Table of Contents

Summary of Contents for Doosan 9/274

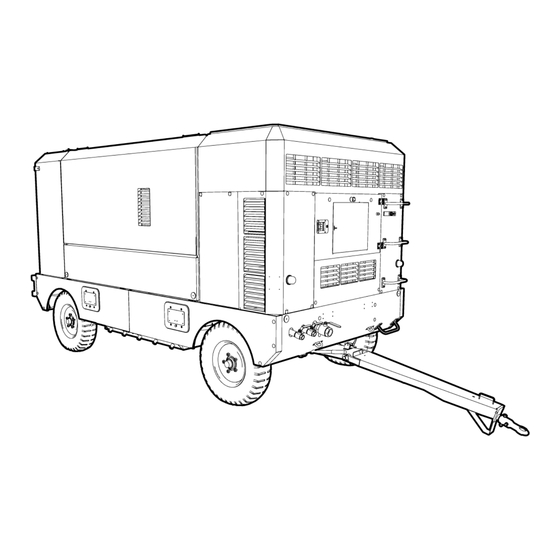

- Page 1 AUTOSTART SYSTEM OPERATION MANUAL 9/274, 9/304, 12/254, 17/244, 21/224 HP915, XP1000, XHP750 This manual contains important safety information and must be made available to personnel who operate and maintain this machine. 46696687_en_A_11/16...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Operation & Maintenance Manual TITLE PAGE FOREWORD ............. . 5 Information . - Page 4 TABLE OF CONTENTS Operation & Maintenance Manual TITLE PAGE...

-

Page 5: Foreword

Foreword... -

Page 6: Information

Operation & Maintenance Manual Foreword Information The contents of this manual are considered to be proprietary and confidential to Doosan Infracore Portable Power (herein referred to as “Portable Power”), and should not be reproduced without the prior written permission of Portable Power. - Page 7 Foreword Operation & Maintenance Manual This compressor should NOT be used: A. For direct or indirect human consumption of the compressed air. B. Outside the ambient temperature range specified in the General Data Section of this manual. C. When an actual or foreseeable risk of hazardous levels of flammable gases or vapors exists.

- Page 8 Operation & Maintenance Manual Foreword...

- Page 9 Safety...

- Page 10 Operation & Maintenance Manual Safety Safety Precautions Never operate the compressor without first observing all safety warnings and carefully reading the Operation and Maintenance Manual shipped from the factory with this compressor. Ensure the operator reads and understands the decals and consults the manuals before operation or performing maintenance.

- Page 11 Safety Operation & Maintenance Manual Compressed Air Compressed air can be dangerous if incorrectly handled. Prior to performing maintenance or service on the compressor, ensure all pressure is vented from the system and the compressor cannot be started accidentally. Ensure the compressor is operating at the rated pressure and the rated pressure is known to all relevant personnel.

- Page 12 Operation & Maintenance Manual Safety Decals Decals are located on the compressor to point out potential safety hazards. Read and follow these instructions. If you do not understand these instructions, inform your supervisor. DANGER (Red Background) Indicates the presence of a hazard which WILL cause serious injury, death, or property damage, if ignored.

- Page 13 Safety Operation & Maintenance Manual DECALS - 9/274, 9/304, 12/254, 17/244, 21/224...

- Page 14 Operation & Maintenance Manual Safety DECALS - HP915, XP1000, XHP750...

-

Page 15: Operating Instructions

Operating Instructions... -

Page 16: Operational Theory

Operating & Maintenance Manual Operating Instructions Operational Theory This AutoStart System is designed to be used with portable air compressors using the View Port and Titan Electronic System. The AutoStart System provides the means of automatic start and stop for a portable air compressor. -

Page 17: Pressure Type Input

Operating Instructions Operating & Maintenance Manual Pressure Type Input The pressure type input uses a sense line from the plant air system to the compressor. This input is on the front of the compressor close to the service air valve. This input connects to a pressure transducer, PT20, on the compressor. - Page 18 Operating & Maintenance Manual Operating Instructions...

-

Page 19: Autostart Setup And Operation Sequence

AutoStart Setup and Operation Sequence... -

Page 20: Autostart System Setup

Operating & Maintenance Manual AutoStart Setup and Operation Sequence AutoStart System Setup 1. Install customer supplied one-way check valve at compressor service outlet. WARNING Do not connect the air discharge on this unit onto a common header with any other unit of any description, or any other source of compressed air, without first making sure a check valve is used between the header and the unit. -

Page 21: Navigation Button

AutoStart Setup and Operation Sequence Operating & Maintenance Manual Navigation Button FIG 1 The Navigation Button is located directly below the Viewport LCD display. The button allows the user to navigate between and within screens, make selections, scroll gauges, manuals, and information. - Page 22 Operating & Maintenance Manual AutoStart Setup and Operation Sequence Setup Screen TILT LEFT to highlight the Set Up Screen and press ENTER. The screen represented by Figure 2 will appear. FIG 2 With AutoStart enabled the icon on the lower right of the ViewPort screen will turn green. The AutoStart panel lamp, mounted on the compressor panel, above the control panel, will glow red.

- Page 23 AutoStart Setup and Operation Sequence Operating & Maintenance Manual FIG 3 AutoStart Signal Control FIG 4 A new screen (AutoStart Signal Control) will open. The new screen displays: • Present State of compressor. • Contact State of compressor supplied AutoStart Initiate Interface. •...

-

Page 24: Automatic Starting

Operating & Maintenance Manual AutoStart Setup and Operation Sequence • Electrical - If customer supplied AutoStart Initiate interface is electrical, navigate to check box and PRESS ENTER. Scroll to select start on open or start on close. • Auto Stop Timeout - Navigate to check box and PRESS ENTER if it is desired to set Autostop time parameter. - Page 25 AutoStart Setup and Operation Sequence Operating & Maintenance Manual FIG 5 5. The Titan Controller will automatically load compressor after a successful start. Normal machine operation can begin depending on air pressure demand. 6. In the event the Titan Controller loses communication with the AutoStart Controller during machine operation, the Titan will issue a Code 73 ALERT (displayed on Viewport Screen).

-

Page 26: Automatic Stop (If Enabled)

Operating & Maintenance Manual AutoStart Setup and Operation Sequence Automatic Stop (if enabled) FIG 6 NOTE: Customer Supplied AutoStart Initiate switch may be Normally OPEN or Normally CLOSED. When AutoStart Initiate Switch is in Selected Contact State: 1. The AutoStart Controller sends a command to the Titan Controller via the J1939 CAN BUS to initiate engine STOP. -

Page 27: Autostart Customer Interface Terminal Block Diagnostics

AutoStart Setup and Operation Sequence Operating & Maintenance Manual AutoStart Customer Interface Terminal Block Diagnostics AutoStart Mode Enabled When the AutoStart is enabled in Viewport setup: • The AutoStart Controller outputs 24 VDC to the AutoStart Enabled Indicator Lamp and to TB1-1. The customer can connect a 24 VDC (2 amp max.load) device across TB1-1 and TB1-2 for remote indication the compressor’s AutoStart system has been enabled. - Page 28 Operating & Maintenance Manual AutoStart Setup and Operation Sequence...

-

Page 29: Wiring Diagrams

Wiring Diagrams... - Page 30 Operation & Maintenance Manual Wiring Diagrams...

-

Page 31: Parts List

Parts List... - Page 32 Operation & Maintenance Manual Parts List Parts List - 9/274, 9/304, 12/254, 17/244, 21/224 Item QTY Part No. Description Notes 46556509 PANEL, BTM INLET 46556629 FOAM 46695379 PANEL, BTM INLET AUTOSTART ASSY. Canopy prepared for Autostart 46695380 PANEL, BTM INLET AUTOSTART...

- Page 33 Parts List Operation & Maintenance Manual Item QTY Part No. Description Notes 46694154 CONDUIT, AUTOSTART Between bottom canopy and air filters area 36793578 FITTING 1/8X1/8 Pressure sensor to canopy 54765946 PRESSURE TRANSDUCER 0-500 Pressure sensor to adapter 35306687 ELBOW, -4 JIC X .125 NPT 90 DEG ZINC To adapter 95257333 CAP, -4 JIC...

- Page 34 Operation & Maintenance Manual Parts List Item QTY Part No. Description Notes 92867449 DECAL REFER TO HANDBOOK Next to Autostart ISO symbol and above Autostart terminal decal 46695378 DECAL, AUTOSTART TERMINAL Next to terminal 46676677 DECAL, AUTOSTART - LARGE On front canopy - left side 46695837 DECAL, AUTOSTART DOOR WARNING...

- Page 35 Parts List Operation & Maintenance Manual Parts List - HP915, XP1000, XHP750 Item QTY Part No. Description Notes 46695382 PANEL, BTM INLET AUTOSTART ASSY. Canopy prepared for Autostart 46671144 CONTROLLER ASSY., AUTOSTART In control panel 96704580 NUT, M5-0.8 HEX NYLON INSERT Titan in control TORQUE LOCK ZINC panel...

- Page 36 Operation & Maintenance Manual Parts List Item QTY Part No. Description Notes 46695483 HARNESS, BATTERY CHARGER Between battery charger and batteries 54749155 DECAL BATTERY CHARGER On batt. charger holder, below charger 22306617 DECAL AUTO START Next to each door 36523421 DECAL, LT AUTO START M Next to AutoStart lamp...

- Page 37 Parts List Operation & Maintenance Manual...

Need help?

Do you have a question about the 9/274 and is the answer not in the manual?

Questions and answers