Summary of Contents for matev FPS-MZW-NH

- Page 1 -MZW-NH Boomer MJ 2021 35/40 45/50/55 Operating Manual matev GmbH Modifications and errors excepted! Nürnbergerstr. 50 Version: 6/29/2021 D-90579 Langenzenn Reference number: BA-FPS-MZW-33001 Phone: +49 (0) 9101 90870...

- Page 2 Order numbers Order no. Designation 131 9043 Engine PTO shaft 1000 rpm CW NH Boomer 35/40 131 9044 Engine PTO shaft 1000 rpm CCW NH Boomer 35/40 131 9045 Engine PTO shaft 2000 rpm CW NH Boomer 35/40 131 9046 Engine PTO shaft 2000 rpm CCW NH Boomer 35/40 131 9053 Engine PTO shaft 1000 rpm CW NH Boomer 45/50/55...

-

Page 3: Table Of Contents

Table of contents Table of contents ........................3 1 Introduction ........................5 2 About this operating manual ....................6 3 Technical data ........................7 Engine PTO shaft NH Boomer 35/40 ................ 7 Engine PTO shaft NH Boomer 45/50/55 ..............7 4 General safety notices ....................... - Page 4 Front PTO shaft NH Boomer 35/40 ................. 20 Ground clearance NH Boomer 45/50/55 ..............21 7 Maintenance ........................22 General information about safety during maintenance (oil change / oil filter change) 8 Repair ..........................26 9 Disposal ........................... 27 10 Guarantee ........................28 11 List of illustrations ......................

-

Page 5: Introduction

1 Introduction Welcome to the matev family and thank you for purchasing a product from matev GmbH; we appreciate your trust. You have acquired a quality product, if contrary to expectations you should have problems with the implement, contact your responsible sales partner. -

Page 6: About This Operating Manual

2 About this operating manual Read this entire manual carefully before operating this machine for the first time. Keep this manual where it is easily accessible. This will enable you to refer to important infor- mation and handling instructions as needed. When the machine is delivered the owner receives instruction regarding operation and maintenance of the machine from his sales partner. -

Page 7: Technical Data

Technical data Engine PTO shaft NH Boomer 35/40 1-3/8” – 6-piece Output shaft PTO output 1000 min CW/CCW, 2000 min CW/CCW Ground clearance (see Fig.9) approx. 200mm Table 1: Technical data Engine PTO shaft NH Boomer 35/40 Engine PTO shaft NH Boomer 45/50/55 Table 2: Technical data NH Engine PTO shaft NH Boomer 45/50/55 1-3/8”... -

Page 8: General Safety Notices

4 General safety notices This chapter summarizes regulations and information that must be observed in connection with machines. Depiction of safety information The safety information in the text is combined with pictograms and signal words which to- gether indicate the severity of the expected risk Danger! Hazardous situations that will result in serious injuries or death. -

Page 9: Instructions For The Owner

Instructions for the owner Qualifications of assembly and maintenance personnel Assembly and maintenance of safety-related components may be carried out only by person- nel with the following qualifications: • They must have completed specialized training as an agricultural machinery me- chanic, motor vehicle mechanic, etc. -

Page 10: Warning Pictograms

Warning pictograms Warning pictograms point out dangers that cannot be counteracted by means of safety measures. Strict observance of the pictograms is necessary to prevent severe injuries or death. Danger! Missing warning notices must be replaced immediately. Do not operate the machine if warning notices are missing. You can order warning pictograms with the spare parts numbers specified in chapter 4.6.2. - Page 11 Engine PTO shaft speed 1000 rpm CW (clockwise)! The specified direction of rotation always refers to the view of the end of the PTO shaft from the front (see Fig.1). The implement must be aligned accordingly! Engine PTO shaft speed 1000 rpm CCW (counter clockwise)! The specified direction of rotation always refers to the view of the end of the PTO shaft from the front (see Fig.1).

-

Page 12: Supplemental Provisions

Supplemental provisions • Ensure that the speed and the direction of rotation of the engine PTO shaft are suitable for driving the implement before coupling an implement to the tractor. • Always switch off the engine PTO shaft and wait until the PTO shaft is no longer turning when you leave the tractor or work on the connected implement. - Page 13 Warning pictograms on the machine Warning pictograms “Drive shaft” Order no.: V0 002 930 Fig. 3: Warning pictogram: Drive shaft Info on oil change and oil type Order no.: V0 003 185 Fig. 4: Warning pictogram: Oil change Page 13...

- Page 14 PTO shaft speed: Order no.: V0 003 196 Order no.: V0 003 186 Order no.: V0 003 383 Order no.: V0 003 194 Fig. 5: Warning pictogram: Engine PTO shaft direction of rotation Caution! Tighten screws Order no.: V0 002 965 Fig.

- Page 15 Position of type plate Matev type plate Engine PTO shaft Fig. 7: Position of type plate Type: Gearbox type Year of manufacture: Production year No.: Serial number Fig. 8: Explanation of type plate Page 15...

-

Page 16: Equipment

5 Equipment Conversion kit CAT. 0 Basic machine, hydraulic kit Extension kit cat. 1 Lower link, upper link Coupling support cat. 1 Coupling support Front power system basic machine Basic unit, hydraulic system, frame trussing Page 16... -

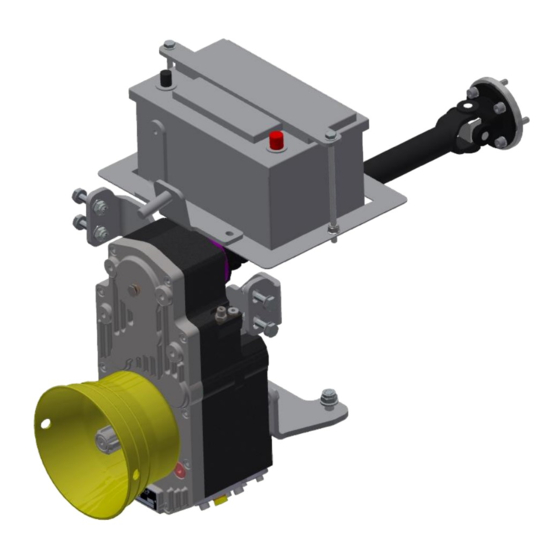

Page 17: Front Pto Shaft

Front PTO shaft Drive shaft, mount, universal joint shaft, protective pot Hydraulic extension kit: BG2-TF and BG3 available BG2-TF couplings, clip covers, hydraulic hoses, holders – for BG2-TF; BG3 couplings, clip covers, hydraulic hoses, holders – for BG3 Pressure accumulator Pressure accumulator, bulkhead fitting –... -

Page 18: Hose Clamp Mount With Bracket For Front Loader

Hose clamp mount with bracket for front loader Hose clamp, mount Hose clamp mount without bracket for front loader Hose clamp, mount Page 18... -

Page 19: Operation Of The Engine Pto Shaft

Switch off the tractor, remove the ignition key and set the hand brake before mounting or dismounting the engine PTO shaft. Install the engine PTO shaft as described in the assembly manual provided. If they are not available to you, please contact matev GmbH. Preparatory measures •... -

Page 20: Front Pto Shaft Nh Boomer 35/40

Front PTO shaft NH Boomer 35/40 Clearance between the ground and the lowest point on the engine PTO shaft gearbox (approx. 200mm) Ground Fig. 9: Ground clearance engine PTO shaft NH Boomer 35/40 The ground clearances are measured with front tires 210/75-15 (28x8.5-15). -

Page 21: Ground Clearance Nh Boomer 45/50/55

Ground clearance NH Boomer 45/50/55 Clearance between the ground and the lowest point on the engine PTO shaft gearbox (approx. 260mm) Ground Fig. 10: Ground clearance engine PTO shaft NH Boomer 45/50/55 The ground clearances are measured with front tires 12-16.5 RG400 N.H.S. -

Page 22: Maintenance

7 Maintenance General information about safety during maintenance (oil change / oil filter change) Switch off the tractor, remove the ignition key and set the hand brake before working on the engine PTO shaft. Repairs to components under tension or pressure (springs, accumulators) require sufficient knowledge and proper tools, and must always be carried out by specialists. - Page 23 To ensure serviceability and compliance with occupational safety requirements, the following tasks must be carried out after each use. • Cleaning the machine. • Check to ensure that all safety notices and safety devices are complete and function- ing. • After 5 to 10 operating hours with a new engine PTO shaft, or after a repair, check to ensure that all bolts are still tightened to the correct torque.

- Page 24 Oil drain plug (M18x1.5) Fig. 12: Position of drain plug Procedure for changing oil 1. Park the tractor on a level surface and shut off the engine. Remove the ignition key and secure the tractor. 2. Place a drip pan under the engine PTO shaft. 3.

- Page 25 Information about gearbox oil Gearbox Oil type Oil quantity type 10 W 30 STOU 0.7l (without coolant) Table 4: Gearbox oil info table With oil fill nozzle: The gearbox must be filled with oil to the lower edge of the oil fill hole. Procedure for changing the oil filter 1.

-

Page 26: Repair

Phone: +49 (0) 9101 9087-0 www.matev.eu info@matev.eu Please note the following information as well: • All repairs must be carried out by a specialized company. • Use only original matev replacement parts. • Modifications to the machine are prohibited. Page 26... -

Page 27: Disposal

The implement must be disposed of in accordance with the applicable regulations of the mu- nicipality or the country. Take the parts to the collection points for residual waste, special waste, or recycle them de- pending on material. matev GmbH does not provide any disposal services. Page 27... -

Page 28: Guarantee

10 Guarantee The general terms and conditions of matev GmbH apply. Page 28... -

Page 29: List Of Illustrations

11 List of illustrations Fig. 1: Definition of orientation and direction of rotation ................6 Fig. 2: Engine PTO shaft safety device ....................12 Fig. 3: Warning pictogram: Drive shaft ....................13 Fig. 4: Warning pictogram: Oil change ....................13 Fig. 5: Warning pictogram: Engine PTO shaft direction of rotation ............14 Fig. -

Page 30: List Of Tables

12 List of tables Table 1: Technical data Engine PTO shaft NH Boomer 35/40 ..............7 Table 2: Technical data NH Engine PTO shaft NH Boomer 45/50/55 ............. 7 Table 3: Screw tightening torques (property class 8.8) ................23 Table 4: Gearbox oil info table .......................25 Page 30... - Page 31 Page 31...

-

Page 32: Ec Declaration Of Conformity

The manufacturer matev GmbH Nürnberger Str. 50 90579 Langenzenn declares that the machine FPS-MZW-NH Boomer 35/40/45/50/55 complies with the provisions of Directive 2006/42/EC and with the national statutory regulations for its implementation. The signer is authorized to compile the technical documents.

Need help?

Do you have a question about the FPS-MZW-NH and is the answer not in the manual?

Questions and answers