Summary of Contents for Alfa level CSI RV-ST

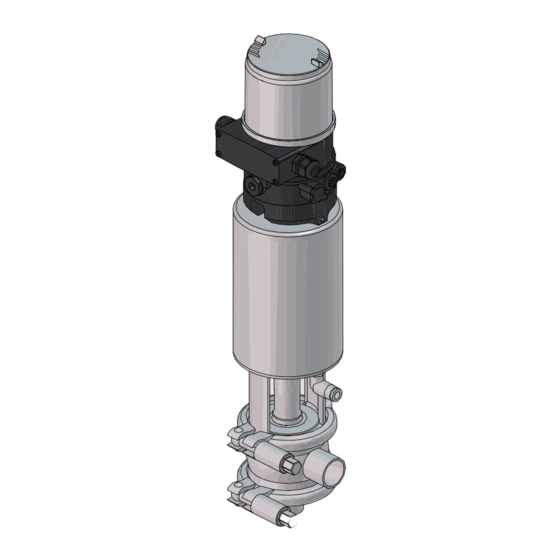

- Page 1 Instruction Manual Unique RV-ST Regulating Valve 2404-0083 ESE02127-EN8 2021-08 Original manual ALFA LAVAL UNIQUE RV-ST VALVE INSTRUCTION MANUAL—REV 8/21...

- Page 2 CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | 417.831.1411 ALFA LAVAL UNIQUE RV-ST VALVE INSTRUCTION MANUAL—REV 8/21...

-

Page 3: Table Of Contents

Table of contents The information herein is correct at the time of issue but may be subject to change without prior notice 1. CE Declaration of Incorporation for Machinery ..........2. Safety ....................2.1. Important information ................2.2. Warning signs ..................2.3. -

Page 4: Ce Declaration Of Incorporation For Machinery

1 CE Declaration of Incorporation for Machinery Revision of Declaration of Conformity: 2012-04-01 The Designated Company Alfa Laval Kolding A/S Company Name Albuen 31, DK-6000 Kolding, Denmark Address +45 79 32 22 00 Phone No. hereby declare that Valve Designation Unique SSV PN10 Type From serial number 5099880 to 29999999999... -

Page 5: Safety

2 Safety Unsafe practices and other important information are emphasised in this manual. Warnings are emphasised by means of special signs. 2.1 Important information A A l l w w a a y y s s read the manual before using the valve! W W A A R R N N I I N N G G Indicates that special procedures must be followed to avoid serious personal injury. - Page 6 2 Safety Unsafe practices and other important information are emphasised in this manual. Warnings are emphasised by means of special signs. D D i i f f f f e e r r e e n n t t a a c c t t u u a a t t o o r r t t y y p p e e s s f f o o r r t t h h e e S S S S V V v v a a l l v v e e In June 2016 the below change was implemented and the “removable yoke with bolts”...

-

Page 7: Warning Signs

2 Safety Unsafe practices and other important information are emphasised in this manual. Warnings are emphasised by means of special signs. 2.2 Warning signs General warning Caustic agents Danger of injury: (an extra yellow label marked on the actuator from June 2016) Do N N O O T T attempt to cut the actuator open due to spring under load. -

Page 8: Safety Precautions

2 Safety All warnings in the manual are summarised on this page. Pay special attention to the instructions below so that serious personal injury and/or damage to the valve are avoided. 2.3 Safety precautions A A c c t t u u a a t t o o r r s s If support air is utilised: - Shock in the actuator must N N E E V V E E R R occur - Support air on high pressure actuator versions is N N O O T T allowed... - Page 9 2 Safety All warnings in the manual are summarised on this page. Pay special attention to the instructions below so that serious personal injury and/or damage to the valve are avoided. G G E E N N E E R R A A L L A A l l w w a a y y s s ensure that personnel must have experience with lifting operations.

- Page 10 2 Safety All warnings in the manual are summarised on this page. Pay special attention to the instructions below so that serious personal injury and/or damage to the valve are avoided. T T R R A A N N S S P P O O R R T T A A T T I I O O N N A A l l w w a a y y s s ensure that compressed air is released A A l l w w a a y y s s ensure that all connections are disconnected before attempting to remove the valve from the installation...

-

Page 11: Installation

3 Installation The instruction manual is part of the delivery. Study the instructions carefully. The items refer to the parts list and service kits section. The valve is supplied as separate parts as standard (for welding). The valve is assembled before delivery, if it is supplied with fittings. 3.1 Unpacking/delivery S S t t e e p p 1 1 C C A A U U T T I I O O N N... - Page 12 3 Installation The instruction manual is part of the delivery. Study the instructions carefully. The items refer to the parts list and service kits section. The valve is supplied as separate parts as standard (for welding). The valve is assembled before delivery, if it is supplied with fittings. S S t t e e p p 4 4 Remove possible packing materials from the valve/valve parts.

-

Page 13: General Installation

3 Installation Study the instructions carefully and pay special attention to the warnings! The valve has welding ends as standard but can also be supplied with fittings. 3.2 General installation S S t t e e p p 1 1 DO NOT DISASSEMBLE Do N N O O T T attempt to disassemble the actuator due to - C C A A U U T T I I O O N N... - Page 14 3 Installation Study the instructions carefully and pay special attention to the warnings! The valve has welding ends as standard but can also be supplied with fittings. S S t t e e p p 3 3 2404-0096 2404-0097 S S t t e e p p 4 4 Avoid stressing the valve.

-

Page 15: Welding

3 Installation Study the instructions carefully. The valve is supplied as separate parts to facilitate welding. The items refer to the parts list and service kits section. Check the valve for smooth operation after welding. 3.3 Welding S S t t e e p p 1 1 A A l l w w a a y y s s install valves with more than one valve body so that the seals between the valve bodies can be replaced. - Page 16 3 Installation Study the instructions carefully. The valve is supplied as separate parts to facilitate welding. The items refer to the parts list and service kits section. Check the valve for smooth operation after welding. S S t t e e p p 3 3 P P r r e e - - u u s s e e c c h h e e c c k k : : 1.

-

Page 17: Electrical Connection

3 Installation Study the instructions carefully. The valve is supplied as separate parts to facilitate welding. The items refer to the parts list and service kits section. Check the valve for smooth operation after welding. 3.4 Electrical connection E E l l e e c c t t r r i i c c a a l l c c o o n n n n e e c c t t i i o o n n Positioner 8694 Without display Terminal strip... -

Page 18: Recycling Information

3 Installation Study the instructions carefully. The valve is supplied as separate parts to facilitate welding. The items refer to the parts list and service kits section. Check the valve for smooth operation after welding. 3.5 Recycling information • • U U n n p p a a c c k k i i n n g g - Packing material consists of wood, plastics, cardboard boxes and in some cases metal straps - Wood and cardboard boxes can be reused, recycled or used for energy recovery - Plastics should be recycled or burnt at a licensed waste incineration plant... -

Page 19: Operation

4 Operation Study the instructions carefully and pay special attention to the warnings! Ensure that the valve operates smoothly. The items refer to the parts list and service kits section. 4.1 Operation S S t t e e p p 1 1 DO NOT DISASSEMBLE - C C A A U U T T I I O O N N Do N N O O T T attempt to disassemble the actuator due to... - Page 20 4 Operation Study the instructions carefully and pay special attention to the warnings! Ensure that the valve operates smoothly. The items refer to the parts list and service kits section. S S t t e e p p 3 3 N N e e v v e e r r touch moving parts if the actuator is supplied with compressed air.

-

Page 21: Troubleshooting

4 Operation Pay attention to possible faults. Study the instructions carefully. The items refer to the parts list and service kits (chapter 7 Parts list and service kits). 4.2 Troubleshooting N N O O T T E E ! ! Study the maintenance instructions carefully before replacing worn parts. -

Page 22: Recommended Cleaning

4 Operation The valve is designed for cleaning in place (CIP). NaOH = Caustic soda. HNO3 = Nitric acid. 4.3 Recommended cleaning S S t t e e p p 1 1 C C a a u u s s t t i i c c d d a a n n g g e e r r ! ! A A l l w w a a y y s s handle lye and acid with great care. - Page 23 4 Operation The valve is designed for cleaning in place (CIP). NaOH = Caustic soda. HNO3 = Nitric acid. S S t t e e p p 4 4 E E x x a a m m p p l l e e s s o o f f c c l l e e a a n n i i n n g g a a g g e e n n t t s s : : Use clean water, free from chlorides.

-

Page 24: Maintenance

5 Maintenance Maintain the valve regularly. Study the instructions carefully and pay special attention to the warnings! Always keep spare rubber seals and lip seals in stock. Check the valve for smooth operation after service. 5.1 General maintenance S S t t e e p p 1 1 DO NOT DISASSEMBLE Do N N O O T T attempt to disassemble the actuator due to - C C A A U U T T I I O O N N... - Page 25 5 Maintenance Maintain the valve regularly. Study the instructions carefully and pay special attention to the warnings! Always keep spare rubber seals and lip seals in stock. Check the valve for smooth operation after service. S S t t e e p p 3 3 N N e e v v e e r r stick your fingers through the valve ports if the actuator is supplied with compressed air.

- Page 26 5 Maintenance Maintain the valve regularly. Study the instructions carefully and pay special attention to the warnings! Always keep spare rubber seals and lip seals in stock. Check the valve for smooth operation after service. B B e e l l o o w w a a r r e e s s o o m m e e g g u u i i d d e e l l i i n n e e s s f f o o r r m m a a i i n n t t e e n n a a n n c c e e a a n n d d l l u u b b r r i i c c a a t t i i o o n n i i n n t t e e r r v v a a l l s s . . P P l l e e a a s s e e n n o o t t e e t t h h a a t t t t h h e e g g u u i i d d e e l l i i n n e e s s a a r r e e f f o o r r n n o o r r m m a a l l w w o o r r k k i i n n g g c c o o n n d d i i t t i i o o n n s s i i n n o o n n e e s s h h i i f f t t .

-

Page 27: Dismantling Of Valve

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. 5.2 Dismantling of valve If the actuator is marked with a danger warning, do N N O O T T attempt to cut the actuator open. DO NOT DISASSEMBLE SPRING UNDER LOAD Do N N O O T T attempt to disassemble the actuator due to spring... -

Page 28: Plug Seal Replacement

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. 5.3 Plug seal replacement A A t t t t e e n n t t i i o o n n ! ! Please be aware that the Needle Valve plug does not have an elastomer seal, and thus the valve will not close 100% tight. - Page 29 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. S S t t e e p p 2 2 Drawing 3 M M o o u u n n t t i i n n g g p p l l u u g g s s e e a a l l r r i i n n g g b b y y h h a a n n d d 1.

- Page 30 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. S S t t e e p p 3 3 M M o o u u n n t t i i n n g g p p l l u u g g s s e e a a l l r r i i n n g g w w i i t t h h A A l l f f a a L L a a v v a a l l p p l l u u g g s s e e a a l l t t o o o o l l M M o o u u n n t t i i n n g g t t o o o o l l f f o o r r e e l l a a s s t t o o m m e e r r D D N N 4 4 0 0 D D N N 5 5 0 0 - - D D N N 6 6 5 5...

-

Page 31: Assembly Of Valve

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. Drawing 1 Drawing 2 Drawing 3 Drawing 4 2404-0109 2404-0115 2404-0115 2404-0117 * = It is important to place the screwdriver underneath the plug. -

Page 32: Assembly Instruction For Positioner

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. 5.5 Assembly instruction for positioner 1. Mount the indication spindle (79) in top of actuator spindle (5). -

Page 33: Actuator Bushing Replacement

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. 5.6 Actuator bushing replacement If the actuator is marked with a danger warning, do N N O O T T attempt to cut the actuator open. DO NOT DISASSEMBLE SPRING UNDER LOAD Do N N O O T T attempt to disassemble the actuator due to spring... - Page 34 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. S S t t e e p p 2 2 I I n n t t r r o o d d u u c c t t i i o o n n - - S S t t a a n n d d a a r r d d s s o o c c k k e e t t w w r r e e n n c c h h Use a 27 mm socket wrench to mount the bushings, as the space in the yoke is limited.

- Page 35 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. S S t t e e p p 4 4 The actuator must be carefully fixed in a vice if it is dismounted from the valve. Be careful not to press the yoke flange oval when fixing the actuator in the vice.

- Page 36 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. S S t t e e p p 6 6 1. Lubricate thoroughly both the actuator spindle and o-rings. 2.

- Page 37 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. S S t t e e p p 8 8 Now pull the aligning spindle to centre the actuator spindle. In this position rotate the b b u u s s h h i i n n g g 180° backwards and then begin to fasten the bushing.

-

Page 38: Dismantling Of Fully Maintainable Actuator (Removable Yoke With Bolts/2006-June 2016)

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. 5.7 Dismantling of fully maintainable actuator (removable yoke with bolts/2006-June 2016) If the actuator is marked with a danger warning, do N N O O T T attempt to cut the actuator open. See also section DO NOT DISASSEMBLE SPRING UNDER LOAD... -

Page 39: Assembly Of Optional Maintainable Actuator

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. 5.8 Assembly of optional maintainable actuator If the actuator is marked with a danger warning, do N N O O T T attempt to cut the actuator open. See also section DO NOT DISASSEMBLE SPRING UNDER LOAD... -

Page 40: Changing Pneumatic Movement On Fully Maintainable Actuator (Nc/No)

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. 5.10 Changing pneumatic movement on fully maintainable actuator (NC/NO) If the actuator is marked with a danger warning, do N N O O T T attempt to cut the actuator open. See also section . -

Page 41: Technical Data

6 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 6.1 Technical data positioner The valve is remote-controlled by a digital electro-pneumatic process controller. It has few and simple moveable parts which results in a very reliable valve. - Page 42 6 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. W W e e i i g g h h t t (kg) 5 5 1 1 2 2 5 5 3 3 8 8 6 6 3 3 .

- Page 43 CONTACT CSI FOR MORE INFORMATION | CSIDESIGNS.COM | SALES@CSIDESIGNS.COM | 417.831.1411 ALFA LAVAL UNIQUE RV-ST VALVE INSTRUCTION MANUAL—REV 8/21...

-

Page 44: Parts List And Service Kits

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.1 Unique RV-ST Regulating Valve (sizes 25mm-51mm/DN25-DN50) If the actuator is marked with a danger warning do N N O O T T attempt to cut the actuator open. DO NOT DISASSEMBLE SPRING UNDER LOAD Do N N O O T T attempt to disassemble the actuator due to spring... - Page 45 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. P P a a r r t t s s l l i i s s t t Pos.

-

Page 46: Unique Rv-St Regulating Valve (Sizes 63.5Mm-101.6Mm/Dn65-Dn100)

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.2 Unique RV-ST Regulating Valve (sizes 63.5mm-101.6mm/DN65-DN100) If the actuator is marked with a danger warning do N N O O T T attempt to cut the actuator open. DO NOT DISASSEMBLE SPRING UNDER LOAD Do N N O O T T attempt to disassemble the actuator due to spring... - Page 47 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. P P a a r r t t s s l l i i s s t t Pos.

-

Page 48: Maintainable Actuator (Sizes 25Mm-51Mm/Dn25-Dn50)

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.3 Maintainable actuator (sizes 25mm-51mm/DN25-DN50) If the actuator is marked with a danger warning do N N O O T T attempt to cut the actuator open. DO NOT DISASSEMBLE SPRING UNDER LOAD Do N N O O T T attempt to disassemble the actuator due to spring... - Page 49 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. P P a a r r t t s s l l i i s s t t Pos.

-

Page 50: Maintainable Actuator (Sizes 63.5Mm-101.6Mm/Dn65-Dn100)

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.4 Maintainable actuator (sizes 63.5mm-101.6mm/DN65-DN100) If the actuator is marked with a danger warning do N N O O T T attempt to cut the actuator open. DO NOT DISASSEMBLE SPRING UNDER LOAD Do N N O O T T attempt to disassemble the actuator due to spring... - Page 51 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. P P a a r r t t s s l l i i s s t t Pos.

- Page 52 H H o o w w t t o o c c o o n n t t a a c c t t A A l l f f a a L L a a v v a a l l Contact details for all countries are continually updated on our website.

Need help?

Do you have a question about the CSI RV-ST and is the answer not in the manual?

Questions and answers