. - Page 78 ⅷ)By closing scanning cover plate, the machine starts to scan the second original, and starts proof printing after scanning. After the first original is scanned, if the master making button is directly pressed without opening the scanning cover plate, the printing position of the second original will be blank. When printing on single side, the method can be used for master making.

-

Page 79: Master Making Of Books And Magazines

ⅲ)Choose [ Book ] ⅳ)Chosen mode will be showed on the screen. ⅴ)Choose the shadow elimination scope as per your requirement. [ If not set, please go to step(ⅵ)directly] During scanning, the floating spine of the book will be formed a shadow, and make shadow to the copy. To avoid it, when it is in [Book] mode, the book spine should be forbidden scanning. - Page 80 v-c)Press [C] to cancel all the setting. v-d)Use numberic button to input the new setting. Set from 6 ㎜ to 70 ㎜. ⅵ)Press [OK] to confirm. Go back the basic interface. Like two-in-one function, during master making for books and magazines, the general specification is A4 and B5, which can be automatically recognized by the machine.

- Page 81 The method will be used easier in the following conditions When two same-sized originals are put on scanning table in parallel for scanning and printing, there will be shadow of boundary line between two originals. In this case, book and magazine mode should be used, and shadow line should be eliminated.

-

Page 82: Ink Saving Mode

Ink saving mode The mode can be used to save ink consumption. After the mode is used, standard setting is OFF. Operation method ⅰ)Choose [Image Mode], enter this mode interface. ⅱ)Press [YES] to choose [Ink saving mode] Go back to the basic interface Maybe there is part rotating sound in the machine, which is normal. -

Page 83: Quick Ink Outlet Function

Quick ink outlet function The master-making master paper should be adhered on drum by force, which is clearer than proof printing after master making. Standard setting is [ OFF ]. Operation method ⅰ)Press 【SET】 key to enter operation setting picture. ⅱ)Select [Quick inking] item ⅲ)Press [OK] to confirm. -

Page 84: Air Run Function

Running without load function This function is to make ink cover on the drum on average during master making. This function is closed in factory standard. Operation method ⅰ)Choose 【SET】to enter the setting interface. ⅱ)Choose【YES】for averaging the ink. ⅳ)Press [OK] to confirm. Go back to the basic interface. - Page 85 Repalcement of consumables (Ink and master) ・ Replacement of ink ・ Replacement of master ・ Wasted maters treatment method Drum treatment method ・ Method of taking out and mounting drum - 80 -...

- Page 86 Replacement of ink When ink used out, there will be remind for used out on screen and the machine will stop working. Repalcement method of ink ⅰ)Open the front door. Please open the front cover when the machine stops. ⅱ)Pull out the switch of ink bracket, the bracket will lie down again our body.

- Page 87 ⅴ)Install the new cartridge in the ink mounting bracket. Install the cartridges into the corresponding positions of the mounting brackets. ⅵ)Gently close the mounting bracket and lock it. There will be a sound of [crack] when locked. ⅶ)Close the front door ⅷ)Start [Printing] - 82...

- Page 88 Notices for changing ink Ink in the uncovered ink box can not be placed for longer time. If air enters the ink box, ink will absorb air. If there is still ink in ink box, but the display screen displays that ink is used up, ink bag should be slightly pressed on the ink box opening.

- Page 89 Change master paper When master paper installed on machine is used up, the display screen will display hints shown in the right figure. (Page 31) Name of component used when changing master a:Thermal head release lever b:Cutter button c:Shaft The front end of the master installation part is operation part. Master paper changing method ⅰ)Open original scanning table.

- Page 90 ⅲ)Take out exhausted master paper. Roll back master paper according to arrow direction, and then take it out. ⅳ)Pull the long preventing creasing axis of the master ⅴ)Take down left and right master paper flanges on masterpaper core. Don’t dispose two flanges on the master There is a part to break away the flanges.

- Page 91 ⅶ)When placing master paper, please pay attention to its direction. ⅷ)Press and feed the front head of master, and hold on the master set button. Master passes under the bar. ・ When the master goes forward for 10cm, left and right fingers release the cutter button.

- Page 92 ⅹ)Short press cutter button. a - Cutter slides to cut out residual master paper, and you can hear cutter sliding sound. Notices (Danger) At this time, do not put your hands in red line indication zone in the right figure. The cutter will cut out residual master paper here.

- Page 93 Notices of changing master paper Master paper is made of thin materials, and will be greatly influenced by humidity. Pay more attention to store master paper, and do not put it in the environment with ultimate high temperature and low humidity.

- Page 94 Waste master paper treatment method When new originals are used for master making, the old one will be automatically discharged in waste box. When the waste box is full, there will be hints. Please throw away old master paper in waste box. Treatment method ⅰ)Press the switch of the waste box to open it.

- Page 95 ⅴ)Hold the paper core by one hand and dispose it to waste box. The core should be sloped down slightly, so as to take down waste master paper easily. Core will be recycled, please do not throw it away. ⅵ)Put the core back to the waste box. ⅶ)By pressing the upper cover, you will hear a sound of “...

- Page 96 Pull out and installation of drum Remove card paper in the machine, and pull out the drum for cleaning the inside of the machine. Before drum is pulled out of the machine, please first confirm whether the place to place drum is flat or not;...

- Page 97 ⅳ)Hold the handle by one hand, and hold the drum frame by other hand and take out the drum. Pull up the drum slightly to make it leave guide rail. ⅴ)Install in opposite sequence. Rotate the drum when it is pulled out of the machine body ・...

- Page 98 - 93 -...

- Page 99 On-line printing function ・ LAN connection The machine is not only used to print single page and originals of books and magazines, can but also send documents and data made in computer to the digital duplicator for printing 3 Ways. ・...

- Page 100 Installation sequence of digital duplicator driver Before installation Since computer will be used in different environments ( Brand, OS and safety prevention ), information in installation process may be different with the Manual or installation may be failed, please understand. The Manual is prepared according to operation system [ Windows7 / 64bit ] Start Please confirm computer operation system, and install according to the operation sequence in Manual step by...

- Page 101 3. Click [ Properties ]. 4. Numbers under [ System type ] are bit numbers of [ Operation system ]. ※ The figure above shows [64bit ver.]。 5. After confirmation, please click the upper right [ Close (C) ] button of the window, then the display window disappears.

- Page 102 Installation of digital duplicator driver Firstly, Digital duplicator driver is installed when the computer is powered on and the power supply of the digital duplicator is powered off. LAN connection / USB data cable connection / U flash disk printing, all the methods need install the digital duplicator drive.

- Page 103 4. Click [ Device and printer ] 5. The printer connected has been recognized and displayed by [ Duplicator ]. Click the right key of mouse in the option. ※ If the “clock’ is still existing, it means printer is not finishing recognizing with computer connection. Please wait till it disappear to start operation.

- Page 104 7. Click [ Hardware ] in [ Duplicator properties ]. 8. Click [ Properties ]. 9. Click [ Change setting ] in [ Duplicator properties ] - 99 -...

- Page 105 10. Click [ Driver ]. 11. Click [ Update driver ]. 12. Click [ Browse my computer for driver software ] in [ How to search drive software ]. - 100 -...

- Page 106 13. Click option in [ Browse for driver software on your computer ]. 14. Double click [ Printer ] in [ Common hardware types ]. ・ After double clicking [ Printer ], click [ Next (N) ] 15. Click [ Have disk ] in [ Add printer wizard ] ・...

- Page 107 16. Install CD attached in computer driver · The operation method should be confirmed through computure actual practice. 17. When [ Autoplay ] picture is automatically displayed, click upper right [ Close (C) ] option. 18. [ Install from Disk ] picture will be displayed, at this time, click [ Browse (B) ] option. ※...

- Page 108 19.Click [▼] key in [ Look in ] in [ Locate file ]. 20. Click [ DVDRW drive ] option in [ Look in ] table. · On file name, it might be a little different as per different computers. 21.

- Page 109 22. Show two files saved in CD. The displays of the files are different as per PC and CD type. 23. [ Operation system ] has been confirmed in page 95 of the book, please double click folder file matched with computer bit numbers.

- Page 110 25.[ Install from Disk ] menu will be displayed, please click [ OK ] option. 26. Click [ Next (N) ]. 27. Program installation related reminding menu will be displayed, inquire [ Whether to continue installation ], click [ Yes (Y) ] option. ・...

- Page 111 28. Digital duplicator driver starts installation, please wait for a moment. 29. When [ Installation completion ] information is displayed, click [ Close (C) ] to complete installation. 30. By clicking upper right [ Close ] button, the picture will disappear. - 106...

- Page 112 Initial setting of digital duplicator driver After computer is connected with digital duplicator, confirmation and change of initial setting is necessary for initial printing and U flash disk printing. 1. Click the lower left [ Start ] button on desktop. 2.

- Page 113 4. Click [ Printing preference (G) ] option. 5. Click [ Advance ]. 6. Click printing quality [ 600 × 600 dots per inch ]. ・If display contents are [ 600 × 600… ], click [OK] , then directly go to Step 9 on page 109. - 108...

- Page 114 7. Click the right [ ▼ ] button 8. Three items will be displayed. Click [ 600 × 600 dots per inch ]. 9. Click [ OK ]. 10. Click upper right [ Close ] button, and close the window that has been set. - 109...

- Page 115 Network printing function Digital duplicator should be connected with network in network covered zone, so that all people in network zone can use the digital duplicator. But before using LAN printing function, each user should install the digital duplicator driver on computer. In add, the administrator need confirm the IP address of the digital duplicator. Confirm IP address If ‘home’...

- Page 116 1. Connect digital duplicator and switch with network cable. 2. Open the power switch of digital duplicator. 3. Press【IP address setting】key. 4. Record IP address ( Used later ) ・ [ 192.168.1.130 ](“ dot” , should be also input ) Also may show[192.168.1.120]...

- Page 117 5. The IP address of the machine is changed After pressing【Last number】at IP address display,then press 【Clear】 key. 5-ⅰ. 5-ⅱ. The usual IP address[192.168.1. ]is shared, only to change the last number(above[130] ). 5-ⅲ. After confirming with administrator, input the IP not used yet.. E.g.

- Page 118 Network connections fo computer ・ Network covered computer and this machine (digital duplicator) should be connected with network first. ・ Take the IP addres on page 111 as an example. 1. Click the lower left [ Start ] button on desktop 2.

- Page 119 4. Click [ Add a network, wireless or Bluetooth printer ]. 5. Click [ The printer that I want isn’t listed ]. 6. After clicking -a) [ Add a printer using a TCP/ IP address or hostname ], click -b) [ Next step (N) ]. - 114...

- Page 120 7 . Input the confirmed, a) Input [ IP address ], click -b) [ Next step (N) ]. IP Address should be rightly input in half-angle state, including [ . ] (eg.: after inputting 192 dot 168 dot 1 dot 130, the port name(P)will automatically displayed.) 8.

- Page 121 10. [ Detecting the driver model… ] will be displayed. According to service environment, detection could take some time, please wait in patient. 11.After [ Printer installation driver ] is displayed, click [ Disk installation(H)]. ・ Printer is still searching for other installed drivers and takes some time, but it still can choose the item Disk installation(H).

- Page 122 13. Click right side[▼]of [ installation position (C ) ]. 14.Click the installed [ RDPrinter3.2 ] in CD by step [ 12 ]. 15.Click[OK]. - 117 -...

- Page 123 16.Click [ Next(N)]. 17.Display the printer name.If ok, then click [ Next(N)] directly. Click [ Next(N) ],there might display some warnings on installation.Just neglect and choose [ Start ] to start. 18. Click [ Printer sharing ]. Click [ Do not share the printer (O) ] when there is only one user. ; click [ Share the printer so that others on your network can find and use it ].

- Page 124 19.If the printer does not need to set "Default Print", click [End (F)]. Click[Print a test page] ,output the test through LAN connection. - 119 -...

- Page 125 LAN / USB on-line printing In a network environment, use the [Online or USB online printing] function to send data directly to the duplicator for printing. You can also use the USB cable to connect the computer and the machine. Printing method 1.

- Page 126 3. Click [ Print ]. 4. Click [ Printer ] displayed under [ Printer types ]. ( All printers connected on computer will be displayed ) ・ It will display the related information when installing the driver if set the duplicator as default printer. 5.

- Page 127 6. The process will be different when printing single or multi- pages. The duplicator cannot print multi-pages..Indentify the page numbers of manuscript; please refer to the content indicated by the arrows in the figure below. a) If single printing, go with the [7] item. b) For multi-pages, click [ Print all pages ] 、-c) click [ Print current page ].

- Page 128 7. Click [Print]. 8. The printer starts automatically (sorting → master-making→ printing) according to the received signal. - 123 -...

- Page 129 U flash disk printing Data in U flash disk will be directly printed by U flash disk. Needed printing data needs to use the installed duplicator driver into the machine required format, and then save in U disk. Data conversion and storage 1.

- Page 130 4. Click [ Print ]. 5. Click [ Printer type ] displayed under [ Printer ]. ( All printers connected on computer will be displayed ) ・ It will display the related information when installing the driver if set the duplicator as default printer.

- Page 131 7. Printed data, according to the singular or complex number, the operation method is not the same, if the complex print data, can not be continuous printing. Press the arrow in the figure to judge singular or complex. 7-a ) Printing the singular numbers, please press [8] item to continue. 7-b ) For multi-pages, click [ Print all pages ] 、-c ) click [ Print current page ].

- Page 132 8. And click [Printed], then click [Printed File]. 9. Click [Print]. 10. Click to save the U flash with data. - 127 -...

- Page 133 11. a) Input the file name、b)click [OK]。 File name requirements: [ Half-width English letters / numbers ]. The digital duplicator can display 8 digits at most. If the former 8 digits are the same, it is difficult to distinguish them, and therefore, please input an easy-recognized name.

- Page 134 2. Insert the U flash disk saved with printing data in the digital duplicator. All parts name and functions(Page 29) 3. U disk data will be displayed. The text entered in advance will be all showed in large text. 4. Choose files that is needed printed. The color for the chosen files will be changed.

- Page 135 Display screen has no display after inserting U flash disk Press the [U disk] button on the panel, the screen will display the data names in U disk. In order to prevent data loss, please note that the data in the U disk backup. It may lead the printing failures due to computer reasons, improper operaiton under the data set /save status.

- Page 136 - 131 -...

- Page 137 Common faults Some faults will be illustrated as examples. When machine is failed or in bad condition, deal with according to the following contents. ・ Power supply can not be connected ・ There is white line in the top-bottom direction (longitudinal direction of printing paper ・...

-

Page 138: Power Supply Can Not Be Connected

Power supply can not be connected ・ Whether power cord is connected or not? ・ Whether power plug is plugged in socket or not? ・ Whether socket is powered on or not? Power cord installation method(Page 37) There is white line in the top-bottom direction (Longitudinal direction) ・... -

Page 139: Overall Background Color Of Printing Paper Is Darker

Overall background color of printing paper is darker ・ Whether originals are recycled paper and newspaper or not? Remove background color(Page 61) Change original mode(Page 63) ・ Whether setting changes or not? Remove background color(Page 61) ・ Whether temperature in service temperature is lower or not? If outer temperature is lower, the lamp for light source is weaker, and then printing contents will be darker integrally. -

Page 140: Incomplete Printing On Two Ends Of Printing Paper (Left And Right)

Incomplete printing on two ends of printing paper (left and right) ・ Whether master paper or printing paper is rolled on pressure roller (under the drum) or not? Pressure roller is below the drum. Please take down the drum for confirmation. Method of taking out and mounting drum(Page 91)... -

Page 141: Lighter Printing Words

Lighter printing words ・ Whether the machine is used in lower environment or not? If temperature is lower, ink will be influenced by temperature, as a result, printing words will be lighter. Please control printing pressure, and select darker master making mode for master making again. -

Page 142: Contents On Rear Printing Ends Run Over

・ Whether machine stops running because printing paper is rolled on drum or not? If printing paper is rolled on drum, ink will leak easily. Please confirm proof printing effect. If proof printing effect is bad, please make new master. On originals(Page 19)... -

Page 143: Frequent Paper Delivery Jam

Frequent paper delivery jam ・ Whether paper delivery pressure / paper separating pressure is appropriate or not? Setting of paper delivery pressure / Paper separating pressure(Page 39) ・ Whether to print on double sides or not? Delivery of printed paper will be influenced by ink and static electricity. Please dry the paper printed on one side on flat place. -

Page 144: Frequent Faults Of Paper Winded On Drum

・ Whether the installation of paper platform is appropriate or not? Whether the width of the positive baffle plate / guide plate of the paper platform is controlled appropriately or not, and delivered paper will knock the positive baffle plate / guide plate. Installation method of paper platform(Page 41)... -

Page 145: Scratches On Front Ends Of Printing Paper

・ Whether originals have more bolds or not?? Even if there is enough page margin, if originals have more bold words or pictures, printing paper will be rolled on drum. Before such type of originals is printed, please reduce master making concentration first, and replace thick paper. Printing concentration adjustment(Page 56)... -

Page 146: Frequent Master Loading Fault

Frequent master loading fault ・ If frisket finger of drum is with ink or oil stain or not? If it is with ink or stain, master unloading will be influenced ormisoperation will be caused. Manually take down master paper on drum surface, and then clean the frisket finger. -

Page 147: Left Paper Jam

Common fault treatment method Left paper jam ⅰ)Lower the paper feeding table. Up-down button of paper feeding table is on its operation part. Press the Up button to lower the paper feeding table. ⅱ)Remove jammed paper. When paper is not much delivered forwards, paper is directly pulled out. -

Page 148: Middle Paper Jam

Middle paper jam ⅰ)Press waste box opening and closing button to open the waste box. ⅱ)Press [ Drum rotating button ] to slowly rotate drum and take out paper. When the drum is rotated, paper arrangement belt will also rotate, please be careful! ⅲ)Press and hold [ Drum rotating button ] till [ Bang ] sound is made slightly. -

Page 149: Right Paper Jam

Right paper jam ⅰ)Press waste box opening and closing button to open the waste box. ⅱ)Press [ Drum rotating button ] to slowly rotate the drum and take out paper. When drum is rotating, paper arrangement belt will also rotate, please be careful! ⅲ)Press and hold [ Drum rotating button ] till [ Bang ] sound is made slightly. -

Page 150: Master Unloading Faults

Master unloading faults ⅰ)Open the front door. Stop machine running before open the front cover. ⅱ)Pull drum mounting handle up, and unlock. ⅲ)Pull out the drum. Please slowly pull out the drum. It will be stopped by brake on the final position. ⅳ)Open frisket finger by clamping handle. - Page 151 ⅴ)Take out master paper above frisket finger. Master paper may be also automatically warped. ⅵ)Disconnect the drum handle, and slightly rotate the drum to left. ⅶ)Take out the master paper when rotating the drum. ⅷ)Rotate the drum to drum handle locking position. ⅸ)Install the drum in opposite sequence.

- Page 152 Simple maintenance ■ Cleaning of scanning table glass Hints: Scanning table glass belongs to high precision component, and should not be knocked or scratched by hard matters; Please wipe the glass by soft cloth or toilet paper. ■Cleaning of scanning table cover plate Please wipe the glass by soft cloth or toilet paper.

- Page 153 - 148 -...

- Page 154 Technical specification Model VR-7625S VR-7428S Operation mode LED touch screen Master way Ditigal thermal master making Scan way Book Printing way High-speed digital plate making and automatic engraving printing Original type Book(≤10kg )、Sheets Image processing mode Text、Picture、Picture&text、Newspaper、Screen、Pencil Master making time In 19s(A4 Vertical)...

- Page 155 Model VR-7625S VR-7428S Confidentiality USB print Auto power off U disk master making Auto-printing pressure adjustment Ink saving mode Power source 220VAC,50Hz Using 1320(W)×720(D)×625(H) Size(W×D×H) Storing 695(W)×720(D)×625(H) Weight Around 108kg Products will be changed at any time without prior notice.

- Page 156 Thanks for using our product. The Manual includes detailed instructions on how to operate and use the equipment as well as notices for use. To use the equipment safely and effectively for long term, please read the Manual carefully before using our product ! NINGBO R.D.C OFFICE EQUIPMENT CO.,LTD Address:No.

Need help?

Do you have a question about the VR-7625S and is the answer not in the manual?

Questions and answers