Table of Contents

Advertisement

Quick Links

Installation and operating

Instruction Combined Gas Valve

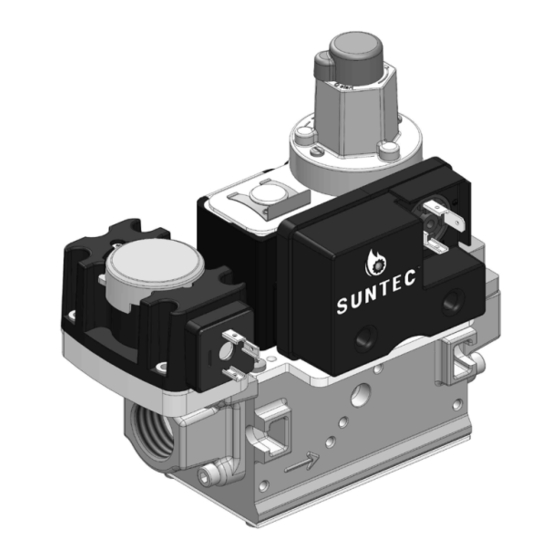

Combined gas valve

with 2 safety valves

for light commercial

pressure jet burners.

Application

The use of the SUNTEC M*N combined gas valve is recommended for all gaseous fuel

appliances where safety shutoff is required. It is suitable for use with 1st, 2nd and 3rd

family gases, according to EN 437, for inlet pressure up to 360mbar (for M2 range) and to

160mbar (for M3 range).

M2 and M3 combined gas valve are available with 2 options : fast opening (M*N**F) or

slow opening (M*N**S).

Approvals

SUNTEC M*N combined gas valve meets all the specifications of EN 13611 and EN 161

standards. It complies with requirements of gas regulation (EU) 2016/426 on appliances

burning gaseous fuels (CE certificate : 1312CU6361).

SUNTEC INDUSTRIES FRANCE - 1, rue Lavoisier - CS 60102 - F-21603 LONGVIC Cedex

Tel. +33 (0) 3 80 70 60 70 - information@suntec.fr - http://www.suntec.fr

M*N

IIM_N - Ed. 1 - May 2022

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SUNTEC MN Series

- Page 1 Application The use of the SUNTEC M*N combined gas valve is recommended for all gaseous fuel appliances where safety shutoff is required. It is suitable for use with 1st, 2nd and 3rd family gases, according to EN 437, for inlet pressure up to 360mbar (for M2 range) and to 160mbar (for M3 range).

-

Page 2: Technical Specifications

Technical specifications General Functioning with Air and gas of 1st, 2nd and 3rd families, according to EN 437 Maximum operating pres- • M2N : 360 mbar sure • M3N : 160 mbar Pipe sizes Inlet / outlet connection with straight flange : DN15 (Rp1/2’’) or DN20 (Rp3/4’’). -

Page 3: Operating Principle

Flow curves P burner = 3 mbar Flange = Rp3/4’’ Maximum flow can be reduced when other flanges are connected with. Operating principle P in : Inlet pressure P1 : Strainer pressure P2 / P3 : Intermediate pressure P out : Outlet pressure F : Strainer V1 : Safety shut-off valve 1 V2 : Safety shut-off valve 2... -

Page 4: Working Principle

Working principle Qstart Qmax ① ③ ② IIM_N - Ed. 1 - May 2022... -

Page 5: Installation

Installation Cautionary statements Please read carefully these instructions before installing, commissioning or using the product ! Hazardous situation or damaging the product may result from their non-observance. Herein specified ratings and product markings must be checked to ensure compatibility with the appliance. -

Page 6: Electrical Connections

Leak proof test Check for gas leaks of all pipe connections with a gas leak detection spray. To ensure an effective leak test of all connections, the gas valve must be energized (through the complete appliance) to raise pressure all over the valve. In case of leak detection, gas supply must be shut off upstream and connection tightness redone. - Page 7 The opening time is factory preset and does not need to be modified (sealing varnish on the needle screw). With the factory setting, the opening time can be adjusted up to 10 seconds by adjus- Caution ting the adjustment sleeve. If necessary, contact SUNTEC for specific adjustment. IIM_N - Ed. 1 - May 2022...

- Page 8 Default configuration for M*N gas valve consists of 1 pressure tap (P out), and 3 plugs (P1, P2 and P3) as shown below. P3 pressure tap can be modified upon demand (consult SUNTEC). Following pressure signal can be selected :...

-

Page 9: Maintenance

DMG 050 2.5 - 50.0 mbar 8161006050 DMG 150 5.0 - 150.0 mbar 8161004150 Electric plug ENC00_G *SUNTEC provides another range of pressure switches adapted for direct threading on the pipelines (the F range). IIM_N - Ed. 1 - May 2022... -

Page 10: Declaration Of Conformity

ISO 9001 : 2015 Certification AFAQ N° 1993/1573 Certificate of testing We certify that all delivered products have been fully tested in accordance with SUNTEC INDUSTRIES France Quality Management System. Declaration of Conformity According to Regulation (EU) 2016/426. Manufacturer’s name: SUNTEC INDUSTRIES FRANCE Manufacturer’s address :... - Page 11 Notes ....................................................................................................................................................................................................................................................................................................................................................................................................................................................IIM_N - Ed. 1 - May 2022...

- Page 12 SUNTEC INDUSTRIES FRANCE 1, rue Lavoisier - CS 60102 - F-21603 LONGVIC Cedex Tel. +33 (0) 3 80 70 60 70 - www.suntec.fr...

Need help?

Do you have a question about the MN Series and is the answer not in the manual?

Questions and answers