Summary of Contents for BAC FXV-1212C-32Q-M/Q

- Page 1 Model FXV-1212C-32Q-M/Q FXV and FXV3 Closed Circuit Cooling Tower CXVB and CXVT Evaporative Condenser OPERATION & MAINTENANCE MANUAL...

- Page 2 Check fan for uniform pitch Check fan for rotation without obstruction Check and recoat steel shafts with RUST VETO ® Check basin heater and stand alone BAC heater control panel Test vibration cutout switch NOTES: DANGER: Rotating equipment will cause severe personal injury or death to persons who come 1.

-

Page 3: Table Of Contents

Coil Freeze Protection Start-Up Procedure Extended Shutdown PART 6 Operation Considerations for Accessories Prolonged Outdoor Storage Basin Heater Stand Alone BAC Heater Control Panels PART 2 Detailed Component Maintenance Procedures Vibration Cutout Switch (VCOS) Cold Water Basin PART 7 Fan Control... -

Page 4: Safety Precautions

“critical speed” which could result in fan failure and possible personal injury or damage. Contact your local BAC Representative regarding any such applications. • WARNING: The recirculating water system may contain chemicals or biological contaminants, including Legionella, which could be harmful if inhaled or ingested. -

Page 5: Equipment Precautions

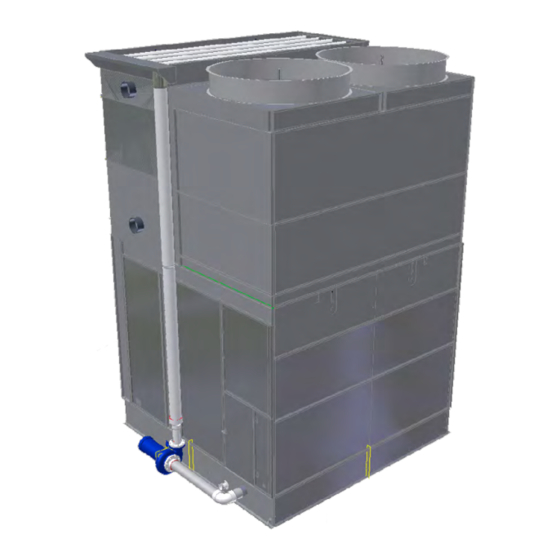

• The basin heater is not designed to prevent icing during unit operation. • BAC units are typically installed immediately after shipment and many operate year round. However, if the unit is to be stored for a prolonged period of time either before or after installation, certain precautions should be observed, as outlined in “Unit Operation and Storage”... - Page 6 FXV, FXV3, CXVB, AND CXVT UNITS Unit Operation and Storage SunScreens Spray Water (Option Not Shown) Distribution System Axial Fan(s) BALTIDRIVE ® Coil Connection: Power Train FXV Fluid Out/ CXV Refrigerant In Coil Connection: FXV Fluid In/ CXVB Refrigerant Out Fan Guard Cold Water Recirculating...

-

Page 7: Start-Up Procedure

Unit Operation and Start-Up Procedure Storage Start-Up Procedure Considerations for Initial Considerations for Initial Start-Up Start-Up General • For units with independent fan control, see Page 41. Cleaning • For units with VFDs, see Page 15. Inspection • For units with vibration cutout switches, see Page 40. Start-Up General •... - Page 8 • On installations where the unit pump was not furnished by BAC, a globe valve should be installed in the pump discharge line and the pump flow rate adjusted to the correct NOTICE: Check to ensure the water flow and pressure (2 psig at spray header connection).

-

Page 9: Extended Shutdown

• For storage prior to installation, coils should be charged with nitrogen at 15 psi in the factory. Units are available charged with nitrogen from BAC for a nominal fee. • Installed units that have been piped but not filled do not require additional precautions. - Page 10 • Apply a weather-resistant lubricant or heavy grease such as Anti-Seize (BAC part # 160069) to all exposed threaded or flanged connections and the adjustable motor base threaded rod.

- Page 11 • For units stored prior to installation, conduct rigging procedures as directed in the unit’s Rigging and Assembly Instructions, available on www.BaltimoreAircoil.com or by contacting your local BAC Representative. • Perform an insulation test of motor windings to ensure satisfactory insulation resistance.

-

Page 12: Detailed Component Maintenance Procedures

FXV, FXV3, CXVB, AND CXVT UNITS Detailed Component Maintenance Procedures Cold Water Basin The fluid (refrigerant) to be cooled (condensed) is circulated inside the tubes of the unit’s heat exchanger. Heat flows from the process fluid through the coil to the spray water outside which is cascading over the tubes. -

Page 13: Fan

– Check each blade in the area of the shank for any signs of cracking. If cracking is on or near the fans, motors, and found, the fan motor should be locked out immediately. Contact your local BAC Representative for assistance. -

Page 14: Fan Drive System

Fan Drive System BALTIDRIVE Power Train, Independent Fan, BALTIGUARD™ ® and BALTIGUARD™ Plus Fan System The BALTIDRIVE Power Train consists of a solid- ® backed, multi-groove, neoprene/polyester belt rated DANGER: Rotating equipment for cooling tower service, and corrosion resistant will cause severe personal injury sheaves. - Page 15 • Belt tension check: Detailed Component – Place a straight edge along the belt from sheave to sheave as shown in Figure 4a, or Maintenance use a tape measure as shown in Figure 4b, to measure belt deflection. Procedures – Apply a moderate force by hand (approximately 40 lbs/275 kPa) evenly across the width of the belt in the center of the span between the sheaves.

- Page 16 Optional ENDURADRIVE Fan System ® The ENDURADRIVE ® Fan System is an option for select FXV3 Closed Circuit Cooling Towers and CXVT Evaporative Condensers. The ENDURADRIVE ® Fan System includes a direct drive motor and variable frequency drive (VFD) designed specifically for the motor. DANGER FOR ThE OPTIONAL ENDURADRIVE FAN SySTEM ®...

- Page 17 See wiring details in your submittal, and address details can be found in the ENDURADRIVE Fan System ACS880 Start Up Guide. For additional protocols, ® contact your local BAC Sales Representative. WW W.BALTI MOREAIR CO IL .C O M WW W.BALTI MOREAIR CO IL .C O M...

- Page 18 Inspection & Maintenance • Inspect the motor at regular intervals, approximately every 500 hours of operation or every 3 months, whichever occurs first. • The following steps should be performed at each inspection: – Turn off the fan motor, and follow the required lockout/tagout procedure. –...

- Page 19 Wye-Delta (Y-) motors. • BAC ships all gear drives filled with oil. The initial oil level should be at or near the middle of the oil level sight glass.

- Page 20 • Check to ensure that all bolts and external fasteners are tight. 15-second time delay for the fan • BAC recommends daily visual inspections and observation for oil leaks and unusual noises and vibrations. If any of these occur, shutdown the unit until the cause is found to slow down before energizing the and corrected.

- Page 21 • When the ambient temperature exceeds 180°F (82°C) or the gear drive is started at lubricants. Contact your local BAC an ambient temperature less than 20°F (-7°C), a synthetic lubricant is recommended. Representative prior to using any When mineral oils are used in operation at ambient temperature less than 20°F (-7°C)

-

Page 22: Fan Shaft Motors

Detailed Component Model Number Gear Model for Standard Fan Standard Fan Maintenance Proce- dures FXV3-1224-xxx-10, 15 and CXVT-xxx-1224-10, 15 FXV3-1224-xxx-20, 30, 40, 50, 60 and CXVT-xxx-1224-20, 30, 40, 50, 60 Fan Drive System FXV3-1224-xxx-75 and CXVT-xxx-1224-75 Gear Drive System FXV3-1426-xxx-15 and CXVT-xxx-1426-15 Fan Motors FXV3-1426-xxx-20, 25, 30, 40 and CXVT-xxx-1426-20, 25, 30, 40 Inspection &... -

Page 23: Fan Shaft Bearings

Fill & Drift Eliminator Inspection & Maintenance Water Distribution System • Only lubricate the bearings with a manual grease gun or BAC’s optional Automatic Bearing Greaser. Do not use high-pressure grease guns since they may rupture the bearing seals. • Only lubricate the bearings with one of the following compatible water resistant NOTE: List of brand names is for greases which are suitable for ambient temperatures ranging from - 65ºF (-53.9ºC) to... -

Page 24: Heat Transfer Section

heat Transfer Section Inspect the coil surface. Any corrosion, damage, or obstructions must be corrected. Fill & Drift Eliminator The FXV, FXV3, CXVB, and CXVT have PVC fill with integral drift eliminators. Inspection & Maintenance • Inspect and clean the fill with the integral eliminators at least quarterly. •... -

Page 25: Water Level Control

Detailed Component Water Level Control Maintenance Procedures There are two types of water level controls used on BAC cooling units: Water Level Control • Mechanical make-up valve assembly Mechanical Make-up Valve • Optional electric water level control package Assembly Optional Electric Water Level... - Page 26 Optional Electric Water Level Control Package As an option, an electric water level control package is available in lieu of the mechanical make-up assembly. The package consists of a probe-type liquid level control assembly and a slow-closing solenoid valve. Stainless steel electrodes, factory-set at predetermined lengths, extend from an electrode holder into the cold water basin.

-

Page 27: Corrosion Protection

FXV, FXV3, CXVB, AND CXVT UNITS Corrosion Protection BAC products are constructed of corrosion-resistant materials. The fill is made of a polyvinyl chloride (PVC), which is not susceptible to rot, decay, rust or biological attack. Other materials listed below are used in the equipment construction: •... -

Page 28: Corrosion And Scale Control

• Scale Formation – Scale, typically a calcium or magnesium based build-up, not only reduces heat transfer and system efficiency, but also may lead to under deposit corrosion. If scale is not controlled, it may continue building on critical components such as the fill and severely impact thermal performance. -

Page 29: Passivation

• BAC discourages acid dosing as means of scale control except for open circuit cooling Corrosion Protection towers with remote sump applications or towers constructed from stainless steel. This should be done at a point in the system where total mixing and dilution occur before Water Treatment reaching the evaporative cooling equipment. -

Page 30: Long Term Care Of Stainless Steel

BAC’s Manufacturing Process BAC takes precautions to prevent cross-contamination, processing galvanized and stainless steel parts separately. Also, stainless steel brushes are used to clean welds on stainless parts and care is taken to avoid scratching parts during processing. Organic cleaners are used to clean the finished product prior to shipping. -

Page 31: System Cleaning

System Cleaning • If the iron chips are not removed with the Scotch-Brite™ Products, electro-chemical cleaning may be required. BAC uses commercially available equipment for electro- chemical cleaning in the field. Contact your local BAC Representative for more information. System Cleaning... - Page 32 The set point is the water conductivity at the desired cycles of vary seasonally. BAC recommends concentration and should be determined by a competent water treatment expert. the use of a conductivity meter to maximize water conservation.

- Page 33 NOTE: Evaporation is proportional E = Q * R * 0.001 = 800 * 10 * 0.001 = 8 USGPM to the load and will vary seasonally. BAC recommends the use of a conductivity meter to maximize = 250 ppm = 5.55 water conservation.

-

Page 34: Cold Weather Operation

FXV, FXV3, CXVB, AND CXVT UNITS Cold Weather Operation Inspection & Maintenance BAC products can be operated at subfreezing ambient temperatures provided proper operating methods are established and diligently followed. • Carry out frequent visual inspections and routine maintenance services during operation in subfreezing weather. -

Page 35: Basin Water And Internal Piping Freeze Protection

• Electric Water Level Control: An electric water level control will maintain the proper water level regardless of the thermal load or variations in make-up water supply pressure. The two-position, slow closing solenoid valve provided with the BAC electric water level control package also minimizes valve freezing problems (see page 24). -

Page 36: Coil Freeze Protection

Coil Freeze Protection For protection against coil freeze-up, recommended solutions are an industrial grade inhibited ethylene glycol or propylene glycol solution. When the use of glycol is not practical, the system must be designed to meet both minimum flow and minimum temperature requirements. - Page 37 Positive Closure Damper hood and Insulation The amount of auxiliary heat required can be substantially reduced by the use of a positive closure damper hood and insulation on the hood and casing. The heat loss data can be found in Tables 3, 4, 6, and 7. Unit with PCD Unit with PCD hood Model Number...

- Page 38 Unit with PCD Unit with PCD hood Model Number Standard Unit hood & Insulation FXV-0818x-12D 225,500 100,900 83,600 FXV-0818x-16D 269,600 98,700 81,800 FXV-0818x-20D 310,600 96,700 80,100 FXV-0818x-24D 381,100 128,500 102,500 FXV-0818x-28D 416,200 126,100 100,600 FXV-0818x-32D 449,100 123,800 98,800 FXV-0818x-36D 479,800 121,700 97,100 FXV-0818x-24T...

- Page 39 Further protection against coil freeze-up is possible with the installation of an alarm to alert personnel when the temperature of the fluid leaving the coil falls below 50ºF (10°C). Contact your local BAC Representative for guidelines on the installation of an emergency coil drain system.

-

Page 40: Operation Considerations For Accessories

Figure 7. Basin Heater submittal packet provided with the unit and contact your local BAC Representative for support. For installations that use a stand alone BAC heater control panel, see below. NOTICE: The basin heater is not designed to prevent icing during unit operation. - Page 41 (If Required) Immersion Heaters Figure 8. Example Wiring Diagram for Stand Alone BAC Heater Control Panel (Refer to Submittal Drawing for Specific Wiring Diagram) WW W.BALTI MOREAIR CO IL .C O M WW W.BALTI MOREAIR CO IL .C O M...

-

Page 42: Stand Alone Bac Heater Control Panels

Accessories The Mechanical Vibration Cutout Switch and the Optional Electronic Vibration Cutout Switch should be tested and field adjusted at start-up and yearly thereafter. Stand Alone BAC heater Control Mechanical Vibration Cutout Switch (Standard) Panel Set Point Adjustment When Installed: Operation 1. -

Page 43: Fan Control

42. • Please refer to the manufacturer’s variable frequency drive recommended start-up procedure for further information or consult with your local BAC Representative for any VFD applications. For projects with BAC controls, visit www.BaltimoreAircoil.com. WW W.BALTI MOREAIR CO IL .C O M... -

Page 44: Resonant Speed Identification Procedure

Resonant Speed Identification Procedure There are several characteristic frequencies at which vibration levels may resonate with unit structural components. These include fan speed, motor speed, bearing frequency, and blade pass frequency. Within the overall operating speed range of a unit, it is not unusual for one or more of these characteristic frequencies to excite the structural components over relatively small speed ranges and create an increase in vibration levels. - Page 45 • As stated previously, when adjusting the VFD speed, proceed slowly while monitoring Fan Control the vibration levels. If the vibration value approaches 0.35 ips (0-peak), slowly “zero in” on the speed where the value equals 0.35 ips, and record the speed at which this Independent Fan Control occurs as the lower end of the lockout range.

-

Page 46: Installation Instructions For Field Connections

Table 7. Supplies for Installing Field Connections connections. Please order the 1. Use the BAC template provided with the accessory to layout and mark the hole pattern recommended supplies listed in on the exterior of the cold water basin. - Page 47 COOLING TOWERS CLOSED CIRCUIT COOLING TOWERS ICE THERMAL STORAGE EVAPORATIVE CONDENSERS HYBRID PRODUCTS PARTS & SERVICES w w w . B a l t i m o r e A i r c o i l . c o m 7600 Dorsey Run Road, Jessup, MD 20794 ›...

Need help?

Do you have a question about the FXV-1212C-32Q-M/Q and is the answer not in the manual?

Questions and answers