Summary of Contents for SABROE ChillPAC

- Page 1 Operating manual ChillPAC and LP ChillPAC Mk 3 Chiller unit with reciprocating compressor...

- Page 3 Manual for ChillPAC Mk 3 with reciprocating compressor The Sabroe chiller unit can be configured with various types of equipment depending on its function and requirements. Some of the equipment may be described in this manual even though it is not featured on your particular unit.

- Page 4 Economiser Desuperheater Subcooler Other Pressure loss, if any, from safety valve to customer connection (based on design pressure) [bar] _____________ Safety valve type: Back-pressure dependent Back-pressure independent Operating manual - ChillPAC and LP ChillPAC Mk 3 4/68 010823 en 2021.06...

-

Page 5: Table Of Contents

2.3.13 Emergency stop ..............26 Design and function ................27 Unit design ................27 3.1.1 The ChillPAC and LP ChillPAC unit in general ....... 27 3.1.2 Components on a ChillPAC (water-cooled condenser) ................. 28 3.1.3 Components on an LP ChillPAC (external condenser) ... 29 Main components .............. - Page 6 Restarting chiller unit after alarm stop (shutdown) ....47 During operation ................ 47 5.4.1 Checks to be performed during operation ......47 5.4.2 Monitoring of operation ............47 Operating manual - ChillPAC and LP ChillPAC Mk 3 6/68 010823 en 2021.06...

- Page 7 Spare parts list for CVUA 1201 oil recovery pot ......56 Declaration of conformity ............57 Set-up guide — AKS 4100 280 mm for ammonia heat pump application ..........58 Index ....................66 Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 7/68...

-

Page 8: Introduction

‘Requirements for competent persons’ section has been added. • ‘F-gas regulation’ section has been updated. • Updated version of declaration of conformity for unit. • And more. Operating manual - ChillPAC and LP ChillPAC Mk 3 8/68 010823 en 2021.06... -

Page 9: Models Covered

The ChillPAC Mk 3 manual concept covers two types of chillers: ChillPAC Mk 3: Liquid refrigeration unit equipped with water-cooled condenser LP ChillPAC Mk 3: Liquid refrigeration unit without condenser. It must be connected to an external condenser. For further information, see www.sabroe.com... -

Page 10: Definition Of Safety Precautions Used In This Manual

Assign only competent personnel instructed in safety and all machine functions to operate or service the compressor/unit according to EN 13313. • Operators and maintenance personnel must carefully read, understand and fully comply with all alarms and instructions. Operating manual - ChillPAC and LP ChillPAC Mk 3 10/68 010823 en 2021.06... -

Page 11: Safety

To evacuate the refrigeration plant of air and moisture. • To put the refrigeration plant under air pressure in view of a pressure testing. • As an air compressor. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 11/68... -

Page 12: Application Of Combustion Engines

All equipment from Johnson Controls Denmark can be identified by one or several name plates posi- tioned as illustrated in the following drawing: Fig. 1: Identification of equipment Name plate for Pos. no. Compressor Evaporator/Cascade cooler Condenser/Receiver Float housing Unit/pipe system Operating manual - ChillPAC and LP ChillPAC Mk 3 12/68 010823 en 2021.06... -

Page 13: Unit/Pipe System Name Plate

Сторона НД Сторона ВД Давление Категория Допустимое давление макс бар Давление ислытания бар Допустимая темп мин/макс °С Fig. 4: Name plate for unit with EurAsian Conformity mark (EAC) Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 13/68... - Page 14 The EurAsian Conformity mark (EAC) indicates that the unit is in com- pliance with all relevant technical regulations of the Eurasian Customs Union. Note: Main supply voltage can be found on the motor and/or electrical panel name plate. Operating manual - ChillPAC and LP ChillPAC Mk 3 14/68 010823 en 2021.06...

-

Page 15: Compressor Name Plates

Allowable pressure Max. psig Test pressure psig Fig. 7: Name plate for compressor with EurAsian Conformity Fig. 8: Name plate for compressor to the USA mark (EAC) Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 15/68... - Page 16 EC ATEX directive. The EurAsian Conformity mark (EAC) indicates that the compressor is in compliance with all relevant technical regulations of the Eurasian Customs Union. Operating manual - ChillPAC and LP ChillPAC Mk 3 16/68 010823 en 2021.06...

-

Page 17: Vessel Name Plate

Union. Note: Depending on the supplier of the pressure vessel/heat exchanger, the layout and content of the vessel name plate may differ from the Sabroe name plate above. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06... -

Page 18: Signs

In such cases, a yellow sign is affixed to a makers or any other implanted medical visible spot on the compressor. electronic device. Operating manual - ChillPAC and LP ChillPAC Mk 3 18/68 010823 en 2021.06... -

Page 19: Safety Precautions

Pressure Danger! A compressor/unit comprises a pressurised system. Never loosen threaded joints while the system is under pressure, and never open pressurised system parts. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 19/68... -

Page 20: Cooling Water Systems

The drive line is connected to voltage. Be aware of live circuits. • Pay close attention to the electrical installation and system maintenance to avoid hazards both during normal operation or in the event of equipment malfunctioning. Operating manual - ChillPAC and LP ChillPAC Mk 3 20/68 010823 en 2021.06... -

Page 21: Lubricating Oils

Synthetic oils based on polyol esters Synthetic oils based on polyalkylene glycols See the Sabroe oil recommendation for the recommended type of oil. Warning! When charging oil, follow the safety instructions given by the oil supplier (MSDS: Material Safety Data Sheet). -

Page 22: F-Gas Regulation (Fluorinated Greenhouse Gases)

It is the operator’s responsibility to ensure that the unit is checked for leakages by a competent person. For units charged with fluorinated greenhouse gases, the following conditions apply depending on type of plant and amount of charge: Operating manual - ChillPAC and LP ChillPAC Mk 3 22/68 010823 en 2021.06... - Page 23 For further information, please see the F-gas regulation in full. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 23/68...

-

Page 24: First Aid For Accidents With Ammonia

Consult a doctor about actual frostbite. After washing, apply wet compresses, wetted with a sterile isotonic (0.9%) NaCl-solution (salt water), to affected areas until medical advice is available. Operating manual - ChillPAC and LP ChillPAC Mk 3 24/68 010823 en 2021.06... -

Page 25: Protecting The Operator As Well As The Environment

%. Certain countries may, however, have official limits different from the ones stated. Halogenated refrigerants HCFC Ammonia R134a R404A R407C R410A R507 R717 R744 Unit Vol. % Time-weighted average 0.005 during a work week. Warning smell Vol. % 0.002 Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 25/68... -

Page 26: Emergency Stop

Fig. 11: UniSAB III built into the electrical panel Emergency stop Fig. 12: UniSAB III as a separate device For resetting and further information, please see the UniSAB III manual. Operating manual - ChillPAC and LP ChillPAC Mk 3 26/68 010823 en 2021.06... -

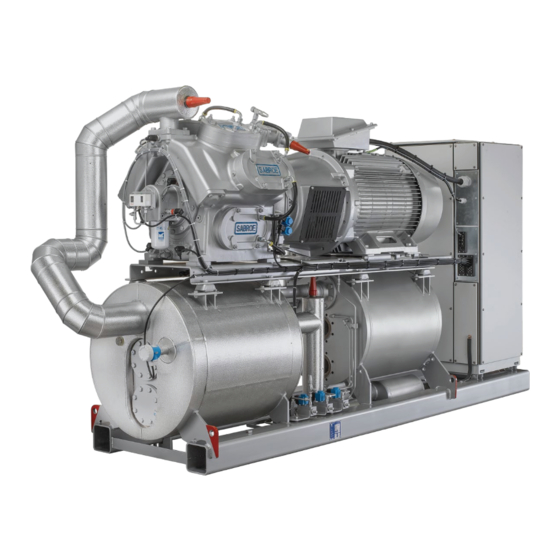

Page 27: Design And Function

The ChillPAC and the LP ChillPAC only use R717 as refrigerant. Once the unit is charged with R717, connected to electricity, and pipe connections to water/brine are established, it is ready for operation. -

Page 28: Components On A Chillpac (Water-Cooled Condenser)

UniSAB III controller and emergency stop (built into electrical panel - optional) Motor Oil recovery system (from evaporator) Oil return system (from oil separator) R717 charge valve Electrical panel High level alarm Operating manual - ChillPAC and LP ChillPAC Mk 3 28/68 010823 en 2021.06... -

Page 29: Components On An Lp Chillpac (External Condenser)

Design and function 3.1.3 Components on an LP ChillPAC (external condenser) Fig. 14: LP ChillPAC Mk 3 with position numbers Pos. no. Component Evaporator/Liquid separator Oil separator Receiver Inlet evaporator Outlet evaporator Expansion valve Liquid level column and level sensor... -

Page 30: Main Components

3.2.4 Condenser The ChillPAC is equipped with a water-cooled condenser. The condenser is a fully welded plate heat ex- changer where plates are welded together into cassettes. R717 condenses between the welded plates which make up the cassettes and cooling water circulates in the channels between the cassettes. -

Page 31: Receiver

3.2.5 Receiver The LP ChillPAC (external condenser) is equipped with a receiver. The purpose of the receiver is to ac- cumulate the liquid coming from the condenser. The receiver has the following connections and sight glasses all located on the flat end cover: Fig. -

Page 32: Hp Regulating System (Water-Cooled Condenser)

Note: The valve at the bottom of the cover, Fig. 16, pos. 4, is used for liquid draining (R717). At the LP ChillPAC (external condenser), the air purge valve is fitted on the top of the receiver, Fig. 15, pos. 10. -

Page 33: Lp Regulating System (External Condenser)

3.2.8 LP regulating system (external condenser) The LP ChillPAC (external condenser) is equipped with an LP regulating system. The principal function of the low pressure system is to keep a constant level of R717 in the evaporator. The LP regulating system consists of: •... -

Page 34: Automatic Oil Recovery System From Evaporator

Note: As shown in Fig. 19, the float ball must be positioned with NO facing upwards. For further information about the oil recovery pot, see chapter 8. Appendices. Operating manual - ChillPAC and LP ChillPAC Mk 3 34/68 010823 en 2021.06... -

Page 35: Automatic Oil Return From The Oil Separator

3.2.11 Alarm for high level in the evaporator The ChillPAC and the LP ChillPAC (external condenser) both have a level switch. If the R717 liquid level becomes too high in the evaporator, the level switch will stop the compressor. This will protect the compressor against liquid hammering. See subsection 6.3 R717 charge for correct charge. -

Page 36: Installation Information

TI 2015-01 Ammonia quality. 12. Turn on power. 13. Check the UniSAB III control system settings including calibration according to the UniSAB III manual. Operating manual - ChillPAC and LP ChillPAC Mk 3 36/68 010823 en 2021.06... - Page 37 18. Check the R717 liquid level again. Note: The liquid level must never be visible in the inspection glass. Note: * ChillPAC units may only be charged with PAO oils. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06...

-

Page 38: Noise And Vibrations

ChillPAC and LP ChillPAC units must be level, and it is therefore recommended to install the unit on ma- chine feet. The load on the machine feet must be distributed evenly so the deflection will be roughly the same on each of the feet, see Fig. -

Page 39: Chillpac With Variable Speed Drive (Vsd)

Cleaning in place It is recommended to install valves and connections for chemical cleaning of open secondary circuits. ChillPAC evaporators and condensers are fully welded heat exchangers and cannot be cleaned mechanically. For more information about chemical cleaning, please contact a Johnson Controls representative. -

Page 40: R717 Detector

Leak detectors should be selected, installed and maintained in cooperation and accordance with the rec- ommendations of the detector supplier. Operating manual - ChillPAC and LP ChillPAC Mk 3 40/68 010823 en 2021.06... -

Page 41: Operating Instructions

Starting procedures Starting and stopping can only be carried out from UniSAB III. The operator must always make sure that the appropriate external starting conditions exist before start-up. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 41/68... -

Page 42: Normal Start-Up Procedure

Check the following on the chiller unit: Mechanical tightness of the external piping, bolts and valves. No oil and refrigerant leaks. If not satisfactory, shut down the chiller and correct the problem. Operating manual - ChillPAC and LP ChillPAC Mk 3 42/68 010823 en 2021.06... -

Page 43: Valve Positions During Operation, Chillpac (Water-Cooled Condenser)

One outlet open / one outlet closed Safety relief valve (Closed) Fixed set point Safety relief valve (Closed) Fixed set point Table 1: Valve positions during operation, ChillPAC Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 43/68... - Page 44 Operating instructions Fig. 22: P&I diagram for ChillPAC Operating manual - ChillPAC and LP ChillPAC Mk 3 44/68 010823 en 2021.06...

-

Page 45: Valve Positions During Operation, Lp Chillpac (External Condenser)

One outlet open / one outlet closed Safety relief valve (Closed) Fixed set point Safety relief valve (Closed) Fixed set point Table 2: Valve positions during operation, LP ChillPAC Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 45/68... - Page 46 Operating instructions Not delivered by Johnson Controls Denmark Fig. 23: P&I diagram for LP ChillPAC Operating manual - ChillPAC and LP ChillPAC Mk 3 46/68 010823 en 2021.06...

-

Page 47: Restarting The Chiller After Power Interruption

Keep the filled-in checklist, and send a copy to Sabroe Factory as documentation that the unit has been installed and commissioned correctly. The checklist will be required in case of a warranty issue. - Page 48 Operating instructions Fig. 24: The checklist, which MUST be filled in during commissioning and start-up. Operating manual - ChillPAC and LP ChillPAC Mk 3 48/68 010823 en 2021.06...

-

Page 49: Stopping Procedures

Irregularities in the plant will often cause changes in the operating conditions but not make the plant stop. Consequently, the operating state of a refrigeration plant must be checked at regular intervals. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06... -

Page 50: Troubleshooting

If the oil continues to disappear from the compressor, the oil return and recovery system must be checked. Operating manual - ChillPAC and LP ChillPAC Mk 3 50/68 010823 en 2021.06... -

Page 51: Testing Of Chillers

It is not a simple task to measure performance. High quality measuring and logger equipment is required to make reliable and accurate measurements. Contact a Johnson Controls representative if a perform- ance test is needed. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 51/68... -

Page 52: Maintenance Instructions

Maintenance intervals are described in detail in the compressor manual. Operating manual - ChillPAC and LP ChillPAC Mk 3 52/68 010823 en 2021.06... -

Page 53: Selecting Lubricating Oil For Chillpac Units

Only use PAO oils (Polyalphaolefin-based oils) for ChillPAC units. PAO oil is a synthetic oil with low vapour pressure. Usually, the ChillPAC units are charged with oil from factory. Do not switch to a different oil type or brand without first consulting Johnson Controls Denmark. -

Page 54: Final Disposal

Batteries Used batteries, for example from the control system backup, must be disposed of in accordance with prevailing national rules and regulations. Operating manual - ChillPAC and LP ChillPAC Mk 3 54/68 010823 en 2021.06... -

Page 55: Appendices

1364.405 HP Float valve HFI 040 3-050 1364.406 HP Float valve HFI 050 3-060 1364.407 HP Float valve HFI 060 3-070 1364.408 HP Float valve HFI 070 Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 55/68... -

Page 56: Spare Parts List For Cvua 1201 Oil Recovery Pot

Piston 3411.009 Oil reservoir 2144.049 Spring 3411.039 Cover 1331.571 O-ring 1425.018 Screw M12 x 30 1427.045/001 Threaded bar M14 1432.034 Nut M14 1344.365 Flange DN25 1336.029 Gasket Operating manual - ChillPAC and LP ChillPAC Mk 3 56/68 010823 en 2021.06... -

Page 57: Declaration Of Conformity

If more than one declaration of conformity is required, all relevant individual declarations will be con- tained in a dossier in accordance with the EU ‘Blue Guide’. Dossiers are uploaded with the other order specific documentation. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 57/68... -

Page 58: Set-Up Guide - Aks 4100 280 Mm For Ammonia Heat Pump Application

When the process connection with probe is properly installed in the system, the HMI display and signal converter should be mounted on the process connection. Fig. 27 Operating manual - ChillPAC and LP ChillPAC Mk 3 58/68 010823 en 2021.06... - Page 59 XXX mm AKS 4100 increase the value. PROBE LENGTH Press 00280 mm QUICK SETUP completed Fig. 28: Quick set-up of AKS 4100 280 mm Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 59/68...

- Page 60 1 2 3 4 Fig. 29 Supervisor passcode = 1-2-3-4-1-2 Press Arrow right (no. 1) once - the first digit 1 is marked, see Fig. 30. Fig. 30 Operating manual - ChillPAC and LP ChillPAC Mk 3 60/68 010823 en 2021.06...

- Page 61 Press Arrow up (no. 4) until 1 has turned to 5. • Press Arrow right (no. 1) – the third digit is marked, see Fig. 33. Fig. 33 Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 61/68...

- Page 62 • + 4.1.2 Empty Area from 280 mm to 260 mm. After the last change, press Return (no. 2) until “STORE NO” is displayed, see Fig. 37. Operating manual - ChillPAC and LP ChillPAC Mk 3 62/68 010823 en 2021.06...

- Page 63 Heat pump application can only be provided if the mentioned recommendations are followed, and the level set point in UniSAB III is set between 20 and 25%. Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 63/68...

- Page 64 Appendices Set point z on e Fig. 38: AKS 4100-280 mm installed in a DN150 receiver. Operating manual - ChillPAC and LP ChillPAC Mk 3 64/68 010823 en 2021.06...

- Page 65 Appendices Extended list – Gas constant for ammonia heat pump application Fig. 39 Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 65/68...

-

Page 66: Index

F-gas regulation..........................22 Final disposal..........................54 First aid for ammonia accidents ...................... 24 Foundation ........................... 38 Greenhouse gases........................22 HP float valve ..........................55 HP regulating system ........................32 Operating manual - ChillPAC and LP ChillPAC Mk 3 66/68 010823 en 2021.06... - Page 67 Spare parts list........................55 –56 Starting procedures........................41 Stopping............................49 Temperature and flow control ......................39 Unit/pipe system name plate ......................13 Valve positions......................... 43, 45 Vessel name plate......................... 17 Operating manual - ChillPAC and LP ChillPAC Mk 3 010823 en 2021.06 67/68...

- Page 68 Vibration dampers ......................... VSD - variable speed drive......................39 Water ............................39 Operating manual - ChillPAC and LP ChillPAC Mk 3 68/68 010823 en 2021.06...

- Page 70 Johnson Controls Denmark ApS Sabroe Factory Christian X's Vej 201 ∙ 8270 Højbjerg Denmark Phone +45 87 36 70 00 www.sabroe.com Version 6...

- Page 71 Letter of compliance for ECO-design, Process & Comfort chiller Directive 2009/125/EC Manufacturer: Johnson Controls Denmark ApS, SABROE Factory Christian X’s Vej 201 · 8270 Højbjerg · Denmark Phone +45 87 36 70 00 We hereby declare that our products within the scope of eco-design, implemented according to regulation No 2015/1095 for low (-25°C) and medium (-8°C) temperatures and No 2016/2281 for high temperatures...

- Page 72 Process Chiller, Reciprocating water/brine cooled High Medium High Medium <400kW ChillPAC28V-A 229 kW <300kW ChillPAC28V-C 113 kW >400kW ChillPAC 112LV-A 1061 kW >300kW ChillPAC 12LV-C 529 kW Sabroe unit Legal limit Sabroe unit Legal limit Sabroe unit Legal limit Sabroe unit...

Need help?

Do you have a question about the ChillPAC and is the answer not in the manual?

Questions and answers