Table of Contents

Advertisement

Operation & Maintenance Manual

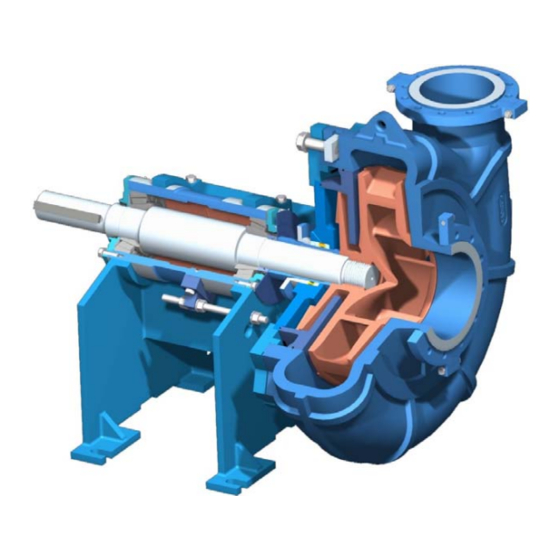

The Orion Series of Horizontal Slurry Pumps

HM200 MHC-S C5

Pump No

301599258.0101 / P-105

Supplier / Order No

Metso Minerals (Austria) GmbH / 308012

Customer Name

Harsco Minerali d.o.o

Note!

This pump is equipped with mechanical shaft sealing.

Mechanical seals must never run dry!

Adjust the quench liquid to the specifications

in chapter 9.5.3

If the seal runs dry it will be destroyed within seconds.

Original language

Date: 2012-08-16

Advertisement

Table of Contents

Summary of Contents for metso minerals HM200 MHC-S C5

- Page 1 The Orion Series of Horizontal Slurry Pumps HM200 MHC-S C5 Pump No 301599258.0101 / P-105 Supplier / Order No Metso Minerals (Austria) GmbH / 308012 Customer Name Harsco Minerali d.o.o Note! This pump is equipped with mechanical shaft sealing. Mechanical seals must never run dry! Adjust the quench liquid to the specifications in chapter 9.5.3...

-

Page 2: Table Of Contents

Slurry Pump GENERAL About this manual Transport and storage Pump specification Customer service DESCRIPTION Product and warning signs Applications Design Materials and maximum working pressures Surface treatment General arrangement Performance curves Certificates & test results HEALTH & SAFETY DESCRIPTION OF OPERATION CONTROL SYSTEM INSTALLATION General... - Page 3 Slurry Pump OPERATING INSTRUCTIONS Starting Stopping Running checks CARE AND MAINTENANCE Safety measures Preventive maintenance & service schedule Tools and special equipment for service and maintenance Lubrication instructions Dismantling and assembly Setting pump clearances 9.5.1 Hydraulic parts and frame - removal and fitting 9.5.2 Shaft seal –...

-

Page 4: General

Any amendments issued by Metso Minerals should be promptly inserted into this manual. © 2004 — Metso Minerals (Sweden) AB. The contents of this manual must not be reproduced without the prior written permission of Metso Minerals (Sweden) AB. - Page 5 Slurry Pump 1.2.2 Handling and lifting Whether at the depot or on site, follow normal handling and lifting procedures and ALWAYS instructions contained or referred to in this manual. Handling of centrifugal pumps requires great care, especially larger or more cumbersome items of machinery.

- Page 6 Slurry Pump 1.2.3 General storage instructions • Re-apply rust inhibitor to all moving parts, at least, every two months. Protect pump against dust and weather by storage indoors or under weatherproof cover Protect pump against impact Turn shaft at least every month General WH03AAEAAA0en_02c.doc 04-W08...

- Page 7 Slurry Pump 1.2.4 Long-term field storage Minimum requirement for storage and maintenance of centrifugal type pumps on site before their installation and start-up. Medium term storage Indoor storage of equipment is recommended in order to prevent the harmful effects of exposed conditions, particularly in dust laden atmospheres.

- Page 8 This work may be done by Metso Minerals and charged to the purchaser under normal rates in force at the time the service is carried out.

- Page 9 Slurry Pump To ensure rubber products maintain their original properties, storage conditions must be controlled. Where practicable, ensure rubber products are: kept sealed in their original packing which should be opaque; kept away from direct sunlight; kept away from electrical machinery -e.g. motors and generators; kept in a cool, dry environment between 15°...

-

Page 10: Pump Specification

Pump HM200 MHC-S C5 Pump specification Headline Description P-105 Order part no: 301599258.01 Complete pump: PDWC55132 Pump type: HM200 MHC-S C5 Product code: Pump no: 301599258.0101 Frame size: FR500 Wear parts, quality: High Chrome Special design: OH motor arr. Metso mechanical slurry seal double (BA095). -

Page 11: Customer Service

Slurry Pump Customer service For any inquiry regarding the servicing and repair of Metso Minerals Slurry pumps please contact the local Metso Minerals Branch. For information on the Metso Minerals Branch closest to you, contact one of the Metso Minerals Global Sites listed below: Metso Minerals (Sweden) AB Norrängsgatan 2... -

Page 12: Description

Slurry Pump DESCRIPTION Product and warning signs 2.1.1 Product signs All product signs attached to the pump are shown below. Motor weight Drive weight Pump weight Total weight Figure 2.1.1-1 Weight plate The weight sign is mounted next to the machine sign. When the pump is supplied without motor and drive, only the weight of the pump is stamped on the sign. - Page 13 Slurry Pump 2.1.2 Warning and caution signs This sign, attached to the drive cover, indicates the direction of rotation of the pump when viewed from the drive end. THERE IS RISK OF SERIOUS DAMAGE TO THE PUMP IF IT IS ALLOWED TO ROTATE IN THE WRONG DIRECTION This sign is a hazard warning and is usually accompanied by text indicating the nature of the hazard.

-

Page 14: Applications

Slurry Pump Applications The Metso Minerals Slurry Pump has been designed for a wide variety of abrasive pumping duties. While the pumps may be used in many different industries, they are all designed for constant use in the most arduous conditions. These high-efficiency pumps are of a simple design, providing ease of maintenance and facilitating replacement of wearing parts. - Page 15 Slurry Pump 2.3.2 Noise level In certain installations and outside the optimum operating conditions, the noise level of 70 dB(A) may be exceeded. The motor generates most of the noise and, in general, the noise level for properly designed installations will be about 2dB(A) above that of the motor. 2.3.3 Vibration The international standard ISO 10816-1 is valid for all slurry pumps.

-

Page 16: Materials And Maximum Working Pressures

Slurry Pump Materials and maximum working pressures Metso Minerals Slurry Pumps are constructed from materials selected to give excellent wear characteristics over the full range of pumping duties. This section lists the materials of construction and working pressures for STANDARD duty applications. Other materials are also used for specialist applications or as specified by the customer –... -

Page 17: Surface Treatment

Slurry Pump Surface treatment 2.5.1 Standard finish The external surfaces of the pump are protected by the anti-corrosive system specified in Table 2.5.1-1, except exposed machined surfaces which are coated with an air drying rust inhibitor. Drive motors are supplied in the original manufacturer’s standard finish. Stainless steel, plastic or elastomeric parts are not painted. -

Page 19: Performance Curves

Pump HM200 C5 Performance curve Full impeller dia Vane diameter Vane config Impeller type No. of vanes Max sphere Impeller material Liner material Full Closed Metal Metal 1500 r/min 77% 78% 1400 1300 1200 1100 H (m) 10,00 m 1000 8,00 m 6,00 m 5,00 m... -

Page 20: Certificates & Test Results

Slurry Pump 2.8 Certificates and test results EC DECLARATION OF CONFORMITY (Original) We, Metso Minerals (Sweden) AB, Norrängsgatan 2, 733 25 SALA, SWEDEN declare that the slurry pump Manufacturer Metso Minerals (Sweden) AB Pump type HM200 MHC-S C5 Pump number 301599258.0101... -

Page 22: Health & Safety

It is strongly recommended that all customers' production and maintenance personnel and site visitors are made fully aware of potential dangers of this equipment. If any doubt exists, please contact Metso Minerals for advice. FOR YOUR OWN PERSONAL SAFETY READ AND TAKE NOTE OF THE FOLLOWING... - Page 23 Slurry Pump LIFTING THE PUMP - Make sure that slings, shackles, etc. are of adequate load carrying capacity. Metso Minerals Slurry pumps may be provided with lifting eyes designed for lifting individual components. These should be used to lift the pump unit or the pump ALWAYS set.

-

Page 24: Description Of Operation

Slurry Pump DESCRIPTION OF OPERATION General Centrifugal pumps work best with minimum wear and other mechanical stress if the operating point is close to the pump's best efficiency point (BEP). To choose a pump that works close to its best efficiency line (BEL), it is important to understand how the pump interacts with the piping system in which it is installed. - Page 25 Slurry Pump When the pump operates at When the pump's flow The magnitude of the radial best efficiency point, uniform capacity is not utilized, force F is greatest when the pressure is obtained in the uniform pressure in the pump runs against closed casing which in its turn pump casing will not be valve = 0 flow.

- Page 26 Slurry Pump The way in which the hydraulic work is affected when the pump does not operate at BEP is shown in Figure 4.3-2 and Figure 4.3-3 This is of decisive importance in slurry pumping. Impeller vane inlet Pump casing nose Figure 4.3-2 Operating outside BEP - At low load 3.

- Page 27 Slurry Pump Hydraulic efficiency is a function of hydraulic turbulence - the more turbulence, the less efficiency. In slurry pumping, a high level of efficiency is therefore important. Little hydraulic turbulence is formed at BEP and the abrasion is chiefly of a sliding nature, since the differential pressure is low when the slurry passes through the impeller and pump casing.

-

Page 28: Control System

Slurry Pump CONTROL SYSTEM (NOT APPLICABLE) WH14AAAAAA0EN_04D.DOC 04-W08 Control system... -

Page 29: Installation

Ideally, the pump and its drive should be mounted on a common bedplate which is fixed to a level foundation of adequate strength. All bedplates supplied by Metso Minerals incorporate holding-down bolt holes. It is recommended that the pump is installed in such a way that maintenance and adjustments can be carried out easily. -

Page 30: Installation Tools And Equipment

Apart from suitable lifting equipment, a standard fitter's tool kit together with suitably-sized hexagon key wrenches and torque wrenches are normally sufficient to install the pump. See Toolkit, sub-section 10.6. Metso Minerals can supply all recommended fixtures and tools at additional cost. Installation WH15AMAAAA0EN_01A.DOC... -

Page 31: Installation Procedure

Slurry Pump Installation procedure 6.4.1 Pump When the foundation has fully cured, the anchor bolts may be installed –refer to Figure 6.2-1 and Figure 6.4-1. Spacing between anchor fixings should normally be more than 10 times their diameter, unless otherwise instructed. Refer to manufacturer’s instructions for specific details. - Page 32 Slurry Pump 6.4.2 Belt driven pumps Make allowances for possible pump shaft forward adjustment when positioning the drive pulley on the shaft. Align the pump and motor pulleys correctly. Misalignment between pulleys could cause excessive belt wear, heat generation and noise. 6.4.3 Direct driven pumps NOTE...

- Page 33 Slurry Pump Ensure that all safety covers are fixed securely in position. 6.4.5 Cold climates Where there is the likelihood of pump being exposed to below freezing conditions the following precautions are strongly recommended. If practical, on site all pumps should be installed with their outlets in position-3 as shown in ‘General Arrangement’, sub-section 2.6.

-

Page 34: Pipe Connections & Pump Sump

ABLE INDICATES THE STANDARD ALLOWABLE FLANGE FORCES PLEASE CONSULT METSO MINERALS SHOULD THE FLANGE LOAD REQUIREMENT BE GREATER PUMPS EQUIPPED WITH AN ADJUSTABLE INLET DOOR MUST HAVE ADEQUATE FLEXIBILITY PROVISION FOR ADJUSTMENT BUILT INTO THEIR INLET PIPES AS A MEANS OF AVOIDING EXTRA... - Page 35 Slurry Pump Q(m /s) < < 2min (4 × D) < < (10 × D) V(m ) 45º-60º Figure 6.5-1 Recommendations for pipework layout WARNING WHERE THE PIPEWORK IS DESIGNED IN SUCH A WAY THAT THE PUMP INLET AND OUTLET LINES CAN BE SHUT OFF OR BLOCKED SIMULTANEOUSLY...

-

Page 36: Shaft Gland

Slurry Pump NOTE INLET PIPE SHOULD HOWEVER HAVE A STRAIGHT LENGTH AT LEAST TIMES ITS DIAMETER TO ENSURE FAVOURABLE FLOW CONDITIONS INTO THE PUMP IF A VALVE FITTED ON THE INLET SIDE IT MUST BE FULLY OPEN WHEN THE PUMP IS RUNNING AND SHOULD HAVE A STRAIGHT FLOW PATH OF THE SAME AREA AS THE CONNECTED PIPE SUCTION PIPES WHICH ARE LONGER THAN TIMES THE DIAMETER SHOULD BE AVOIDED... -

Page 37: Commissioning

Slurry Pump COMMISSIONING WARNING BEFORE CARRYING OUT THE FOLLOWING CHECKS ISOLATE THE ELECTRICAL SUPPLY TO THE MOTOR NOTE SEE ALSO THE WARNING IN SECTION If the pipework has not been connected to the pump on installation, ensure that the pump case and associated pipework are clear of any construction debris, slurry etc. before connection. -

Page 38: Operating Instructions

Slurry Pump OPERATING INSTRUCTIONS Start-up If the pump has just been maintained or has not been put into operation for some time, then carry out the pre-start checks as described in Commissioning, section 7. Open the pump inlet and outlet valves. WARNING NEVER RUN THE PUMP WITH BOTH INLET AND OUTLET VALVES CLOSED SEE THE WARNING NOTICE... -

Page 39: Running Checks

Slurry Pump NOTE REVERSE FLOW IN ADDITION TO POSING A RISK OF DAMAGE TO THE SHAFT SEAL CAN ALSO CAUSE THE IMPELLER TO SPIN IN THE REVERSE DIRECTION STARTING THE PUMP UNDER THESE CONDITIONS MIGHT CAUSE DAMAGE TO A MECHANICAL SEAL IF FITTED OR CAN IN EXTREME CASES CAUSE THE SHAFT TO SHEAR... -

Page 40: Care And Maintenance

Slurry Pump CARE AND MAINTENANCE Safety measures WARNINGS BEFORE COMMENCING ANY ISOLATE THE PUMP FROM ALL SOURCES OF ELECTRICITY AND POWER MAINTENANCE WORK ALWAYS ASCERTAIN THE NATURE OF THE PROCESS LIQUID BEFORE COMMENCING WORK ON A PUMP AND FOLLOW THE HEALTH AND SAFETY PROCEDURES RELEVANT TO THE PROCESS LIQUID MAY BE HARMFUL TO HEALTH Should the process liquid be of a harmful or hazardous nature take the following precautions as a minimum;... - Page 41 Slurry Pump RUNNING HOURS ITEM ACTION 100 250 1000 × Water flushing gland seal. Check stuffing box connection for leaks. Rectify as necessary. × Centrifugal Gland Seal Tighten gland follower screws or renew seal as necessary. × Lubricate bearings. See section 9.4.

- Page 42 Slurry Pump 9.2.2 Maintenance recommendations Metso Minerals recommends that the following actions are carried out prior to any maintenance: • clean down the pump, removing any accumulation of debris and/or slurry; • ensure that inlet and outlet pipeline valves, if fitted, are closed;...

-

Page 43: Tools And Special Equipment For Service And Maintenance

Slurry Pump Tools and special equipment for service and maintenance NOTE THE FOLLOWING SPECIAL TOOLS ARE AVAILABLE FOR PUMPS WITH EITHER SINGLE DOUBLE ADJUSTMENT FRAMES A special crank-handle to fit over the drive-shaft end diameter and locate the drive key is advantageous when fitting the impeller to the shaft. See Dismantling and Fitting the Hydraulic Parts, section 9.5.2. - Page 44 Slurry Pump Two proprietary packing extractors to facilitate the removal of the packing will also be advantageous. Figure 9.3-2 Packing extractor Back-liners for large pumps are very heavy. Specially designed back-liner lifting tools allow safe handling of the components. Figure 9.3-3 Back-liner lifting tool for metal pumps WH16AM1TAA0EN_02A.DOC 04-W51 Care and maintenance...

- Page 45 11.3) to lift the case assembly is required. CAUTION ONLY USE A SOFT SLING TO PREVENT DAMAGE STROP TO LIFT THE CASE All of the above special tools can be obtained from Metso Minerals. See section 10.6. WH16AM1TAA0EN_02A.DOC 04-W51 Care and maintenance...

- Page 46 9.4.1 First-fill and re-packing after major servicing Metso Minerals Slurry pumps are lubricated with SKF LGMT3 before dispatch. When renewing or re-fitting the bearings, they must again be re-packed with grease of the same specification as detailed in Table 9.4.1-1. The required quantity for each bearing is specified in Table 9.4.1-2.

- Page 47 Slurry Pump 9.4.2 Lubrication interval The bearings may be re-greased with any lithium-based grease that conforms to the specification detailed in Table 9.4.1-1. The lubrication interval depends upon the shaft speed and the bearing operating temperature, as shown in Table 9.4.2-1. Frame Grease Pump speed (rpm) Size...

- Page 48 Slurry Pump 9.4.3 Lubrication points The pumps have two bearing lubrication points. See Figure 9.4.3-1. Part Position Qty.(cc) Frequency Lubricant See Table Bearing cylinder SKF LGMT3 or equivalent - Table 9.4.2-1. see Table 9.4.1-1. 9.4.2-1. Motor and/or See manufacturer’s instruction –...

-

Page 49: Dismantling And Assembly

Slurry Pump Dismantling and assembly 9.5.1 Setting pump clearances • Impeller clearance adjustment This adjustment enables the impeller inlet-side running clearance to be kept to a minimum so that maximum operating efficiency is maintained throughout the wear life of the pump. When no further adjustment is possible, the pump must be disassembled and inspected and worn parts renewed. - Page 50 Slurry Pump Loosen housing clamp fixings (P16 & P27), and slacken bearing housing clamps (P29). Ensure that the bearing cylinder assembly is free to move. While rotating the shaft (B11) manually, take up the inlet-side clearance (C) by tightening adjustment screw locknut (P38 a) until impeller (W3) makes contact with the case assembly on the inlet-side.

- Page 51 Slurry Pump 9.5.2 Hydraulic parts and frame - dismantling and fitting Opening and closing the pump – fixed base WARNING MAKE SURE THAT ALL SLINGS SHACKLES ARE OF ADEQUATE LOAD CARRYING CAPACITY APPROXIMATE WEIGHTS OF MAJOR COMPONENTS ARE PROVIDED IN SUB SECTION 11.3 LIFTING POINTS INCORPORATED IN INDIVIDUAL COMPONENTS ARE INTENDED SOLELY FOR LIFTING...

- Page 52 Slurry Pump Opening the pump Figure 9.5.2-1 and parts list drawings in section 10.4 identify parts referenced in this section. Run the pump on clean water or flush clean the inside of the case. Isolate the pipework and drain the pump case. Isolate the drive motor and attach suitable warning plates to the relevant switches.

- Page 53 WHERE APPLICABLE ENSURE CASE SHIMS ARE IN POSITION CASE SHIMS MAY BE NECESSARY IF THE CASE HAS BEEN RENEWED CONTACT METSO MINERALS SPARES – 10.3 DEPARTMENT SEE SECTION Ensure that case fixings (B) enter their respective holes around the flange joint.

- Page 54 Slurry Pump 9.5.2 Hydraulic parts and frame - dismantling and fitting (ii) Wet-end - disassembly and reassembly General Case (W1), impeller (W3) and back-liner (W4) are high quality, high-chrome iron castings. Larger size pump cases are ribbed and incorporate a number of lifting lugs. The inlet and outlet branches are fitted with joint seals (F2, F4) and split flanges (F1, F3) to provide a leak-proof and secure pipework connection.

- Page 55 Slurry Pump Remove nuts (W20) from the four back liner bolts (W19) and withdraw back liner (W4). The bolts are retained in position by a rubber strap. WARNING BACK LINERS ON LARGE PUMPS ARE EXTREMELY HEAVY USE THE BACK LINER LIFTING TOOL RECOMMENDED IN SECTION Inspection Clean and inspect case (W1), impeller (W3) and back-liner (W4) for severe...

- Page 56 Slurry Pump 9.5.2 Hydraulic parts and frame - dismantling and fitting (iii) Impeller Release Mechanism (IRM) Not applicable. WH18IRMAAA0EN_01C.DOC 04-W08 Care and maintenance...

- Page 57 Slurry Pump 9.5.2 Hydraulic parts and frame - dismantling and fitting (iv) Hydraulic system Not applicable WH18HYDAAA0EN_01D.DOC 04-W08 Care and maintenance...

- Page 58 Metso Minerals Mechanical Seal (H3) – Double General observations A large variety of mechanical seals are suitable for use with the Metso Minerals Slurry pumps. The Metso Minerals Mechanical Seal, however, is designed to provide excellent performance when fitted to Metso Minerals Slurry pumps.

- Page 59 Slurry Pump Operating considerations The double acting Metso Minerals Mechanical Seal has silicon carbide seal faces on both the product and the atmospheric sides. The seal requires flushing liquid at all times during operation, otherwise the seal faces are destroyed within seconds.

- Page 60 Slurry Pump The required water quality is specified as follows: R (rpm) R (rpm) Solid particles : max. 10 mg/l Particle size : 10-50 µm 3950 Critical particle size : 2 -5 µm (to be avoided) 1150 4200 Permanganate value : max. 30 (free from humus) 1400 4900 Ferro content...

- Page 61 ARE AVAILABLE ON REQUEST A SERVICE TRAINING VIDEO SHOWING THE PROCEDURE FOR REPAIRING THE MECHANICAL SEAL IS ALSO AVAILABLE ON CD METSO MINERALS ALSO PROVIDE A SERVICE EXCHANGE PROGRAMME WHERE THE SEALS ARE RETURNED FOR SERVICE Assembly If the seal did not leak before dismantling it may be fitted back in the pump, otherwise a new seal must be fitted.

-

Page 62: Shaft And Bearing Assembly - Removal And Fitting

Slurry Pump 9.5.4 Shaft and bearing assembly - removal and fitting The following instructions assume that the pump is installed complete with the drive unit and is connected to the suction and discharge pipework. Removal Remove the wet end assembly (refer to sections 9.5.2 & 9.5.3). Remove the drive safety guard and disconnect the drive belts, or drive coupling, as applicable. - Page 63 Slurry Pump Re-fitting Clean and degrease the bearing frame contact surfaces. Coat the machined surfaces with anti-seize compound. Lift the bearing cylinder assembly, as shown in Figure 9.5.4-1, and lower it onto bearing frame (P14). Rotate (Ra or Rc as convenient) the bearing cylinder assembly in the bearing frame so that the tapped holes for the saddle screws are in-line with the slot in the frame for impeller adjusting screw (P19).

-

Page 64: Shaft And Bearings - Disassembly And Re-Assembly

Slurry Pump 9.5.5 Shaft and bearings - disassembly and re-assembly General The bearing cylinder assembly connects the drive to the impeller. Its general layout is shown in Figure 9.5.5-1. It consists of a steel shaft, one end of which is threaded to receive the impeller, and the other end of which is keyed to accept a coupling or a belt drive arrangement. - Page 65 Slurry Pump Disassembly With bearing cylinder assembly resting horizontally on V-blocks, remove flinger (B1) from the wet-end and the V-ring seal (B22.2) from the dry end. Remove seal (B16) from flinger (B1). Support the bearing cylinder assembly vertically in a secure stand, dry-end pointing down, as shown in Figure 9.5.5-2, and clamp it in position using securing screws (E).

- Page 66 Slurry Pump Assembly Support shaft (B11) in V-blocks and ensure all its surfaces are clean. NOTE DO NOT GREASE BEARING LANDS Press wet-end bearing (B8.1) onto the shaft, making sure that it is tight against the shaft inner shoulder. Similarly, assemble inner race (B8.2a) of dry-end bearing –see Figure 9.5.5-3.

- Page 67 Slurry Pump Lift the shaft assembly, as shown in Figure 9.5.5-3, and lower it into the bearing housing –dry-end first. CAUTION TAKE CARE NOT TO DAMAGE THE DRY END BEARING ROLLERS AS THE SHAFT ASSEMBLY IS LOWERED MAKE SURE WET END BEARING OUTER RACE IS SEATED SQUARELY AGAINST THE BEARING HOUSING SHOULDER Clean wet-end cover (B2.1), and assemble it to bearing housing (B14) using...

- Page 68 Slurry Pump 9.5.6 Pump drive - removal and re-fitting • V-drive Dismantling the drive WARNING ENSURE THAT THE PUMP MOTOR IS ISOLATED AND THE ISOLATOR IS LOCKED IN THE ISOLATED POSITION BEFORE REMOVING THE DRIVE GUARD TO PREVENT REVERSE MOTORING OF THE PUMP ENSURE THAT THE DISCHARGE LINE IS ISOLATED BEFORE REMOVING THE DRIVE GUARD...

- Page 69 Slurry Pump Pulley – removal Slacken, by several turns, all screws in the Taper Lock® bush. Remove one or two, according to the number of jacking holes (shown as ‘ ’ in Figure 9.5.6-1). Oil the thread of each screw, the point of grub screws and under the head of cap screws.

- Page 70 Slurry Pump repeat the hammering and tightening a further once or twice to achieve maximum grip on the shaft; after the drive has run under load for a short time, stop the pump and check the screws for tightness; fill the empty holes with grease to exclude dirt and other arisings. Drive belt re-fitting CAUTION DO NOT USE WEDGES...

- Page 71 Slurry Pump Stop the drive, check the tension as previously described and re-set to the ‘basic’ value, if necessary. ‘ ‘ 1.25× NOTE COGGED RAW EDGED BELTS SHOULD BE RESET TO SETTING There should be no need for further attention during the life of the belts. When comparing forces with the force range given in Table 9.5.6-2, if the measured force falls within the given range, the tension should be satisfactory.

- Page 72 Slurry Pump SPAN FORCE DEFLECTION Figure 9.5.6-2 Drive belt tension diagram Trouble shooting Small cracks on V-belt side and base This is generally caused by shortage of belt tension but excessive heat and/or chemical fumes can also give same failure. V-belt swelling or softening This is caused by excessive contamination by oil, certain cutting fluids or rubber solvent.

- Page 73 Slurry Pump Drive alignment It is important that drive belts are correctly aligned. Belt misalignment results in increased noise, increased power absorption and reduced belt life. Figure 9.5.6-3 shows examples of parallel and angular misalignment. <4mm/m PARALLEL MISALIGNMENT <1mm/m ANGULAR MISALIGNMENT Figure 9.5.6-3 Drive belt misalignment The motor and pump pulleys are fitted to their shafts with Taper Lock®...

- Page 74 A multimeter, a test lamp and appropriate circuit diagrams will be required to carry out checks on electrical equipment. NOTE IF ALL FAILS CONTACT METSO MINERALS FOR FURTHER ADVICE 9.6.2 Pump fails to start Is power supply live ? No⇒ Check that: •...

- Page 75 Slurry Pump 9.6.3 The pump starts but the motor protection trips Has flow path or pipe run been Yes⇒ modified ? • Alter the flow path or pipe run, or adjust the rating of the drive motor and pump to suit ⇓...

- Page 76 Slurry Pump 9.6.5 The pump runs unevenly or vibrates Is the inlet flow uneven or is the pump drawing air ? Yes⇒ • Either adjust the feed to the pump, or adjust the rating of the drive, motor and pump to ⇓...

-

Page 77: Spare Parts

Impeller Back-liner W4 (+ W6) Back-liner seal (O-ring) Metso Minerals mechanical seal Metso Minerals mech. seal repair kit S1 (+ S2) Metso Minerals mech. seal O-ring kit Bearing cylinder assembly Set of seals – Bearing (B16, B19.1, B19.2, B22.1, B22.2) - Page 78 • Build Number • Approximate date of purchase • Part Number and Description of Required Spare Parts This information should then be forwarded to the local Metso Minerals branch for action - - see sub-section 1.4. Spare parts WH23AM1S040EN_05B.DOC 07-W15...

-

Page 79: Spare Parts Drawing

Slurry Pump 10.4 Spare part drawing WH24AAAAAA0EN_03B.DOC 04-W08 Spare parts... - Page 80 Slurry Pump Spare parts WH24AM1W010XX_03A.DOC 07-W46...

- Page 81 Slurry Pump FR250 SA982048 SA986258 SA986264 FR300 SA983074 SA986259 SA986265 FR400 SA986254 SA986260 SA986266 FR500 SA986255 SA986261 SA986267 FR600 SA986256 SA986262 SA986268 FR750 SA986257 SA986263 SA986269 Spare parts WH24AA1G130xx_02a.doc 08-W26...

- Page 82 Slurry Pump FR250 SABA047,5-S1 SABA047,5-S2 FR300 SABA063-S1 SABA063-S2 FR400 SABA075-S1 SABA075-S2 FR500 SABA095-S1 SABA095-S2 FR600 SABA111,7-S1 SABA111,7-S2 FR750 SABA120-S1 SABA120-S2 Spare parts WH24AA1G130xx_02a.doc 08-W26...

- Page 83 Slurry Pump B2.1 B22.1 B19.1 B - B B8.1 B8.2 B2.2 B22.2 A - A WH24AA1B053XX_04B.DOC 04-W08 Spare parts...

- Page 84 Slurry Pump Spare parts WH24AAEF010XX_03A.DOC 07-W07...

-

Page 85: Parts List

PUMP HM200 MHC-S C5 Parts list Item Part No. Description Qty Unit weight Wear parts PDCH2034 Case 0.00 PDCH2019 Impeller 0.00 PDCH2021 Back-liner 0.00 SA981239 O-ring (incl. in w04) 0.00 Shaft seal SABA095 Mechanical seal 0.00 Bearing assembly parts B02.1 SA502077-1 End cover 0.00... -

Page 86: Special Tools

Slurry Pump 10.6 Toolkit 10.6.1 Standard tools In addition to the special tools detailed in sub-section 9.3 and Table 10.6-2, and installation tools and equipment detailed in sub-section 6.3, Table 10.6-1 lists a basic toolkit for performing normal maintenance operations on the pump. A dial test indicator may also be required to set bearing clearances –... -

Page 87: Appendices

Slurry Pump APPENDICES 11.1 Torque table The following table gives the recommended torque values for tightening bolts and screws. ±5%. NOTE ALL TORQUE VALUE TOLERANCES ARE TORQUE VALUES (Nm) (Single Adjustment Pumps) ITEM HM50 HM75 HM100 HM150 HM200 HM250 HM300 Case fixings (B) (M16) (M16) - Page 88 Slurry Pump 11.2 Reference publications WEG - Motor Appendices WH26HMEAAA0EN_04B.DOC 08-W05...

-

Page 98: Weights Table

Slurry Pump 11.3 Weights table Item Description Weight (kg) Bare shaft pump 1005 Case Impeller Backliner Frame Bearing cylinder assembly Shaft seal assembly Back pull-out assembly WH27HME2000EN_01C.DOC 04-W08 Appendices...

Need help?

Do you have a question about the HM200 MHC-S C5 and is the answer not in the manual?

Questions and answers