Table of Contents

Advertisement

Quick Links

This manual provides an overview of the general safety, features, installation, operation, preventative maintenance, and

troubleshooting procedures of an F/T sensor system. For a comprehensive glossary of terms, refer to the following web

page: https://www.ati-ia.com/library/Glossary_of_Robotic_Terminology.aspx. Components of the F/T sensor system are

covered in the following modular manual sections:

A. Introduction

General information to contact an ATI representative, general safety guidelines, and terms and conditions of sale.

The ATI manual part number for this modular manual section is: 9620-05-A-Introduction.

B. Sensor

The sensor mechanical body that converts a detected loads into electrical signals. Sensors are available in several

different payload and communication interface versions. This manual provides an overview, installation, operation,

maintenance, and specifications applicable to a sensor model, regardless of the communication interface version.

The ATI manual part number for this modular manual section is: 9620-05-B-XX (XX signifies the

sensor model name).

C. Communication Interface Version

The software standard that the customer device uses to apply features to the sensor and for the sensor to report data,

for example: EtherCAT, Ethernet, and RS422. This manual provides information on electrical and software features

of a specific communication interface version and applicable cables.

The ATI manual part number for this modular manual section is: 9620-05-C-XX (XX signifies the communication

interface version).

D. Custom Application

Additional information needed for the sensor system to work within a custom application.

The ATI manual part number for this modular manual section is: 9620-05-D-XX (XX signifies the

custom application).

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 •

Force/Torque (F/T) Manual

Introduction

Engineered Products for Robotic Productivity

www.ati-ia.com

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Novanta ATI Axia130

- Page 1 Force/Torque (F/T) Manual Introduction This manual provides an overview of the general safety, features, installation, operation, preventative maintenance, and troubleshooting procedures of an F/T sensor system. For a comprehensive glossary of terms, refer to the following web page: https://www.ati-ia.com/library/Glossary_of_Robotic_Terminology.aspx. Components of the F/T sensor system are covered in the following modular manual sections: A.

- Page 2 Manual, F/T Sensor, Introduction Document #9620-05-A-Introduction-01 A. Introduction Please contact ATI Industrial Automation with any questions concerning a particular model. WARNING: Only use ATI products for applications approved by the manufacturer. Using ATI products in applications other than what was intended by the manufacturer could result in damage to equipment and injury to personnel.

- Page 3 Manual. F/T Sensor, Introduction Document #9620-05-A-Introduction-01 1. Safety The safety section describes general safety guidelines to be followed with this product, explanations of the notifications found in this manual, and safety precautions that apply to the product. Product specific notifications are imbedded within the sections of this manual (where they apply).

- Page 4 Manual, F/T Sensor, Introduction Document #9620-05-A-Introduction-01 2. Terms and Conditions of Sale The following Terms and Conditions are a supplement to and include a portion of ATI’s Standard Terms and Conditions, which are on file at ATI and available upon request. ATI warrants to Purchaser that robotic Tool Changer products purchased hereunder will be free from defects in material and workmanship under normal use for a period of three (3) years from the date of shipment.

- Page 5 Axia130 F/T Sensor Manual Document #: 9620-05-B-Axia130 Engineered Products for Robotic Productivity Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com...

- Page 6 Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 Foreword Information contained in this document is the property of ATI Industrial Automation, Inc. and shall not be reproduced in whole or in part without prior written approval of ATI Industrial Automation, Inc. The information herein is subject to change without notice and should not be construed as a commitment of ATI Industrial Automation, Inc.

-

Page 7: Table Of Contents

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 Table of Contents Glossary ............................B-4 Safety ............................B-6 1.1 Explanation of Notifications ..................... B-6 General Safety Guidelines ......................B-6 Safety Precautions ........................B-7 Product Overview ........................B-8 2.1 Groove Identification for Axia130 Models ................B-9 Installation ...........................B-10 Interface Plates ........................B-10 3.1.1 ATI Interface Plate Kits ....................B-12 Routing the Cable ........................ -

Page 8: Glossary

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 Glossary Definition Term Bias may also be referred to as “zero out” or “tare” the sensor. Biasing is useful for eliminating the effects of gravity (tool weight) or other acting forces, as well as the effects of drift. When the bias function is used, the Bias software collects data for the forces and torques that are currently acting on the sensor and use these readings as a reference for future readings. - Page 9 Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 Definition Term Not Applicable The condition where more load is applied to the transducer than it can Overload measure. This will result in saturation. Part Number The point on the sensor from which all forces and torques are measured. Point of Origin When a user removes and then restores power to a device.

-

Page 10: Safety

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 1. Safety The safety section describes general safety guidelines to be followed with this product, explanations of the notifications found in this manual, and safety precautions that apply to the product. Product specific notifications are imbedded within the sections of this manual (where they apply). -

Page 11: Safety Precautions

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 1.3 Safety Precautions CAUTION: Modifying or disassembly of the sensor could cause damage and void the warranty. CAUTION: Probing openings in the sensor causes damage to the instrumentation. Avoid prying into openings of the sensor. CAUTION: Do not overload the sensor. -

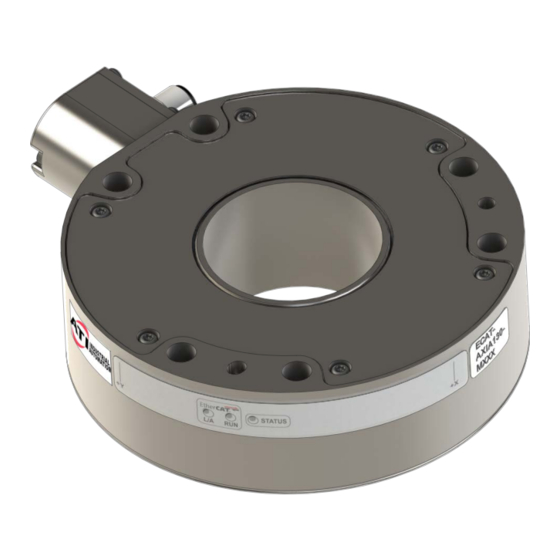

Page 12: Product Overview

For the connector pin assignments on the sensor and cables, sensor cable part numbers, and more information about the LEDs, refer to the applicable ATI communication interface manual in Table 2.1. The ATI Axia130 sensor customer drawing is available here: http://www.ati-ia.com/app_content/ Documents/9630-05-0006.auto.pdf. The Axia130 sensor has the following additional features: •... -

Page 13: Groove Identification For Axia130 Models

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 For more information on the electrical and software features of a specific communication interface version and the applicable cable, refer to the ATI manual in the following table: Table 2.1—Communication/Software ATI Manual Reference Sensor Model Communication ATI Cable P/N Refer to the ATI Manual... -

Page 14: Installation

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 3. Installation WARNING: Performing maintenance or repair on the sensor when circuits (e.g. power, water, and air) are energized could result in death or serious injury. Discharge and verify all energized circuits are de-energized in accordance with the customer’s safety practices and policies. - Page 15 Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 If the customer chooses to design and build an interface plate, consider the following points: • The interface plate should include bolt holes for mounting fasteners as well as dowel pin and a boss for accurate positioning to the robot or customer’s device.

-

Page 16: Ati Interface Plate Kits

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 3.1.1 ATI Interface Plate Kits ATI offers the following ISO 9409-1 compliant interface plate kit options. These options are for mounting the sensor to common robot flange bolt patterns and replicating those common patterns on the sensor’s tool side. -

Page 17: Routing The Cable

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 3.2 Routing the Cable The routing and bending radius of the cable depends upon the customer application. Unlike motionless applications, where the cable is in a static condition, dynamic applications subject the cable to a repetitive motion. - Page 18 Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 Route the sensor cable so that it is not stressed, pulled, kinked, cut, or otherwise damaged throughout the full range of motion. Use a robot dresspack solution, if possible. An example of how to route the cable, if a dresspack is not available, are shown in the following figures and descriptions.

-

Page 19: Cable Kits

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 CAUTION: Do not damage or crush the cable by over tightening the straps on the cable. CAUTION: When routing cables do not bend less than the minimum bending radius specified in Table 3.2. A bend radius too small causes the cable to fail from fatigue of the robot’s repetitive motion. -

Page 20: Adjust The Connector Block Orientation

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 3.3.1 Adjust the Connector Block Orientation WARNING: Do not adjust the connector block orientation if the sensor is not completely dry or is powered on. NOTICE: Position 1 is the default orientation of the connector block. When ATI ships Axia130 sensors to the customer, the connector block is in the default position. -

Page 21: Install The Sensor

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 3.4 Install the Sensor Figure 3.5 ATI sensor drawing Parts required: Refer to and the Tools required: 4 mm, 5 mm, and 6 mm hex key ® Supplies required: Clean cloth, Loctite 1. Clean the mounting surfaces. 2. Use the mounting fasteners to attach the interface plate to the mounting surface. NOTICE: When installing an interface plate: •... - Page 22 Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 Figure 3.5—Installation of the Axia130 Sensor to the Robot robot arm interface plate (robot side) Use this M5X0.8 10 mm threaded hole to attach a P-clip for cable routing. The P-clip is either customer supplied or included in ATI kit mounting hardware to the robot (customer supplied P/N 9105-CKIT-ZC28-ZC28-5.

-

Page 23: Remove The Sensor

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 3.5 Remove the Sensor Tools required: 5 mm and 6 mm hex key 1. Turn off all energized circuits, for example: electrical. 2. Remove the cable from the sensor’s connection. 3. Remove customer tooling from the sensor. Supporting the customer tooling and/or interface plate, use a 5 mm hex key to remove the (12) M6 socket head cap screws. -

Page 24: Accuracy Check Procedure

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 3.6 Accuracy Check Procedure Complete the following procedures after the initial installation of the sensor to the robot and once annually for maintenance. NOTICE: The mass on the tool side can be the weight of the tooling used in the application. 1. -

Page 25: Detecting Sensitivity Changes

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 6. The calculated tooling masses for all (6) points should deviate from each other by less than twice the worst accuracy rating of the sensor. • For example: the Axia130-M125 sensor’s rated accuracy is 2% the range on all axes. For a 2000 N F range and a 4000 N F range, the allowable errors of any single data point would be ±... -

Page 26: Operation

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 4. Operation Information that applies generally to all Axia130 sensors is in the following section. For more information specific to the communication protocol of the sensor, such as sampling rate, LEDs, operation commands, refer to the applicable manual in Table 2.1. -

Page 27: Tool Transformation

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 4.2 Tool Transformation By default, the forces and torques are reported with respect to a point of origin on the sensor that is set by ATI. For the sensor’s point of origin, refer to the ATI sensor drawing. The tool transformation function allows measurement of the forces and torques at a reference point other than the sensor’s point of origin. - Page 28 Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 After the displacements, the user point of origin rotates in the following order: 1. The first rotation is about the X-axis. • Recall in this example R = +90° rotation. The user point of origin rotates +90° about the X-axis, in the following figure.

-

Page 29: Avoid Overloading The Sensor During Tool Transformation

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 4.2.1 Avoid Overloading the Sensor During Tool Transformation It is possible for the user to set a reference point of origin that does not detect that a torque is applied to the customer tooling, and by extension, the sensor. Torque is the force multiplied by the distance of that force from a reference point of origin. -

Page 30: Troubleshooting

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 6. Troubleshooting This section includes solutions to some issues that might arise when setting-up and using the sensor. For questions 2.1. Answers to frequently and troubleshooting assistance with software, refer to the appropriate manual in Table asked questions are available from the ATI website: https://www.ati-ia.com/library/documents/FT_FAQ.pdf. -

Page 31: Basic Guidance For Troubleshooting

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 6.1 Basic Guidance for Troubleshooting Basic symptoms of inaccurate data and errors are listed in the following section. For each symptom, causes and appropriate solutions are suggested. Cause: Noise can be caused by mechanical vibrations and electrical Symptom: Noise —... - Page 32 Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 Cause: Mechanical coupling or internal failure can cause Hysteresis which Symptom: Hysteresis — is outside of the sensor’s specified and acceptable measurement when the sensor uncertainty (error) range. is loaded from a zeroed or biased Solution: Verify the sensor is properly installed, fasteners are state and then the...

- Page 33 Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 Symptom: The F/T values Cause: The sensor may be in a mode that reports gage data instead of F/T data. do not match Gage data is not a 1:1 correlation to F/T axis data. View expected values, Solution: F/T data instead of gage data;...

-

Page 34: Specifications

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 7. Specifications Some requirements and specifications for the Axia130 sensor interface are covered in the following sections. For ATI sensor more information, refer to the drawing. 7.1 Storage and Operating Conditions Table 7.1—Environmental Conditions Parameter Value Storage Temperature, °C -45 to +85... -

Page 35: Default Peak Values

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 7.4 Default Peak Values When powered on, the sensor records the peak values seen on any single axis. The following values are the default values programmed at the factory during calibration. If the sensor shows peak values higher than these defaults, the sensor has been loaded past the intended calibrated sensing range. -

Page 36: Terms And Conditions Of Sale

Manual, F/T Sensor, Axia130 Document #9620-05-B-Axia130-02 8. Terms and Conditions of Sale The following Terms and Conditions are a supplement to and include a portion of ATI’s Standard Terms and Conditions, which are on file at ATI and available upon request. ATI warrants to Purchaser that force torque sensor products purchased hereunder will be free from defects in material and workmanship under normal use for a period of one (1) year from the date of shipment. - Page 37 RS422 Axia Manual Document #: 9620-05-C-RS422 Axia Engineered Products for Robotic Productivity Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com...

-

Page 38: Foreword

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Foreword Information contained in this document is the property of ATI Industrial Automation, Inc. and shall not be reproduced in whole or in part without prior written approval of ATI Industrial Automation, Inc. The information herein is subject to change without notice and should not be construed as a commitment on the part of ATI Industrial Automation, Inc. - Page 39 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Table of Contents Foreword ............................2 Glossary ............................6 Safety ............................8 1.1 Explanation of Notifications ......................8 General Safety Guidelines ......................8 Safety Precautions ........................9 Product Overview ........................10 Installation ..........................11 Installation of the Sensor to the Robot ..................11 Pin and Wire Assignments for Connectors ................

- Page 40 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Bias Command: “bias” ....................... 33 5.4.1 Secondary Bias Commands: “on”, “off”, “[values]” ............33 Peak Command: “peak” ......................33 5.5.1 Peak Command in Counts: “peak C” ................34 5.5.2 Peak Reset Command: “peak reset” ................34 Save All Command: “saveall” ....................34 Set Command: “set”...

- Page 41 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Troubleshoot ........................... 50 LED Errors ........................... 51 Basic Guidance for Troubleshooting ..................52 Reducing Noise ........................... 56 8.3.1 Mechanical Vibration ......................56 8.3.2 Electrical Interference ....................... 56 9. Specifications ......................... 57 9.1 Electrical Specifications ......................

-

Page 42: Glossary

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Glossary Definitions Term Active Configuration The configuration that the system is currently using. Analog-to-digital converter. Biasing is useful for eliminating the effects of gravity (tool weight) or other acting forces. When the bias function is used, the software collects data for the forces and torques that are currently acting on the sensor and use these readings as a reference Bias for future readings. - Page 43 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Definitions Term When an external object such as customer tooling or utilities contacts a sensor’s Mechanical Coupling surface between the sensor’s mounting side and tool side. Not applicable. Non-Volatile Memory. Storage of information or device memory that can be retrieved even after the device goes through a power cycle (turned off and then back on).

-

Page 44: Safety

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 1. Safety The safety section describes general safety guidelines to be followed with this product, explanations of the notifications found in this manual, and safety precautions that apply to the product. Product specific notifications are imbedded within the sections of this manual (where they apply). -

Page 45: Safety Precautions

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 1.3 Safety Precautions CAUTION: Modifying or disassembly of the sensor could cause damage and void the warranty. Use the supplied mounting interface plate and the provided tool side mounting bolt pattern to mount the sensor to the robot and customer tooling to the sensor. -

Page 46: Product Overview

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 2. Product Overview The RS422 Axia Force/Torque (F/T) sensor measures six components of force and torque (F ) and communicates this data to a device (such as a personal computer, robot, or PLC) that is compatible with an RS422 serial communication interface. -

Page 47: Installation

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 3. Installation WARNING: Performing maintenance or repair on the sensor when circuits (for example: power, water, and air) are energized could result in death or serious injury. Discharge and verify all energized circuits are de-energized in accordance with the customer’s safety practices and policies. -

Page 48: Axia F/T Sensor

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 3.2.1 Axia F/T Sensor Signals and corresponding pin numbers for the Axia models are listed in the following sections. 3.2.1.1 Axia80 and Axia90 Pin Assignment for the 8-pin M8 Male Sensor Connector Table 3.2—Axia80 and Axia90 Sensor Connector, M8, 8-pin, Male Connector Schematic Pin Number... -

Page 49: Axia80 And Axia90 Sensor Cable (P/N 9105-C-Zc27-Zc28)

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 3.2.2 Axia80 and Axia90 Sensor Cable (P/N 9105-C-ZC27-ZC28) Table 3.4—ZC27 Connector, M8, 8-pin, Female Connector Schematic Pin Number Signal Clock Sync Ground V - / Ground Tx - Rx + Tx + Clock Sync Rx - Shell... -

Page 50: Axia130 Sensor Cable (P/N 9105-C-Zc28-Zc28)

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 3.2.3 Axia130 Sensor Cable (P/N 9105-C-ZC28-ZC28) Table 3.6—ZC28 Connector, M12, 8-pin, Female Connector Schematic Pin Number Signal Clock Sync Ground V - / Ground Tx - Rx + Tx + Clock Sync Rx - Shell Shield... -

Page 51: Set-Up Of The Rs422 Communication Interface

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 3.3 Set-up of the RS422 Communication Interface The RS422 Axia sensor is a serial device that is used programmatically with the user’s application. When the sensor is attached via cable to the customer’s device such as a personal computer or robot, the computer assigns the sensor a COM port. - Page 52 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5. Set the configuration: Under Connection type: select the radio button for Serial. Figure 3.2—Set the Connection Type to Serial b. In the Serial Line field, enter the assigned COM port from step 3. In the Speed field, enter the default baud rate of 115200 or the baud rate to which the user has set the RS422 Axia sensor.

- Page 53 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 After a terminal window opens, the user can then start entering commands. After a command is entered from Section 5—RS422 Commands Section 6—RS422 Axia Sensor “Robot Mode”, press the (enter) key to send the command. NOTICE: Commands which are entered are not case sensitive.

-

Page 54: Operation

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 4. Operation For general operation information about the sensor, refer to the appropriate sensor manual in Table 2.1. 4.1 Clock Sync Functionality Clock sync functionality activates when the user applies a rising edge of at least 5 V to the conductors (refer Section 3.2—Pin and Wire Assignments for Connectors). -

Page 55: Led Self-Test Sequence

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 4.2 LED Self-Test Sequence The RS422 Axia sensor has three LEDs: Sensor Status, Link/Activity, and Diag. When the user applies power, the sensor completes a self-test, during which the LEDs under firmware control turn-on individually. Table 4.1—LED Self-Test Sequence Sequence State... -

Page 56: Led Normal Operation

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 4.3 LED Normal Operation 4.3.1 Sensor Status LED One LED signals the health status of the sensor as follows: Table 4.2—Sensor Status LED LED Color State Description No power Electricity is not supplied to the sensor. The sensor’s electronics are functioning and Green Normal Operation... -

Page 57: Sample Rate

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 4.4 Sample Rate The power-on default sample rate is the rate the user sets before removing power. The sample rate is stored to nonvolatile memory. The ADC rate controls the current sample rate. The following table lists the rounded and exact sample rates. - Page 58 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Figure 4.3—Filter Attenuation at 0.5 kHz Sample Rate 0.0 dB 200 Hz 60 Hz -6.0 dB 22 Hz 10 Hz -12.0 dB 5 Hz Attenuation 2.5 Hz -18.0 dB 1.3 Hz 0.6 Hz 0.3 Hz -24.0 dB -30.0 dB...

- Page 59 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Figure 4.5—Filter Attenuation at 2 kHz Sample Rate 0.0 dB 500 Hz 235 Hz 90 Hz -6.0 dB 43 Hz 20 Hz -12.0 dB 10 Hz Attenuation 5 Hz 2.4 Hz -18.0 dB 1.4 Hz -24.0 dB -30.0 dB...

- Page 60 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Figure 4.7—Filter Attenuation at 8 kHz Sample Rate 0.0 dB 2000 Hz 958 Hz 935.10 Hz -6.0 dB 373 Hz 364.04 Hz -12.0 dB Attenuation 169.52 Hz 81.24 Hz -18.0 dB 39.84 Hz 20.31 Hz -24.0 dB 9.37 Hz...

-

Page 61: Status Code

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 4.6 Status Code A bitmap from bit number 0 to 31 for the current condition of the sensor is in the following table. The user can retrieve the status code using the RS422 commands (refer to Section 5.3.4—How to Interpret the Output from “!”... -

Page 62: Status Code: Force/Torque Out Of Range Or Sensing Range Exceeded

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 4.6.1 Status Code: Force/Torque Out of Range or Sensing Range Exceeded Bit 30 in is set when an F/T load is outside the sensor’s detection capability. Bit 30 is set Table 4.7 when either of the following conditions are TRUE: • The total percentage of the calibrated range used by F axes is greater than 105%. - Page 63 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 The F equation simplifies as follows: Because the F equation simplified to TRUE, bit 30 in Table 4.7 is set. Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com...

-

Page 64: Rs422 Commands

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5. RS422 Commands These commands can be used to view the status, parameters, and adjust settings of the sensor. For setting up a console, refer to Section 3.3—Set-up of the RS422 Communication Interface. -

Page 65: Reset Sensor Command: "Reset

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.2 Reset Sensor Command: “reset” The “reset” command resets the MCU. “reset” command example format (the response varies per configuration of the system): user: reset response: BL4I0+I1+C= ======================================================================== RESET due to: SoftwareReset I2C EEPROM verified 0.000 N 0.000 N... - Page 66 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Table 5.1—Secondary “S” or “C” Commands Secondary Command Category Notes Specifier Gage values are printed in counts only. Gage number(s) As many as all gage numbers can be reported or as few as a single gage number.

-

Page 67: Examples Of Secondary Commands (Specifiers)

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.3.3 Examples of Secondary Commands (Specifiers) The following are examples of an “S” or “C” command with specifiers: 1. C XTY is interpreted as: user: S XTY response: 0.001 N 0.0009 Nm The C is a command for reporting continuous lines of data. b. -

Page 68: How To Interpret The Output From "!" Specifier

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.3.4 How to Interpret the Output from “!” Specifier The output from “!” specifier reports an output in hexadecimals that must be converted to a 32-bit binary number that correlates to a status code from Table 4.7. Refer to the following table for an example of bit patterns: Table 5.2—Bit Pattern Examples Simple Description... -

Page 69: Bias Command: "Bias

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.4 Bias Command: “bias” The “bias” command reports the current bias status of the sensor. “bias” command format: user: bias response: BIAS OFF In this case, the command reports the status that the bias feature is off. 5.4.1 Secondary Bias Commands: “on”, “off”, “[values]”... -

Page 70: Peak Command In Counts: "Peak C

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.5.1 Peak Command in Counts: “peak C” The “peak c” command reports the highest and lowest of F in counts that occurred for a run-time and for all-time. The peak reset command resets the run-time peaks only. All time peaks are largest values seen while the sensor was powered on and operating. -

Page 71: Set Command: "Set

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.7 Set Command: “set” The “set” command reports all settings. Note that “CAL” is synonymous for “set”, but in this manual, the command is referenced to as “set”. Many settings are read-only fields that are configured onto the sensor during ATI factory calibration. - Page 72 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Table 5.3—“set” Fields User Description Example Field Long Name Read/ (and if applicable, Type Contents Write Secondary Commands Force units, secondary commands: 0 = Lbf forceUnits Force Units 1 = N 2 = Klbf 3 = kN 4 = Kg 8-bit...

- Page 73 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Table 5.3—“set” Fields User Description Example Field Long Name Read/ (and if applicable, Type Contents Write Secondary Commands The RDT transmission Read rate in units of Hz. rdtRate The RDT transmission Write rate must be 1 to the adcRate.

- Page 74 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Table 5.3—“set” Fields User Description Example Field Long Name Read/ (and if applicable, Type Contents Write Secondary Commands UART baud rate. Must be in range from 300 Read baud to 3M baud. baud Any baud rate change 115200...

-

Page 75: Calibration Commands

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.8 Calibration Commands 5.8.1 Calibration Range Command: “ set calib” The user can set the calibration range or index number, where: 0 = calibration range 0. 1 = calibration range 1. The calibration ranges for the sensor are listed in more detail in the specific ATI sensor manual that is listed in Table 2.1. -

Page 76: Example Of Switching Between Calibration Ranges

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.8.3 Example of Switching Between Calibration Ranges To safely switch between calibration ranges, use the following procedure as a guide: 1. Read the name of the current active calibration: >set partNum Field Value ----- -----... -

Page 77: Baud Rate Command: "Set Baud

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.9 Baud Rate Command: “set baud” The user can set the baud rate of the sensor. The baud rate must be a value from 300 to 3000000. “set baud” read and write command format: user: set baud response:... -

Page 78: Simmulated Error Command: "Simerr

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.10 Simmulated Error Command: “simerr” The “simerr” command refers to bit 28 from 4.7. The command can be issued to view status of bit 28 Table or turn bit 28 on or off. The simulated error command is useful for customers, who need to test their error- handling routines. -

Page 79: Status Command: "Status

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 5.12 Status Command: “status” If there could be an underlying problem within the sensor hardware, the “status” command can be used to retrieve detailed information or for the user to send the information to ATI for troubleshooting. “status”... -

Page 80: Rs422 Axia Sensor "Robot Mode

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 6. RS422 Axia Sensor “Robot Mode” “Robot mode” is not required to communicate with all robots, but it presents the data in a useful format for certain robot integrations. When in “robot mode” the RS422 Axia sensor is able to complete these following actions: •... -

Page 81: Print And Stop A Continuous Output Or High Speed Streaming Of Ft Values: "S" And "E" Command

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 6.3 Print and Stop a Continuous Output or High Speed Streaming of FT Values: “S” and “E” command To receive a continuous output or start high speed streaming of FT values in each axis, type the character “s”. -

Page 82: How To Interpret Robot Mode Readings

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 6.5 How to Interpret Robot Mode Readings The following is an example of how to interpret “robot mode” FT readings into decimal values. The “P” counts per force and counts per torque command and “R” single FT reading command have the following outputs: P = 15.2588, 15.2588, 15.2588, 15.2588, 15.2588, 15.2588 R = 1FFFF00000023000000000000... -

Page 83: Set The Adc Sample Rate: "A" Command

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 6.6.2 Set the ADC Sample Rate: “A” command The ADC sample rate that is set for the sensor must match the same sample rate set on the console; refer to Figure 5.1. Type the character “A”... -

Page 84: Pseudocode Example

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 7. Pseudocode Example The following pseudocode provides a general idea of how to communicate with a sensor over a terminal interface from a user’s custom software. 7.1 Assumed Functions For Pseudocode To use the example pseudocode, the user must already have the following functions. These functions are dependent on the user’s specific programming language and environment. -

Page 85: Pseudocode To Read Tool Transform Distance Units

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 7.3 Pseudocode to Read Tool Transform Distance Units The command “C !FXYZTXYZ” instructs the sensor to begin streaming, with each sample include: • the status code (the “!” specifier) • the three force axes(“FXYZ”) • the three torque axes (“TXYZ”) Example record: 00000000... -

Page 86: Troubleshoot

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 8. Troubleshoot This section includes answers to some issues that might arise when using RS422 with the ATI F/T Axia sensor. For more troubleshooting guidance, refer to the appropriate sensor manual in Table 2.1. -

Page 87: Led Errors

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 8.1 LED Errors Symptom: Status LED stays red Solution: Check the sensor cable connections. after the (20) second Verify the sensor cable is not damaged. power up phase. There may be an internal error in the sensor. -

Page 88: Basic Guidance For Troubleshooting

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 8.2 Basic Guidance for Troubleshooting Basic symptoms of inaccurate data and system errors are listed in the following section. For each symptom, causes and appropriate solutions are suggested. Symptom: Noise — jumps in Cause: Noise can be caused by mechanical vibrations and electrical disturbances that are possibly from a poor ground. - Page 89 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Cause: Mechanical coupling or internal failure can cause Hysteresis which Symptom: Hysteresis — is outside of the sensor’s specified and acceptable measurement when the sensor is loaded from a uncertainty (error) range. Verify the sensor is properly installed, fasteners are zeroed or biased Solution:...

- Page 90 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Cause: The sensor has insufficient power supply. Symptom: The sensor is Verify the power supply meets the requirements listed in not responsive. Solution: Section 9—Specifications. Verify the cables are not damaged and are properly routed per the Installation Section in the applicable ATI manual in Table...

- Page 91 Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 Symptom: The sensor Cause: The sensor may have been overloaded beyond its calibration limits. For calibration limits, refer to the applicable ATI manual does not report accurate F/T data. listed in Table 2.1.

-

Page 92: Reducing Noise

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 8.3 Reducing Noise 8.3.1 Mechanical Vibration In many cases, perceived noise is actually a real fluctuation of force and/or torque, caused by vibrations in the tooling or the robot arm. The Axia sensor offers digital low-pass filters that can dampen frequencies above a certain threshold. -

Page 93: Specifications

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 9. Specifications 9.1 Electrical Specifications Table 9.1—Power Supply Voltage Power Consumption Power Source Minimum Nominal Maximum Maximum DC Power 12 V 24 V 30 V 1.5 W Notes: The power supply input is reverse polarity protected. If the power and ground to the power supply inputs are plugged in reverse, then the reverse polarity protection stops the incorrectly wired supply input from damaging or powering on the sensor. -

Page 94: Terms And Conditions Of Sale

Manual, F/T Sensor, RS422 Axia Document #9620-05-C-RS422 Axia-02 10. Terms and Conditions of Sale The following Terms and Conditions are a supplement to and include a portion of ATI’s Standard Terms and Conditions, which are on file at ATI and available upon request. ATI warrants to Purchaser that force torque sensor products purchased hereunder will be free from defects in material and workmanship under normal use for a period of one (1) year from the date of shipment. - Page 95 Manual, F/T Sensor, Custom Application Document #9620-05-D-NA-02 D. Custom Application This modular manual section does not apply to this sensor system. Please contact an ATI representative for assistance, if needed: Sale, Service and Information about ATI products: ATI Industrial Automation 1031 Goodworth Drive Apex, NC 27539 USA www.ati-ia.com...

Need help?

Do you have a question about the ATI Axia130 and is the answer not in the manual?

Questions and answers