Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ACTUATECH GD08

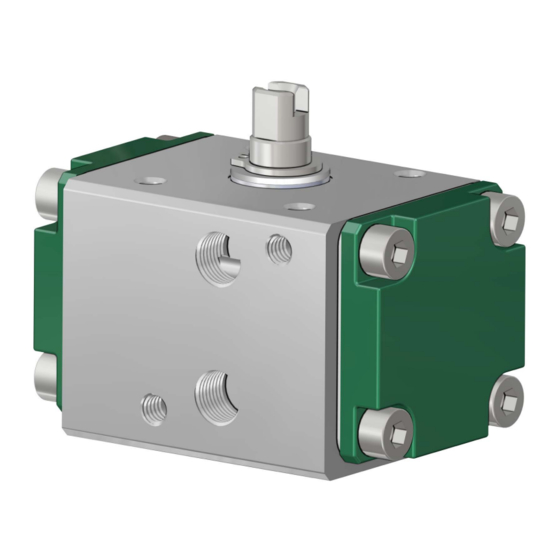

- Page 1 INSTRUCTION MANUAL SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR GD08 ACTUATECH S.p.A Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • +39 030 8908142 • +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com EN - Rif. MAN80938 - 02/22...

- Page 2 Environmentally friendly: under the green leaf icon you can find the instructions for a correct and environmentally friendly handling of the product. ACTUATECH will be free to change all the specifications and data included in this manual at any time, so as to improve the quality and the performance of its products.

-

Page 3: General Features

- Scotch – Yoke is a mechanical system that allows to transform the linear force into a rotary torque. ACTUATECH applies the scotch - yoke system for its actuator production to transfer the pistons linear force to a driving shaft torque. - Page 4 GD08 e) Operating drive rotation. The part turn actuator rotation angle is nominally 90°. ACTUATECH actuator provides a stroke of 92° rotation, from –1° to 91°. f) Cycle time. The cycle time is dependent on different operating and installation factors such as the supply pressure, the flow capacity, the con- nection pipe size, the solenoid valve performance, the valve torque and characteristics, environmental temperature condition.

- Page 5 GD08 k) Marking and classification All ACTUATECH actuators bodies are marked with the Manufacturer name and address, the actuator Type code including the Series and Size, and its range of Pressure and Temperatures working conditions and limits. 1. Name of the company in charge of marketing the product in the E.U.

- Page 6 Standard Double Acting actuators shall be Clockwise (CW) direction to valve Close, and Counter Clockwise (CCW) direction to valve Open. ACTUATECH S.p.A Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • +39 030 8908142 • +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com EN - Rif. MAN80938 - 02/22...

-

Page 7: Safety Notice

- The actuator installation shall be done according to and in observance with the local and national laws regulation. - ACTUATECH S.p.A can not be responsible for any damage to people, animals or things due to an improper use of the product. - Page 8 Should it be necessary to replace its pistons sealing, these operations must be done by ACTUATECH trained people with proper tools, we recommend to return the actuator to ACTUATECH where the actuator will be overhauled and than tested for a correct re- placement.

- Page 9 * Parts included in the spare parts kit. Type Kit code GD08 KGGI0010 ACTUATECH S.p.A Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • +39 030 8908142 • +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com EN - Rif. MAN80938 - 02/22...

-

Page 10: Maintenance

GD08 7. MAINTENANCE The ACTUATECH S.p.A. actuator, when installed and used properly, does not require maintenance, under normal use, as it’s provi- ded with sufficient lubrication for standard duration. Send the actuator directly to ACTUATECH S.p.A. for inspection or extraordinary maintenance. - Page 11 F) Insert the pistons (part N°2) in the scotch-yoke grooves (part N° 4) and press simultaneously the two pistons inside of the cylinder (part N° 1). The ACTUATECH scotch-yoke system will avoid pistons misalignment. Holding the actuator on a vice rotate the shaft to verify the shaft rotation direction and the easy movement.

- Page 12 In conformance with the European Directive ATEX 2014/34 UE for the suitability of the equipment intended for the use in Potentially Explosive Atmosphere, ACTUATECH declare the conformity of the scotch-yoke actuator of the above mentioned Atex directive in the limits of its Classification and Zone Classification.

-

Page 13: Troubleshooting

GD08 9. STORAGE The ACTUATECH actuator has been packaged to provide protection during shipment, however, it can be damaged in transport. Prior to storage, inspect the actuator for shipping damage. Keep the actuators in their original packing box during storage. -

Page 14: Declaration Of Conformity

11. DISPOSAL OF PRODUCTS AT THE END OF THEIR LIFE CYCLE The ACTUATECH products are designed so that when they are at the end of their life cycle they can be completely disassembled, separating the different materials for the proper disposal and/or recovery. All materials have been selected in order to ensure minimal environmental impact, health and safety of personnel during their installation and maintenance, provided that, during use, they are not contaminated by hazardous substances.

Need help?

Do you have a question about the GD08 and is the answer not in the manual?

Questions and answers