Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Ketterer KuLi Series

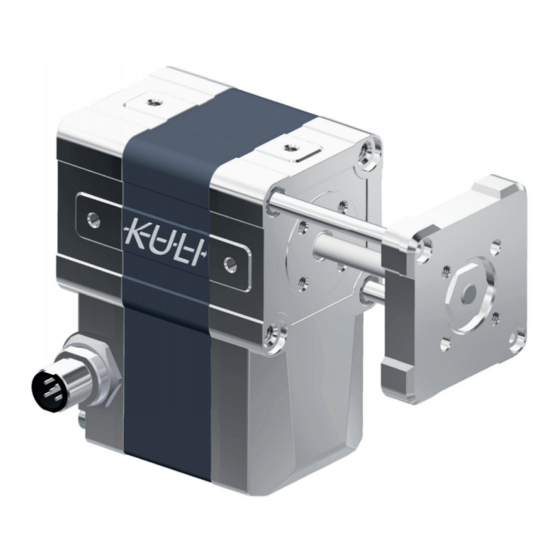

- Page 1 Assembly instructions „KuLi - electric short stroke linear actuator“ 3215.00-XXXX Original assembly instructions for partly completed machines According to machinery directive 2006/42/EG Attachment VI Document No. 3215.72-01i01 04 / 2022 3215.72-01i01 Rev. A...

- Page 2 All rights reserved, in particular the right of reproduction, distribution and translation. No part of this manual may be reproduced in any form or saved, processed, duplicated or distributed using electronic systems without the written consent of B. Ketterer Söhne GmbH & Co. KG. Subject to modifications.

-

Page 3: Table Of Contents

Scope Introduction Content Scope Standards and directives Warnings and symbols used 1.4.1 Structure of the section-specific warnings 1.4.2 Structure of the embedded warnings Safety Instructions Personnel - Qualification und obligations Obligations of the operator General safety instructions 2.4.1 Intended use 2.4.2 Foreseeable misuse Residual risks... - Page 4 7.2.1 Reference run during operation 7.2.2 Teach run during operation 7.2.3 Teaching the travel range after switching on Operation Disassembly / Shutdown Maintenance Self-help and diagnosis in case of malfunction Disposal Repair EC Declaration of incorporation 3215.72-01i01 Rev. A...

-

Page 5: Introduction

Introduction 1 Introduction 1.1 Content This documentation is intended to help you work safely on and with the "Kuli". It contains safety instructions that must be followed for all work performed on and with the Kuli system. The documentation must be made accessible to all persons who work on and with the Kuli. -

Page 6: Warnings And Symbols Used

Introduction 1.4 Warnings and symbols used The safety sign visually represents a source of hazard. The safety signs in these assembly instructions comply with DIN EN ISO 7010. The following pictograms and signal words are used in this documentation to indicate hazards and important information: Pictogram Description Warning of a general hazard... - Page 7 Introduction Pictogram Description Warning of unexpected / automatic start-up. This warning sign stands in front of activities where an unexpected / automatic start-up of rotating components can occur. Warning of crushing hazard This warning sign stands for activities where hazards exist due to crushing and shearing points which can lead to crushing injuries.

- Page 8 Introduction In these assembly instructions, the following danger levels are used to indicate potentially hazardous situations and important safety instructions: Hazard level Description Indicates a hazardous situation which, if not avoided, will result in death or serious irreversible injury. DANGER! Indicates a hazardous situation which, if not avoided, could result in death or serious irreversible injury.

-

Page 9: Structure Of The Section-Specific Warnings

Introduction 1.4.1 Structure of the section-specific warnings The section-specific warnings apply not only to one specific action, but to several actions within a chapter. The hazard symbols used indicate either a general or specific hazard. The warning is structured as follows: SIGNAL WORD! Nature of the hazard and its source. -

Page 10: Safety Instructions

Safety Instructions 2 Safety Instructions Read the safety instructions and information on safe operation in these assembly instructions carefully before starting work. Keep these assembly instructions in a safe place and give them to others if necessary. It is very important for your safety that you understand and follow all safety instructions. -

Page 11: Obligations Of The Operator

Safety Instructions 2.2 Obligations of the operator Every person who works with the Kuli has a responsibility to ensure safety and health protection. They must be trained in the use of the Kuli. A safety-related condition and use of the Kuli is a requirement for safe operation. -

Page 12: Use

Safety Instructions 2.4 Use The KuLi is only intended for industrial systems, for installation in machines within the meaning of MRL 2006/42/EC. The KuLi has been designed and built for use in accordance with its intended use. If you use the KuLi for a purpose other than the one listed, the manufacturer cannot be made liable for any damage resulting from this. -

Page 13: Residual Risks

Safety Instructions 2.5 Residual risks Despite all actions taken to integrate safety in the design, safety provisions and additional protective actions, non-obvious residual risks cannot be completely avoided. You can reduce residual risks by carefully following the safety instructions and the intended use. -

Page 14: Product Description

Product description 3 Product description 3.1 Description of the Kuli The KuLi is a compact and fast electrically driven linear actuator. The Kuli is intended for use in automation and material handling technology. There it can replace pneumatic cylinders, for example. -

Page 15: Visualization Of The Possible Connector Positions

Product description 3.2.1 Visualization of the possible connector positions The following connector positions are possible: 3.2.2 Available accessories Connect Box (part number 3215.49-01) The KuLi "Connect-Box" parameterization adapter is designed to transfer programming from the PC to the KuLi and, in combination with a PC software, it allows various parameters to be set. -

Page 16: Technical Data / Operating Conditions

Product description 3.3 Technical data / operating conditions INFORMATION! The data was determined at an ambient temperature of 20°C. The technical data applies to KuLi versions with 6mm spindle pitch (KuLi-B6-XX-X-XX-X-X). The technical data for KuLi with 1mm pitch (KuLi-B1-XX-X-EX-X-X) are available in consultation with the manufacturer. - Page 17 Individual parameterization in the EX software variant (Expert Mode) must be carried out by Ketterer. After parameterization, start-up must also be carried out in coordination with Ketterer. The parameterization in Expert mode offers the following value ranges:...

- Page 18 Product description The lifetime may vary depending on operating and installation conditions and is load dependent. See following figure. P a g e 3215.72-01i01 Rev. A...

-

Page 19: Dimensions

Product description 3.4 Dimensions The dimensions of the KuLi for all possible connector positions are shown below: P a g e 3215.72-01i01 Rev. A... -

Page 20: General Requirements For The Master Control System

Product description 3.5 General requirements for the master control system The controller must have the following functionalities: I/O control: The KuLi short-stroke linear actuator can be connected to the control system using a simple M12 cable. In I/O mode, the actuator is controlled via the digital input (control input). -

Page 21: Packing / Transport / Unpacking / Storage

Transport / Unpacking / Storage 4 Transport / Unpacking / Storage CAUTION! Danger due to sharp edges on parts of the housing. When handling the KuLi, sharp edges and corners can cause cuts. Wear your personal protective equipment depending on ►... -

Page 22: Assembly

Assembly 5 Assembly 5.1 Mechanical mounting instructions CAUTION! Danger due to sharp edges on parts of the housing. When handling the KuLi, sharp edges and corners can cause cuts. Wear your personal protective equipment depending on the ► ambient conditions, but at least safety shoes protection class 2, suitable protective gloves. -

Page 23: Fixing The Kuli In The Application

Assembly 5.1.1 Fixing the KuLi in the application Fix the KuLi in your application using the 4x M6 (12 mm deep) mounting holes on the back. Use screws of a suitable length for your application. Tighten them with a torque according to the manufacturer's specifications of the screws. -

Page 24: Effect Of Radial Forces

Assembly 5.1.3 Effect of radial forces CAUTION! Risk of damage to the KuLi due to the effect of radial forces. The effect of radial forces may cause the KuLi to break. This may result in damage to the corresponding application. When connecting the KuLi to your application, avoid the effect of radial forces. -

Page 25: Installation Instructions For The Qualified Electrician

Assembly 5.2 Installation instructions for the qualified electrician DANGER! Danger due to electric shock. Incorrect installation or damage to the live cables during installation may result in an electrical hazard and thus in death or serious injury. Carry out all assembly work only in a de-energized state. ►... -

Page 26: Start-Up

Start-Up 6 Start-Up DANGER! Danger due to electric shock. Incorrect installation or damage to the live cables during installation can result in an electrical hazard and therefore death and serious injury. For safety reasons, be sure to connect all PE protective ►... - Page 27 Start-Up WARNING! Danger due to breakage. Incorrect mounting or disregard of the permissible operating data of the KuLi can lead to breakage. Blocking or bending components can cause damage to the entire system. Observe the notes in these assembly instructions for ►...

- Page 28 Start-Up Start-Up: 1. Switch on the supply voltage. 2. In the standard version, the actuator is controlled via the control input. If 24 V is applied to this input, the actuator moves to the outer position (extended). When not triggered, the actuator moves to the inner position (retracted).

-

Page 29: Programming

Individual parameterization in the EX software version (Expert Mode) must be carried out by Ketterer. After parameterization, start-up must also be carried out in cooperation with Ketterer. Qualification of the personnel “Connect-Box” The installation and electrical connection of the device may only be carried out by a qualified electrician. -

Page 30: Assembly And Start-Up Of The Connect Box

Programming 7.1.1 Assembly and start-up of the Connect Box If the KuLi is connected to the PC/laptop and the connect box in the extended state and this connection gets disconnected when the supply voltage is switched on, the KuLi moves to the inner reference point. The following cables are required to connect the Connect-Box: (1) Connection cable SPS 5 pol. -

Page 31: Parameterization Software

Programming 7.1.2 Parameterization software Set the movement characteristics: For this purpose, the slider in the corresponding field is moved to the desired position. The corresponding setting data is automatically transferred to the KuLi. During this transfer, the other operating elements are deactivated. The path to be moved by the KuLi can be set via the software. - Page 32 Programming Button „REFERENCE RUN“ The KuLi does not have an absolute measuring system. Therefore, the positioning system must be referenced after each start-up. The "REFERENCE RUN" button starts this referencing, which is carried out with reduced force and speed settings.

- Page 33 Programming Behaviour on blocking If an end position cannot be reached due to an excessive load, this is recognized by the KuLi as a blockage. The user can set how the KuLi should behave in this situation: Continue After a blockage, the KuLi attempts to move to the end position. For this purpose, new movement commands are periodically generated by the KuLi until the end position is reached or the control changes the end position.

-

Page 34: Programming Via Master Control

Programming 7.2 Programming via master control The following programming / settings can be made on the KuLi by using the master control. 7.2.1 Reference run during operation It is also possible to perform a reference run during operation. For this purpose, a sequence of 4 pulses must be sent to the control input. -

Page 35: Teach Run During Operation

Programming 7.2.2 Teach run during operation It is also possible to perform a teach run during operation. For this purpose, a sequence with six pulses must be sent to the control input. After the sixth pulse, which is longer than 100 ms, the Kuli activates both outputs. -

Page 36: Teaching The Travel Range After Switching On

Programming 7.2.3 Teaching the travel range after switching on If the control input remains at the 24 V level for more than five seconds after switching on and the first flank change, both outputs become active and the Kuli is in teach mode, i.e. it now wants to teach in the two end positions. -

Page 37: Operation

Operation 8 Operation DANGER! Danger due to electric shock. Incorrect installation or damage to the live cables during installation can result in an electrical hazard and thus in death and serious injury. Have the electrical equipment checked by a qualified ►... - Page 38 Operation WARNING! Danger due to breakage. Incorrect mounting or disregarding the permissible operating data of the KuLi can lead to breakage. Blocking or bending components can cause damage to the entire system. For correct mounting, observe the notes in these assembly ►...

-

Page 39: Disassembly / Shutdown

Disassembly / Shutdown 9 Disassembly / Shutdown DANGER! Danger due to electric shock. Disassembly without prior shutdown may result in an electrical hazard and thus in death or serious injury. Only perform disassembly when all components are ► voltage-free. Observe the 5 electrical safety rules. ►... - Page 40 Disassembly / Shutdown WARNING! Danger due to unauthorized restart. During shutdown, the KuLi may start unexpectedly if it is started by a third party. This may result in a crushing, shearing or impact point. Protect the system against unauthorized restarting, e.g. by ►...

-

Page 41: Maintenance

Maintenance 10 Maintenance DANGER! Danger due to electric shock. Damage to the live cables during maintenance may result in an electrical hazard and thus in death and serious injury. Only perform maintenance when all components are de- ► energized. Observe the 5 electrical safety rules. WARNING! Danger due to unauthorized restart. -

Page 42: Self-Help And Diagnosis In Case Of Malfunction

Self-help and diagnosis in case of malfunction Preparatory activities for maintenance: Maintenance work may only be performed by qualified personnel. Qualified personnel are persons with appropriate specialized training and experience who understand the construction requirements, the design of the KuLi and the safety regulations. -

Page 43: Disposal

13 Repair In case of service or repair contact: B. Ketterer Söhne GmbH & Co. KG Bahnhofstraße 20 78120 Furtwangen Phone: +49(0)77 23 / 9323-0 E-mail: info@ketterer.de...

Need help?

Do you have a question about the KuLi Series and is the answer not in the manual?

Questions and answers