Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Christ MAGNUM C5X00

- Page 1 Commercial vehicle wash unit MAGNUM C5X00 Operation manual 6501288-EN / 04...

- Page 3 Document Original operation manual Language English Ident. No. 6501288-EN Revision Date 2018-01-25 Postal address Otto Christ AG Wash Systems PO Box 12 54 87682 MEMMINGEN GERMANY Factory & office Memminger Str. 51 87734 BENNINGEN GERMANY Telephone +49 8331 857-0 E-mail info@christ-ag.com...

-

Page 5: Table Of Contents

Table of contents Table of contents Introduction ............................8 About this manual ..........................9 ....Definition ............................9 Safety-related information ......................10 ....Usage ............................10 ....Structure of the warnings ......................10 ....Fundamental safety pointers ......................11 ....Safety devices .......................... - Page 6 Table of contents ..8.5.1.6 Set the service code to access the CPU menu ................36 ..8.5.1.7 Display the software version ......................37 ..8.5.1.8 Open the card slot ........................37 ....Wash ............................38 .... 8.6.1 Preparation and positioning ......................38 ....

- Page 7 Table of contents ..9.3.4.2 Network function .......................... 80 ..9.3.4.3 E-mail function..........................81 .... 9.3.5 Program recording ........................82 Disturbance removal ........................84 Maintenance ............................. 87 ..... 11.1 Safety pointers ..........................87 ..... 11.2 Prepare the installation ........................ 87 .....

-

Page 8: Introduction

Chapter 1 Introduction Introduction Liability exclusion Otto Christ AG will not hold damages and operation malfunctions caused by the non- observance of this manual liable. Copyright No part of this documentation may in any form whatsoever be reproduced, nor used, copied or distributed by means of electronic systems without previous written permission by Otto Christ AG. -

Page 9: About This Manual

INFORMATION Denotes application pointers and other useful information. These maintenance points will be performed during a maintenance order by a customer service authorised by Otto Christ AG. Refers to another part of the document or another document. Describes a condition that shall be fulfilled before beginning the activity. -

Page 10: Safety-Related Information

Chapter 3 Safety-related information Safety-related information Usage Directed usage Wash only vehicles which fulfil the following conditions. • The vehicles shall not exceed the maximum wash height and wash width. • Vehicles that are damaged or not painted professionally shall only be washed after the assessment and the agreement of the operator. -

Page 11: Fundamental Safety Pointers

Chapter 3 Safety-related information WARNING Denotes a possibly dangerous situation. Not observing this pointer may be life threatening or lead to serious injuries. CAUTION Denotes a possibly dangerous situation. Not observing this pointer can cause minor inju- ries. ATTENTION Denotes a possibly dangerous situation. Not observing this pointer can cause material damage. - Page 12 Chapter 3 Safety-related information A risk of injury exists due to falling objects. • Wear a helmet. • Wear non-skid safety shoes. A risk of injury exists due to obstacles on the floor. • Consider stumbling and spraining areas. • Provide sufficient lighting. Loud noise can impair the hearing.

-

Page 13: Safety Devices

• The staff judges the effect of the work for the safe operation of the installation. Otto Christ AG recommends every operator to require the confirmation in writing regard- ing the knowledge of this manual from the staff (form in annex). - Page 14 Chapter 3 Safety-related information Improper check and maintenance work leads to the guarantee loss. • Carry out the check and maintenance work properly. • Document the check and maintenance work with the date, name and signature (form in annex). The staff shall follow the information contained in this instruction. If difficulties arise, con- tact the customer service.

-

Page 15: About This Product

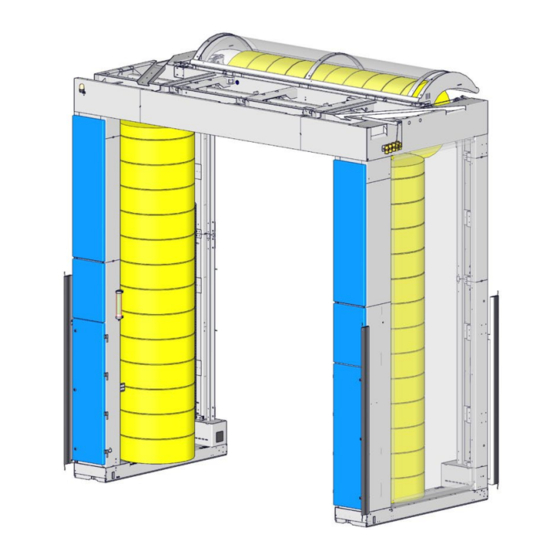

Chapter 4 About this product About this product System overview 4.1.1 General INFORMATION The representation of the unit and its details may differ from the order specific one. 4.1.1.1 Basic version C5000 / C5100 Front view pic. 1 Motion rail Drive unit with tilt safety device Vertical, left, with switchboard plant and panelling Vertical, right, with dosing system and panelling... -

Page 16: Basic Version C5200 / C5300

Chapter 4 About this product 4.1.1.2 Basic version C5200 / C5300 Dimensional repre- sentation pic. 2 Motion rail Drive unit with tilt safety device Vertical, left, with switchboard plant and panelling Vertical, right, with dosing system and panelling Cross member with panelling Lateral brush system 1, left Lateral brush system 1, right Lateral brush system 2, left... - Page 17 Chapter 4 About this product • Backward cycle of the installation – Brush wash with fresh water and drying aid Program Function description Program 0 • The unit goes into basic position. • Light contact pressure of the brushes (configura- tion car) •...

- Page 18 Chapter 4 About this product Program Function description Truck with trailer • Strong contact pressure of the brushes (configu- ration bus / truck) • Cross over wash at the front of the vehicle • Wash height of the horizontal brush at front of the vehicle: 800 mm •...

-

Page 19: Wash Programs For Semi-Stationary Bus Wash (Only C5200 / C5300)

Chapter 4 About this product Program Function description Recreational vehicle • Medium contact pressure of the brushes (config- uration mini bus) • Cross over wash at the front and rear of the vehi- cle (optional without rear wash) • Wash height of the horizontal brush at the front and rear of the vehicle: 800 mm (optional without horizontal wash) Swap body... -

Page 20: Wash Course Of Semi-Stationary Bus Wash

Chapter 4 About this product Program Function description Program 5 Horizontal horizontal wash brush: rear wash Lateral short crossover wash at the front, brushes: avoiding the mirror lateral wash crossover wash at the rear 4.2.2.1 Wash course of semi-stationary bus wash Basic position The access and positioning lights indicate the forward symbol and clear the access into the unit’s action area. -

Page 21: Optional Additional Programs

Chapter 4 About this product Program Function description Windscreen mirror • The horizontal brush avoids the area of the wind- screen mirror. • No front wash in backward cycle 4.2.3.2 Optional additional programs Program Function description Pre-wash Stationary pre-wash equipment, external •... -

Page 22: Technical Data

Chapter 5 Technical data Technical data Requirements on site 5.1.1 Climbing aid In order to carry out the maintenance and repair work, an adequate climbing aid (such as a ladder) complying with the local regulations must be available on site. 5.1.2 Water quality Designation... -

Page 23: Basic Version

Chapter 5 Technical data Basic version Designation Unit Passage height Installation height at standstill • Measurements – Wash height 3200 3340 3885 3300 3440 3985 3400 3540 4085 3500 3640 4185 3600 3740 4285 3700 3840 4385 ... - Page 24 Chapter 5 Technical data Designation Unit Value • Weight, quantity 3400 3700 3400 3700 brushes / passage width – Wash height 3200 1800 1825 2000 2025 3300 1815 1840 2015 2040 3400 1830 1855 2030 2055 3500 1845 1870 2045...

- Page 25 Chapter 5 Technical data Designation Unit Value • Weight, quantity 3400 3700 3400 3700 brushes / passage width – Wash height 3200 2850 2875 3100 3125 3300 2875 2900 3125 3150 3400 2900 2925 3150 3175 3500 2925 2950 3175...

-

Page 26: Operation Terminal

Chapter 5 Technical data Operation terminal Designation Unit Value • Measurements – Width – Height – Depth aluminium • Material 14.5 • Weight • Operation panel – Key quantity piece 39 + 2 – Key-operated switch piece • Electric connection –... -

Page 27: Transport And Storage

Transport and storage The transport of the installation requires special knowledge and if necessary transporta- tion devices. The loading and unloading of the installation is performed by Otto Christ AG or a subcontractor commissioned by Otto Christ AG, who is exclusively responsible. -

Page 28: Installation And Commissioning

Installation and commissioning Installation and commissioning Installation / first The installation / first commissioning of the installation is carried out by Otto Christ AG or commissioning by a commissioned subcontractor, who is exclusively responsible with the assistance of order specific instructions. -

Page 29: Operation

Chapter 8 Operation Operation Safety pointers The automatic wash course may lead to a risk of injury due to moving components of the installation. • Do not commission the installation if someone is in its operation area. • Ensure that people on board are in the passenger compartment during the automatic wash or the passage. -

Page 30: Dosing Pumps

6. If the function "lock the unit" is assigned to the key-operated switch of the operation panel: release the installation with the key-operated switch. The installation is operational. If the installation is operational, then the following will be displayed: CHRIST MAGNUM xx, yy.yy.yyyy zz:zz Select wash program Acknowl yy.yy.yyyy... -

Page 31: Operation Devices

Chapter 8 Operation Operation devices pic. 4 operation panel, operation terminal Emergency-stop button Navigation keys Deactivation key, horizontal brush Deactivation key, lateral brushes Button, drive unit Display Key-operated switch, function according to the order Knowledge key Start button Program keys according to the order Program keys according to the order pic. -

Page 32: Operation Panel

Chapter 8 Operation pic. 6 clamping box, storage tank Key to open the fresh water valve of the storage tank by hand • Keep the key pressed to open the fresh water valve of the storage tank. Operation panel pic. 7 Key assignment The keys on the operation panel are assigned as follows. -

Page 33: Set / Test The Operation Panel

Chapter 8 Operation Softkey: depending on the indication displayed • Scroll in the menu and a menu level. • Confirm the selection. • Activate or deactivate components. Start the selected program. 8.5.1 Set / test the operation panel 8.5.1.1 Access the menu for operation panel Proceed as follows to access the menu. -

Page 34: Adjust The Contrast

Chapter 8 Operation Softkey [Tx/Rx]: the light-emitting diodes next to the key show the con- nection activities with the control of the installation. Softkey [ ]: go the menu Software version. 8.5.1.2 Adjust the contrast INFORMATION Modifications are accepted immediately, even after pressing the [Cancel] softkey to exit the menu. -

Page 35: Test The Bar-Code Scanner

Chapter 8 Operation The card is returned with the [Return] softkey. The serial number of the card is read and displayed in the abc field with the [UID] softkey. No function Exit the operation panel with the [Cancel] softkey. Go back to the previous menu point with the [Return] softkey. Go to the next menu point with the [Resume] softkey. -

Page 36: Set The Operator Code For The Cpu Menu

Chapter 8 Operation 8.5.1.5 Set the operator code for the CPU menu Cancel Key assignment The keys on the operation panel are assigned as follows. xxxx Operator code Softkey [ ]: open the card slot. The red light-emitting diode next to the button shines during the signal's duration. -

Page 37: Display The Software Version

Chapter 8 Operation 8.5.1.7 Display the software version Cancel Key assignment The keys on the operation panel are assigned as follows. Software version of the control of the installation Software version of the printed circuit board of the CPU for the opera- tion panel Exit the operation panel with the [Cancel] softkey. -

Page 38: Wash

Chapter 8 Operation Wash 8.6.1 Preparation and positioning Preparation Before the vehicles accesses the unit’s action area, ensure that • the doors and the windows are closed, • the outside mirrors are turn inwards or removed, • the antennas are retracted or removed, •... - Page 39 Chapter 8 Operation CHRIST MAGNUM xx, yy.yy.yyyy zz:zz Select wash program Acknowl yy.yy.yyyy date zz:zz time Program selection In order to select the wash program on the operation panel • press the program key or • input the program number by means of the [numeric keys] or •...

-

Page 40: Manual Program Start

Chapter 8 Operation • Confirm with the key [E]. CHRIST MAGNUM xx: yyyy zz:*vvvv Acknowl wash program No. yyyy wash program name additional program No. pointer: the indicated additional program is selected vvvv additional program name indicator arrow directed to the selected additional program, which ... -

Page 41: Wash Program Interruption / Cancellation

They automatically start as the vehicle reaches their operation area. INFORMATION In case of automatic start the wash program will start automatically after the positioning of the vehicle. 8.6.3 Wash program interruption / cancellation CHRIST MAGNUM xx: yyyy running sss Acknowl program number... -

Page 42: End Of The Program

Chapter 8 Operation CHRIST MAGNUM xx: yyyy interrupted <Start> continue, <C> cancel Acknowl • Press the [Start] key. – Resume the wash program. • Press the [C] key. – Cancel the wash program. Put the installation into basic position as follows. -

Page 43: Drive Unit

Chapter 8 Operation Provided that no program runs, proceed as follows to select equipment on the operation panel. Access • Press the key [H]. CHRIST MAGNUM Manual <H> Home, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. -

Page 44: Horizontal Brush

• Put the drive unit forward into final position. • Exit the menu progressively. 8.7.2 Horizontal brush • Select the menu Horizontal brush with the key [] or []. CHRIST MAGNUM Horizontal brush <H>, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. -

Page 45: Horizontal Beam / Support For Horizontal Nozzles

Chapter 8 Operation CHRIST MAGNUM Lateral brushes <H>, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. CHRIST MAGNUM Lateral brushes <> Outwards, <> Inwards, <C>, <H> Acknowl Key assignment The keys on the operation panel are assigned as follows. -

Page 46: Dosing Pumps

• Exit the menu progressively. 8.7.5 Dosing pumps • Select the menu Dosing pumps with the key [] or []. CHRIST MAGNUM Dosing pumps <H>, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. -

Page 47: Water Supply, Portal

Chapter 8 Operation 8.7.6 Water supply, portal • Select the menu Water supply, portal with the key [] or []. CHRIST MAGNUM Water supply portal <H>, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. CHRIST MAGNUM <1> Water supply forward cycle | <H>... -

Page 48: Pre-Wash

• Switch off the water supplies • Exit the menu progressively. 8.7.8 Pre-wash • Select the menu Pre-wash with the key [] or []. CHRIST MAGNUM Pre-wash <H>, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. -

Page 49: Active Foam Device

Chapter 8 Operation CHRIST MAGNUM Osmosis water <H>, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. CHRIST MAGNUM <1> Osmosis water ON | <H> <C> Osmosis water OFF Acknowl Key assignment The keys on the operation panel are assigned as follows. -

Page 50: Under-Chassis Wash

• Switch on the water supply, the dosing pump and the air valve • Exit the menu progressively. 8.7.11 Under-chassis wash • Select the menu Under-chassis wash with the key [] or []. CHRIST MAGNUM Under-chassis wash <H>, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. -

Page 51: Doors

Chapter 8 Operation CHRIST MAGNUM <1> Water emptying start | <H> <C> Water emptying stop Acknowl Key assignment The keys on the operation panel are assigned as follows. • Start the water emptying. • Stop the water emptying. • Exit the menu progressively. -

Page 52: Error Memory

The error memory indicates the last 99 inputs of the operation data memory. The counting number indicates the last input. • Select the menu Error memory with the key [] or []. CHRIST MAGNUM Error memory <H> Home, <E> Enter, <>, <>... -

Page 53: Storm Protection

Chapter 8 Operation Storm protection Attention Wind strength Movement of the installation due to the wind strength If the wind speed exceeds 50 km/h ensure that the installation is locked in place with the storm protection. If the wind speed exceeds 50 km/h ensure that the installation is not taken into opera- tion. -

Page 54: Shut Down

Chapter 8 Operation Shut down 8.9.1 General pointers In case of danger of frost empty the water lines. If the installation is shut down, the basic position of the components will not be monitored. Exclude the access in the action area of the installation. 8.9.2 Dosing pumps INFORMATION... -

Page 55: Software

/ they will not be activated. The activation during the wash program is impossible. INFORMATION A configuration makes it possible to stop the outwards / inwards motion during the self- service operation. CHRIST MAGNUM xx: yyyy running sss <> DW, <> SW, <0> FW, <H> man, <C>... -

Page 56: Direction Change

The drive unit stands still during the outwards motion. 9.1.2 Direction change INFORMATION The manual control enables the direction change during the wash program. CHRIST MAGNUM xx: yyyy running sss <> DW, <> SW, <0> FW, <H> man, <C> Acknowl... -

Page 57: Manual Control Of The Horizontal Brush And The Drive Unit

Manual control of the horizontal brush and the drive unit INFORMATION During the wash program there is the possibility to manually control the horizontal brush (having a higher contact pressure) and the drive unit separately. CHRIST MAGNUM xx: yyyy running sss <>... -

Page 58: Wash Program Interruption / Cancellation

Chapter 9 Software 9.1.4 Wash program interruption / cancellation CHRIST MAGNUM xx: yyyy running sss <> DW, <> SW, <0> FW, <H> man, <C> Acknowl program number yyyy program name program section Proceed as follows on the operation panel to interrupt the wash program. -

Page 59: Access

Access Proceed as follows on the operation panel, to access the menu Machine, operation ter- minal or Wash cards and theirs menus. Access • Press the key [H]. CHRIST MAGNUM Manual <H> Home, <E> Enter, <>, <> Acknowl • Select the menu level Menu with the key [] or []. -

Page 60: Menu Machine

Chapter 9 Software • Select the menu level Machine, Operation terminal or Wash cards with the key [] or [] and confirm with the key [E]. Key assignment The keys on the operation panel are assigned as follows. • Increase the value. •... -

Page 61: Menu Counter Contents

> 120 distance too big In order to access the menu Information, proceed as follows on the operation panel, in the menu Machine. • Select the menu level Information with the key [] or []. CHRIST MAGNUM Information <H> Home, <E> Enter, <>, <>... -

Page 62: Door Control

In order to access the menu Counter contents, proceed as follows on the operation panel, in the menu Machine. • Select the menu level Counter contents with the key [] or []. CHRIST MAGNUM Counter contents <H> Home, <E> Enter, <>, <>... -

Page 63: Menu Release Hp Lances Time

Chapter 9 Software CHRIST MAGNUM Door control <H> Home, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. CHRIST MAGNUM Door control <H>, <C> Clear, <> +, <> -, <>, <> Acknowl Key assignment • 9.2.1 Access, page 59. -

Page 64: Menu Information

In order to access the menu Information, proceed as follows on the operation panel, in the menu Operation terminal. • Select the menu level Information with the key [] or []. CHRIST MAGNUM Information <H> Home, <E> Enter, <>, <>... -

Page 65: 9.2.3.2.1 Modify Operator Code

Proceed as follows on the operation panel, in the menu Operation terminal, to access the menu Program selection. • Select the menu level Program selection with the key [] or []. CHRIST MAGNUM Program selection <H> Home, <E> Enter, <>, <>... -

Page 66: Modify Time / Date

Chapter 9 Software • Select the menu level Operator code with the key [] or []. CHRIST MAGNUM Operator code **** <H>, <C> Clear, <> +, <> -, <>, <> Acknowl **** operator code Modify the operator • Input the new operator code by means of the numeric keys and confirm with the key code [E]. - Page 67 Chapter 9 Software INFORMATION The value mentioned between the flashing parenthesis can be reset to 00 with the key [C] or to the desired value with the key [] or []. The weekday is calculated with the date. 6501288-EN / 04...

-

Page 68: Menu Cis-Magnum

2: yes, always In order to access the menu CIS-Magnum, proceed as follows on the operation panel, in the menu Operation terminal. • Select the menu level CIS-Magnum with the key [] or []. CHRIST MAGNUM CIS-Magnum <H> Home, <E> Enter, <>, <>... -

Page 69: Menu Wash Cards

Lock manual movement Lock manual movement Number of UBT Quantity of connected opera- tion terminals • Select the menu UBT with the key [] or []. CHRIST MAGNUM <H> Home, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. CHRIST... - Page 70 Chapter 9 Software CHRIST MAGNUM Read wash cards <H> Home, <E> Enter, <>, <> Acknowl • Confirm with the [E] key. CHRIST MAGNUM Read wash cards Insert card, <H> Home Acknowl • Insert the card into the card reader. INFORMATION Every data belonging to this card is indicated on the display.

-

Page 71: Programme Wash Cards

– single card • 1 to 98 – multiple card • 99 – permanent card Rest remaining washes on the card PNo. program number and selected additional programs CHRIST MAGNUM Val. card: Unit:. xx; CNo:. xx Credit xxx,xx x, Code: xx Acknowl... - Page 72 Chapter 9 Software CHRIST MAGNUM Programme wash cards:0 :Single card, Card number: 0 Acknowl • Activate the menu with the key [1]. • Press the key []. • Input the quantity of washes by means of the [numeric keys] on the card.

-

Page 73: Programme Value Cards

Chapter 9 Software CHRIST MAGNUM xx, yy.yy.yyyy zz:zz Select wash program Acknowl yy.yy.yyyy date zz:zz time Alternating with the indication CHRIST MAGNUM xx, yy.yy.yyyy zz:zz Programme: KKK KNr Acknowl single, multiple or permanent card CNo. card number • Select the desired wash program and if necessary the additional program (8.6.2 Selection and start of the wash and additional programs, page 38. -

Page 74: Pc Visualisation And Evaluation Software

Chapter 9 Software CHRIST MAGNUM Value card: Code: xx Credit: xxx,xx x card number: zz Acknowl Code code of the card required after the insertion of the card Credit credit with currency • Input the values by means of the [numeric keys]. - Page 75 Software Information from the • In order to use the functions of the visualisation, transmit the following information to IT department the customer service of Otto Christ AG. • General – IP address of the control • Function "Send archive"...

-

Page 76: Operation Terminal

Chapter 9 Software 9.3.1 Operation terminal pic. 13 Part of the display on the operation panel Key for knowledge, acknowledge the error removal Key for cancellation, cancel or end the program Start key to start the selected program or drive into basic position Depending on the configuration the key can be hidden. -

Page 77: Wash Counts

Chapter 9 Software 9.3.2 Wash counts pic. 14 Send archive; provided that the status indication in the upper corner left of the key lights up green, the content of the archive on the memory card will be copied in the configured folder of the network. - Page 78 Chapter 9 Software pic. 15 Operation data memory (the last 50 inputs are saved in this ring memory) Window selection (the current window is colour-accentuated) 6501288-EN / 04...

-

Page 79: Configuration Settings

(Christ_net) on the PC. Any existing files with the same name will be overwritten. The content of the Christ folder of the control will be copied in a subfolder (Christ) on the USB drive. Any existing files with the same name will be overwritten. -

Page 80: Network Function

Chapter 9 Software 9.3.4.2 Network function The network function serves to transmit the files recorded in the PLC (CF card) to the PC by means of the network connectivity. Network connectivi- Connect the PLC (connection IF2) and the PC with an Ethernet cable to the same net- work. -

Page 81: E-Mail Function

Chapter 9 Software Settings The following fields in the visualisation under the menu point "Configuration" shall be filled in 9.3.4.1 Configurations, page 79 . IP address IP address of the PC Protocol "cifs" Enable name archive enable name of the folder sharing User name local user name Password... -

Page 82: Program Recording

Chapter 9 Software Status The status of the e-mail function is represented in colour in the upper left corner of the button "Send e-mail". settings incomplete • Red: input complete • Orange: sending e-mail (in process) • White: e-mail successfully sent •... - Page 83 Chapter 9 Software INFORMATION If a USB drive with 100 MB free storage location is connected to the USB interface of the control, the content of the archive folder stored on the memory card will be automatically copied on the USB drive. Any existing files with the same name will be overwritten. 6501288-EN / 04...

-

Page 84: Disturbance Removal

If an error occurs during the program, this one stops in the sequence in which the error occurred. The error is displayed on the operation panel. The light emitting diode next to the softkey [Knowledge] flashes red. CHRIST MAGNUM Fxxx: TTTT | YY <>, <E>... - Page 85 Customer service If it is impossible to remove an error, contact the customer service under the address mentioned in 12.1 Customer service, page 111. The following is displayed after the error removal, knowledge or suppression. CHRIST MAGNUM xx: yyyy interrupted...

- Page 86 Chapter 10 Disturbance removal • Press the [Start] key. – Resume the wash program. • Press the [C] key. – Cancel the wash program. Put the installation into basic position as follows. • Press the button [C]. – The selected program might be deleted. •...

-

Page 87: Maintenance

Chapter 11 Maintenance Maintenance 11.1 Safety pointers Check and maintenance work may only be carried out by instructed personnel. The work may only be carried out with intact tools, devices and test equipment intended for this purpose. 11.2 Prepare the installation Prepare the installation: 1. -

Page 88: Overview

Chapter 11 Maintenance 11.3 Overview Interval Designation Chapter on request Clean the installation, the action area and the motion 11.4.1.1 rails on request Clean the trimming 11.4.1.2 on request Check the detergent level in the containers and refill if 11.4.2 necessary. -

Page 89: Check And Maintenance On Request

Clean the installation, the action area and the motion rails pic. 17 INFORMATION Otto Christ AG assumes no liability for damages due to the • inappropriate detergent or • inappropriate use of the detergent Clean the installation, the action area and the motion rails: 1. -

Page 90: Check The Detergent Level In The Containers And Refill If Necessary

Tools: − Spray bottle − Detergent "Christ CAIMAN - alkaline special detergent" with a dilution of 1:10 1. Spray detergent and let it work without drying. 2. Rinse the wash brush with a lot of water, to eliminate the foam completely. - Page 91 Chapter 11 Maintenance Check the level: 1. Check the detergent level in the containers and refill if necessary. Fill the container: Attention Mixture of detergents Damage of the dosing system Never mix different detergents together. Never mix detergents from different manufacturers together. ...

-

Page 92: Deaerate The Dosing Pumps

Chapter 11 Maintenance 1. Use the personal protective equipment. 2. Fill the pitcher with the storage container containing the same detergent as the one contained in the detergent container. 3. Fill the detergent container with the pitcher. INFORMATION The dosing pump shall be deaerated for an error free operation. Deaerate after each dry run / container replacement. -

Page 93: Carry Out The First Oil Change

Chapter 11 Maintenance ATTENTION Overheating of the dosing pump Leakage / deformation of the pump head Avoid the dry-running. Commission the dosing pump with liquid only. Deaerate the dosing pump: Requirement: The detergent container is full. The installation is operational. 1. -

Page 94: Daily Check And Maintenance

Chapter 11 Maintenance 11.5 Daily check and maintenance 11.5.1 Check the emergency-stop devices pic. 23 Emergency-stop device, operation panel pic. 24 Emergency-stop button pic. 25 Emergency-stop device at the front / rear, left / right Check the safety shutdown: 1. Switch on the main switch. 2. -

Page 95: Check The High-Pressure Pump

Chapter 11 Maintenance 11.5.2 Check the high-pressure pump pic. 26 Oil filling aperture Manometer Safety valve Oil drain screw Check the state: 1. Check the safety valve for a perfect state. 2. Check the manometer. When powered off the pointer goes back to 0. ... -

Page 96: Check The Light Barriers

Chapter 11 Maintenance 11.5.3 Check the light barriers pic. 27 Light barrier, external pic. 28 Light barrier, internal ATTENTION Inappropriate detergents Scratching of the light barriers Do not use scour powder. Clean the light barriers with a humid cloth. Check the light barriers: 1. -

Page 97: Look For Foreign Objects In The Trimming

Chapter 11 Maintenance 11.5.4 Look for foreign objects in the trimming Horizontal brush Lateral brush Look for foreign objects in the trimming: 1. Look for foreign objects in the trimming (plastic particles, dirt, small stones, etc.). 2. Remove the foreign objects. 11.6 Weekly check and maintenance 11.6.1... -

Page 98: Check The Hoses And Lines

Chapter 11 Maintenance 1. Open the ball valve for emptying. 2. Open the exhaust valve. 3. Open the filter cover. 4. Remove the filter element. 5. Clean the filter element. 6. Clean the filter box. 7. Replace the cleaned filter element in the casing. 8. -

Page 99: Check The Tilt Safety Device For Lose Screwing And Damage

Chapter 11 Maintenance pic. 32 Nozzles, under-chassis wash device with station nozzle cane Check the spray quality of the nozzles: 1. Check the spray quality during the wash. 2. If the water distribution is insufficient, clean or replace the nozzles. 11.7.2 Check the tilt safety device for lose screwing and damage. -

Page 100: Check And Grease The Wire Ropes

Chapter 11 Maintenance 11.7.3 Check and grease the wire ropes pic. 34 Wire rope Check the wire rope: 1. Check the wire ropes for mechanical damage and corrosion. 2. In case of mechanical damage and corrosion contact the customer service. Grease the wire rope: 1. -

Page 101: Grease The Driving Device Of The Brushes

Chapter 11 Maintenance pic. 36 Guide pulley Check the guide pulley: 1. Check the guide pulleys for damage and wearout. In case of damage or wearout con- tact the customer service. 11.8.2 Grease the driving device of the brushes pic. 37 Brush system left / right pic. -

Page 102: Clean And Check The Storage Tank

Chapter 11 Maintenance Grease the driving device: Requirement: Turn off the main switch and avoid its reconnection. Use the personal protective equipment (fall protection, helmet, non-skid safety shoes, gloves). Tools: − Proper means of climbing − Aviacal 2 LD or any similar product from another manufacturer −... - Page 103 Chapter 11 Maintenance pic. 40 Overflow Float switch Check the ease of movement of the float switch: Requirement: Turn off the main switch and avoid its reconnection. 1. Remove the cover. 2. Check the ease of movement of the float switch for the overflow protection. In the case of bad mobility contact the customer service.

-

Page 104: Half-Yearly Check And Maintenance

Chapter 11 Maintenance 11.9 Half-yearly check and maintenance 11.9.1 Check the trimming for wearout. Horizontal brush Lateral brush Check the trimming for wearout: 1. Check the trimming for wearout. In case of wearout, contact the customer service. 11.9.2 Carry out the oil change pic. -

Page 105: Have The Antisiphon Device Checked

Chapter 11 Maintenance 11.9.3 Have the antisiphon device checked pic. 42 antisiphon device Have the antisiphon device checked: 1. Have the antisiphon device checked according to DIN EN 806-5 by an installation company and with a testing device. 11.9.4 Check the drive unit pic. -

Page 106: Grease The Counter-Bearing Of The Horizontal Brush

Chapter 11 Maintenance 11.9.5 Grease the counter-bearing of the horizontal brush pic. 44 Greasing nipple, abutment, horizontal brush Grease the bearing: Tools: − Use a cartridge to apply Aviacal 2 LD or any similar product from another manufactur- − Grease gun 1. -

Page 107: Grease The Knuckle Eyes

Chapter 11 Maintenance pic. 46 Greasing nipple, counter-bearing Greasing nipple, bearing, rotating union Grease the bearing: Tools: − Use a cartridge to apply Aviacal 2 LD or any similar product from another manufactur- − Grease gun 1. Insert 2 strokes grease in each greasing nipple by means of the grease gun. 11.9.7 Grease the knuckle eyes pic. - Page 108 Chapter 11 Maintenance pic. 48 Knuckle eyes without lubricating nipples Knuckle eyes with lubricating nipples Grease the knuckle eyes: Tools: − Grease spray − Use a cartridge to apply Aviacal 2 LD or any similar product from another manufactur- − Grease gun 1.

-

Page 109: Yearly Check And Maintenance

Chapter 11 Maintenance 11.10 Yearly check and maintenance 11.10.1 Have the antisiphon device maintained pic. 49 antisiphon device Have the antisiphon device maintained: 1. Have the antisiphon device maintained according to DIN EN 806-5 by an installation company and with a testing device. 11.10.2 Check the cables and cable connections. -

Page 110: Every 2 Years

Have the electric installations and equipment checked INFORMATION The safe state of the electric installations and the equipment shall be checked at regular intervals. Otto Christ AG has defined a check interval of 2 years. Execution Check the electric installations and the equipment •... -

Page 111: Repair

The repair of the installation requires special knowledge and if necessary special tools. Repairs on the installation shall only be performed by the customer service. 12.1 Customer service Otto Christ AG Customer service headquarter Memminger Straße 51 87734 BENNINGEN GERMANY... -

Page 112: Disassembly And Disposal

Chapter 13 Disassembly and disposal Disassembly and disposal The disassembly of the installation requires special knowledge. The disassembly and the disposal shall be performed by the customer service or a local entrepreneur with relevant experience. Observe the applicable laws, regulations, directives and if available factory regulations effective on the operation site. -

Page 113: Annexes

Chapter 14 Annexes Annexes 14.1 Overview • Table of errors • Form – Confirmation of knowledge of the manual – Confirmation of the check and maintenance work • Index • Declaration of conformity • Circuit diagram – Separate 6501288-EN / 04... -

Page 114: Table Of Errors

Chapter 14 Annexes 14.2 Table of errors Error Cause Switching Input Refer element ence value F002: Inclination SW left Lateral brush 1 left goes too far K0.E42.1 outwards F003: Storage tank osmosis Storage tank osmosis empty or B13, B14 -K1.E5.11 overflow F004: Osmosis unit Error in the osmosis unit... - Page 115 Chapter 14 Annexes Error Cause Switching Input Refer element ence value F056: Water shortage brush wash Water pressure for brush wash K0.E42.9 insufficient F057: Water shortage brush/pre- Water pressure for brush wash / B159 K1.E2.9 wash pre-wash insufficient F058: Water shortage high- Water pressure for high- B161 K1.E2.11...

- Page 116 Chapter 14 Annexes Error Cause Switching Input Refer element ence value F100: LS length detection not free Light barriers for length detec- K0.E42.11 tion not free, defective or dirty F101: LS rear wash not free Light barriers for rear wash not K0.E44.12 free, defective or dirty F102: LS signal light stop not free...

-

Page 117: Confirmation, Knowledge Of The Manual

Chapter 14 Annexes 14.3 Confirmation, knowledge of the manual I hereby confirm to have read and understood the manual of the MAGNUM C5X00. Location, date Surname, first name Signature 6501288-EN / 04... -

Page 119: Confirmation, Check And Maintenance Work

Chapter 14 Annexes 14.4 Confirmation, check and maintenance work I hereby confirm to have executed the check and maintenance work today on the MAGNUM C5X00, according the chapter 11 Maintenance . Check and Location, date Surname, first Signature maintenance name... - Page 121 Index Index Disposal Disturbance removal Door control Additional program 20, 38, 73 High-pressure lateral wash High-pressure underbody wash High-pressure wash Electric installations Loading ramp protection Emergency-stop devices Pre-wash End of the program Underbody wash Equality Windscreen mirror Address Delivery address First commissioning Postal address Function description...

- Page 122 Index Horizontal beam / support for horizontal nozzles Repair Horizontal brush Requirements on site Lateral brushes Residual risk Osmosis rinsing equipment Rope rupture Water supply, portal Menu Access CIS-Magnum Safety devices Counter contents External Information 60, 64 Internal Machine Safety pointers Operation terminal Self-service operation Program selection...

- Page 123 EU - Konformitätserklärung EC – Declaration of conformity Hersteller: Otto Christ AG Wash Systems Manufacturer: Anschrift: Postfach 12 54 Address: 87682 MEMMINGEN DEUTSCHLAND / GERMANY Werk & Büro: Memmingerstraße 51 Factory & office: 87734 BENNINGEN DEUTSCHLAND / GERMANY Produktbezeichnung: Nutzfahrzeug-Waschanlage...

Need help?

Do you have a question about the MAGNUM C5X00 and is the answer not in the manual?

Questions and answers