Table of Contents

Advertisement

Quick Links

Operating Instructions

EGES14020T

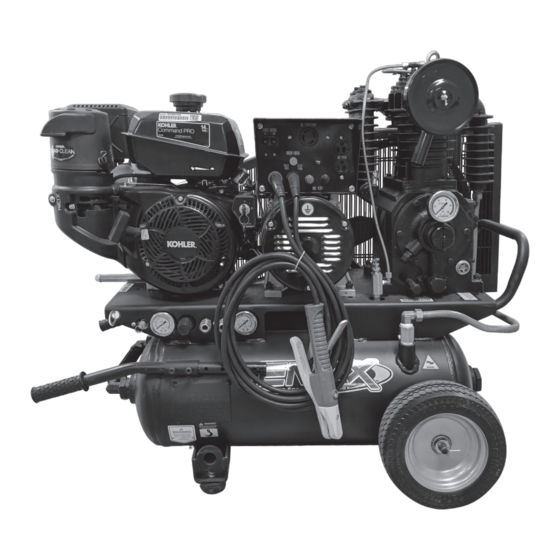

3 IN 1

COMPRESSOR WELDER GENERATOR

EMAX designs and manufactures products for safe operation. However, operators and

maintenance persons are responsible for maintaining safety. All safety precautions are included

to provide a guideline for minimizing the possibility of accidents and property damage while

equipment is in operation. Keep these instructions for reference.

EGES14020T man v.190417

Advertisement

Table of Contents

Summary of Contents for Emax EGES14020T

- Page 1 3 IN 1 COMPRESSOR WELDER GENERATOR EMAX designs and manufactures products for safe operation. However, operators and maintenance persons are responsible for maintaining safety. All safety precautions are included to provide a guideline for minimizing the possibility of accidents and property damage while equipment is in operation.

-

Page 2: Table Of Contents

Gas Powered 3-in-1 Compressor / Generator / Welder Table of Contents Retain this information ………………………………… 2 Electrical Shock ………………………………………… 17 Model Specifications …………………………………… 3 Fumes and Gases ……………………………………… 18 Functional Description ………………………………… 4 Flash Hazards; UV and IR Arc Rays ……………… 19 Safety Symbols ……………………………………………... -

Page 3: Model Specifications

Operating Instructions Model Specifications EMAX Gas Powered 3-in-1 Compressor / Welder / Generator Power Type 4 stroke gasoline engine Features • OHV • Cast iron cylinder liner • Aluminum block - Low oil sentry: switch designed to prevent engine from starting in a low oil or no oil condition. -

Page 4: Functional Description

Gas Powered 3-in-1 Compressor / Generator / Welder Functional Description The EGES14020T was designed as a mobile and stationary power source, providing power in the form of either compressed air or electricity, to drive pneumatic and electrical equipment, or for welding metals. Its base motive force is provided by an air-cooled 4 cycle 14 horsepower Kohler gasoline engine. - Page 5 Engine valve cover Electric starter Compressor pump details Gear reduction system Bumper/lift handle Lifting point eyebolts (3) Generator Tank condensate pet cock (2) Wheel (2) * remove foot pads adjacent to tires if using the compressor for portable applications EGES14020T man v.190417...

- Page 6 Gas Powered 3-in-1 Compressor / Generator / Welder Functional Description fig.3 Detail of Air Delivery Cluster Key Letter Description Key Letter Description Left air supply quick-connect Safety valve Right air supply quick-connect Left air supply pressure gauge Right regulated pressure gauge Supply pressure regulator fig.4 Engine details...

- Page 7 20 amp 115 / 230 volt power supply for twist-lock plug 115 volt power supply duplex socket Fuse 12 V DC negative (black) terminal 12 V DC positive (red) terminal Alternator housing Welding ground clamp cable (black) plug-in Welding electrode cable (red) plug-in Welding power control EGES14020T man v.190417...

- Page 8 Gas Powered 3-in-1 Compressor / Generator / Welder Functional Description fig.6 Compressor Pump- salient points Key Letter Description Key Letter Description Compressor sump oil fill Pilot valve (pressure relief) Compressed air output tube Oil regulator Compressor pump oil sight glass Oil pump Compressor pump reusable screen oil filter Oil pressure gauge Oil drain...

-

Page 9: Safety Symbols

California Proposition 65 Warnings This product can expose you WA R NIN G to chemicals including DEHP, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov. This product, when used for DA N G ER welding or cutting, produces fumes or gases which contain chemicals known to the State of California to cause EGES14020T man v.190417... -

Page 10: Inspection

Gas Powered 3-in-1 Compressor / Generator / Welder Inspection Gasoline Engine Safety This unit is powered by a gasoline engine. The Inspect equipment prior to use of a gasoline engine to power the pump brings any use. Check for external a particular set of safety considerations into play, damage that might have primarily dictating outdoor use only. -

Page 11: Airflow

NEARBY which is properly charged. Be familiar with its use. 4. PROVIDE BATTERY-OPERATED OR BATTERY BACK-UP TYPE CARBON MONOXIDE ALARMS in any structure that is in close proximity to the running engine. Asphyxiation. Running engines produce carbon monoxide (CO), a colorless, odorless poisonous gas. The CO generated by the engine can rapidly accumulate, even in areas that appear to be well ventilated, resulting in dangerous and fatal concentrations within minutes. EGES14020T man v.190417... -

Page 12: Compressor Safety

Gas Powered 3-in-1 Compressor / Generator / Welder Compressor Safety DO NOT install compressor in boiler room, paint spray room, or area where Breathable Air sandblasting occurs. Make 1. NEVER USE AIR FROM THIS EQUIPMENT sure inlet air is away from FOR BREATHABLE AIR except in full exhaust fumes or other toxic, compliance with OSHA Standards 29 CFR 1910 noxious or corrosive fumes or substances. and any other Federal, State or Local codes or regulations. -

Page 13: Truck Installation

PIPING. Keep all piping and fittings the same Battery Component size in the piping system. Most EMax compressors are equipped with an 5. FOR PERMANENT INSTALLATIONS OF electric starter but require a customer supplied, 12 COMPRESSED AIR SYSTEMS, DETERMINE volt motorcycle-style battery for operation. -

Page 14: Generator Safety

Gas Powered 3-in-1 Compressor / Generator / Welder Generator Safety 12. GENERATOR SHOULD ONLY BE PLUGGED INTO ELECTRICAL DEVICES, either directly or with an extension cord. NEVER connect to The engine that powers this a building electrical system without a qualified generator produces electrician. Such connections must comply poisonous carbon monoxide with local electrical laws and codes. -

Page 15: Welder Safety

ACCESSORIES. Use only recommended Never leave the equipment running unattended. accessories as required, otherwise personal Switch it off and do not walk away until it comes injury may result. to a complete stop. EGES14020T man v.190417... -

Page 16: Equipment Use And Safety

Gas Powered 3-in-1 Compressor / Generator / Welder 2. DRESS PROPERLY. Operators should 2. KNOW YOUR EQUIPMENT. Read and protect their body by wearing dry, closed, non- understand the owner’s manual and the labels flammable protective clothing, without pockets or attached to the tool. -

Page 17: Safety While Servicing

POSITION. Maintain a secure stance while welding current circuit includes the workpiece welding to prevent accidents. If you are working and any conductive material in contact with it, the above ground, wear a safety harness to prevent EGES14020T man v.190417... -

Page 18: Fumes And Gases

Gas Powered 3-in-1 Compressor / Generator / Welder ground clamp, the electrode, and any metal parts 18. INSPECT ALL CABLES AND CORDS FOR on the electrode holder. ANY EXPOSED WIRE . and If found, replace any cracked, abraded, or damaged parts such 2. -

Page 19: Flash Hazards; Uv And Ir Arc Rays

OR HELMETS FITTED WITH A #10 SHADE this welding equipment, or is a bystander in the FILTER LENS and do not strike a welding arc welding area, understands and follows these safety until all bystanders and you (the operator) have instructions as well. EGES14020T man v.190417... -

Page 20: Hot Materials

Gas Powered 3-in-1 Compressor / Generator / Welder Arc welding, by nature, 10. DO NOT WEAR GLOVES OR OTHER CLOTHING THAT CONTAIN OIL , grease, or produces sparks, hot spatter, other flammable substances. molten metal drops, hot slag, 11. HAVE FIRE EXTINGUISHING EQUIPMENT and hot metal parts that can READY to hand for immediate use! DO NOT start fires, burn the skin, and USE WATER. -

Page 21: Electromagnetic Fields

OSHA STANDARD 29 CFR, PART 1910, SUBPART Q. — WELDING, CUTTING AND BRAZING available from your state OSHA office or from: U. S. Dept. of Labor OSHA, Office of Public Affairs Room N3647, 200 Constitution Ave. NW Washington, DC 20210 www.osha.gov EGES14020T man v.190417... -

Page 22: Unpacking

Gas Powered 3-in-1 Compressor / Generator / Welder Unpacking Make sure to use all three lifting hooks while lifting the Unpacking your EGES14020T, check it thoroughly compressor-welder. Failure to do this can for any damage that it may have incurred in transit. cause injury. Be sure all fittings, bolts, etc. are present, as well as 5. -

Page 23: Piping / Tank Installation

This unit is shipped with compressor pump break-in complete. oil and should be ready to operate. 3. Check the oil level. It should show in center of the . Refer to JF, fig.6 compressor pump oil sight glass and fig.8, below. EGES14020T man v.190417... -

Page 24: Battery Set-Up And Connections

Check proper oil level fig.9 Back view- battery & starter wiring Use only EMAX USA oil (PN: 1. The battery must be fully charged before use. OIL004) for the compressor 2. Use the supplied cables to connect to the pump. Use of any other product will cause battery. -

Page 25: Operation

DO NOT exceed manufacturer’s rated safe operating pressures for 7. Before the first start, add fresh gasoline to the these items. tank (see maintenance label for specifications). Fill it to 5/8" (16 mm) below the gas tank filler EGES14020T man v.190417... -

Page 26: Engine Throttle

Gas Powered 3-in-1 Compressor / Generator / Welder 11. For cold engine start, move choke lever all the neck, leaving the top of the gas tank and neck way left to the full choke (closed) position (2, empty to allow expansion room. fig.12). -

Page 27: Engine Break-In

Also use effective chip guarding and personal protective equipment per OSHA standard 29 CFR 1910.242 (b). 11. Clean up all oils spills immediately to prevent slipping. (Mark spill area accordingly.) Compressor components can become hot during operation. Avoid bodily contact with hot liquids, hot surfaces and sharp edges and corners. EGES14020T man v.190417... -

Page 28: Maintenance

Be sure to relieve all system oil within first 50 hours or 30 days of operation, pressure then lock out power whichever comes first. and tag compressor to prevent DO NOT use automotive-type oil. unexpected movement of the Use only EMAX USA oil (PN: unit. OIL004). Inspect belt tension after first 30 Use of any other lubricant will cause product hours of operation, then every 30 days. damage and void the warranty. -

Page 29: Maintenance

Tighten the belts as needed to ensure they do not slip. EGES14020T man v.190417... -

Page 30: Troubleshooting Chart

USA oil (PN: OIL004). Use of any other product will cause product damage and void the warranty. Low air 1. Pilot valve not set properly 1. Call EMAX Service or local dealer to adjust valve pressure 2. Head unloader sticking 2. Lubricate valve with industrial grade grease 3. -

Page 31: Warranty

EMAX USA warrants that each new reciprocating pump sold and used under normal use and service, will be free from defects in material and workmanship for a period of 5 years from the date of purchase. EMAX USA obligation under this warranty period shall be limited to repair and replacement. EMAX USA is not responsible for downtime during warranty period.

Need help?

Do you have a question about the EGES14020T and is the answer not in the manual?

Questions and answers