Summary of Contents for GENOMICA Autoclart Plus

- Page 1 ® autoclart plus – User Manual USER MANUAL autoclart® plus User Manual Version 3, February 2017...

- Page 2 CLART, CLART-Strip and SAICLART are brands registered by GENOMICA. For greater detail in relation to the information set forth in this manual please access the following website: www.genomica.com GENOMICA, S.A.U. Parque Empresarial Alvento, Edificio B Calle Vía de los Poblados, 1 – 1ª planta 28033 Madrid, Spain www.genomica.com...

-

Page 3: Table Of Contents

1. TABLE OF CONTENTS 1. TABLE OF CONTENTS ....................3 2. PRINCIPLE OF THE ASSAY ..................... 6 3. INTENDED PURPOSE ....................8 4. USE ........................... 8 5. CLASSIFICATION ......................9 6. PRODUCT TRADE NAME AND REFERENCES ..............9 7. DESCRIPTION ......................10 8. - Page 4 13. PRECAUTIONS OF USE ....................21 14. PREPARATION OF THE FACILITY PRIOR TO INSTALLATION ..........23 15. INSTALLATION ......................24 16. TURNING THE EQUIPMENT ON AND OFF ..............26 16.1. ON ......................... 26 16.2. OFF ........................ 27 17. START OF THE ANALYSIS .................... 28 17.1.

- Page 5 22.5. BACK-UP / EXPORT ..................58 22.6. SERVICE ......................59 DECONTAMINATION PROGRAM ..................60 CLEANING PROGRAM ......................61 26. MAINTENANCE / CALIBRATION .................. 62 27. CLEANING ....................... 62 28. CARING FOR THE EQUIPMENT AFTER USE ..............64 29. FAQ ........................65 29.1 UPDATING AND INSTALLATION OF SOFTWARE ............

-

Page 6: Principle Of The Assay

PRINCIPLE OF THE ASSAY autoclart® plus has been developed for the automation of both viewing and reading and interpreting the results of the in vitro diagnostic kit manufactured by GENOMICA. The technique is based on: The viewing of a specific reaction through the precipitation of an insoluble product in microarray areas in which the amplified products have undergone hybridization. - Page 7 The analysis of the microarray image is conducted using the SAICLART® software developed by GENOMICA for the interpretation of microarrays. The analysis of the image is fully automatic, preventing subjectivity and the interaction of the user, thereby ensuring accurate results in a rapid and repeatable manner.

-

Page 8: Intended Purpose

3. INTENDED PURPOSE The equipment will be used exclusively by personnel from accredited laboratories and using GENOMICA S.A.U. in vitro diagnostic kits, illustrated on the website www.genomica.com Any use other than that specified may undermine the performance of the equipment. -

Page 9: Classification

1662/2000 of 29 September 2000, and is classified under “other products” in Appendix III of the Directive. Moreover, GENOMICA S.A.U. declares that the autoclart® plus equipment has been manufactured in accordance with the following safety and quality standards and requirements in force (EN ISO 13485, EN 61010-2-101 and EN 61326-2-6). -

Page 10: Description

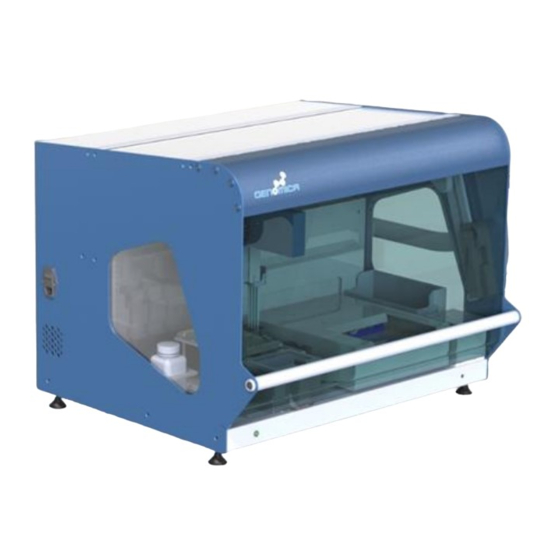

7. DESCRIPTION Figure 1. autoclart® plus autoclart® plus is a fully automated system for processing plate format assays. The tool is designed for processing the sample, the addition of reagents, the removal of liquids, heating, cooling, agitating the incubation plate and scanning the plate at the end of the assay. -

Page 11: Components / Consumables

The autoclart® plus is equipped with a computer which operates by means of a touch screen and an interface designed specifically for the equipment. The user can use the touch screen to view the number of samples and the assay to be executed, whereby it is possible to process a minimum of 4 and a maximum of 96 samples per assay. -

Page 12: Consumables

The instructions for the assembly of the different components of the equipment are set forth in the table below. Remember that most of the components need to be placed in a specific position. Place the holder on the markers in the position Distilled water bottle marked 1. -

Page 13: Accessories

Take particular care to ensure the USB device used both for updating software and exporting data is not infected with a virus. GENOMICA will not be held liable for removing a virus which has infected the system as a result of improper use by the user. - Page 14 Used to connect the equipment to the power mains with a plug. autoclart® plus has been designed for use with GENOMICA diagnostic kits, and , as such, no other type of tube, vial or material should be used. The use of autoclart®...

-

Page 15: Characteristics

10. CHARACTERISTICS. Type of instrument Table equipment Processing capacity 4 to 96 samples per assay Processing time Normally less than 3 hours for 96 samples Temperature control. PID control 3 L to 100 L Processing volume Piston pumps: 3-10 µL ±10% Dispensing and tolerance system ... -

Page 16: Unpacking, Storage And Packing

The use of gloves is recommended when handling the equipment as some of the components of the container may have sharp edges. On receiving the equipment check the packaging is not damaged; if it is, please notify GENOMICA immediately. autoclart® plus User Manual Version 3, February 2017... - Page 17 Follow the steps below to open the packaging: Place the box in a vertical position to open it. Open the box and remove the user manual; continue in accordance with the instructions set forth in the manual. Remove the flaps and the lid. Pull off the outer wooden cover and remove the protective bubble paper.

-

Page 18: Storing The Packaging

11.2. STORING THE PACKAGING. Fold the wooden box in order to store the packaging correctly. Keep the original packaging materials! Equipment returned for repair should be dispatched in the original packaging material in order to protect it from damage during transportation. 11.3. -

Page 19: Packing

11.5. PACKING. The safety screw and the three new fastening straps must be in place when transporting the equipment. Follow the respective instructions below: Turn off the equipment completely. Unplug the equipment from all power sources. Place the safety screw in its housing located on the lower right-hand side in the rear of the working area and screw it in. - Page 20 Altitude Up to 2000 m. Temperature Ambient temperature: 18 °C – 24 °C. Maximum relative humidity of 80% for temperatures of up to 31 °C Humidity decreasing linearly to around 50% for 40 °C. Network voltage 100 to 240 VAC – 5A 50/60 Hz with variations of up to ± 10 %. Transport and From 5 °C to 50 °C.

-

Page 21: Precautions Of Use

13. PRECAUTIONS OF USE Please read the following warnings carefully. All the precautions contained on this page should be strictly complied with in order to prevent harm to individuals and/or damage to the equipment. In the event of a malfunction, contact the technical support service and do not attempt to deal with the problem using your own means. - Page 22 Do not touch any of the equipment´s electronic components. In the event of breakage or failure contact the GENOMICA technical support service. Always unplug autoclart® plus when performing work involving the use of liquids or when conducting maintenance on the electrical system or the equipment´s internal parts.

-

Page 23: Preparation Of The Facility Prior To Installation

Gloves should always be worn when handling potentially infectious substances (such as human samples and reagents) and which may come into contact with the skin. The user should take care not to contaminate the inside or outside of the equipment with biological samples. PREPARATION OF THE FACILITY PRIOR TO INSTALLATION Follow the detailed instructions below carefully for the correct preparation of the facility prior to installation:... -

Page 24: Installation

Before connecting the equipment to the power mains, check that the voltage is 110-230 V (AC) and 50/60 Hz and that the system is earthed. Do not install autoclart® plus near a source of light, intense heat or external vibrations. Never touch the switches with wet hands. - Page 25 15.1. INSTALLATION OF THE TOUCH SCREEN Follow the steps detailed below carefully: 1. Check the device is on a level surface. 2. Fasten the arm of the screen by tightening the rear clamp using the M6 x 80 screw. 3. Insert the M4 screw on the other side to limit the inclination of the touch screen.

-

Page 26: Turning The Equipment On And Off

TURNING THE EQUIPMENT ON AND OFF 16.1. ON Follow the steps detailed below carefully: Connect the power cable to the panel on the side of the equipment and plug it into the mains (connecting the equipment to the mains automatically ensures the connection to earth). -

Page 27: Off

Figure 6. Starting up the equipment The main screen will appear once the equipment start up has concluded. 16.2. OFF Remove the microplate from the equipment if you have not done so already. Remove the deionized water bottle from its bracket. Remove the waste troughs (liquids and solids) and dispose of the waste in accordance with local and state provisions. -

Page 28: Start Of The Analysis

Figure 7. The main menu. The OFF button is highlighted in red. We recommend disconnecting the equipment completely for long periods of inactivity. 17. START OF THE ANALYSIS The reading and analysis of a sample is a simple sequential process consisting of a series of menus from which to select the different options involved in the process. - Page 29 Figure 9. Diagram of a microplate on the “New Analysis” menu. This is the application´s most important menu, as it enables the user to establish: The number of samples to be analysed. The assay reference number. The sample reference number. autoclart®...

-

Page 30: Entry Of The Type Of Assay

All the CS will appear in light-grey in the microplate diagram, indicating that the assay has not been selected. Then, read the specific bar code for the test provided by GENOMICA and the CS in which the assay has been defined will automatically change to its specific colour. -

Page 31: Entry Of The Sample References

Figure 11. Selection of the bands to be processed Figure 12. Manual entry of the assay references. N.B: Remember that if you intend to conduct the same assay in all the bands, press “AUTO SEL” after selecting the assay. The symbol “A” will appear alongside the assay selected. 17.2. - Page 32 In the event no specific reference is assigned to the sample, the software will assign each sample a consecutive number from 1 to 96, starting with the sample located in position 1A. Automatic entry of sample references A bar code reader needs to be connected to autoclart® plus in order to enter the sample references automatically.

-

Page 33: Work List

Figure 14. Entry of samples. Positions sub-menu. Automatic entry of sample references from files To enter references automatically from files, first contact the GENOMICA product specialist. The work list will enable us to check all the data entered up to now is 17.3. -

Page 34: Analysis Settings

Figure 14. Work list 17.4. ANALYSIS SETTINGS. The equipment can be used in three different settings: To add samples automatically. To add samples manually. For reading only. Select the desired option on the touch screen. Figure 15. Analysis settings 18. - Page 35 STEP 1/11: LOAD COMPLETE NEW TIP RACKS Figure 16. Loading tip racks. Place the tip racks in their holder, taking into account there is only one possible position. 1 ml tip racks at the back of the holder (red rack). ...

- Page 36 Step 2/11: LOADING THE MICROPLATE Figure 18. Loading the Microplate Raise the microplate holder cover and insert the plate with as many CS as required for the analysis of the samples, as illustrated in the image on the right. Ensure position A1 is in the top left corner Figure 19.

- Page 37 Step 3/11: CHECK THE USED TIP TROUGH IS IN PLACE AND EMPTY. Figure 21. Empty tip trough Step 4/11: CHECK THE WASTE TROUGH IS IN PLACE AND EMPTY. Figure 22. Empty waste trough Step 5/11: CONNECT THE TUBE TO THE WASTE TROUGH.

- Page 38 Place the waste trough in its position. Attach the connecting tube to the waste trough and put on the cover as illustrated in the image on the right. Figure 23 b. Connecting the tube to the waste trough, as highlighted in yellow.

- Page 39 Fill the bottle with 250 ml of distilled water and place it in its holder. Take into account that the consumption of water is the same regardless of the number of samples processed. The bottle should be refilled prior to each assay.

- Page 40 Take note that the viewing reagent troughs only fit in the correct position. Troughs Troughs Figure 26. Position of the viewing reagent troughs Step 7/11. PLACE SPECIFIED VOLUME OF WASH BUFFER IN THE TANK. Figure 27. Wash buffer volume. autoclart® plus User Manual Version 3, February 2017...

- Page 41 Step 8/11. PLACE SPECIFIED VOLUME OF HYBRIDISATION SOLUTION IN THE TANK. Figure 28. Volume of hybridisation solution. Step 9/11 – PLACE THE SPECIFIED VOLUME OF DILUTED CONJUGATE IN THE TANK. Figure 29. Volume of conjugate Step 10/11. PLACE SPECIFIED VOLUME OF DEVELOPER IN THE TANK. Figure 30.

- Page 42 Step 11/11 – LOAD THE AMPLIFICATION PLATE. Figure 30 a. Load PCR plate. Open the cover and place the PCR plate in the holder. Check the PCR plate is in the correct position and position A1 is in the top left corner and press it firmly downwards.

-

Page 43: Analysis Adding The Sample Manually

Once all these steps have been completed, close the cover to the equipment and press the continue button (white arrow) to start the analysis. The screen will show the estimated time of the end of the assay, the processing phase (which will change throughout the assay) and the warning not to open the door to the equipment. - Page 44 Check the following list of steps (as explained in item 2 of the previous section) on the touch screen. Press the blue arrow (“next step”) to move on to the next step. Figure 32. Manual addition of the samples. Once all these steps have been completed, close the cover to the equipment and press the continue button (white arrow) to start the analysis.

-

Page 45: Reading Only Analysis

READING ONLY ANALYSIS Select the “reading” option. Figure 34. Analysis reading settings. Load the microplate with the desired number of CS to be read and turn the lock. Close the equipment and press the white arrow to continue. READING When the test has been concluded the equipment will automatically read the microplate for the purpose of analysis. -

Page 46: Results

Figure 35. Reading progress bar Figure 36. End of the reading When the progress bar reaches 100% the test has been completed and the results can be viewed, exported and/or printed out. 22. RESULTS 22.1. VIEWING RESULTS Press “report” to view the results of the complete run. The work list will reappear, which will now include the information on the results. - Page 47 In order to view the results in an individual manner press the corresponding will in the image of the microplate. This will access the specific report on the sample. Figure 37. Individual results. The following information is available on this sub-menu: data: Provides access to the numeric, raw and standarised values obtained from the analysis of the arrays.

- Page 48 Export: Enables the user to export the information to an external server, LIMS or mass data storage system established as an export route beforehand. 22.2. OTHER OPTIONS. The following options appear on the results menu: Export: Enables the user to export the complete assay, reports and results to an external server, LIMS or mass data storage system established as an export route beforehand.

- Page 49 Reports: Once the analysis of the samples has ended autoclart® plus will generate two types of report. A report with the results of the complete assay (work list) and individual reports for each of the samples (see item 22.1.). The work list includes the following information: Date and time of the process Position of the sample in the microplate The code of the analysis conducted...

-

Page 50: Reanalysis Of The Sample

23. REANALYSIS OF THE SAMPLE If, after having analysed the plate, a sample is colored red, this means the grid could not be aligned automatically by the software. However, the user may reanalyse the sample, or in other words, align the grid manually. In order to reanalyse a sample press the same and the “Reanalysis”... - Page 51 Figure 43. Procedure for the manual alignment of the grid. To put the markers in place, simply press on them on the screen and drag them into their final position. Once the markers are in position the software provides a general view of how the grid would fit on the array.

- Page 52 Aligning the grid manually implies the intervention of the user in the results, which will be registered in the final report generated in the form of the following message. The image has been reanalysed by the user. Figure 45. Message on the manual alignment of the samples. autoclart®...

-

Page 53: Main Menu Records

24. MAIN MENU RECORDS The “records” option on the main menu provides a results search tool. Figure 46. The main menu. Access to assay records This results search tool can be used for an analysis or run or a sample. 22.1. - Page 54 Two dates established by the user, one for the start and one for the end of the search. Search parameter: There are three different search parameters to choose from: run ID, assay and plate. Figure 48. Search parameters. Once the parameters have been established, a list will appear with all the assays which comply with the search parameters defined.

-

Page 55: Search By Sample

22.2. SEARCH BY SAMPLE. Figure 50. Search by sample. On selecting “Search by sample” a sub-menu will appear as in the “Search by run” procedure, which will enable the user to set the parameters by date, run ID, assay ID, plate ID, and particularly, sample ID. -

Page 56: Installing / Updating A Program

Figure 51. Settings. Press the “Settings” option to access a sub-menu with a number of options for configuring autoclart® plus. Figure 52. Settings sub-menu 22.3. INSTALLING / UPDATING A PROGRAM. Select the “install / update” option to access a sub-menu containing a list of all the programs currently installed in the equipment and their version. -

Page 57: System

Select the .Zip file provided by GENOMICA to install the program. The installation is automatic. Figure 53. Assay install / update menu. 22.4. SYSTEM The “System” option provides the user with information on the software, hardware and the serial number of the equipment. -

Page 58: Back-Up / Export

Export: Select the export route. Pressing the “…” symbol will access a browser tab from which to select the external memory or LIMS network you wish to use to export results. Back-up: Select the back-up route. Pressing the “…” symbol will access a browser tab from which to select the external memory you wish to use for the back-up of the assays stored in the equipment (see item 24.3). -

Page 59: Service

Figure 55. The back-up process. 22.6. SERVICE Press “Service” in the settings menu where you will find three protocols for the maintenance of the equipment. Decontamination: This program decontaminates the equipment using UV light. Cleaning: This program cleans the equipment´s tubing and pump system. Technical Assistance: This menu is for the exclusive use of specialised technical assistance personnel. -

Page 60: Decontamination Program

DECONTAMINATION PROGRAM Select the “decontamination” program on the “services” menu. Then complete the following 6 steps displayed on the touch screen: 1. Put the empty tip holders in place. 2. Load the empty used tip trough. 3. Put the empty sand dry waste trough in place. 4. -

Page 61: Cleaning Program

Figure 57. The decontamination process. An audio signal will indicate the end of the decontamination process. CLEANING PROGRAM Select the “cleaning” program on the “services” menu and follow the instructions which appear on the touch screen. 1. Fill the bottle with disinfectant: Fill the extra bottle with bleach diluted at 4% or another disinfectant whenever no foam is formed. -

Page 62: Maintenance / Calibration

26. MAINTENANCE / CALIBRATION Both the maintenance and the calibration of the equipment should be conducted yearly by qualified personnel. In the event of an incident contact your GENOMICA technical assistance department using the following email address: genomica.sat@genomica.com your distributor. - Page 63 In the event of doubt in relation to the compatibility of the decontamination or cleaning agents, please contact your local agent or the GENOMICA technical assistance department. autoclart® plus User Manual...

-

Page 64: Caring For The Equipment After Use

N.B: With regard to recycling, please contact GENOMICA or the supplier of the equipment for instructions on how to return equipment whose life cycle has ended for appropriate disposal. -

Page 65: Faq

Take particular care to ensure USB device used both for updating software and exporting data is not infected with a virus. GENOMICA will not be held liable for removing a virus which has infected the system as a result of improper use by the user. -

Page 66: Technical Assistance Service

Remember to quote these messages in your request for assistance. 30. TECHNICAL ASSISTANCE SERVICE Remember that only GENOMICA SAU technical service personnel or associates may conduct authorised repairs and services. You may contact the GENOMICA, S.A.U. technical assistance department on:... -

Page 67: Appendix A. Table Of Frequent Errors And Respective Solutions

APPENDIX A. TABLE OF FREQUENT ERRORS AND RESPECTIVE SOLUTIONS N.B: the correct working order of this equipment should be checked after all maintenance, servicing or repair operations. Dealing with simple problems Visual inspection A comprehensive visual inspection of the equipment prior to using it will often reveal real or potential problems. - Page 68 The specific functions of the equipment should be checked during the start-up process. The table below provides details of the start-up process: Step Action Comment Possible cause Consequence Solution Pass Master Controller Check BUS cables Corrupt data constant load, check Immediately if Check modules modules and the...

- Page 69 Error codes The equipment features an error management mechanism with parameters which can be monitored in real time. In the event of an error the device will stop immediately and an error code will appear on the touch screen. The error codes are stored in a register. ALL CASES of error codes (S) should be reported to the service provider immediately for analysis, stating in which phase of the assay the error occurred.

-

Page 70: Appendix B. Declaration Of Ce Conformity

Classification Class A. Rule 5. Appendix VII. Genomica, S.A.U. hereby declares that the product autoclart ®Plus complies with the requirements of Directive 98/79/CE of 27 October on health products for in vitro diagnostic, registered in Spanish law under Royal Decree 1662/2000 of 29 September 2000. -

Page 71: Appendix C. Abbreviations Used

APPENDIX C. ABBREVIATIONS USED CS: CLART-strip® Fig: Figure PCR: Polymerase Chain Reaction PDF: Portable Document Format generated by Adobe. LIMS: Laboratory Information Management System USB: Universal Serial Bus autoclart® plus User Manual Version 3, February 2017... -

Page 72: Appendix D. Warning Symbols And Signs

APPENDIX D. WARNING SYMBOLS AND SIGNS. This symbol indicates the danger of harm being caused to both the operator and the robot. This symbol warns of the possible damage or harm the operator may suffer in the event the normal robot function is interrupted. This symbol warns of the danger of possible damage or harm caused by the high voltage of the equipment. - Page 73 CE marking Fuses 2 x T4H250 V (5 x 20 mm) Electrical and electronic products, do not mix with standard waste Colour Standard Description Location Symbol Symbol and Identifying label on Alternate Current Border: IEC 60417 –5032 Black equipment Symbol switch with Border:...

-

Page 74: Appendix E. Decontamination Certificate

APPENDIX E. DECONTAMINATION CERTIFICATE. Decontamination Certificate This equipment: Model: ____________ Serial number: ____________ Has not been in contact with biological samples of an infectious nature. Date: Signature: autoclart® plus User Manual Version 3, February 2017...

Need help?

Do you have a question about the Autoclart Plus and is the answer not in the manual?

Questions and answers