Summary of Contents for Hiten 2H

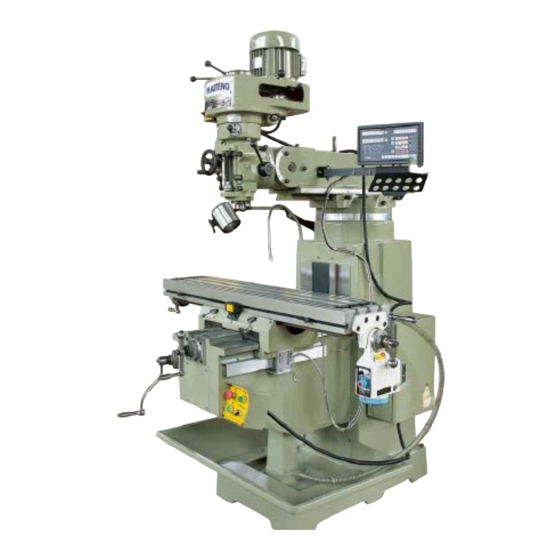

- Page 1 VERTICAL TURRET MILLING MACHINE OPERATION MANUAL Model: 2H 4H 5H The machine has been inspected and found to be up to the ...

- Page 2 No. Inspection item figure tolerance measured a)in the cross Straightness and vertical Within 0.025 at of knee surface(YZ) 300 arbitrary G1 vertical b)in a length movement (W longitudinal measurement axis) and vertical surface(ZX) Right and left Per/0.025/300 direction Squareness of upper ...

- Page 3 a)0.01 G6 Run out of spindle b)0.01 At fixed end 0.01 of test bar Main spindle G7 taper hole run‐out At point 300 0.02 Right and left Per 0.025/300 Squareness of direction upper surface G8 of table to Forward and centre line of backward 0.025/300 spindle ...

- Page 4 Squareness of forward and backward movement of table G11 Per 300 0.02 to side of middle T slot of table Parallelism of forward and G12 backward movement of 0.035/300 overarm with table surface Parallelism of left and right G13 movement of swivel turret 0.035 ...

- Page 5 HT-2H001 HT-4H002 HT-5H003 Operation Info Max. Drilling Capacity (steel) 1-1/4" 1-1/4" 1-1/4" Max. Drilling Capacity (lron) 1-1/2" 1-1/2" 1-1/2" Max. End Milling Capacity 1" 1" 1" Max. Face Milling Capacity 3" 3" 3" Max. Distance Spindle to Column 17-29/32" 21-27/32" 21-27/32"...

-

Page 6: Table Of Contents

CONTENTS CHAPTER 1. SAFETY INFORMATION ■ 1‐1 IMPORTANT SAFETY INFORMATION ‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐1 ■ 1‐2 SAFETY RULES DURING AND /OR BEFORE OPERATION‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐2 ■ 1‐3 SAFETY DURING ELECTRICAL CONNECTION OR DIS CONNECTION‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐3 ■ 1‐4 DESCRIPTION FOR THE SAFETY FUNCTION OF THIS MACHINE‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐3 ■ 1‐5 SAFETY INSPECTION ‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐4 CHAPTER 2. INSTALLATION ■ 2‐1 SAFETY PRECAUTIONS‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐5 ■ 2‐2 INSTALLATION/CLEANING‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐6 ■ 2‐3 MACHINE DIMENSION‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐7 ■ 2‐4 FOUNDATION PLAN‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐8 ■ 2‐5 POWER SUPPLY‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐9 ■ 2‐6 INITIAL SETTING‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐10 CHAPTER 3. OPERATION ■ 3‐1 SWIVEL TURRET ‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐11 ■ 3‐2 MOVE RAM SLIDE‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐11 ■ 3‐3 CLAMPING TABLE,SADDLE AND KNEE‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐12 ■... - Page 7 CHAPTER 4. MAINTENANCE ■ 4‐1 MILLING HEAD LUBRICATION SYSTEM‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐23 ■ 4‐2 AXIAL LUBRICATION SYSTEM X/Y /Z‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐24 ■ 4‐3 LUBRICATION SYSTEM‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐25 ■ 4‐4 GIB ADJUSTMENT‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐26 ■ 4‐5 BACKLASH ADJUSTMENT(X AXIS)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐27 ■ 4‐6 BACKLASH ADJUSTMENT(Y XIS)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐28 ■ 4‐7 CLOCK SPRING REPLACEMENT‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐29 ■ 4‐8 COLLET ALIGNING SCREW REPLACEMENT(R8)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐30 ■ 4‐9 ADJUSTING SPINDLE BEARING AND REPLACE BEARING(NT30#)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐31 ■ 4‐10 REMOVE MOTOR‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐32 ■ 4‐11 DRIVING EELT REPLACEMENT (WITH STEP PULLEY CONTROLLED)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐33 ■ 4‐12 BRAKE DRUM&TIMING BELT REPLACEMENT(WITH STEP PULLEY CONTROLLED)‐‐‐33 ■ 4‐13 DRIVING BELT REPLACEMENT(WITH STEP VARIABLE SPEED MOTOR)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐34 ■ 4‐14 DRIVING BELT REPLACEMENT(WITH VARIABLE SPEED MOTOR)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐35 ■ 4‐15 BRAKE DRUM REPLACEMENT(WITH VARIABLE SPEED MOTOR)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐35 ■ 4‐16 FEED TRIP ADJUSTMENT‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐36 CHAPTER 5. PARTS LIST ■ 5‐1 HEAD TOP HOUSING ASSEMBLY STEP PULLEY/A001~A087‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐38 ■...

- Page 8 **INTRODUCTION** THIS MANUAL HAS BEEN CAREFULLY PREPARED, PLEASE STUDY IT THOROUGHLY BEFORE TRYING TO OPERATE THE MACHINE. **A FEW MINUTES GIVEN TO READING THIS MANUAL CAREFULLY,COULD ...

-

Page 9: Chapter 1. Safety Information

CHAPTER 1. SAFETY INFORMATION 1‐1 IMPORTANT SAFETY INFORMATION: A. Application of the milling machine The milling machine is designed and constructed for the cutting of metal and similar materials. The machine is along with all the necessary safety requirements. Only fully trained &fully qualified operators should be allowed to operate this machine. B. Prohibition: ‐Untrained operators are prohibited from using this machine. ‐Modifications that change the function or specification of this machine is prohibited. ‐Operation of this machine before reading through this instruction manual, is prohibited. C. Airborne noise level: ‐The airborne noise level during operation is about 70~75Db (A). D. lighting: ‐Appropriate lighting must be provided, according to local regulation. ‐Minimum lighting for this machine is 300 LUX, if there are no any local other local regulations. E. Environment: 1. Ambient air temperature :+41℉~+131℉ in free air, and the average ambient air temperature over a period of 24 hours shall not exceed +122℉ 2. Humidity : 30%~95%. 3. Altitude :up to 1000m above mean see level. 4. Transportation & storage condition: ‐77℉~+131℉, and for short periods not exceeding 24 hours up to +158℉ ... -

Page 10: Safety Rules During And/Or Before Operation

1‐2 SAFETY RULES DURING AND/OR BEFORE OPERATION A. Be sure the instruction manual are fully understood. B. Use safety protective equipment such as safety shoes, goggles, clothes, etc. C. Work table near the machine must be strong enough to prevent accidents and be sure articles will never slip off the table surface to interfere with the act of machining. D. Tools and any unnecessary items are not allowed to be placed on the machine table, moving parts, or similar locations. E. Before operating switches, always check if the switches are the right ones and never touch a switch accidentally or it may cause malfunctions or danger. F. Do not operate switches with gloves on. This could cause malfunctions or even danger. G. Do not touch switches with wet hands, an electric shock could occur. H. Warm up the machine before use, especially the spindle and feeding axes by running them for 10 to 20 minutes. It is very important for maintaining machine accuracy. I. If job is to be done by two or more operators, the function of each must be well known, what action will be done and what danger may occur, before the next step is taken. J. Tools should conform to the machine‘s specifications, such as dimensions, weight and types. K. Grip workpieces securely to minimize movement or vibration between workpiece and cutting tool or it may injure personnel, or damage the machine or workpiece. L. Never touch tool nose and cutting chips with bare hands. M. Never try to touch a turning workpiece or spindle in any way. N. Stop the machine before replacing a workpiece and provide plenty of distance between workpiece and tool to avoid impact between workpiece and tool during ... -

Page 11: Safety During Electrical Connection Or Disconnection

reached by the operator, and keep them for available & in good condition for use. W. Please always quote the machine model and serial number in order for us to deal with any request, as quickly as possible. X. The machine surface is smeared with anti‐rust protection when delivered. It should be carefully cleaned & then smeared with protection oil. 1‐3 SAFETY DURING ELECTRICAL CONNECTION OR DISCONNECTION A. Electrical connection: 1. A cable with three wires is supplied to connect your machine into 3 phase power supply. 2. The exact power source voltage, frequency, and number of phase shall be checked according to the installation diagram and circuit diagram. 3. The correct directions of spindle should be checked after connecting. B. Electrical disconnection: 1. The disconnection is carried out by hand‐operated disconnecting device, which is on the door of control box as an option or connected before the power source. 2. Be sure to disconnect this machine from power source, when you want to stop the job for maintenance or adjustment. C. Grounding: The grounding of this model is carried out by connecting the yellow/green terminal of supply cable to the grounding terminal of power source. Be sure to ground your machine before connecting machine to power source in any situation. WARNING! DO NOT DISCONNECT GROUNDING TERMINAL BEFORE DISCONNECTING POWER SOURCE D. Where a portion of the machine and its associated equipment is changed or modified, must be approved by the manufacturer first, and following retest shall ... -

Page 12: Safety Inspection

correction is that the door of control cabinet could be open only when this switch of this device is switched off, and after this device is switched off, it is possible to be locked with some appropriate locking .as soon as this device is switched off, no any operation is possible and there would be no any electricity on the control circuit except the wring before this device. B. The emergency stop device: It is constructed to stop machine as fast as possible while in emergency situation. as soon as this device is actuated, any movement will be stopped in a short time .after the actuation of emergency button, the further operation is possible only when this button is disengaged and the restart key is actuated. Be sure to check that machine action will stop immediately after this button is pushed and will not cause any action when this button is disengaged. 1‐5 SAFETY INSPECTION To ensure safety, it is necessary to do the following inspections for this machine after installation. A. Check if the transportation procedure has influenced the accuracy and functions of the machine. B. Check if the foundation of the machine is appropriate. C. Check if the factory has the correct thunder‐preventing system under 25. The machine’s power switch should also have earth wiring connected. D. Use the multitester to check if the three‐phase voltage is stable and phases are in order. E. Check if spindle rotation is normal F. Check if the control panel function and push button are functioning (including indicator lamp, load and rpm meter). G. Check emergency stop function H. Check if safety protection accessories are functioning well. I. Check if other accessories, including hydraulic and pneumatic ones, are connected well (including transformer etc.). ... -

Page 13: Chapter 2. Installation

CHAPTER 2. INSTALLATION 2‐1 SAFETY PRECAUTIONS 1. Be sure the instruction manual is fully understood. Must follow instruction manual to operate machine carefully. 2. The operator without training or being authorized is prohibited to operate this machine. 3. Set all covers in position before operation. 4. Use safety protective equipment such as safety shoes, goggles, clothes, etc. and do not wear gloves or ornaments. 5. Must not touch running cutters. 6. Never try to touch workpiece or clean chips while cutters is running. 7. Keep head & hands clear from running machine parts. 8. Turn power off before maintenance. 5 ... -

Page 14: Installation/Cleaning

2‐2 INSTALLATION METHOD 1 Insert 3/4” (whitworth) eye bolt into hole. Ensure bolt is fully secured before lifting. It is advisable to swivel head before lifting machine. METHOD 2 Use rope sling as illustrated . Insert parts of soft cloth Between rope and machine. It is advisable to lift the head before lifting the machine. CLEANING 1. Remove rust preventative before moving any slide ways. 2. The coating is best removed by Using paraffin applied with clean rags. ... -

Page 15: Machine Dimension

2‐3 MACHINE DIMENSION Unit: mm Model Specifications 2H (X6323) 4H 5H (X6325) 5H (X6330) 5H (X6333) A Overall height 2006 (79”) 2235 (88”) 2130 (84”) 2180 (86”) B Overall depth 1600 (63”) 2156 (85”) 2057(81”) ... -

Page 16: Foundation Plan

Unit : mm DIMENSION L A B MODEL 2H (X6323 series) 1500 740 520 4H 5H (X6325 series) 1500 889 540 5H (X6330 series) ... -

Page 17: Power Supply

2‐5 POWER SUPPLY A). Machine supplied with electrical box Check and confirm correct voltage from factory power source. Turn machine main power switch “OFF”, connect machine main power cable and ground wire to factory power source. Power “ON” machine and check motor rotation direction, if it rotates reverse, switch main power 2 cables connection to correct it. B). Machine supplied without control panel Check the motor voltages against supply. Turn power ”OFF”, connect main power and ground wire, then machine is ready. Power “ON” machine and check motor rotation direction, if it rotates reverse, switch main power 2 cables connection to correct it. ... -

Page 18: Initial Setting

2‐6 INITIAL SETTING If the machine was delivered in a crate, the slide way handles have been taken off. These should be re‐fitted. The machine head was turned down for shipping purpose, machine head must be turned up before positioning. How to turn machine head up: ○ 1) Loosen E hexagon nut a little bit, and turn machine head. ○ 2) One person hold machine head, and the other person turn F hexagon screw to turn machine head up. To set milling head square to table(for horizontal plane): 1) An indicator mounted in a spindle nose travelling in a 115MM(4.5”)90° ○ radus,then tighten G lock handle. ○ ○ 2) Loosen E hexagon nut (4 PCS.),turn F hexagon screw, then adjust the point c&d. To set milling head square to the table(for cross plane): 1) An indicator mounted in a spindle nose travelling in a 115MM(4.5”) 90° ○... -

Page 19: Chapter 3. Operation

CHAPTER 3. OPERATION 3‐1 SWIVEL TURRET Use spanner to loosen the 4 bolts. Index to the required setting. Tighten the 4 bolts. 3‐2 MOVE RAM SLIDE Use spanner to loosen the 2 bolts. Turn the handle to move the slide to the desired position. Lock and tighten the 2 bolts. ... -

Page 20: Clamping Table,Saddle And Knee

3‐3 CLAMPING TABLE, SADDLE AND KNEE When milling with longitudinal Table feed only, it is advisable to clamp the knee to the column and the saddle to the knee to add rigidity to these members and provide for heavier cuts with a minimum of vibration. The saddle locking lever is located on the left‐hand side of saddle. ... -

Page 21: Main Part Of Milling Head(With Step Pulley Controlled)

3‐4 MAIN PART OF MILLING HEAD(WITH STEP PULLEY CONTROLLED) 13 ... -

Page 22: Main Part Of Milling Head(With Variable Speedmotor)

3‐5 MAIN PART OF MILLING HEAD(WITH VARIABLE SPEEDMOTOR) 14 ... -

Page 23: Main Part Of Milling Head

3‐6 MAIN PART OF MILLING HEAD(WITH INVERTER CONTROLLED VARIABLE SPEED) 15 ... - Page 24 3‐7 SPINDLE SPEED (WITH STEP PULLEY CONTROLLED) ■STEP PULLY CONTROLLED (8 SPEEDS) HIGH 50HZ 60HZ LOW 50HZ 60HZ 1 2330 540 1 270 325 2 1550 360 2 180 215 3 975 220 3 110 135 4 590 130 4 65 80 ■STEP PULLY CONTROLLED (16 SPEEDS) MOTOR HIGH 2P MOTOR LOW 4P 50HZ HIGH SPEED LOW SPEED HIGH SPEED ...

-

Page 25: Spindle Speed(With Step Pulley Controller)

3‐8 SPINDLE SPEED (WITH VARIABLE SPEED MOTOR & INVERTER CONTROLLED VARIABLE) ■VARIBLE SPEED MOTOR HZ HIGH SPEED LOW SPEED 1 470~3550 50~410 2 550~4300 60~500 ***CHANGING SPEED WHILE MOTOR IS RUNNING ■INVERTER CONTROLLED VARIABLE HIGH SPINDLE LOW SPINDLE HIGH SPINDLE LOW SPINDLE HZ HZ RANGE r.p.m RANGE r.p.m RANGE r.p.m RANGE r.p.m 20 575 65 70 2005 230 25 715 82 ... -

Page 26: Fine Head Feed

3‐9 FIND HEAD FEED Disengage auto quill feed “A”. Locate “C” in mid (neutral) position. Engage feed trip lever “B”. The quill is now under hand wheel control. 3‐10 AUTOMATIC FEED Maximum loading 9.5mm (3/8”) diameter drill in steel. Ensure quill lock ‘D’ is off. Set micrometer dial E’ ,to required depth. When motor has stopped, engage auto quill feed A’. Select feed rate ‘F’ & feed direction ‘C’. Engage feed trip lever ‘B’. Feed will automatically trip out within +/‐0.25mm (0.005”) of required depth. Press hand feed to dead stop for repeating accuracy of +/‐0.025mm (0.001”). ***NOTE : DO NOT ENGAGE QUILL FEED ‘A’ OVER 3000 R.P.M. 18 ... -

Page 27: Spindle Speed Selection(With Step Pulley Controlled)

3‐11 SPINDLE FEED SELECTION (WITH STEP PULLEY CONTROLLED) CHANGE SPEED Isolate machine ‘A’. Select high/low speed ‘B’ as required. Release the handle ‘C’. Position belt ‘D’ on appropriate pulleys. Slide motor to the rear to tension vee belt, then tighten the handle ‘C’. ... -

Page 28: Spindle Speed Selection(With Variable Speed Motor)

3‐12 SPINDLE FEED SELECTION (WITH VARIABLE SPEED MOTOR) CHANGE SPEED WHEEL 1. Do not turn ‘A’ when Spindle stopped. 2. Turn wheel ‘A’ to choose speed. CHANGE HANDLE CHANGE SPEED FROM HIGH SPEED TO LOW SPEED 1. Turn off motor. 2. Moving handle ‘C’ through Neutral to low speed. 3. Turn on the motor. CHANGE SPEED FROM LOW SPEED TO HIGH SPEED 1. Turn off motor. 2. Moving handle ‘C’ through Neutral to high speed. 3. Turning spindle to match clutch. 4. Turn on the motor. ... -

Page 29: Swing Milling Head Forward & Backward

3‐13 SWING MILLING HEAD FORWARD & BACKWARD 1. Loosen “B” adaptor locking bolt (3 pieces), but do not loosen them too much or remove them away from machine. 2. Turn slowly “C” vertical adjusting worm shaft to swing milling head to your required angle. While swinging milling head, use your hand(s) to support it from falling, after milling head at position, lock “B” adaptor locking bolt (3 pieces) tightly. 3. Loosen “B” adaptor locking bolt (3 pieces), then turn “C” vertical adjusting worm shaft to return milling head back to original position. While turning milling head, use your hand(s) to push it upwards. 21 ... -

Page 30: Swing Milling Head Leaf-Side &Right-Sid

3‐14 SWING MILLING HEAD LEFT‐SIDE & RIGHT‐SIDE 1. Loosen “B” tee bolt (4 pieces), but do not loosen them too much or remove them away from machine. 2. Turn slowly “C” adjusting worm shaft to swing milling head to your required angle. While swinging milling head, use your hands to support it form falling. After milling head at position, lock “B” tee bolt (4 pieces) tightly. 3. Loosen “B” tee bolt (4 pieces), then turn “C” adjusting worm shaft to return milling head back to original position. While turning milling head, use your hands to push it upwards. 22 ... -

Page 31: Chapter 4. Maintenance

CHAPTER 4. MAINTENANCE 4‐1 MILLING HEAD LUBRICATION SYSTEM FREQUENCY LUBRICATE LUBRICANT QUANTITY LUB.AT VACTRA HEAVY TWICE WEEKLY CAP RING 5 DROPS 1 MEDIUM TWICE DAILY SPINDLE GEAR GREASE TOP‐UP 2 VACTRA HEAVY TWICE DAILY QUILL 5 DROPS 3 MEDIUM **NOTE: FAILURE TO LUBRICATE “QUILL” AT 3 CAN RESULT IN TIGHT QUILLS ... -

Page 32: Axial Lubrication System X/Y

4‐2 AXIAL LUBRICATION SYSTEM REGULAR LUBRICATION 1. Please use lubrication slide way oil NO. 68 (for example: oil Mobil No.2) 2. Please push lube system at least one time every day. 24 ... -

Page 33: Lubrication System

4‐3 LUBRICATION SYSTEM 25 ... -

Page 34: Gib Adjustment

4‐4 GIB ADJUSTMENT A. TABLE SADDLE WAYS 1. Remove all swarf from area. 2. Loosen right table gib screw and turn left table gib screwclock wise until slight drag is felt. B. SADDLE KNEE WAYS 1.Remove all swarf from area. 2. Remove cover. 3. Loosen back saddle gib screw and turn front saddle gib screw, clock wise until slight drag is felt. 4. Replace the wiper. C. KNEE COLUMN WAYS 1. Remove all swarf from area. 2. Remove cover. 3. Loosen bottom knee gib screw and turn top knee gib screwclock wise until slight drag is felt. 4. Replace the wiper. 26 ... -

Page 35: Backlash Adjustment(X Axis)

4‐5 BACKLASH ADJUSTMENT (X AXIS) TABLE SCREW ASSEMBLY 1. Move the table to the left 2. Loosen 2 PCS lock screw “A” 3. Tighten nut “B” (clockwise) 4. Then tighten 2 PCS lock screw “A” **NOTE: THE BACKLASH ADJUSTMENT DOSE NOT APPLY, IF MACHINE IS EQUIPPED WITH X AXIS BALL SCREW. 27 ... -

Page 36: Backlash Adjustment(Y Xis)

4‐6 BACKLASH ADJUSTMENT (Y AXIS) CROSS SCREW ASSEMBLY 1. Move the saddle to the middle position. 2. Loosen 2 PCS lock screw “D”. 3. Tighten nut “C” (counter‐clockwise) 4. Then tighten 2 PCS lock screw “D”. 28 ... -

Page 37: Clock Spring Replacement

4‐7 CLOCK SPRING REPLACEMENT 1. With quill at top of movement, apply quill lock “G” lock handle. 2. Remove “A” set screw, hub “B” pinion shaft hub sleeve. 3. Remove “D” round head Allen screw (2 PCS), rotate “E” spring cover counter clock‐wise, to release spring tension, be sure to turn the cover slowly and gently. 4. Remove end of “H” clock spring from the peg on “F” spring pin. 5. Remove “H” clock spring (beware of the spring tension, so you can avoid being hurt), and refit a new good “H” clock spring. 6. Refit spring in reverse order, test spring reverse tension, adjust “H” clock spring tension as required, as follows: Remove the first screw “D” round head Allen screw, insert a pin, then remove the second “D” round head Allen screw, adjust angle of “E” spring cover as required, tighten the tension clockwise, release the tension counter‐clockwise. 29 ... -

Page 38: Collet Aligning Screw Replacement(R8)

4‐8 collet aligning screw replacement (R8) 1. Remove set screw “A”. 2. Unscrew nose cap “B” (left hand thread & beware that the spindle goes down) 3. Remove lock screw “C” & collet aligning screw. 4. Aim the slot of R8 collet at screw “D” adjust screw “D” to the proper position (do not overtighten grip on the collet) 5. Replace lock screw “C”. 6. Replace and lock nose cap “B” properly (do not lock tight, or this will cause quill distortion). 7. Replace and lock set screw “A” properly (do not lock tight, or this will cause quill distortion). 8. Check if there is a gap between nose cap “B” and quill, if there is no gap, remove nose cap “B”, machining it until there is a gap. 30 ... -

Page 39: Adjusting Spindle Bearing And Replace Bearing(Nt30#)

4‐9 ADJUSTING SPINDLE BEARING AND REPLACE BEARING (NT30#) 1. Remove milling chuck and draw bar. 2. Take off set screw “A”. 3. Loosen adjusting nut “B” (left‐hand thread) until disengaged from quill, and hold spindle which will not falls off. 4. Remove whole set spindle, then pull open circlip “D” and adjusting nut “C” until bushing “E” to tighten to death. 5. Replace spindle, tighten adjusting nut “B” to death, check there is a gap “F” about 0.5‐1MM between nut and quill, if there is not, take off nut and machining it use a scale to measure dimension before assembly. 6. Fit set screw “A” re‐drill a hole and tighten it properly (not too tight). 31 ... -

Page 40: Remove Motor

4‐10 REMOVE MOTOR 1. Adjust spindle speed to highest speed. 2. Turn off main power. 3. Remove 3 screw “A” & cover “B”. 4. Separate the connecting wire between forward/reverse switch and motor. 5. Remove the 4 locking nut “D”. 6. Remove the motor. 32 ... -

Page 41: Driving Eelt Replacement (With Step Pulley Controlled)

4‐11 DRIVING BELT REPLACEMENT (WITH STEP PULLEY CONTROLLED) 1. Isolate machine. 2. Remove draw bar “H”. 3. Remove motor “C” 4. Lower quill to full extension. 5. Remove screws “A” 3 PCS. 6. Remove bearing retainer “B” 7. Remove screw “D” 6 PCS. 8. Remove belt housing “E”. 9. Replace new driving belt. 4‐12 BRAKE DRUM & TIMING BELT REPLACEMENT (WITH STEP PULLEY CONTROLLED) 1. Repeat sequence item 1 to 9. (same as above) 2. Remove screws “J” 4 PCS. 3. Remove brake base “K”. 4. Replace brake drum or timing belt. 33 ... - Page 42 4‐13 TIMING BELT REPLACEMENT (WITH VARIABLE SPEED MOTOR) 1. Remove the motor. 2. Remove draw bar “H” and milling cutter. 3. Remove screws “A” 3 PCS and bearing housing “B”. 4. Remove screws “E” 2 PCS and the bushing “C”. 5. Remove screws “D” 6 PCS. 6. Remove the 2 screws which are at the bottom of the 4 screws of the speed change “F”. 7. Remove top housing “G” and the speed change “F”. 8. Remove the 4 Allen head screw “J”. 9. Remove brake base “K”. 10. Refit a new, good belt. 34 ...

-

Page 43: Driving Belt Replacement(With Variable Speed Motor)

4‐14 DRIVING BELT REPLACEMENT (WITH VARIABLE SPEED MOTOR) 1. Item 1 to 7 same as above. 2. Replace a new/good belt. 4‐15 BRAKE DRUM REPLACEMENT (WITH VARIABLE SPEED MOTOR) 1. Remove the motor. 2. Same as timing belt replacement item 1 to 9. 3. Remove “E”, “F”, “G” (Aim at the slot and re‐mark first). 4. Remove “H” circuit. 5. Remove clutch gear shaft “I” from lower side. 6. Remove “J” circlip. 7. Remove “K” variable speed pulley from upper side. 8. Remove “A” Allen head screw. 9. Remove “D” brake bearing base. 10. Refit a new/good brake shoe. 35 ... -

Page 44: Feed Trip Adjustment

4‐16 FEED TRIP ADJUSTMENT 1. Release locknut “A”. 2. Engage trip handle “C”. 3. Adjust micrometer nut “E” against quill stop knob “B”. 4. Slowly turn adjusting screw “D” until cam rod “C” trips. 5. Then tighten hexagon nut “A”. 6. Engage cam rod “C”. 7. Fit hand wheel “F”, adjust quill stop knob “B” against micrometer nut “E”, check that smart trip action is obtained. 36 ... -

Page 45: Chapter 5. Parts List

CHAPTER 5. PARTS LIST WHEN ORDERING REPLACEMENT PARTS, PLEASE QUOTE: THE MACHINE MODEL NUMBER THE MACHINE SERIAL NUMBER PARTS NUMBER DESCRIPTION QUANTITY ***PARTS OBTAINABLE IN INCH OR METRIC 37 ... -

Page 46: Head Top Housing Assembly Step Pulley/A001~A087

5‐1 HEAD TOP HOUSING ASSEMBLY STEP PULLEY/ A001‐A087 38 ... - Page 47 PARTS DESCRIPTION SPEC QTY NO. ...

- Page 48 A‐033 SNAP RING E5 1 A‐034 ...

- Page 49 A‐066 GEAR HOUSING 1 A‐067 ...

-

Page 50: Head Top Housing Assembly For Variable Speed /Vs001~Vs155

42 ... - Page 51 PARTS NO. DESCRIPTION SPEC Q’TY VS‐001 ...

- Page 52 VS‐034 BOLT BASE 1 VS‐035 ...

- Page 53 VS‐067 GEAR SHAFT 1 VS‐068 ...

- Page 54 VS‐101 COVER 1 VS‐102 ...

- Page 55 VS‐134 WASHER 5/16” 1 VS‐135 ...

- Page 56 48 ...

- Page 57 PARTS NO. DESCRIPTION SPEC QTY VS‐001 DRAW BAR 1 EVS‐002 ...

- Page 58 EVS‐034 GEAR SHAFT 1 EVS‐037 ...

-

Page 59: Evs103

EVS‐092 ADJUSTING BLOCK 1 EVS‐093 ... -

Page 60: Machine Head Assembly/B001~B192

52 ... - Page 61 PARTS NO. DESCRIPTION SPEC QTY B‐001 ...

- Page 62 B‐036 FEED DRIVING GEAR 1 B‐037 ...

- Page 63 B‐076 SET SCREW M6*6 1 B‐077 ...

- Page 64 B‐112 SNAP RING E5 1 B‐113 ...

- Page 65 B‐145 FEED TRIP LEVER 1 B‐146 ...

- Page 66 B‐178 CLOCK SPRING 1 B‐183 ...

-

Page 67: X.y Axis Leadscrew Assembly/D001~D028

59 ... - Page 68 PARTS NO. DESCRIPTION SPEC. Q’TY D‐001 HEXGON NUT 1/2”*20NF 3 D‐002 ...

-

Page 69: Basic Machine Assembly/2C001~2C133

61 ... - Page 70 PARTS NO. DESCRIPTION SPEC. Q’TY 2C‐001 QUILL HOUSING ADJUSTING GEAR 1 2C‐002 ...

- Page 71 2C‐032 TABLE STOP PIECE 2 2C‐033 ...

- Page 72 2C‐077 BEVEL GREAR 1 2C‐078 ...

- Page 73 2C‐110 SET SCREW 2 2C‐111 ...

-

Page 74: Chapter 6. Electrical Diagram

6. Electrical Diagram 66 ... - Page 75 67 ...

Need help?

Do you have a question about the 2H and is the answer not in the manual?

Questions and answers