Summary of Contents for Piranha P65

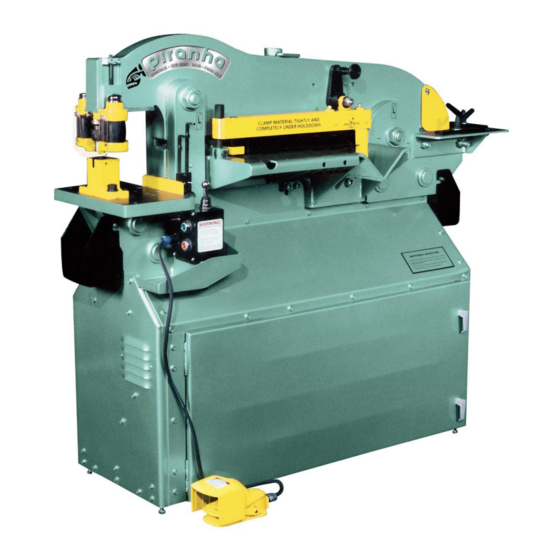

- Page 1 IRONWORKER MODEL NUMBER P65 For Serial Numbers P65-3001 to Current Models Publication Date: May 3, 2022 Call us: 800-338-5471...

- Page 2 Piranha Optional Tooling and Attachments Enhance your Ironworker’s Versatility Oversize Punch Attachments • Expand punching capacity up to 5" Quickset Gauging Table • Allows you to quickly set-up your punch end for multiple holes. • Includes an angle gauge bar to index off the heel of your angle and a plate gauge bar, which indexes off the end of your plate.

- Page 3 Ironworker Manual Model P65 Be sure to register your model and serial number to receive Piranha Service and Product Updates. Support Please have the serial number or model ready when calling. For technical support: Via Phone: 815.490.0473 Via Email: service@piranhafab.com For ordering parts and consumables: Via Phone: 800.338.5471...

-

Page 4: Table Of Contents

Installation ..........................12 Operating Instructions .......................13 Lubrication ..........................21 Maintenance ..........................22 Troubleshooting ........................23 Tonnage Required for Punching Holes in Mild Steel ..............27 Maintenance Tools List ......................28 Ordering Repair Parts .......................29 Service Record Chart ........................51 Piranha Optional Tooling and Attachments ................53 Table of Contents... -

Page 5: Foreword

Warranty Piranha / MegaFab will replace (F.O.B. our factory) or refund the purchase price for any goods which are defective in materials and workmanship within 12 months of date of purchase. The buyer must return the warranty registration card within thirty-(30) days of... -

Page 6: Introduction

About Piranha Piranha is a subsidiary of MegaFab, based in Rockford Illinois. MegaFab is a manufacturer of metal fabrication machinery, including laser cutting machines, plasma cutting machines, ironworkers, press brakes, bending rolls, combination punching and cutting machines, and structural steel punching equipment. -

Page 7: Safety Precautions

Contact the factory for limit switch adjustments on special tooling. Turn selector switch to the "OFF" position when changing tooling or performing defined., Figure “B”). maintenance work. Reference Page Error! Bookmark not Piranha Ironworker P65... -

Page 8: Machine Specifications

Machine Specifications HYDRAULIC SYSTEM Drive Motor 7.5HP 230 / 460 Volt / 3 Phase Hydraulic Tank Capacity 18 Gallons Hydraulic Tank - Initial Fill 13.5 Gallons Hydraulic Oil AW-32 or Equivalent (ISO Grade 32) Consult your local distributor for a cross reference WORKING SURFACE Platen Table 10"... -

Page 9: Functional Diagram

Coper Guard Coper Guides Punch Attachment COPER END PUNCH END Coper Table Platen Table Chip Bucket Chip Bucket Fixed Hold-down Must be used when shearing 1" x 4" plate Front Control Serial Number Plate Location Foot Switch Piranha Ironworker P65... -

Page 10: Dimensional Data

Dimensional Data 60" 42" 24" 66" Dimensional Data... -

Page 11: Standards Compliance

In addition, all of the machines meet the current "Ontario Hydro" electrical code for proper manufacture of the electrical circuits. Hydraulic System Design/Manufacture: Hydraulic components used in Piranha machines are approved by NFPA (National Fluid Power Association), and those approval numbers can be traced through the manufacturer's part numbers. -

Page 12: Installation

To maintain the accurate alignment built into the Piranha, and to prevent undue stress on the moving parts under a load, the Piranha should be placed on a stable base or floor adequately constructed to withstand the unit weight. NOTE: Use the leveling bolts provided with the machine. -

Page 13: Operating Instructions

Operating Instructions The Piranha Ironworker comes pre-assembled and pre-wired, requiring only the addition of hydraulic fluid in the reservoir to the mark on the fill cap dipstick and a power source from a disconnect to the electrical enclosure box located inside the cabinet. - Page 14 Joystick Operation The ironworker is hand controlled by a five-position momentary joystick operator. When the joystick is released from any of the four positions, it will return to the neutral (center) position stopping machine movement instantly. The joysticks are located on top of the control box at each end of the machine.

- Page 15 ▪ Completion of downward cycle is accomplished by depressing footswitch lever again. Machine movement is down until limit setting is met (reference Figure F4). ▪ Removing foot pressure from the switch entirely allows machine movement upward to limit setting, completing upstroke cycle (reference Figure F5). Piranha Ironworker P65...

- Page 16 Footswitch Limit Switches The footswitch is used in conjunction with the upstroke and downstroke limit switches located on the machine side off the front control box only, see figure C. ▪ The front limit switch (closest to the punch end and the lower switch of the two switches) controls the downstroke limit.

- Page 17 12. Set the limit switches to control the length of stroke. Reference previous page. 13. Start operation. 14. Remove all tooling from the punch end before starting shearing or coping operations. Piranha Ironworker P65...

- Page 18 Stripper Assembly Adjustment NOTE: The selector switch should be in the "OFF" position until all tooling changes are complete. Reference page 13, figure B. The adjustment of the stripper assembly to compensate for varying punch lengths should be accomplished in the following manner. (Reference page for a visual reference).

- Page 19 8. Using the wrench supplied with the machine, tighten flanged nuts on the setscrews to hold the base assembly firmly to the platen. 9. Set the limit switches to control the length of stroke (reference procedures previously listed). 10. Start operation. Piranha Ironworker P65...

- Page 20 Shear Hold-Down Assembly Adjustment The adjustment on the hold-down assembly should be accomplished by the following manner. (Reference page 35). 1. Raise the upper beam to its full upstroke limit. 2. Adjust the three-position hold-down locator per the following instructions: •...

-

Page 21: Lubrication

Hold-down Link Hold-down Bar (2 Places) Hold-down Pin Stripper Assembly (2 Places) Clevis Pin Lower Pull Arm Hinge Pin Crank Arm Hinge Pin Drive Motor One Shot One Shot Multi-Purpose Per Year from Grease Grease Drive Motor Piranha Ironworker P65... -

Page 22: Maintenance

Hydraulic Oil Level The Piranha ironworker is equipped with a dipstick indicator on the fill cap located inside the access door. The dipstick is marked to help maintain proper fluid level. This should be checked as part of your normal maintenance cycle. -

Page 23: Troubleshooting

Many of these problems can be solved by following a step-by-step procedure for isolating the issue. Take notes on the steps tried, and the outcomes. This way if you are not able to fix the issue, you can pass on what has been done and tried already to the Piranha technician. - Page 24 P2 - Machine Starts but Will Not Operate Determine if the problem is electrical or hydraulic by using the manual override buttons located on the directional valve top and bottom sides. (Refer to page 45, Item 11). If the machine operates, the problem is electrical. Follow the procedure below: Determine if problem exists in the front control box only, the rear control box only, or in both control boxes.

- Page 25 C. Knives may have been ground. Shim to recommended clearance. 2. Knives may be dull and are creating a pulling effect on the shearing edge. 3. Material may be too hard. 4. Material may be thicker than rated capacities. Piranha Ironworker P65...

- Page 26 P6 - Machine Leaves Burr When Shearing 1. Knife clearance: .007" to .010". If not, follow procedure in P-5. 2. Check shear knives for sharpness 3. Check that the automatic hold-down is adjusted to clamp the material securely. P7 - Bent or Broken Shear Hold-Down Swing Bolt 1.

-

Page 27: Tonnage Required For Punching Holes In Mild Steel

NOTE: Do not punch a hole with a smaller diameter than the thickness of the material. Punch Size Material Thickness 1/8 5/16 1/4 5/16 3/8 7/16 1/2 9/16 5/8 11/16 3/4 13/16 7/8 15/16 3/32 3/16 5/16 7/16 9/16 11/16 13/16 15/16 Piranha Ironworker P65... -

Page 28: Maintenance Tools List

Maintenance Tools List The following tools are required for performing maintenance and to assist you in troubleshooting your machine: 1. Grease gun with a flexible connection 2. Open end wrenches - 3/4" thru 1-1/4" 3. Adjustable wrench – 1-1/2" thru 2-1/4" opening 4. -

Page 29: Ordering Repair Parts

The following assembly parts lists are shown in four columns. In the first column are the index numbers of the parts illustrated. The second column contains the Piranha part number, followed by the description in the third column. The last column shows the quantity of parts required for the assembly. - Page 30 Repair Parts Table of Contents Page No. P65 Basic Machine Illustrated ................31 Shear Hold-Down Assembly Illustration ..............35 Punch Assembly Illustration ................... 37 8" Bending Assembly (Optional) Illustration ............39 Electrical Enclosure Assembly ................41 Front Box Assembly ....................43 Rear Box Assembly ....................

-

Page 31: P65 Basic Machine Illustrated

P65 Basic Machine Illustrated Piranha Ironworker P65... - Page 32 Basic Machine Part Numbers ALWAYS PROVIDE THE COMPLETE SERIAL NUMBER FOR PARTS AND SERVICE Figure and Part Description Qty. Index No. Number 0230142 Coper Guard 0531351 3/8" x 1" Roll Pin 0230117-1 Coper End Knife Support 0531118 3/4" x 7-1/2" HH 0531255 3/4"...

- Page 33 1/2" x 2" SSS 1/4” x 1/2” Button Head Cap Screw 0531005 0581140 1/4" HN 0531088 1/2" x 1-1/2" Carriage Bolt 0330128 Coper Table Guide 0531307 1/2" Flat Plated Washer 0531715 KP79 (1/2-13) Plastic Handle 0531094 5/8" x 2-1/2" HHCS Piranha Ironworker P65...

- Page 34 Basic Machine Part Numbers – Continued ALWAYS PROVIDE THE COMPLETE SERIAL NUMBER FOR PARTS AND SERVICE Figure and Part Description Qty. Index No. Number 0531060 3/8" x 3/4" HCS GR8 0531253 5/8" JN 0531400 Lifting Lug 0230276 Coper Knife- Lower Side and End 0276274 Angle Knife - Lower 0531050...

-

Page 35: Shear Hold-Down Assembly Illustration

Shear Hold-Down Assembly Illustration Piranha Ironworker P65... - Page 36 Shear Hold-Down Assembly Part Numbers Part Number 02302001 ALWAYS PROVIDE THE COMPLETE SERIAL NUMBER FOR PARTS AND SERVICE Figure and Part Description Qty. Index No. Number 0531271 1-1/4-12 JN 02302011 Hold-down Pin 0330202 Hold-down Link 0531300 3/4" Hard Black Fit. Washer 0531255 3/4"...

-

Page 37: Punch Assembly Illustration

Punch Assembly Illustration Piranha Ironworker P65... - Page 38 Punch Assembly Part Numbers Part Number 02304011 Figure and Part Description Qty. Index No. Number 02304001 1-13/16" Die Block Cast 0531002 1/4" x 3/4" SSS 0531055 3/8" x 1/2" SSS 0531100 5/8" x 3" SSS 0531251 5/8" CL-4 FLDG Nut 03304011 Stripper Foot Cast 0531356...

-

Page 39: 8" Bending Assembly (Optional) Illustration

8" Bending Assembly (Optional) Illustration Piranha Ironworker P65... - Page 40 8" Bending Assembly (Optional) Part Numbers Part Number 4431648 Figure and Part Description Qty. Index No. Number 0330500 Bending Dovetail Slide 0531039 3/8" x 3/4" SHCS 0330501 Bending Punch Slide Plate 0531114 3/4" x 3" SB 0531250 5/8" Nylock HN 0330502 8"...

-

Page 41: Electrical Enclosure Assembly

PRIMARY FUSE HOLDER FRONT RECP. REAR RECP. 10 PRIMARY FUSES STARTER 6 TRANSFORMER TRANSFORMER SHOWN TAPPED AT 230 VOLT HEATERS, 3 EA 208V B45 SECONDARY 230V B40 VALVE RECP. FUSE HOLDER SECONDARY 460V B19.5 FUSE 575V B17.5 Piranha Ironworker P65... - Page 42 Ordering Repair Parts...

-

Page 43: Front Box Assembly

05316781-1 Contact Block ZB4BE101 0531678-1 Mounting Base with 2 each N.O. Contacts *ZB4BZ103 0531696-1 Contact Block w/base ZB4BZ101* * Replacement contacts for item Number 18 requires 2 each of part Number ZB4BE101. Item Number 19 requires 1 each. Piranha Ironworker P65... -

Page 44: Rear Box Assembly

Rear Box Assembly Part Number 02316302-1 Figure and Part Description Qty. Index No. Number 05316301 Rear Control Box - With Covers Joystick 9001 K35 – With Contact Blocks 0531608-1 0531609 KA-1 Contact Block 0531644 KA-2 Contact Block 05316101-1 Start Button ZB4BA3 05316111-1 Stop Button ZB4BL4 05316121-1... -

Page 45: Valve Body Assembly Illustrated

Valve Body Assembly Illustrated Part Number 0231530-2 & 0.109 ORIFICE DISK Piranha Ironworker P65... - Page 46 Valve Body Assembly Part Number 0231530-2 Figure and Part Description Qty. Index No. Number T3572 Pilot Valve 2-Way 0551566-1 Counterbalance Valve 0551559-1 Pressure Relief Valve 35/26 0531567-1 Check Valve 0531566-1 Single Pilot Piston Valve 0531562-1 Pressure Relief Valve 25/12 0551561-1 Solenoid Valve (N.C.) T3574 115V AC Solenoid Coil...

-

Page 47: Motor Assembly

Filter Assembly 4" Ikron 0521551-2 Filter Element 4" Ikron 0531508 6801-10-12LP JM6 Hydraulic Fitting 0571532 32" Hose to Valve Body 0531544 48" Hose to Tank 0541531 304-C-6 Hydraulic Fitting 0531514 6503-6-4 Hydraulic Fitting 0541542 Pressure Gauge PGD-25-5000S Piranha Ironworker P65... -

Page 48: Cylinder Assembly

Cylinder Assembly Figure and Part Description Qty. Index No. Number Cylinder- Tata, 2019 models and newer (For 0531503-3 older models, please call) 0230171S Clevis Pin 0230152 Clevis 0531340 5103-125 Snap Ring 0531362 1652B Zerk Str 1/4-28 0531085 1/2" x 1/2" SSS 02301721S Cylinder Pin 0531509... -

Page 49: Foot Switch Assembly

0531655 Foot Switch 0531636 Cord Grip 0531637 16 - 4 SEO Cord (sold by the foot) 6 ft 0531617 4 Pole Plug NOTE: Limit Switches in Foot Pedal are not a stock item but can be obtained. Piranha Ironworker P65... -

Page 50: Knives

Knives Part Index No. Description Qty. Number 02302501 Flat Shear Knives x 12.125" 0230252 3/8" Round Bar Knife 0230253 Blank Round Bar Knife ½” Round Bar Knife 0230254 0230256 5/8" Round Bar Knife 0230258 3/4" Round Bar Knife 0230260 7/8" Round Bar Knife 0230262 1"... -

Page 51: Service Record Chart

Service Record Chart Piranha Ironworker P65... -

Page 53: Piranha Optional Tooling And Attachments

Slug must be slid out the front of the channel shear after each cut. • A pinned slide block is adjusted to accommodate different widths of channel. Piranha Optional Tooling and Attachments Enhance your Piranha’s versatility! Pressbrake Tooling Holders • Allows you to use pressbrake punches and dies in your ironworker for higher precision bending.

Need help?

Do you have a question about the P65 and is the answer not in the manual?

Questions and answers