Summary of Contents for HART VVP10-H

- Page 1 INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL June/2022 VVP10-H HART ® VALVE POSITIONER...

- Page 2 ® HART is a registered mark of HART Communication Foundation. NOTE We have reviewed this manual with great care to maintain compliance with the hardware and software versions described herein. However, due to the dynamic development and version upgrades, the possibility of technical deviations cannot be ruled out.

-

Page 3: Table Of Contents

LIQUID CRYSTAL DISPLAY (LCD) ......................21 ® 3.4. HART PROGRAMMER ..........................21 3.5. LOCAL ADJUST CONFIGURATION TREE ....................22 3.6. HART CONFIGURATOR PROGRAMMING TREE ..................23 3.7. CONTROL CONFIGURATION ........................26 3.8. CALIBRATION ............................. 32 3.9. DIAGNOSIS ..............................34 3.10. FDT/DTM CONFIGURATION ........................47 MAINTENANCE .............................. - Page 4 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ WARNING It is extremely important that all the safety instructions, installation and operation in this manual are followed faithfully. The manufacturer is not liable for damage or malfunction caused by improper use of this equipment.

-

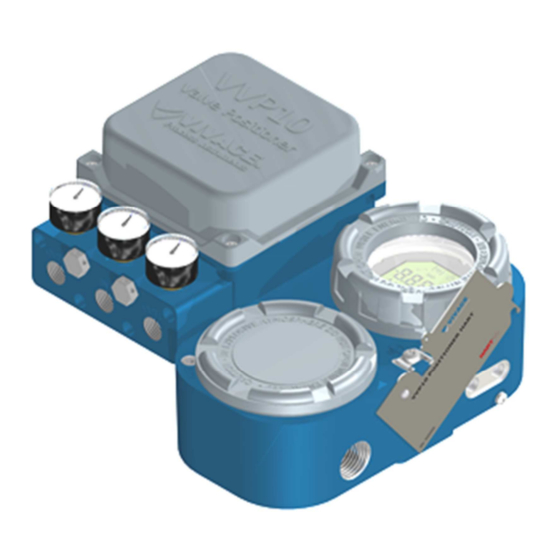

Page 5: Equipment Description

Auto Travel Calibration, PID Auto Tune, check calibrations, diagnostics and monitoring. It is also possible to configure VVP10 HART via local adjustment using a magnetic tool. Prioritizing its high performance and robustness, VVP10 HART is designed with the latest electronics and materials technologies, ensuring long-term reliability for systems of any scale. - Page 6 The display board has the controller block that interfaces LCD with CPU, adapting the messages to be displayed. ® The main board CPU can be related to the positioner's brain, executing all time controls, HART state machine, PID control, diagnostics and transmitters common routines such as configuration, calibration and generation of the digital output value for the current, proportional to the variable PV.

-

Page 7: Installation

VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ 2 INSTALLATION RECOMMENDATION When taking the equipment to the installation location, transfer it in the original packaging. Unpack the equipment at the installation location to avoid damage during transportation. -

Page 8: Installation Conditions

As the operating principle of the position sensor of the VVP10 HART is magnetic with no mechanical contact, light vibrations should not influence the correct operation of the positioner. However, it is important that there is no large variation of the magnetic field on the position sensor, which can happen if large vibrations in the positioner body are applied. - Page 9 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Figure 2.2 – Dimensional drawing for VVP10 HART.

- Page 10 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Figure 2.3 identifies the input and output connections for the supply air that will move the positioner. When the positioner is used in a single action set, simply close output 2 using the supplied plug (item 13 in figure 4.1), turning the valve into a 3-way system (figure 2.4).

- Page 11 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ The installation of VVP10 positioner reference magnet in the desired system should be done first by positioning the magnet in the system so as to allow the sensor to traverse all the useful extension to be measured and aligning the magnet arrow with the positioner arrow on central position (50% of the range) where the sensor will be located (arrow on the bottom of the positioner housing).

-

Page 12: Electrical Connection

Figure 2.11 shows power terminals, ground terminals (one internal and one external), plus communication terminals, 4-20 mA current return and tests for standard VVP10 HART. Figure 2.12 shows terminals for digital I/O model (complete). To power the equipment, it is recommended to use twisted-pair 22 AWG cables. - Page 13 VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Figures 2.13 and 2.14 ilustrate the electrical connections of power supplies and HART communication for the positioner on standard and complete versions, respectively. NOTE All the cables used for connection between VVP10 ®...

-

Page 14: Magnet Specification

VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ 2.4. MAGNET SPECIFICATION WARNING Correct magnet dimensioning is a primordial for perfect performance of position measurement, allowing sensor to achieve all system length with the highest magnetic field variation possible. - Page 15 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Linear 100 Option 3 on Ordering Code Used on linear systems of 70 mm to 100 mm, with measurement from 0 to 100 mm (minimum span of 70 mm between inferior and superior points).

-

Page 16: Remote Sensor

Figure 2.18 shows the dimensional drawing of VVP10 HART remote sensor components. At the left we can see the positioner side that receives remote sensor signal, while on the right side we can find the opposite cable side, containing the magnetic sensor already adapted to a fixation support. -

Page 17: Brackets

VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ 2.6. BRACKETS For applications with linear and rotative magnets in various actuators, Vivace provides compatible brackets, adjusting the positioner to the most diverse combinations. The following figures detail the available brackets and the positioner installation using them. - Page 18 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ ROTATIVE BRACKET Figure 2.21 – Bracket mounting for rotative actuators on VVP10.

-

Page 19: Configuration

User can use a tablet, Android smartphone, HART 375, 475, PC programmer via FDT/DTM tools or a PALM. Another way to configure the VVP10 HART is through local adjustment using a Vivace magnetic key. 3.1. LOCAL CONFIGURATION The equipment local configuration is executed by using Vivace’s magnetic screwdriver on Z and S... -

Page 20: Jumper Configuration For Local Adjust And Write Protection

After that, simply reconfigure it with the desired values for the application. 3.2. JUMPER CONFIGURATION FOR LOCAL ADJUST AND WRITE PROTECTION VVP10 HART has two jumpers on its main board to protect data writing (WP1) and also enabling/disabling local adjust (ADJL1). Figure 3.2 presents those jumpers. -

Page 21: Liquid Crystal Display (Lcd)

Table 3.2 – LCD icon description. 3.4. HART ® PROGRAMMER ® Configuration of the equipment can be done by means of a HART compatible programmer. Vivace offers VCI10-H ® ® (USB, Android or Bluetooth HART ) interfaces as a solution for identifying, configuring and monitoring HART line devices. -

Page 22: Local Adjust Configuration Tree

VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ 3.5. LOCAL ADJUST CONFIGURATION TREE Figure 3.6 shows the fields available for local configuration of the positioner and the sequence in which they are provided by the actuation of the magnetic key in the hole Z. -

Page 23: Hart Configurator Programming Tree

Here the positioner is configured in relation to the variables of communication, sensor operation and temperature reading. Hart - In this directory user can configure the parameters of address, current mode, number of preambles and write protection, all related to HART communication. - Page 24 *This menu is only available for complete model. HART Communication – It informs the number of communication packets received by the equipment (RX), as well as those answered by it (TX), displaying the communication loss rate per hour (Loss/h). It also informs the total...

- Page 25 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________...

-

Page 26: Control Configuration

Loop Current Mode It can be set to Enabled or Disabled. This parameter is available on the "HART" menu as it is a configuration common to all equipment that has this communication protocol. Enabled: Setpoint will follow the 4-20 mA current of the positioner's power supply (in the percentage of the operation range configured in "Range"... - Page 27 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Local Setpoint It sets the Setpoint value manually when Loop Current Mode is Disabled. WARNING When Loop Current Mode is disabled, Setpoint starts to follow parameter Local Setpoint directly, not considering any other Setpoint configuration.

- Page 28 Figure 3.11 – Linear, equal percentage and quick opening functions for Setpoint characterization (respectively). User Table Used in measurements that require custom output. VVP10 HART has a user table with 16 points with input and output as a percentage (depending on the input signal).

- Page 29 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ User Table Configuration using Local Adjust The user can configure the table points using the local adjustment (Table Point option) for five predefined points: 0%, 25%, 50%, 75%and 100%.

- Page 30 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Auto Tuning It performs the automatic tuning procedure for PID control, calculating the optimized values of Proportional (Kp), Integral (Tr) and Derivative (Td) parameters through data collected in repeated oscillations of the system (according to the applied pressure).

- Page 31 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ PID CONTROL This directory (Specific/PID Control) allows user to freely configure the parameters of the PID control, for fine control tuning. Proportional Factor Kp (PID Kp) It sets the proportional parameter of the control, also called gain, responsible for control speed, in relation to the error (SP% - PV%).

-

Page 32: Calibration

From there, via configurator, user must position system in the desired position, entering the step to be given by the positioner (on display or HART monitoring), since it is lower thano 10%. For example, with the valve in 0%, execute Lower Position Trim, sending the value (-5%). The valve will go to 5% and the user can confirm the new position, which will become the new 0% (lower reference) of the stroke course. - Page 33 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Figure 3.17 – Assembly for position return current trim. Figure 3.18 – Assembly for loop current trim. PRESSURE WARNING Pressure calibration will be available only for positioner models with installed pressure sensors. Verify the Ordering Code for this characteristc (section 6.2).

-

Page 34: Diagnosis

PV OUT OF LIMITS The primary variable is outside normal limits (-1.25% and 103.125%). A variable other than primary has a value outside normal range. For VVP10 HART NON-PV OUT OF LIMITS this variable could be the temperature or the input pressure. - Page 35 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Alarmes Preditivos Não Persistentes Alarmes não persistentes que indicam alteração no funcionamento do sistema, além dos valores configurados como aceitáveis. Caso o problema seja corrigido, o alarme será desativado automaticamente.

- Page 36 STEP RESPONSE TEST procedure, see the Step Response Test item in this section. WARNING During the execution af any of the procedures, the positioner will NOT accept any write command, either by HART configurator – answering "Busy" – or local adjustment.

- Page 37 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Test Error Alarms Persistent alarms that indicate errors in performing procedures in order to invalidate the parameters obtained. For more information about the procedures, see the respective items, in this section.

- Page 38 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ PREDICTIVE DIAGNOSTICS OF POSITION Reversal Diagnostic for verification of course transitions from the control system. With each reversal of sense of the movement, a counter is increased. The reversal is accounted for when the valve reverses its direction with a moving above Reversal Deadband, configured by the user between 0% and 20%.

- Page 39 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Furthermore, the user can configure the maximum value for the counter (Stroke Counter Limit), in order to generate an alarm (Stroke Limit Alert) when it is exceeded. This alarm is persistent, forcing the user to manually deactivate it, after verifying the cause of the extremity position alert.

- Page 40 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Example 1: Assuming Mileage Deadband = 1% and PV = 50%. When the valve goes to 45%, the sum will be incremented by 5%. If the valve returns to 50%, the sum will be increased again by 5%.

- Page 41 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Position Histogram Diagnosis that provides the user with a history of the positions traveled by the valve during its operating period. It enables the visualization of a graph (via DTM or another configurator that offers graphs) with the percentages of time in each of the 5% ranges of the valve travel.

- Page 42 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ If the system is double acting, the only graphic change will be in the pressure curve, which will portray the difference between OUT2 and OUT1 output pressures, resulting in a more horizontal curve. However, the hysteresis and settling characteristics will be observed in the same way.

- Page 43 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ In the graphs of the following figures, we have the example of a curve in a double acting system after the Partial Stroke Test for opening a safety valve (PST Type = 'Opening').

- Page 44 (Rate Open/Close) to the highest performing (fastest) possible values. Enable/Disable/Reset The VVP10 Hart positioner offers the user the option to enable diagnostics individually, as well as restart them for new comparisons. The table below shows the functions available for each of the diagnoses.

- Page 45 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ OTHER PREDICTIVE DIAGNOSTICS Input Pressure WARNING This diagnostic will only be available for models that have pressure sensors installed. Check the Product Order Code for this feature (section 6.2).

- Page 46 Order Code for this feature (section 6.2). The VVP10 HART has an auxiliary function for monitoring discrete input signals (superior and inferior), such as valve end switches, for example. With the digital input function enabled in the Dig Input Mode parameter, the Dig Input Low and Dig Input High alarms will be activated when the terminal inputs DI1 and DI2 are activated, respectively.

-

Page 47: Fdt/Dtm Configuration

PACTware is property of PACTware Consortium and can be found on http://www.vega.com/en/home_br/Downloads. The following figures exemplify DTM configuration screens for VVP10 HART using Vivace’s VCI10-UH interface and ® PACTware . Note that the directory with the menus available for the DTM (OnLine Parameterize) follows the configuration tree format shown in item 3.6 (figure 3.7). -

Page 48: Maintenance

4 MAINTENANCE VVP10 HART Valve Positioner, like all Vivace products, is rigorously evaluated and inspected before being shipped to the customer. However, in case of a malfunction, diagnosis can be made to verify that the problem is located in the sensor installation, in the configuration of the equipment or if it is a problem of the positioner. - Page 49 4 Check for the existence of three insulating rings under the analog plate, in versions with pressure sensors. Each has two o-rings to seal the pressures around the sensors on the analog board. Figure 4.2 shows optional remote sensor components. Figure 4.2 – Exploded view of VVP10 HART remote sensor.

-

Page 50: Spare Parts

INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ 4.2. SPARE PARTS All the spare parts available for VVP10 HART can be bought directly from Vivace Process Instruments. Those parts are listed on table 4.1. VVP10 HART – SPARE PARTS LIST DESCRIPTION REF –... -

Page 51: Certification

The VVP10 is designed to meet national and international intrinsic safety standards and explosion proof, and has Inmetro certificate, whose identification plates are displayed below. Figure 5.1 – Ex ia plate for VVP10 HART. Figure 5.2 – Ex d plate for VVP10 HART. -

Page 52: Technical Characteristics

INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ 6 TECHNICAL CHARACTERISTICS 6.1. IDENTIFICATION VVP10 HART has an identification plate affixed to the top of the housing, specifying the model and serial number, as shown in figure 6.1. *For plate models with specific certification, see section 5. -

Page 53: Technical Specification

VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ 6.3. TECHNICAL SPECIFICATION The following table shows the technical specifications for VVP10 HART. Performance Linearity: < ±0.1% Full Scale (using user table) Resolution: < 0.1% Full Scale Repetibility:< 0.1% Full Scale Hysteresis: <... -

Page 54: Warranty

VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ 7 WARRANTY 7.1. GENERAL CONDITIONS Vivace ensures its equipment from any defect on manufacturing or component quality. Problems caused by misuse, improper installation or exposure to extreme conditions are not covered by this warranty. -

Page 55: Appendix I - Information For Classified Areas

(for example, from HART/4-20mA In explosive atmospheres with intrinsic or non -light to Profibus-PA, or vice versa, as the Vivace product line safety requirements, always note the circuit input offers this possibility). In this case, it will be necessary parameters and applicable installation procedures. - Page 56 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ Explosion Proof/Flame Proof Applications Attention The certificate number is finalized by the letter “X” to only certified explosion-proof/flameproof indicate that: connectors, adapters and cable glands. The electrical...

-

Page 57: Appendix Ii - Technical Analysis Request

VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________ APPENDIX II – TECHNICAL ANALYSIS REQUEST FSAT Technical Analysis Request Form Company: Unit/Department: Shipping Invoice nº: Standard Warranty: ( )Yes ( )No Extended Warranty: ( )Yes ( )No Buying Invoice nº:... - Page 58 VVP10 HART HART ® VALVE POSITIONER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL ______________________________________________________________________________________________________________________________...

Need help?

Do you have a question about the VVP10-H and is the answer not in the manual?

Questions and answers