Summary of Contents for JLL 2000 Series

- Page 1 USER’S MANUAL HYDRAULIC ELEVATOR CONTROLLER CANBUS PROCESSOR JLL-2000 SERIES VERSION 2.02.000...

-

Page 3: Table Of Contents

TABLE OF CONTENT LCD USE (JRT-LCD): ................................1-1 1.1. K : ..................................1-1 EYBOARD 1.2. M : ....................................1-2 ENUS 1.2.1. Monitoring menu: ..............................1-3 1.2.2. Register Access menu: ............................1-4 1.2.3. Active faults list menu: ............................1-6 1.2.4. Construction mode menu: ............................. 1-7 1.2.5. - Page 4 8.2.11. Emergency power: .............................. 8-28 8.2.12. Hydraulic cylinder reset sequence: ........................8-29 8.2.13. Blue code/Free car sequence: ..........................8-29 8.2.14. Other Parameters: .............................. 8-29 8.2.15. How to change displayed values for each floors on a microcomm or Canbus PI..........8-30 SYMBOLS LISTING: ................................

- Page 6 NOTES AND PRECAUTIONS • The controller must be installed by competent people who possess the suitable training and cards for the installation of elevator controllers; • The controller’s power supply must come from a fuse switch supplied by others. The fuses value must respect the electrical code;...

- Page 7 General information: JLL-2000 series controllers were developed for a quick and easy installation and operation. The controllers have functions of internal self-diagnosis, which allow an easy maintenance. There are also several functions that are programmable by the user. It is very important to read thoroughly the manual, for a quick and secure installation.

-

Page 8: Lcd Use (Jrt-Lcd)

1. LCD USE (JRT-LCD): This section is a summary of the supervision utility. Refer to appendix C for a complete description. The LCD lets you visualize the state of the elevator controller (floor, speed in FPM, perforated tape position, alarms, etc.), modify the CPU’s configuration registers and also to record car calls and hall calls from a distance. -

Page 9: Menus

1.2. MENUS: The "LCD" utility contains differents menus available to the users. To access a menu: • Press "ESC" to access to the main menus list. • Press on the "UP/DOWN" keys to select a menu. • Press "ENTER" to access the menu. The "LCD"... -

Page 10: Monitoring Menu

1.2.1. Monitoring menu: The "Monitoring" menu shows, in actual time, the elevator’s status data. This information may be used during the temporary and final start-up. At a start-up or after 2 hours of keyboard inactivity, the following screen will appear: IN AUTOMATIC PI=12 STOP... -

Page 11: Register Access Menu

1.2.2. Register Access menu: This menu allows reading and writing in one of the CPU’s register. The "DM" registers are used to configure the elevator. • Press "ESC" to go back to the main menus. • Press "UP/DOWN" keys to select the main menu "REGISTERS ACCES". •... - Page 12 REGISTER NUMBER ->DM0000 Register Value: The register value is shown in hexadecimal and binary formats. • Press "ENTER" to modify the selected register value. • Press "ESC" to go back to the previous menu. DM0000 = 0001 0000000000000001 15 ^ 8 4 0 ENTER = CHG Modifying the register value: •...

-

Page 13: Active Faults List Menu

1.2.3. Active faults list menu: LOW OIL LEVEL DETECTED HR8000 ENTER->ERASE This menu allows visualising the different alarms in the elevator controller. The utility "LCD" displays "NO ALARM" when the elevator controller has no more alarms. Visualizing the alarms: • Press "ESC" to return to the main menus. •... -

Page 14: Construction Mode Menu

1.2.4. Construction mode menu: The Construction mode disables temporarily certain detections to facilitate the elevator car construction in Inspection mode. As soon as the elevator controller is placed in Automatic mode and that a call has been placed, the Construction mode will be deactivated automatically and all signals will be in function. - Page 15 • Press on "UP/DOWN" keys to change the number. • Press on "ENTER" to save the new value and exit edition mode. • Press on "ESC" key to exit without saving. • Repeat for all parameters that you want to change.

-

Page 16: Password Menu

1.2.6. Password menu: This menu allows entering a password to unlock the parameters modification menus. The default password is "0000". PASSWORD : 0000 • Press "ESC" to return to the main menus. • Press "UP/DOWN" keys to select the main menu "PASSWORD". •... -

Page 17: Use Of The Programming Console (Pro01 Ou Pro27)

2. USE OF THE PROGRAMMING CONSOLE (PRO01 OU PRO27): Not available... -

Page 18: Temporary Start-Up

3. TEMPORARY START-UP: Install jumpers between the following terminals: • "J0" and "J5" (bypass security line); • "J5" and "J9" (if there is no car top inspection box); • "J9" and "J10" (car stop); • "J11" and "LNH" (normal up limit); •... - Page 19 • If Solid-State starter (Sprecher+Schuh): ➢ Set the DIP Switch #15 OFF if 6 wires or ON if 3 wires. ➢ Set the blue potentiometer according to: ▪ If 6 wires, take the nameplate current and fallow the scale ∆I ▪...

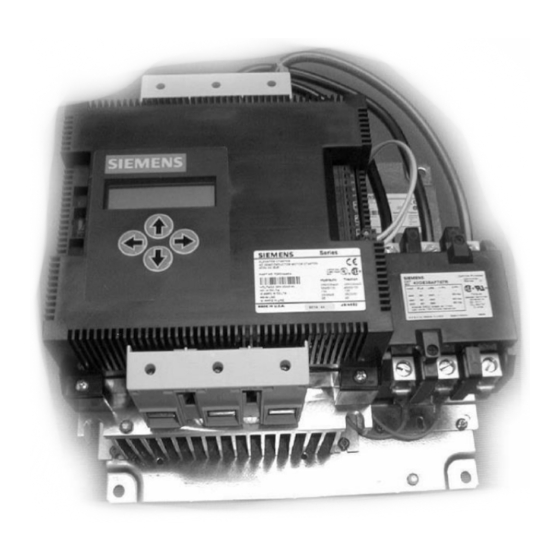

- Page 20 • If Solid-State starter (Siemens): When the soft-starter is powered, it automatically detects the connection of the motor (IN DELTA or IN LINE). In the Configuration menu, the Rated Amps parameter will indicate the type of connection of the motor Exemple: 30 HP 600 volts 32 amps motor Rated Amps = 32A IN LINE Rated Amps = 18.48A IN DELTA (32 amps ÷...

- Page 21 Measure: • Controller power voltage (see drawings) • 120 VAC between "J" and "N", "JC" and "N". • 24 VDC between "+A" and "COM", "+AC" and "COM", "+GR" and "COM", ("+DC" and "COM") (internal voltage), "V+" and "V-" (Victory door operator). Synchronize the reverse phase module: •...

- Page 22 CONSTRUCTION MODE: The "construction" mode deactivates temporarily certain detections to facilitate the elevator car construction in "inspection" mode. As soon as the elevator controller is placed in "automatic" mode and that a call has been placed, the "construction" mode will be deactivated automatically and all signals will be in function.

- Page 23 The relays: • INS must not be activated. • CDC,HDC and RED must be activated. • RPA must be activated (if required). • RPR must be in phase (is Across the line or Y-Delta start). The alarms: • Hold for 2.5 seconds the « MANUAL RESET » button on the controller inspection board to reset the controller and clear the alarms.

-

Page 24: Final Start-Up

4. FINAL START-UP: Be sure that all sections of the temporary start-up are done. Proceed to the installation and the mechanical adjustment of the slowdown limits (Standard Tape Selector: section 6.1.2). Proceed to the adjustment of the Selector Tape (Standard Tape Selector: section 6.1) Adjust the hoistway access travelling limits (Standard Tape Selector: section 6.1.3). -

Page 25: Controller Type

5. CONTROLLER TYPE: Section not applicable... -

Page 26: Operation Principle For Car Zoning And Levelling

6. OPERATION PRINCIPLE FOR CAR ZONING AND LEVELLING: 6.1. WITH A STANDARD TAPE SELECTOR: (IP8300 W6 LULA): 6.1.1. Installation of the standard tape The setup of a tape selector replaces the PM switches and the vanes in the hoistway and also the cam and the reed switches on the car. - Page 27 It is strongly recommended not to stick the magnets immediately to the steel tape. If a mistake should happen in the positioning, it would still be easy to move the magnets on the tape. Wait until you have made successful tests before sticking definitely the magnets to the tape. •...

- Page 28 Standard tape selector installation:...

-

Page 29: End Of Travel Limit Switches Installation

6.1.2. End of travel limit switches installation: The same corresponding limit switches are found at the bottom floor: LNB. The down normal limit switch must be activated as soon as the car goes 1-2 inches lower than the bottom floor. Make sure that normal stops at top and bottom floors are engaged by the magnets, not by the limit switches (LNH-LNB). - Page 30 • The travel may be limited with a mechanical limit switch as shown in the figure below or by installing a 7-inch north magnet to activate the "P1" detector of the selector tape. • Repeat is you have a bottom hoistway access. Car at the upper landing.

-

Page 31: With Astandard Tape Selector (Jrt-Tape2-Hyd)

6.2. WITH A STANDARD TAPE SELECTOR (JRT-TAPE2-HYD): 6.2.1. Installation of the standard tape The setup of a tape selector replaces the PM switches and the vanes in the hoistway and also the cam and the reed switches on the car. The steel tape is installed in the hoistway and is composed of two rows of magnets. -

Page 32: Tape Reader Installation

FIG. 2 Note: Leave enough space between the bracket and the car's bottom to avoid damaging it in the event that the cabin would reach the buffer. Once the tape is attached, lower the bracket down by tightening the screws. Continue until the tape's tension is adequate. - Page 33 Plastic guideshoe FIG. 5 Complete installation of the selector tape and magnetic reader (see Fig. 6). FIG. 6...

-

Page 34: Magnet Installation

6.2.4. Magnet installation: : Sensors NOTE: We recommend not sticking the magnets immediately. If there is an error in the positioning, it will be easier to move the magnets on the tape. However, do not forget to stick when everything is adjusted properly and the elevator works. •... -

Page 35: Barcode Magnets Installation

• The magnet DZO North 7 ½ should be placed 1 ½ inches below the drawn line. The barcode will be glued later when the floor stops are properly adjusted. • Place the template's window on the line (see Fig. 8, 9 and 10). NOTE: For the bottom landing, the cab cannot be lowered by 24 inches. - Page 36 Magnets required for the binary code Binary Length code Nbr. (inches) Floors 2 ¼ 2 ¼ 2 ¼ 2 ¼ 2 ¼ 2 ¼ 2 ¼ • At the lower level, the code 1 "P1" is not required if the "LRB" limit is installed. •...

-

Page 37: Electric Installation Of The Selector Tape

Example: Car calls for elevator "B" of a duplex begin at 3Z. The barcode must begin at level 3 thus P1 and P2 activated. 6.2.6. Electric installation of the selector tape The selector tape's electric junction box possesses a connector permitting the entry of electric wires (see photo 1). -

Page 38: Dzo/Dzo1 Signals Configuration

6.2.8. DZO/DZO1 signals configuration The circuit, situated in the top of car junction box, offers 4 options for DZO and DZO1 signals (see Fig. 12). Option #1: Allows separating the DZO and DZO1 signals in two distinct negative signals (COM). Option #2: Allows separating the DZO and DZO1 signals in two distinct positive signals (+). -

Page 39: End Of Travel Limit Switches Installation

All the other signals possess a bidirectional output operable either at positive (+) or negative (COM). The output chip, model LAA127, is on a plug-in base and can thus be easily replaced if faulty. NOTE: All the signals are visible using DEL placed in the magnetic head and in the electrical junction box. - Page 40 If the speed is 150’/min (0.75m/s.) or less, hoistway access switches shall be provided at the top landing when the distance from the top of the car to the landing still exceeds 900mm (35 in.) when the car platform is levelled with the second landing from the top.

-

Page 41: With A Standard Tape Selector: (Ip8300 Bin3 W9)

6.3. WITH A STANDARD TAPE SELECTOR: (IP8300 BIN3 W9): 6.3.1. Installation of the standard tape The setup of a tape selector replaces the PM switches and the vanes in the hoistway and also the cam and the reed switches on the car. The steel tape is installed in the hoistway and is composed of three rows of magnets;... - Page 42 • Leveling magnets (7" north magnet): Bring the car even with the floor. Place the magnet centered on the steel tape so that the DZO/DZO1 sensors are energized but the LU and LD sensors are not. The use of two DZO sensors gives the redundancy for the door zone. •...

- Page 43 Procedure: • Position the elevator even with the floor. • Position the row’s guide as shown in figure 1. • Lower the car and place the provided magnet guide as shown in figure 2. • Position the JRT template under the magnet as shown in figure 3. •...

- Page 44 6-19...

-

Page 45: End Of Travel Limit Switches Installation

6.3.2. End of travel limit switches installation: The same corresponding limit switches are found at the bottom floor: LNB. The down normal limit switch must be activated as soon as the car goes 1-2 inches lower than the bottom floor. Make sure that normal stops at top and bottom floors are engaged by the magnets, not by the limit switches (LNH-LNB). - Page 46 • The travel may be limited with a mechanical limit switch as shown in the figure below or by installing a 7-inch north magnet to activate the "P1" detector of the selector tape. • Repeat is you have a bottom hoistway access. Car at the upper landing.

-

Page 47: Terminal Speed Reducing Device For Elevator Greater Than 50'/Min

7. TERMINAL SPEED REDUCING DEVICE FOR ELEVATOR GREATER THAN 50’/MIN: Section not applicable 7-22... -

Page 48: Internal Functions And Controller Configuration

8. INTERNAL FUNCTIONS AND CONTROLLER CONFIGURATION: Many functions and timers may be configured and adjusted in the elevator controller. 8.1. MODIFYING THE DM WITH THE LCD: With the LCD screen, follow these instructions: • Press "ESC" to return to the main menus. •... -

Page 49: Motor Protections

8.2.1. Motor Protections: OPTION DESCRIPTION UNIT DEACTIVATE Deactivation of motor temperature protection YES/NO 0183 THERMAL CONTACT "THM" input. Maximum time permitted to get to another floor. LONG TRAVEL That time needs to be long enough to move from 0.1s 0008 PROTECTION DELAY bottom to top floor plus a safety margin. -

Page 50: Encoder/Perforated Tape

8.2.5. Encoder/Perforated tape: OPTION DESCRIPTION UNIT Number of holes counted to slow down the elevator. In general, this is the slow down distance for 1 floor run. If the car contract DECEL DISTANCE speed is 200 FPM and less, this is the only ¾... -

Page 51: Parking Level & Timers

not operational during that timing. That feature is most of the time used in hospital or building with people with reduced mobility. RESET HALL DOOR As soon the photocell is cut or released, the door YES/NO 0027 TIMER ON PH opened timer on hall call is reset. -

Page 52: Gong/Buzzer Pi & Voice

8.2.9. Gong/Buzzer PI & voice: OPTION DESCRIPTION UNIT Fire buzzer turn off delay. If the fire buzzer FIRE RETURN needs to be eared during all the main floor 0.1s 0151 BUZ.TURN OFF DELAY return, write 9999 in that register. CAR CALL Activation of the car call acceptance Buzzer YES/NO 0086... -

Page 53: Emergency Recall (Fire)

8.2.10. Emergency recall (Fire): OPTION DESCRIPTION UNIT DESIGNATED LEVEL Enter the designated floor recall level. 0098 RECALL FLOOR ALTERNATE LEVEL Enter the alternate floor recall level. 0099 RECALL FLOOR DESIGNATED LEVEL Specify if the designated level has to open the YES/NO 0148 REAR DOOR ? -

Page 54: Hydraulic Cylinder Reset Sequence

8.2.12. Hydraulic cylinder reset sequence: OPTION DESCRIPTION UNIT TELES. CYLINDERS Activation of the cylinders reset sequence. YES/NO 0375 RESET SEQUENCE Reset sequence days selection. DAY (0 = SUN, 7 = (0= Sunday, 1= Monday, 2= Tuesday, 3= 0 to 7 0376 EVERY DAYS) Wednesday, 4= Thursday, 5= Friday, 6=... -

Page 55: How To Change Displayed Values For Each Floors On A Microcomm Or Canbus Pi

8.2.15. How to change displayed values for each floors on a microcomm or Canbus PI. If you use a Microcomm or Canbus PI, you can easily change the displayed name for each floor. To do so you will have to change the appropriate DM through the LCD screen of the controller. DMs 0452 to 0481 are used to define which characters are displayed. - Page 56 To modify a value, you need to use a hexadecimal code related to an ASCII code. Use the table below to know what value to use: HEXA Digit HEXA Digit HEXA Digit SPACE " & < > For example, to display ’’SS’’ at the bottom floor and ’’RC’’ at the second floor, you should enter 5353 into DM0452 and 5243 into DM0454.

-

Page 57: Symbols Listing

9. SYMBOLS LISTING: Car stop switch signal HDC: Landing door relay HDL: Landing door locked CDC: Car door relay LNB: Down normal limit switch LNH: Up normal limit switch LRH: Up slowdown limit switch LRB: Down slowdown limit switch DZO/DZO1: Door zone Up levelling Down levelling... - Page 58 GEN2: Pre Emergency power signal UG1,UG2: Emergency power selector AIF/CIF: Position indicator supply FS (output): Low speed nudging relay INC: Phase 1 activated BUZ: Phase 1, nudging, car call acceptance buzzer FS (input): Main floor recall on fire alarm ALT: Alternative floor recall on fire alarm FMR: Fire machine room alarm...

-

Page 59: Maintenance

10. MAINTENANCE: 10.1. ALARMS AND FAULTS: 10.1.1. Alarms and status list: The CPU memorizes several alarms and status which can be seen using the LCD screen. All status and alarms are memorized in retentive registers "HR" and will be retained on a power loss. To reset all the alarms (2 different ways): ➢... - Page 60 10-2...

-

Page 61: Alarms Description

10.2. ALARMS DESCRIPTION: Alarms #: Description: Causes et verifications HR7600 Custom, refer to user manual list. HR7601 RHDC relay did not activate. Verify RHDC relay operation, because it did not activate when the PLC RHDC input activated. HR7602 RHDC relay has remained closed. Verify RHDC relay operation, because it remained closed when the PLC RHDC input deactivated. - Page 62 Alarms #: Description: Causes et verifications HR7711 Custom, refer to user manual list. HR7712 Custom, refer to user manual list. HR7713 Custom, refer to user manual list. HR7714 Custom, refer to user manual list. HR7715 Custom, refer to user manual list. HR7800 Custom, refer to user manual list.

- Page 63 Alarms #: Description: Causes et verifications HR7911 Custom, refer to user manual list. HR7912 Custom, refer to user manual list. HR7913 Custom, refer to user manual list. HR7914 Custom, refer to user manual list. HR7915 Custom, refer to user manual list. HR8000 Low oil level detected.

- Page 64 Alarms #: Description: Causes et verifications HR8013 DCL did not close when front door opened. Verify DCL switch operation. The switch did not close when the front door opened, with DOL switch opened, CDC and HDC switches closed. The DCL switch opened more than a half second while the front door was completely opened.

- Page 65 Alarms #: Description: Causes et verifications HR8105 CDC car doors contact did not close when doors closed Verify CDC car doors contact. The contact did not close when door was fully closed, after 20 seconds, DCL and RDCL opened CL and RCL relays activated. Verify DCL and RDCL switches operations.

- Page 66 Alarms #: Description: Causes et verifications indicators operation on the processor (they should be flashing when the elevator is moving). Clean both infrared transmitters and the hoistway mirror. HR8201 Servo valve failure (EMV from Maxton, LRV from Bucher … After 3 attempts to reset the servo valve (in 2 minutes), refer to drawings) the elevator is shut down.

- Page 67 Alarms #: Description: Causes et verifications door zone. can occur when mechanics open the hall doors with a lunar key while the elevator is moving. HR8211 Custom, refer to user manual list. HR8212 Custom, refer to user manual list. HR8213 Excessive re-levelling attempts at the same floor.

- Page 68 Alarms #: Description: Causes et verifications HR8405 Custom, refer to user manual list. HR8406 Custom, refer to user manual list. HR8407 Custom, refer to user manual list. HR8408 Custom, refer to user manual list. HR8409 Custom, refer to user manual list. HR8410 Custom, refer to user manual list.

- Page 69 Alarms #: Description: Causes et verifications HR8514 BAC relay has remained closed. Verify BAC relay operation, because it remained closed when the CPU BAC input deactivated. Verify electrical wiring of the in-car stop switch (refer to drawings). HR8515 Custom, refer to user manual list. HR8600 FCSB relay has remained closed.

- Page 70 Alarms #: Description: Causes et verifications HR8614 UC contactor did not activate. Verify UC contactor operation, because it did not activate when the CPU UCA output activated HR8615 UC contactor has remained closed. Verify UC contactor operation, because it remained closed when the CPU UCA output deactivated HR8700 RCT relay did not activate.

- Page 71 Alarms #: Description: Causes et verifications (See CANBUS manual) HR8801 Communication loss with the JRT-CAN-HCI Verify connections, supply and switches configuration. (See CANBUS manual) HR8802 Communication loss with the Car B duplex Verify connections, supply and switches configuration. (See CANBUS manual) HR8803 Communication loss with the module 0 JRT-CAN-24IO Verify connections, supply and switches configuration.

- Page 72 Alarms #: Description: Causes et verifications supplied. Check the door opening. 10-14...

Need help?

Do you have a question about the 2000 Series and is the answer not in the manual?

Questions and answers