Summary of Contents for WTE TReX-460

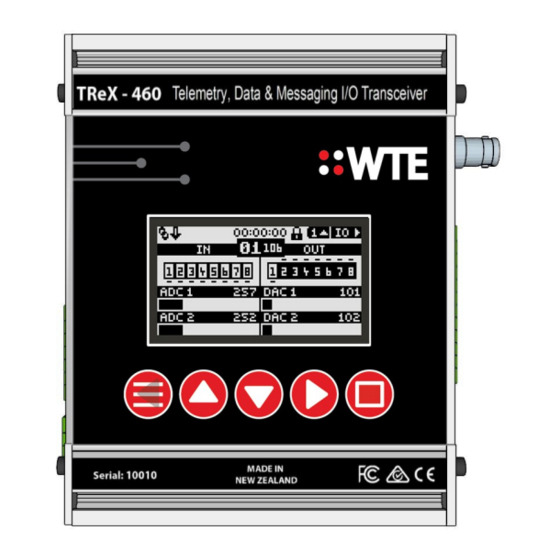

- Page 1 TReX User Manual v15.30 Firmware WTE TReX IoT, TELEMETRY, MESSAGING I/O TRANSCEIVER + PLC User Manual Page 1 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 2: Table Of Contents

*ENCRYPT........105 RF Menu..........50 *BYPASS........105 ENCRYPTION Sub-Menu....52 *LAB..........106 RX Menu..........53 *POPUP.........106 FILTERS..........55 Transmit Commands......108 TX Menu..........58 *TX_FREQ........108 MISMATCH Sub-Menu....61 *TX_PROTO.........108 PROTOCOL Menu.......63 *TX_BAUD........108 MQTT Sub-Menu......65 *TX_PWR........108 TCP-IP Menu........67 *TX_MODE........109 Page 2 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 3 Modbus..........151 *MISMATCH_DATA....125 Modbus RTU........151 DMR Commands........127 Modbus TCP........151 *DMR_CAL........127 Function Codes.......151 *DMR_DB........127 Modbus Mapping Table....152 System Commands......128 Software Integration.......153 *TREX_LANG......128 RAW Protocol........154 *TREX_BACKLIGHT....128 *RAW_TIMEOUT......154 *TREX_SOUND......128 *RAW_END........154 *TREX_RS232......128 *RAW_CONFIG......154 Page 3 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 4 Operating as a TLS Client....246 Running Simulated Programs.....196 Notes...........246 Adding Rung Branches.......198 TLS Connection Error Codes.....246 Rung Comments.........199 Repeater Operation Modes....248 Importing TReX Configuration Files..200 Store Forward Operation....249 Page 4 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 5 2 Wire Connection......269 Manufacturing marking and labels..293 Bus Terminating Resistor....269 Maintenance...........293 RF Connections........271 Product End Of Life......294 Power Connections........272 Product Warranty........295 Ethernet Interface........273 Abbreviations and Glossary....296 TReX Firmware Upgrade.....274 Specifications..........297 Page 5 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 6: Introduction

Support for an unlimited number of IoT devices to publish to a MQTT broker service. • Support for two-way paging. Provides receipt of delivery and optionally receipt for accepted jobs. Page 6 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 7 Support for additional protocols upon request and negotiation. • Firmware upgradable. • High stability oscillator ensuring a maximum of 80Hz drift (at 160MHz) over the entire specified temperature range. Page 7 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 8 Antenna mismatch detection capability. • High sensitivity receiver. • Internal real time clock. • Long-life design uses no moving or electromechanical parts. No limited life components such as electrolytic capacitors. Page 8 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 9: Trex Versions

◦ 8 relay outputs (normally open contacts) ◦ 2 analog outputs (1-10V or 4-20mA) For more information on these TReX I/O variations please refer to the Installation section on this manual. Page 9 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 10: Safety Information

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury NOTICE NOTICE is used to address practices not related to physical injury. Page 10 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 11 System control paths may include communication links. Consideration must be given to the implications of anticipated transmission delays or failures of the link. Failure to follow these instructions can result in death or serious injury Page 11 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 12 The TReX was NOT designed to operate and/or be connected directly to live main voltages. The TReX must be connected to a certified, suitably rated low voltage DC supply. Failure to follow these instructions can result in death or serious injury Page 12 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 13 Care when stacking TReX boxes must be taken to not damage part of the radio, such as connectors. NOTICE introduction of foreign object into the TReX radio enclosure will void warranty. Page 13 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 14 For more information regarding recycling, contact the dealer where the product was originally purchased. Page 14 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 15: Operation

The TReX outputs are driven high or low, or for a particular period of time depending on configuration. The outputs are controlled via the WTE Output Control Protocol message received and decoded. Each output can be configured to operate under various error states (Refer to Outputs). -

Page 16: Buttons

Used to select file related items from within the MAIN SCREENS. When in the PLC configuration menus, this button allows the currently edited PLC ladder program page to be viewed. Page 16 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 17: Main Screens

The “X” indicates a loss of an active link. This occurs when there has been no messages received for a configured period of time. The “link-fail” output if enabled will operate when this icon is shown. Page 17 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 18 The padlock icon indicates that transmissions are AES encrypted. The icon “P” indicates that the PLC is operational and controlling outputs as programmed. Page 18 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 19: Io Screens

FAIL TIME each time a message is decoded. This “link count” reduces, and if reaches 0, the link fail output can be operated. MASTER TReX units allow the “link count” to be viewed for all remote TReX SLAVE units. Page 19 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 20 The large tick icon indicates that a particular alert is enabled. The bell icon for each alert shows if there are new alerts that have been raised. See Alert Handling for details on alert configuration. Page 20 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 21: Tx Screens

TX logging has been enabled (MENU->TX->MSG LOG). When an entry is selected pressing the UP/DOWN buttons, pressing the ENTER button displays the entire message. Page 21 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 22 The POWER ADC count is used to indicate forward power. RF TEMP relates to the RF amplifier temperature (not ambient) in degrees Celsius. VOLTS is the supply voltage and AMPS is the total supply current. Page 22 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 23: Rx Screens

Note that messages are only available here when RX logging has been enabled (MENU->RX- >MSG LOG). Messages starting with “*” are messages that met the ALERT filter requirements, and were eligible to operate the ALERT output when logged. Page 23 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 24 Displays the last received message in large font. If the message exceeds the screen size, the DOWN button allows scrolling. RX (4): Displays the signal strength of the configured channel in real time. Displays signal strength from -128dBm to 0dBm. Page 24 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 25: Plc Screens

TReX User Manual v15.30 Firmware PLC Screens The PL screen is a main screen of the TReX-460 that displays the currently configured ladders in groups of six lines. Further lines can be reached by pressing the DOWN button on the front of the device. -

Page 26: Site Configuration Tools

-125dBm making and is suitable for site inspection. This is an optional feature that requires a feature key to be purchased. Page 26 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 27: Demodulated Signal Viewer

This is useful for viewing channel activity. This facility is available for 2 level modulation modes of operation. 4 level modulation modes will display as straight lines. Page 27 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 28: Radio Link Encryption

Radio Links The TReX can be configured to use industry leading AES 256-bit, block chained encryption for all used radio data links. This means messaging between WTE TReX radios cannot be intercepted without sharing of a key between devices. A unique, non repeating timestamp is transmitted with every packet, ensuring that same content messages are not repeated, and also allows for protection against replay attacks. -

Page 29: Dmr Messaging

All protocols implemented support direct DMR messaging. In order for a protocol to transmit directly to a DMR radio the DMR_DB database should be configured with group IDs, together with colour code, radio type and DMR radio frequency. Page 29 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 30: Programmable Logic Controller

TReX User Manual v15.30 Firmware Programmable Logic Controller An optional feature of the TReX-460 is a telemetry-optimised PLC. This allows automated control of outputs and transmissions based on configurable inputs, serial input, received messages, counters, comparators and timers. This PLC utility uses a ladder logic programming similar to other commercially available PLC devices. -

Page 31: Two-Way Paging

Accepting the job can be performed with a simple keypress that will send receipt to the dispatch system that the vehicle is on-route. See WTE Ack and Confirm Protocol for usage details. With a single keypress, key messages can be responded to. Details of the responder are returned and logged. -

Page 32: Configuration Methods

2. Wait for the TReX to appear as a mass storage device. 3. Copy the backed up file WTE_CONF.INI to the TReX, replacing the existing file. 4. Restart the TReX. Page 32 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 33: Front Panel Menu Configuration

Pressing the MENU button again moves back one level, until the top is reached, and then the TReX leaves the MENU mode. If any change has been made, changes will only be written to internal storage when leaving the MENU mode. Page 33 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 34 UP/DOWN buttons. To make the text shorter or to delete a character, highlight the BACK arrow and press the ENTER button. Press the BACK button to exit the editor. Page 34 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 35: Web Browser Configuration

This is located in SYSTEM->IP. In this menu section network parameters can be configured such as the IP, Mask and gateway. Only a single connection to the TReX should be allowed. Multiple connections will result in impaired responsiveness. Page 35 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 36 Changes can now be made and committed by pressing the SEND button. This text box can also be used to transmit messages for a configured protocol. Page 36 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 37: Serial Command Configuration

In order for any configuration changes made via serial to be saved the command *SAVE<CR> must be sent to the TReX before removing power or restarting. Note: Although most configuration changes are applied immediately, it is a good practice to Page 37 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 38 TReX User Manual v15.30 Firmware restart the unit after changing configuration. This can be achieved by removing power to the unit or sending the *REBOOT<CR> command. Page 38 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 39: Menu Configuration

“Chrome” or “Firefox” web browser, TCP client or TCP server. TELEMETRY Determines if operation is on a controlled protocol basis, or autonomously operating input states to a remote TReX device. Page 39 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 40 Configuration of the paging store and forward repeater operation including duplicate reject. Configuration of programmable controller ladder logic program. INPUTS Configuration of all inputs. OUTPUTS Configuration of all outputs. ALERTS Configuration of all alerts. Page 40 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 41: System Menu

Setting to 0 disables the backlight completely. CONTRAST The screen contrast setting. Although the display is temperature compensated across the TReX operating range, at times improved viewing is possible through this contrast adjustment. Page 41 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 42 TIME Sets the internal clock. UNIT ID This is the unit ID that is used by the WTE output control protocol. This can be any number or alpha numeric description. e.g. “01” or “Unit-A” SOUND Allows control of system sounds that may be heard on an ALERT and also key beeps.

- Page 43 Regulatory items such as FCC-ID*. *Note: Publication number 784748-D02, FCC-Part 90 allows for devices with integrated display to not require a printed label on the device holding this information. Page 43 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 44: Test Sub Menu

TReX User Manual v15.30 Firmware TEST Sub Menu Digital output to test. Pressing up pulls the output to ground for 60 seconds. Pressing down releases the output. Page 44 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 45: Factory Sub Menu

Used to set the TReX back to factory defaults. Calibration data is not cleared. This may be used at any time to restore the unit to a known starting point. Page 45 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 46 If this minimum level is not reached, there will be a transmit warning and the RF OUTPUT (Shared with the MISMATCH output) will operate if configured. This parameter should NOT be changed without instruction from WTE. MAX PWR Specifies the maximum power level as read from the forward ADC during a transmission.

-

Page 47: Time Sub Menu

SEQ TEST takes the time from national paging network (used in N.Z. only). • NONE only uses the internal processor clock. This will only be the time since last reset. Page 47 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 48: Spectrum Menu

Defines the base signal level on the screen. When set to -100, only signals with a strength greater than -100 dBm will be displayed. Range is -130 dBm to -60 dBm. Page 48 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 49 TReX User Manual v15.30 Firmware dB/DIV Scales the signal level displayed. Either 10 dB/DIV or 20 dB/DIV can be set. When 20 is set a dynamic range of 120 dB is possible. Page 49 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 50: Rf Menu

(such as receiving in FLEX on one frequency and transmitting in POCSAG on another). RX_DISABLED disables all receiver functions. TX_DISABLED disables all transmitter functions. When RX_DISABLED is selected an operating current reduction of 50mA is typical. Page 50 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 51 Transmitter configuration items. Includes output power level, power limits and other TX only parameters. Receiver configuration items. Includes RIC ranges, alerting options plus RF parameters such as frequency when RF has been configured to be DUPLEX. Page 51 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 52: Encryption Sub-Menu

TReX transmitting with a matching LOCAL ID. LOCAL ID This is the TELEMETRY->LOCAL ID, and must be unique for every TReX transmitting in a system. Page 52 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 53: Rx Menu

See ALERT FILTER. If the ALERT output is enabled the configured output will also operate. Can be configured from 0-250 seconds. When set to 0 the alert is disabled. Page 53 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 54 All messages displayed are written to internal SD card and can be viewed on the message history screen. CLEAR: Setting to CLEAR will result in RX-LOG.TXT being deleted when exiting the menu. Page 54 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 55: Filters

‘*’ to the message. In all the following examples: ALERTS->ALERT OUT set to 2. ALERTS->MSG set to ENABLED. OUTPUTS->2->MODE set to DISABLED (to ensure no other IO function shares output 2) Page 55 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 56 OK indicators and timers will continue to operate normally. INCL FILT set to DISABLED: Messages are not filtered INCL FILT set to ENABLED: Messages are filtered Page 56 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 57 WTE_EN must be used in order to receive 8 bit characters (POCSAG_A transmits 7 bit characters only). • FLEX must be used in order to receive and decode 2 level 1600 baud FLEX messages. Page 57 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 58: Tx Menu

Long preambles are typically used in conjunction with a matching receiver to save battery power when the receivers is in deep sleep mode. The POCSAG standard uses a preamble of 576 bits. This very long preamble means that Page 58 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 59 POCSAG messages originating from other sources. PERIODIC If DISABLED the configured PERIODIC MSG is not transmitted. When not DISABLED, the value is the time in seconds between transmitting the PERIODIC MSG. PERIODIC MSG Page 59 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 60 All messages displayed are written to internal SD card and can be viewed on the message history screen. CLEAR: Setting to CLEAR will result in TX-LOG.TXT being deleted when exiting the menu. Page 60 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 61: Mismatch Sub-Menu

7. Test the system by either changing or removing the antenna, then transmitting a message. Perform this test with care, and infrequently since this will place stress on the transmitter. The selected output will operate and pop-up will be seen. Page 61 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 62 This should not need to be changed. This is the permitted variation in transmit current. Decreasing this value will result in higher rate of false MISMATCH alerts but greater sensitivity to small changes. Typically a value of 50 will be appropriate. Page 62 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 63: Protocol Menu

TReX User Manual v15.30 Firmware PROTOCOL Menu Specifies the protocol to apply for serial input. Accepts WTE, CUSTOM, RAW, AUX and in some cases others as required or specified. Specifies the protocol to apply for serial output. Accepts WTE, CUSTOM, RAW, AUX and in some cases others as required or specified. - Page 64 Specifies parameters used for the “MQTT” protocol. This is a common “IoT” service protocol. MODBUS Specifies parameters used for the “MODBUS” protocol. Specifies parameters used for the “RAW” protocol. Page 64 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 65: Mqtt Sub-Menu

Password to be used to log in to the broker. Not all brokers require this. UNIT ID This is the unit ID that is used by the WTE output control protocol. This can be any number of alpha numeric description. e.g. “01” or “Unit-A”. The UNIT ID is part of the published MQTT topic. - Page 66 (10 minutes) and can be incremented or decremented by 10 seconds at a time through the menu. For finer control over the republish period, refer to the *MQTT_CONFIG command section of the manual. Page 66 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 67: Tcp-Ip Menu

REMOTE IP. SERVER would typically be used if a remote device required a long duration or permanent connection. This would be desirable if monitoring decoded messages. WEB+SERVER: Concurrent WEB and SERVER functionality. WEB+CLIENT: Concurrent WEB and CLIENT functionality. Page 67 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 68 HOST This is the name that can be associated to the TReX. This name can be used directly instead of the IP address to address the TReX. By default is “WTE-TReX” LOCAL IP IP Address for access to the TReX.

- Page 69 Can be specified in steps of 60 seconds up to a max of 5 minutes. Provides RS232, visual and audible notification of the reboot. Non-editable MAC address. SECURITY Configuration of TCP security settings. Page 69 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 70: Security Sub-Menu

TReX User Manual v15.30 Firmware SECURITY Sub-Menu When ENABLED, the TReX will attempt to use Transport Layer Security over the TCP connection. Page 70 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 71: Telemetry Menu

It is possible to have many TReX units operating on the same frequency. This is the ID that the REMOTE TReX needs to use in its REMOTE ID field in order to communicate. Page 71 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 72 This is the raw ADC count that is a value up to 1023. Min value is 10 to ensure that very small changes do not result in continuous transmissions in an electrically noisy environment. SERIAL LINK Configuration of all SERIAL LINK Settings Page 72 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 73 TReX User Manual v15.30 Firmware MODBUS Configuration of all MODBUS Settings Page 73 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 74: Serial Link Menu

The TX TIMEOUT item takes priority. The value of this configuration item is the decimal value of the ASCII character. Please refer to a standard ASCII chart for decimal values for ASCII characters (1-127). Page 74 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 75: Store Fwd Menu

Duplicate reject only tests the previous 10 messages in the historic transmit queue. Page 75 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 76: Plc Menu

Note: When the PLC program is edited through the menu, the file wte_plc.ini is regenerated. This means that any additional information in the PLC configuration file (such as comments) will be lost. Page 76 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 77 NOT visible. LOGGING When logging is ENABLED, Any TReX output changes are timestamped and logged to the TReX internal SD card. Please see PLC Support for logging details. Page 77 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 78: Ladder Program Quick-View

Note: The edited PLC program is not saved until leaving the menu system. Entering the “Quick-View” screen does not save the program. Page 78 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 79: Rungs Sub-Menu

Each POS TYPE entry is used to control the type of input used at the corresponding position in the rung. The possible types are: • INPUT [I:]: Input will be active when the corresponding input of the TReX-460 is level high. Each of the following inputs are available for local and remotely accessed TReX units. - Page 80 ◦ Input 12: Link status, input indicates if the unit is actively receiving messages. Useful to act on remote units that are no longer communicating. • OUTPUT [Q]: Input will be active when the corresponding output of the TReX-460 is closed. •...

- Page 81 TReX User Manual v15.30 Firmware energised. • OUTPUT (SQ): Sets (latches) a specified digital output of the TReX-460 when the rung is energised. • OUTPUT (RQ): Resets (releases latch) of a specified digital output of the TReX-460 when the rung is energised.

- Page 82 Note: Remote devices use the character ‘i’ to indicate inputs, ‘g’ to indicate ADC comparators and ‘o’ to indicate outputs. The local unit uses the convention “I:” for inputs, “G:” for ADC comparators and “Q:” for outputs. Page 82 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 83: Timers Sub-Menu

Retentive On Timer. Same as TON, but timer does not auto reset when the rung is de- energised. In order to manually reset the timer the RT output must be operated. STATE: The current value of the timer, and any set timer flags. Page 83 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 84: Counters Sub-Menu

5 transitions. The max count rate is 10Hz, or less depending on remote input radio data rates. There are 16 independent counters available. STATE: The current value of the counter, and any set counter flags. Page 84 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 85: Comparator Sub-Menu

The ADC to use for the comparison. This can be either ADC1 or ADC2. There are 16 independent comparators available. Each comparator can be applied to the local MASTER TReX unit or any remote SLAVE TReX device. Page 85 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 86: Alarms Sub-Menu

PLC program to perform more complex timing tasks such as alarms that allow air conditioning to turn on during weekdays, but only between certain hours. Page 86 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 87 TReX User Manual v15.30 Firmware Page 87 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 88: Macros Sub-Menu

The MACROS sub-menu is used to view configured macros. Editing of macros is not possible directly on the TReX. See PLC Support. There are 64 macros that can be viewed. Macros are set and edited in the file MACRO.TXT Page 88 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 89: Match Sub-Menu

Access to the text editor to allow the serial input string to be viewed and modified. WORK BIT: This is the associated work bit (B:1-B:64) that can be set when the input string is matched. Page 89 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 90: Inputs Menu

Treated as input 12. The link fail count is configurable on any unit. Should any TReX fail to receive any message within this period, messages may be transmitted or this status used as a PLC program input. ADC CAL This manages calibration of analog inputs. Page 90 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 91: Adc Cal Sub-Menu

This is a read only field that displays a value from 0-1023. INPUT This is a read only field that displays the raw analog input value from 0-1023. The INPUT is Page 91 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 92 8. Check that when a mid voltage between the maximum and minimum is connected, the SCALED field displays a mid value between 0 and 1023. 9. Exit MENU and settings will be saved. Page 92 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 93: Input Config Sub-Menu

UNSET The input state is read on start-up. There will not be a transmission until the input changes (if configured to transmit on that HIGH or LOW level). Page 93 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 94 An ADC count below this may result in an ADC input transmission if configured. MSG LOW The message that is transmitted when the input moves to the LOW level. Input messages must always use WT Protocol. Page 94 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 95 Note: The BATT input threshold settings are also used to set the battery icon on the main screens. MSG HI The message that is transmitted when the input moves to the HIGH level. Input messages must always use WT Protocol. Page 95 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 96: Outputs Menu

In general, assignment of an output to more than one function is not recommended. DAC CAL Configures calibration of analog output 1 and 2. See DAC CAL Sub-Menu. Page 96 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 97: Output Config Sub-Menu

LOW state after this period of time has passed. ALERT If ENABLED, the output is able to generate an ALERT when operated. See Alert Handling. Page 97 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 98: Dac Cal Sub-Menu

This is the maximum used unscaled DAC count of interest. If no scaling is to be applied set to 1023. This sets the output as a value between 0-1023 that is scaled and applied between the MIN and Page 98 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 99 4. Adjust DAC->MIN until output current is approximately 4mA. 5. Set DAC output to 1023 6. Adjust DAC->MAX until output current is approximately 20mA. 7. Exit MENU and settings will be saved. Page 99 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 100: Alerts Menu

TEMP When ENABLED, an alert will be raised when the TReX has reached the max temperature. The max temperature is set in MENU->SYSTEM->OVERTEMP. This is the TReX board Page 100 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 101 When set to an output from 1-8, this is the output that can be operated when ANY alert is raised. SOUND Enables sound for alerts and key presses. Page 101 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 102: Serial Command Configuration

*DEFAULTS Forces to reset temporary to factory default settings. The user must issue the *SAVE<CR> command in order to write these default settings to internal memory. Usage: *DEFAULTS<CR> Page 102 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 103: Rssi

Output states for all 8 outputs follow, then ADC inputs 1 and 2 and finally the current DAC settings. Page 103 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 104: Temp

DD is day of the month (1-31) MM is the month (1-12) YY is the year (0-99) W is optional day of the week, MON-SUN (1-7) Typical Usage: Page 104 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 105: Rtc_Time

(in the case below “Test Message”) to arrive as a message, a RIC range must be configured in the TReX to suit. *BYPASS=[NNNNNNN:L]MMMMMMMM<CR> where: [ is the character ‘[’ Page 105 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 106: Lab

*BYPASS=[1234567:1][[01]12345-8]<CR> “[[01]12345-8]” will be added to the RX message screens, logged etc., as if received across the air. In this case, the message will also be processed as a WTE Output Protocol message and immediately operate the TReX outputs. *LAB Set the unit in transmit mode, it can be configured to transmit carrier only or modulated. - Page 107 LINE1 is the content to display on the first content line. Max 20 characters. LINE2 is optional, the content to display on the second content line. Max 20 characters. Page 107 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 108: Transmit Commands

TReX User Manual v15.30 Firmware Transmit Commands *TX_FREQ Specifies the transmit frequency in Hz. For the TReX-460 the minimum is 421000000 and maximum is 480000000. Typical usage: *TX_FREQ=460000000<CR> *TX_PROTO Specifies the protocol to apply for serial input. Accepts WTE, RAW and AUX. -

Page 109: Tx_Mode

9 codes can be specified. The TX_CAP code would be used when a protocol supplied code is to be overridden, and sent to a single or multiple other recipients instead. TX_CAP syntax: Page 109 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 110: Tx_Dmr

MMMM is the periodic message to transmit (up to 50 characters). Typical usage: *TX_PERIODIC=10,WT1234560A10 Test_Message<CR> *TX_PREAMBLE Sets the preamble length in multiples of 32 bits. Short preambles allows the messages to be transmitted quickly. Page 110 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 111: Tx_Lead

ALL entries in the databases being used for retransmitted messages. *TX_REPEAT=A,BB<CR> where: A is the number of repeated transmissions. Max 5. Default 0. Page 111 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 112 TReX User Manual v15.30 Firmware BB is the delay in seconds between repeated transmissions. Max 60, min 1. Typical usage: *TX_REPEAT=3,10<CR> Page 112 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 113: Rf_Key

All TReX devices in a system must share this key. Typical usage: *RF_KEY=1,1,1, 452948404D635166546A576E5A7234753777217A25432A462D4A614E64526 <CR> *RF_KEY? Typical response: *RF_KEY=1,1,1,- **** 4529 Note: only the first 4 characters of the key are displayed. Page 113 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 114: Receive Commands

2400_6, 4800_25, 4800_12, 4800-4L_6, 9600_25, 9600-4L_25, 9600-4L_12, 16K-4L_25, 16K-4L_12, 32K-4L_25 Typical usage: *RX_BAUD=512_25<CR> *RX_PROTO Specifies the protocol to apply for serial output, accepts WTE, RAW and AUX. See protocol section for more detail on protocols and configuration. Typical usage: *RX_PROTO=WTE<CR> Page 114 of 302... -

Page 115: Rx_Mode

In this example the channel will be considered “busy” if signal strength is above -80dBm. Typical usage: *RX_BUSY=1,-80,5<CR> Note: If the TReX continually reports BUSY, issue the command *RSSI<CR> to view the current noise floor and adjust the busy level appropriately. Page 115 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 116: Rx_Link

*RX_LOG Enables logging of received messages to the file RX-LOG.TXT. If set to 0, disables logging, 1 enables logging, and 2 deletes the log file. Typical usage: *RX_LOG=0<CR> Page 116 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 117: Store Forward Commands

5 messages in the historic transmit queue. For example, to configure to use a 2 second clearing delay after each transmission and 10 second message duplicate reject: *STORE_FWD=20,10<CR> Page 117 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 118: Protocol Commands

WT1234560A10 Test If the command WT1234560A11 TEST is sent to the TReX, the serial output will echo the full WT protocol command including the message payload. Page 118 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 119: Mqtt_Config

This command is used for customer-specific protocol implementations. Please contact info@wte.co.nz for more details. It is not recommended to use this command unless instructed to do so by WTE Ltd. Page 119 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 120: Input Commands

*IN_MSG_L command. Usage is as follows: *IN_CONFIG_L=I:N,D,R,A,L<CR> Where: I = The input to configure (1-11 valid). Input 9 is the VIN input, 10 is ADC 1 and 11 is Page 120 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 121: In_Config_H

At this repeating interval, if non-zero, a there will be another single transmission. Example. Configure input 1 to send 2 messages after input is debounced by 300 milliseconds Page 121 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 122: In_Msg_L

2H = ADC1 voltage high ADC count 2L = ADC1 voltage low ADC count 3H = ADC2 voltage high ADC count 3L = ADC2 voltage low ADC count Typical usage: *IN_ANALOG=138,114,200,100,500,400<CR> Page 122 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 123: Output Commands

Output Commands The output commands allow the GPIO pins to be configured as outputs or inputs. Following configuration of the pins as outputs, they are controlled using the WTE Output Control Protocol. Note: Please refer to Input Output Hardware Connection section on this manual for examples of how to connect the input and output pins on the TReX board. -

Page 124: Unit_Id

XX are any characters (up to 12 either numeric or alphanumeric) that are used to uniquely address each TReX when used in conjunction with the WTE Output Control Protocol. By default this ID is “01”, allowing numeric paging to be used to transmit messages. -

Page 125: Mismatch Commands

BB = the min forward power permitted (ADC count). CC = the max forward power permitted (ADC count). DD = the min permitted TX current (mA). EE = the max permitted TX current (mA). Page 125 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 126 TReX User Manual v15.30 Firmware Typical usage: *MISMATCH_DATA=7,70<CR>(sets DAC variation to 7, current variation to 70mA) Page 126 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 127: Dmr Commands

A = DMR Radio Type (0-2) B = DMR transmission Colour Code (1-16) C = DMR Slot (not used for Tier 1) D = DMR transmit frequency. Typical usage: *DMR_DB=0,6,0,458600000<CR> Page 127 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 128: System Commands

Typical usage: *TREX_SOUND=1<CR> *TREX_RS232 Sets the serial baud rate of the RS232 port. The second parameter should be set to 1 if EVEN parity is required. Typical usage: *TREX_RS232=9600,0<CR> Page 128 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 129: Trex_Rs422

Configures the over-temperature set-point. This is the TReX board operating temperature and NOT the ambient temperature. See Alert Handling. *TREX_OVERTEMP=T Where: T is the RF temperature sensor set point. Typical usage: *TREX_OVERTEMP =95<CR> Page 129 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 130: Trex_Filters

Note: Telemetry parameters should be set taking the data transmission rate into account. High data rates, such as 16K baud will send and process acknowledgements in around 200ms, Page 130 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 131: Trex_Screen

Sets parameters used to calibrate the analog outputs and inputs. See DAC and ADC CAL Sub- Menus for more information. *TREX_DAC_CAL=AA,BB,CC,DD<CR> where: AA = DAC1 minimum count. Default 0. BB = DAC1 maximum count. Default 1023. CC = DAC2 minimum count. Default 0. Page 131 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 132: Limits

Sets the method by which the TReX maintains internal time. *TIME_SOURCE=X where: X is the method of maintaining internal time 0 = NONE 1 = FLEX 2 = SEQ TEST 3 = RTC Page 132 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 133 TReX User Manual v15.30 Firmware Typical usage: *TIME_SOURCE=0<CR> Page 133 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 134: Plc Commands

XXX is the ladder logic for the rung. Typical Usage: PLC Configuration: *PLC_RUNG=01:[I:1]-------[I:4]-------[I:5]-------(T:3) *PLC_RUNG=02:[-] +----[TT3]-------[TT4]---+ *PLC_RUNG=03:[TT3]-------[/TD3]------[-]---------(Q:2) *PLC_RUNG=04: *PLC_RUNG=05:[Q:2]-------[I:6]-------[/I:8]------(Q:7) *PLC_RUNG=06: The above configuration will result in the following ladder logic equivalent program. Page 134 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 135: Plc_Opts

B is the LOGGING output change enabled state. When set to 1, any physical output change will be saved to internal SD card. See PLC Support. Typical Usage: *PLC_OPTS=1,0<CR> Page 135 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 136: Plc_Tmr

A is the ADC used for the comparison. If 1, uses ADC1, if 2 uses ADC2. • B is the comparator threshold. Can be set from 0-1023. Typical Usage: *PLC_CMP=1:1,400<CR> Page 136 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 137: Plc_Alarm

To match on the serial inputs “AT\r” then set work bit 4 (B:4) on a match, and also set work bit 5 (B:5) on match of “B\r\n”: *PLC_MATCH=1:4,AT$0D<CR> *PLC_MATCH=2:5,AT$0D$0A<CR> Page 137 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 138 In this example, work bit 4 is set when a serial match is detected. Output Q:8 is set immediately when work bit 4 is set. In order to detect another serial match, the work bit 4 is immediately cleared when used. Page 138 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 139: Tcp-Ip Commands

Specifies the default TReX IP address and the server address. *IP_ADD=LLL,SSS<CR> where: LLL = the local IP (the default IP is 192.168.1.21) SSS = the server IP or address. Page 139 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 140: Ip_Port

*IP_DNS=aaa.bbb.ccc.ddd,eee.fff.ggg.hhh where: aaa.bbb.ccc.ddd = first DNS server IP, eee.fff.ggg.hhh = second DNS server IP Typical usage: *IP_DNS=192.168.1.1,0.0.0.0<CR> Note: The IPs are separated by the use a “,” (COMMA) Page 140 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 141: Ip_Mac

This item is useful for testing connectivity. If the TReX cannot successfully PING the SERVER, it is likely that a firewall network filtering rule is preventing the connection. Usage: *PING<CR> Page 141 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 142: Protocols

WT Protocol The WT Protocol is the default protocol used by WTE products. It allows for a variety of over the air transport methods (such as POCSAG and DMR paging) to be used and a variety of baud rates. - Page 143 = 4800 4 Level GFSK NOTE: Although the protocol supports the following modulation types and channel spacings, the supplied WTE product may only support a subset of these modulation rates (determined by regional restrictions). <SPACE> is a single space character.

-

Page 144: Serial Only Output

All messages received come out via the serial port as configured in by the *RX_PROTO setting: If *RX_PROTO=WTE then the output will look like: WT1234567A10<SPACE>TEST<CR> The exact same format allows units to be connected together, or protocols to be converted from one type to another. -

Page 145: Level Modulations

4 Level Modulations All WTE 4L modulations, regardless of the used channel spacing, transmit data using the WTE_EN transport method. 4L modulations also do not include forward error correction information as all 2L modulation supported do. This gives much faster possible transmission speeds. - Page 146 RIC codes 0201234 and 0005647 as a 1200 baud POCSAG message. WT1234560A10WT1222222A10WT0201234A11WT0005647A11<SPACE>TEST<CR> 4 messages will be transmitted, batched in 2 transmissions, one for 512 baud messages and another transmission for the 1200 baud messages. Page 146 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 147: Dmr Message Format

Messages transmitted will have the TReX serial number as the source. If the TReX unit ID is configured to a numeric value greater than 1, then this becomes the transmitted source ID. Page 147 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 148: Variable Content Macros

This database is able to store up to 9 cap codes and 9 DMR codes that can be configured through the RF->TX menu. The DMR database menu is also used to configure the transmission frequency, colour code and type. Page 148 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 149 Note: DMR transmissions of any type, regardless of whether a DMR DB entry (forced by using the 0000008 cap code), will always use the frequency specified by the DMR DB menu. Page 149 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 150 TReX User Manual v15.30 Firmware If there are no entries in either the RIC or DMR DB, then WT0000008XXX messages will be directed to ID 0000008. Page 150 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 151: Modbus

Note: in the following mapping, provision has been allowed for multiple SLAVE units. The first single register (and in the case of discrete I/O, 8 registers) are for the MASTER unit, and Page 151 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 152: Modbus Mapping Table

Modbus Mapping Table Base Address Num Registers Description Bits Digital Out (discrete) 10001 Digital In (discrete) 30001 ADC 1 (raw count 0-1023) 30257 ADC 2(raw count 0-1023 ) Page 152 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 153: Software Integration

Master. Software Integration An example integration of the TReX into the control software LabVIEW is provided by WTE on request. This integration consists of the virtual interface (VI) file TReX-SCADA.vi. This VI provides basic control over the different inputs and outputs of the connected master TReX device as well as the slave devices communicating wirelessly with the master device. -

Page 154: Raw Protocol

Parameter 1 specifies the time of inactivity in 25ms steps before sending all stored data (max 255). Parameter 2 specifies a character that results in immediate transmission (0 if unused). Decimal value of ASCII character, Typical usage: *RAW_CONFIG=4,13<CR> Page 154 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 155: Mqtt

While operating an MQTT IoT network, the network continues to operate normally for paging messages, allowing notifications to be delivered to any paging receiver or TReX operating within the MQTT IoT network. Page 155 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 156: Configuration

There are many topics published from the TReX, in fact an unlimited number is possible that can be configured to be any topic required by the user. Published Topics By default published topic format is TREX/01/XXX where XXX is the input or output. Page 156 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 157 TREX/01/Do2 Digital Output 2 0 or 1 TREX/01/Do3 Digital Output 3 0 or 1 TREX/01/Do4 Digital Output 4 0 or 1 TREX/01/Do5 Digital Output 5 0 or 1 Page 157 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 158: Rotating Message Out

This also allows a new client to view the last 100 messages sent by the TReX before the initial connection by the client to the broker. Page 158 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 159: Full System Operation

Using this method any number of remote devices can be used that will uniquely publish an unlimited number of MQTT topics that can be displayed on any MQTT device (smartphone etc.). Page 159 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 160: Plc Support

TReX User Manual v15.30 Firmware PLC Support An optional feature of the TReX-460 is a telemetry-optimised PLC. This allows automated control of outputs and transmissions based on configurable inputs, received messages, counters, comparators and timers. This PLC utility uses a ladder logic interface similar to other commercially available PLC devices. -

Page 161: Key Terminology

TReX User Manual v15.30 Firmware examples to act as starting points when designing a PLC program for the TReX-460. Key Terminology Inputs: These are sometimes referred to as relays or relay inputs in historical PLC devices. The TReX PLC supports: •... -

Page 162: Plc Logging

Date and time are logged, together with the rung of the PLC program that resulted in the change, and the output that did change. Finally the new output state is displayed (1 or 0). Page 162 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 163: Plc Macros

If input 2 is active, macro 2 (M:2) will be executed. Macro 2 will: 1. Send out the serial port “Test Serial Output\r\n” (See WT Protocol) 2. Display a popup on the screen as shown below. Page 163 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 164: Macro Sequencing

4. All macro flags are reset after macro 3 is done allowing activating of input 1 again to repeat the sequence. Note: macro flags do not need to be cleared to executed macros again. Macros are normally executed each time the rung is energised. Page 164 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 165: Plc Equivalent Structures

Register Bit 1. Multi-Branch Rungs The TReX-460 does not directly support the implementation of multiple separate branches on a single rung. If multiple branches from a single main rung are required, these branches must be... -

Page 166: Plc Parallel Outputs

(note, is also an input), the following Q:4 is not affected by this change. All outputs are applied simultaneously, without any application affecting the rung energised state. Page 166 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 167: Plc Examples

One Input to One Output In this example, the input 2 directly controls the output 3 PLC->RUNGS Menu configuration: Page 167 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 168: Two Input To One Output

Two Input to One Output In this example, the input 2 and input 3 directly controls the output 3, here demonstrated in two different ways. Using Main type rungs only Using Branches Page 168 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 169: Using Main Rungs

TReX User Manual v15.30 Firmware Using MAIN Rungs PLC->RUNGS Menu configuration: RUNG 1 RUNG 2 PLC RUNG configuration: *PLC_RUNG=01:[I:2]-------[-]---------[-]---------(Q:3) Page 169 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 170: Using Main And Branch Rungs

TReX User Manual v15.30 Firmware *PLC_RUNG=02:[I:3]-------[-]---------[-]---------(Q:3) *PLC_RUNG=03: *PLC_RUNG=04: *PLC_RUNG=05: *PLC_RUNG=06: Using MAIN and BRANCH Rungs PLC->RUNGS Menu configuration: RUNG 1 RUNG 2 Page 170 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 171: One Input To Many Outputs

*PLC_RUNG=03: *PLC_RUNG=04: *PLC_RUNG=05: *PLC_RUNG=06: One Input to many Outputs In this example, the input 2 controls the output 3 and output 4 and output 5 PLC->RUNGS Menu configuration: Page 171 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 172 TReX User Manual v15.30 Firmware RUNG 1 RUNG 2 RUNG 3 PLC RUNG configuration: *PLC_RUNG=01:[I:2]-------[-]---------[-]---------(B:1) *PLC_RUNG=02: +-(Q:2) *PLC_RUNG=03: +-(Q:4) *PLC_RUNG=04: *PLC_RUNG=05: *PLC_RUNG=06: Page 172 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 173: One Input To One Slave Output

TReX User Manual v15.30 Firmware One Input to one slave output In this example, the input 2 controls the output 3 on a remote unit 6 (slave) TReX-460 PLC->RUNGS Menu configuration: Page 173 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 174: One Slave Input To Master Output

*PLC_RUNG=02: *PLC_RUNG=03: *PLC_RUNG=04: *PLC_RUNG=05: *PLC_RUNG=06: One Slave Input to master output In this example, the slave 3 input 2 controls the master unit output 7 PLC->RUNGS Menu configuration: Page 174 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 175: Output Controlled By A Timer

In this example, the input 3 will reset the timer 1 and after 20 seconds the output 4 will be energised. First the Timer 1 needs to be configured for 20 seconds. PLC->TIMERS Menu: Page 175 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 176 Timer 1 Done to control the output 4The following images shows the PLC RUNGS configurations: PLC->RUNGS Menu configuration: RUNG 1 RUNG 2 RUNG 3 PLC RUNG configuration: *PLC_RUNG=01:[-]---------[-]---------[-]---------(T:1) *PLC_RUNG=02:[I:3]-------[-]---------[-]---------(RT1) *PLC_RUNG=03:[TD1]-------[-]---------[-]---------(Q:4) *PLC_RUNG=04: *PLC_RUNG=05: *PLC_RUNG=06: PLC TIMER configuration: *PLC_TMR=1:TON,200 Page 176 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 177: Output Controlled By An Alarm

TReX User Manual v15.30 Firmware Output controlled by an Alarm In this example, the output 4 will be energised every Sunday from 3:30AM to 1:00PM Setting the Alarm via the PLC->ALARMS Menu: Page 177 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 178 TReX User Manual v15.30 Firmware PLC->RUNGS Menu configuration: PLC Rung configuration: *PLC_RUNG=01:[AE1]-------[-]---------[-]---------(Q:4) *PLC_RUNG=02: *PLC_RUNG=03: *PLC_RUNG=04: *PLC_RUNG=05: *PLC_RUNG=06: PLC ALARM configuration: *PLC_ALARM=1:7,03:30,7,13:00 Page 178 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 179: Output Controlled By A Counter

In this example, the output 3 will be energised only after the input 4 toggles 10 times, and the input 6 resets the counter. First the COUNTER 1 needs to be configured. PLC->COUNTERS Menu: PLC->RUNGS Menu configuration: RUNG 1 RUNG 2 RUNG 3 Page 179 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 180 TReX User Manual v15.30 Firmware PLC RUNG configuration: *PLC_RUNG=01:[I:4]-------[-]---------[-]---------(C:1) *PLC_RUNG=02:[CD1]-------[-]---------[-]---------(Q:3) *PLC_RUNG=03:[I:6]-------[-]---------[-]---------(RC1) *PLC_RUNG=04: *PLC_RUNG=05: *PLC_RUNG=05: *PLC_RUNG=06: PLC Counter configuration: *PLC_CNTR=1:CTU,10 Page 180 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 181: Latched Motor Starter

TReX User Manual v15.30 Firmware Latched Motor Starter A TReX-460 is set up with a normally open start button connected to Digital Input 1 and a normally closed stop button connected to Digital Input 2. Digital Output 1 of the TReX is configured to control a pump motor (through external relay or contactor). -

Page 182: Motion-Activated Lights

TReX User Manual v15.30 Firmware Motion-Activated Lights A TReX-460 is set up with two motion sensors connected to Input 1 and Input 2 that provide a normally open input signal until movement is detected and two lights connected to the TReX via inputs on Output 1 and Output 2. - Page 183 PLC Configuration: *PLC_RUNG=01:[I:1]-------[-]---------[-]---------(B:1) *PLC_RUNG=02:[I:2]---+ *PLC_RUNG=03:[B:1]-------[-]---------[-]---------(RT1) *PLC_RUNG=04:[B:1]-------[-]---------[-]---------(T:1) *PLC_RUNG=05:[TT1]---+ *PLC_RUNG=06: *PLC_RUNG=07:[TE1]-------[-]---------[-]---------(Q:1) *PLC_RUNG=08: +-(Q:2) *PLC_RUNG=09: *PLC_RUNG=10: *PLC_RUNG=11: *PLC_RUNG=12: Page 183 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 184: Wireless Motion Activated Light

+-(RQ8) //Keep the timer running as long as the light is turned on. *PLC_RUNG=04:[Q:1]-------[-]---------[-]---------(T:1) //As soon as the timer expires through inactivity, turn off the light *PLC_RUNG=05:[TD1]-------[-]---------[-]---------(RQ1) *PLC_RUNG=06: Page 184 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 185: Delayed Action Transmitter

TReX User Manual v15.30 Firmware Delayed Action Transmitter A TReX-460 is set up with a single normally closed button connected to Input 1. The intended behaviour is to have the TReX transmit a message when the button is held open for 30 seconds. - Page 186 Timer 1 completes, Timer 1 will be reset. Rung 2 manually triggers Macro 1 once Timer 1 has completed. Once Macro 1 has been triggered, the message is transmitted. Page 186 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 187: Alert-Based Cooling System

TReX User Manual v15.30 Firmware Alert-Based Cooling System In this example, a TReX-460 is set up in a hot environment with a cooling fan controlled from Digital Output 4. The intended behaviour is that the TReX will turn on the cooling fan for 10 minutes whenever it’s onboard temperature sensor passes 90°C. - Page 188 TReX User Manual v15.30 Firmware This PLC program takes advantage of the Alert Output functionality of the TReX-460 to provide an intelligent response to alert events. This is achieved by using the configured alert output (Output 8) as an input to the PLC program.

-

Page 189: Simple Multi Unit Alarm System

TReX User Manual v15.30 Firmware Simple Multi Unit Alarm System In this example, one TReX-460 is configured as a SCADA Master Device and two TReX- 460s are configured as SCADA Slave Devices. The Master Device has two LED indicators connected to Output 1 and Output 2, while both slave devices have smoke sensors connected to Input 6. - Page 190 TReX User Manual v15.30 Firmware PLC Configuration: *PLC_RUNG=01:[1i6]-------[-]---------[-]---------(Q:1) *PLC_RUNG=02:[2i6]-------[-]---------[-]---------(Q:2) *PLC_RUNG=03: *PLC_RUNG=04: *PLC_RUNG=05: Slave Unit 1 Configuration (ID:02) Slave Unit 2 Configuration (ID:03) Page 190 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 191: Plc Advanced Programming

• Macros (defined in MACRO.TXT) to manage outgoing serial content, and to provide user feedback. • Timers to control state transitions and notify on error conditions. PLC Program: Page 191 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 192: Initiating A Transmission

Macro 3 uses: <M:3>WTS$W2$1A</> Serial output from the TReX will be: Message Body<\x1a> Macro 4 has multiple commands that are executed. First a popup is displayed, then serial Page 192 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 193 TReX User Manual v15.30 Firmware output of “FAILED<CR>”. Page 193 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 194: Plc Configuration Tool

The WTE PLC Configuration Tool is a desktop application designed to enable fast development of TReX PLC programs. This tool is available free of charge. The WTE PLC Configuration tool gives the ability to not only construct TReX PLC programs, but to also run and debug these programs in a simulated TReX environment. -

Page 195: Adding/Modifying Rung Inputs

To remedy this, the annotation (I:1) can be selected and a nickname to the input can be given. In this case, the input is named “Light Switch”. Page 195 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 196: Saving Projects

This PLC Program now has a basic level of functionality. To save this program, select either the “Save” button in the toolbar at the top of the program, or select File->Save Project. This will allow the project to be saved as a WTE PLC file (.wtplc). Running Simulated Programs This PLC program can be tested in a simulated TReX environment. - Page 197 This will open the PLC Simulator screen, which provides simulated IO for one local unit and nine remote units. This example currently only makes use of the “Local” unit. Page 197 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 198: Adding Rung Branches

The next step in this example is to add a branching path to the first rung of the program. First, to continue editing the program, select the “Stop” icon from the application toolbar. Note that Page 198 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 199 This will convert the empty rung into a new branch, with a default input at position 1. To insert a new branch rather than overwrite an existing rung, select Insert->New Branch. Page 199 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 200: Rung Comments

This will open a dialog window through which the PLC configuration file (typically named WTE_PLC.INI) can be selected. Upon selection, the PLC program will be displayed on the Page 200 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 201: Exporting Plc Configuration Files

Selecting “Yes” will open the folder in using the system file browser. These files can be loaded onto a WTE TReX PLC device through the device’s USB Mass Storage functionality. Once loaded, the PLC program can be run locally on the device. -

Page 202: Main Window

9. Redo Previous Edit 21. Currently Debugged Rung 10. Rung Control Menu Button 22. Current Program Run Time 11. PLC Rung Input 23. Current RTC Values 12. Rung Input Annotation Page 202 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 203: Simulator Window

The simulated RTC does not change over time and must be manually set when the user wishes to trigger/clear alarms. Page 203 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 204: Input Configuration Window

7. Input Unit Selection (Digital Inputs, 13. Alarm Off Day (Alarms Only) Digital Outputs and Comparators Only) 14. Alarm Off Hour (Alarms Only) 15. Alarm Off Minute (Alarms Only) Page 204 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 205: Output Editor Window

The macro editor window supports up to 8 separate commands with the total length of all commands being 300 characters. Text input will not be accepted by the editor beyond this limit. Page 205 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 206: Debugging

Project Examples The WTE PLC Configuration Tool installation includes several example projects of varying complexity and usage of available resources. These examples are available in the “Examples” subdirectory of the program installation. Selecting “Load Project” for the first time will open this directory by default. -

Page 207: Scada Support

There may be up to 10 slave units, all located in different locations around a site, all monitoring and controlling different aspects of the SCADA system. To set the TReX as a slave set MENU->TELEMETRY->MODE to SLAVE. Page 207 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 208 “RapidSCADA”. SCADA applications have the advantages to provide a means to notify through; email, paging messages, SMS or to generate alarms of critical system events. Page 208 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 209: Scada System Single Trex Configuration

TReX User Manual v15.30 Firmware SCADA System Single TReX Configuration This is a system that requires no expansion through use of SLAVE units. Page 209 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 210: Unit Configuration

MENU->PROTOCOL->MODBUS is used to configure the key SCADA parameters, such as unit ID and the protocol. Typically, if an Ethernet connection is used, the TCP protocol will be used. See MODBUS Protocol for more Modbus information. Page 210 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 211: Scada System Multiple Trex Configuration

Note: Refreshing of SCADA status is immediate on any digital input change or any analogue input that changes by more than ADC counts configured in DELTA ADC TX. Page 211 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 212: Units Configuration

SLAVE units 1-9. If the MASTER is configured to have an ID of 43, SLAVE 1 must be configured to have an ID of 44. MODBUS ID can be any value from 0-127 (except 42 or 87). Page 212 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 213 The SCADA application will report inputs 1-8 to be from “Remote Station”, inputs 9-16 from “Pump Station 1” and inputs 17-24 from “Pump Station 2”. See Modbus Protocol for more information. Page 213 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 214: Viewing Multiple Trex Unit Io On The Master Unit

This number is reset whenever a new message is decoded from a SLAVE unit. Pressing the DOWN button will cycle through all the remote UNIT IDs in the system, displaying all system IO, link states, temperatures and battery voltages. Page 214 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 215: Io Mirror Operation

MODE, the output must be configured to be TELEMETRY. It is possible to restrict outputs(s) that are updated by DISABLING outputs on the REMOTE ID device. REMOTE ID devices are automatically controlled using the WTE output control protocol. When there is any input change, or an analog input changes by more than a configured threshold amount, there is an immediate transmission that updates a REMOTE ID device outputs. - Page 216 TReX User Manual v15.30 Firmware the system to be ready to test before deployment. NOTE: Make sure the REMOTE ID of one device matches the LOCAL ID of the other. Page 216 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 217: Serial Link Operation

If the buffering capacity of the TReX is exceeded then the TReX will respond with “FULL<CR>”. Prior to each transmission the channel checks if TReX is clear to transmit, meaning that in some cases transmissions could be slower depending on channel usage. Page 217 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 218 3. MENU->SYSTEM->RS232 BAUD (to set serial baud rate – that should be a higher rate than the over the air transmit rate). 4. Exit from menu to save configuration. Page 218 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 219: Alert Handling

Many alert conditions are auto-clearing as described below. Once all ALERTS sources have been cleared (either automatically or manually) then the ALERT output will not longer operate and the audible beep will cease (if configured). Page 219 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 220 Whenever an alert is raised the alert bell icon is displayed, except when in the menu. If an alert has been raised in the menu, the alert will be visible upon leaving the menu. Page 220 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 221 4. Set ALERTS->ALERT OUT to 8. 5. Set ALERTS->SOUND to ENABLED. 6. Set ALERTS->ALERT REPEAT to 30. The alert configuration will be as follows (assuming initial state was the factory default state): Page 221 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 222 Since there is at least one ALERT active, the main IO screen shows that output 8 has been operated. Page 222 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 223: Clearing Alerts

Disable the audible beep (if sound is enabled and no other alerts are active). • Clear the bell from the top icon bar (if no other alerts are active). Page 223 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 224: Input Handling

The protocol being used is WT protocol, and the message for each input message is “IN 1 LOW” and “IN 2 LOW”. Message is to be transmitted as POCSAG alphanumeric to cap code Page 224 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 225: Controlling Outputs From Inputs

Any input (including battery and analog inputs) can be used to control any output(s) if required. The WTE output control protocol can be used as the payload of any message. Desired control solution 1: To close output 2 when the battery voltage is low. The assumption in this case is that the unit ID is the default ID of 01. - Page 226 Change the message to: *IN_MSG_L=9:[[01]2]WT1234560A13 BATT LOW<CR> Output 2 will now close and will be latched or a mono-shot operation as configured. In addition the following BATT LOW will be transmitted. Page 226 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 227: Output Handling

The TReX supports up to 8 outputs. One of these outputs can be shared with the ALERTS- >ALERT OUT output. Outputs are configured using the commands: *OUT_CONFIG *OUT_ID The outputs are controlled through messages received that conform to the WTE output control protocol. Page 227 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 228: Wte Output Control Protocol

This section describes how to control the outputs of WTE Products via transmission payloads. The WTE protocol needs to be able to switch many outputs on, and many off in a single message. Receivers need to be able to be uniquely addressed, and in a manner that is maintainable. - Page 229 OFF output1 and 2 on the Unit_C; Message payload: [[Unit_A]12-] [[Unit_B]1-2] [[Unit_C]-12] Scenario 7: To turn output 1 and 2 ON in the Unit_A and on Unit_B: Message payload: [[Unit_A,Unit_B]12-] Page 229 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 230: Analog & Digital Output Format

TReX User Manual v15.30 Firmware Analog & Digital Output Format The WTE output control protocol allows the direct control of analog outputs. [[ID]UZ[AA]CCC-OOOO] Where: [ is the character ‘[’ ] is the character ‘]’ ID is the UNIT_ID that must match the TReX to be controlled.. -

Page 231: Remote Command Output Format

RX_RANGE and/or a more complex OUT_ID. Remote Command Output Format The WTE output control protocol allows the direct control of remote units. This allows specific TReX units to accept commands or protocols for processing “over the air”. [[ID]U0[AA]] Where: [ is the character ‘[’... - Page 232 POCSAG belt pager. Page 232 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 233: Wte Ack And Confirm Protocol

The WTE Ack and Confirm Protocol can be embedded into the payload of any message. Typically the protocol message would be attached to the end of a message, so that paging messages would display normally for typical users. - Page 234 Message payload to have delivery acknowledged is transmitted. Message Payload: Bob, go to Pukeko Place urgently.-[345-1]<CR> Remote TReX responds with: ACK[345] Example 2: Message payload to have delivery acknowledged and confirmed is transmitted. Page 234 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 235 Note: The WT Protocol must be used to automatically expand the **01 macro to an automatically incremented ticket id. The remote TReX unit immediately displays: In this case, the received message has not requested delivery confirmation, only confirmation of acceptance. Page 235 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 236 Should the user ACCEPT the message to attend, the remote TReX transmits to the base-station the message: ACC[666-Unit A] where: 666 is the ticket id. - is the character ‘-’ “Unit A” is the unit ID programmed through SYSTEM->ID Page 236 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 237: Solt Transmitter Support

3. Set RF-RX_MODE to SOLT 4. Specify transmit frequency for belt pagers or DMR radios if required. 5. Create a text file SOLT.TXT and store on the TReX internal USB storage. Page 237 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 238: Creating A Solt Translation Table

All messages are specified in the WT protocol allowing for many pager types, DMR radios to be supported (see WT Protocol). Also allows content to be redirected out the serial/TCP port. Page 238 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 239: Rf Security

POCSAG_A transport method. POCSAG_A can be used in most cases when a standard format is required, or encryption for nationwide paging is desired. Both transport methods include forward error correction for high receiver sensitivity. Page 239 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 240 The receiving TReX does NOT need to have the time set if it does not transmit. When correctly configured, the padlock icon is displayed in the top icon bar. RX screen content is normally readable if correctly decrypted. Page 240 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 241: Secure Nationwide Paging

Secure Nationwide Paging In order to transmit secure messages across an existing nationwide paging service (to be decoded by a TReX-460) the message must be encrypted by another TReX, and the encrypted message then provided to a nationwide paging service provider. - Page 242 TReX User Manual v15.30 Firmware The message will be decrypted, and displayed on the RX screen. If the selected output protocol is WTE, then the decoded message will also be returned out the serial port. This method allows secure activation of TReX outputs or reception of sensitive information for processing or retransmission.

-

Page 243: Transport Layer Security

Generating RSA private key, 2048 bit long modulus (2 primes) ...+++++ ..........+++++ e is 65537 (0x010001) Enter pass phrase for cakey.pem: Verifying - Enter pass phrase for cakey.pem: Page 243 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 244 Country Name (2 letter code) [AU]:NZ State or Province Name (full name) [Some-State]:Canterbury Locality Name (eg, city) []:Christchurch Organization Name (eg, company) [Internet Widgits Pty Ltd]:WTE Ltd Organizational Unit Name (eg, section) []:IT Department Common Name (e.g. server FQDN or YOUR name) []:WTE-TReX Email Address []:info@wte.co.nz...

- Page 245 > openssl x509 -req -sha256 -days 365 -in server.csr -signkey key.pem -out server.pem Signature ok subject=C = NZ, ST = Canterbury, L = Christchurch, O = WTE Ltd, OU = IT Department, CN = WTE-TReX, emailAddress = info@wte.co.nz Getting Private key Enter pass phrase for key.pem:...

-

Page 246: Operating As A Tls Client

Care should be taken when integrating the device into a network that only approved and trusted clients are able to connect to the device. TLS Connection Error Codes Error Code Error Certificate file missing or invalid Page 246 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 247 TReX User Manual v15.30 Firmware Server key file missing or invalid DH Parameters file missing or invalid TLS Handshake failed Page 247 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 248: Repeater Operation Modes

Store forward and DMR licenses are required for these modes of operation. Store Forward In this mode, a TReX can intercept a POCSAG paging message, either from a WTE transmitter or a third party paging transmitter. This message, after being received is then transmitted again. -

Page 249: Store Forward Operation

See the Configuration section on this document for more details on command usage if required. Page 249 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 250: Dmr Translate Repeat Operation

DMR messages. All DMR messages are transmitted as a “Group” ID using the DMR database. If required, use the command *DMR_DB to serially configure DMR radio colour code, type and TX frequency. Page 250 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 251: Multi-Site Repeat Operation

This receiver rate may much higher than the repeater transmit rates. For the following examples, the rate between sites is fixed at 2400 baud, for a 12.5kHz channel. Page 251 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 252 WT1234560A1C [[01,02,03]U0[WT1234555A10 ASSIST]] Example 3: Sending a 512 baud, 25kHz channel POCSAG message “ASSIST” to RIC 1234555 on site “03” ONLY. All units, must receive the payload of: Page 252 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 253 The transmitter frequency must be restored to the default frequency after use. The frequency change will not be saved to the configuration and is only temporary unless the *SAVE command is issued. Page 253 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 254: Installation

If cables are to be supplied, these must be ordered at time of purchase. Page 254 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 255: Connecting To The Trex

1. Connection to a 50 ohm antenna constructed for the frequency of interest. Mismatched antennas may result in increased current draw and reduced power output. 2. 13.8V, 3A supply connected to the power terminals Page 255 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 256: Connector Pin Descriptions

Input – Analog 1 Input – Analog 2 Output – Analog 1 Output – Analog 2 Output – Digital 1 Output – Digital 2 Output – Digital 3 Page 256 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 257 Output – Digital 4 Relay CM Relay (NO / NC) Input – Digital 8 Input – Digital 7 Input – Digital 6 Input – Digital 5 Input – Digital 4 Page 257 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 258: Rhs Trex-460-I8O8

Note: The second connector with pins 13-24 are fitted upside down. This means that the screw terminals are pointing down and wiring must be secured before inserting the connector. Page 258 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 259 Relay 5 NO Relay 5 CM Relay 4 NO Relay 4 CM Relay 3 NO Relay 3 CM Relay 2 NO Relay 2 CM Relay 1 NO Relay 1 CM Page 259 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 260: Lhs Trex-460-I8O1

RS422 RX- (IN-) RS422 TX- (OUT-) RS422 TX+ (OUT+) RS232 TX RS232 RX Ground (GND) Power Connector: Power Connector Pin Number Description Ground (GND) +13.8V Not Connected (N.C.) Page 260 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 261: Lhs Trex-460-I8O8

RS422 RX- (IN-) RS422 TX- (OUT-) RS422 TX+ (OUT+) RS232 TX RS232 RX Ground (GND) Power Connector: Power Connector Pin Number Description Ground (GND) +13.8V Not Connected (N.C.) Page 261 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 262 Relay 7 CM Relay 8 NO Relay 8 CM Input – Digital 4 Input – Digital 5 Input – Digital 6 Input – Digital 7 Input – Digital 8 Page 262 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

- Page 263 7 and 8 are connected to ground via a 75R resistor Do not connect a Power over Ethernet (PoE) connection to the TReX Ethernet port as this will result in damage. Page 263 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 264: Input Output Hardware Connection

TReX User Manual v15.30 Firmware Input Output Hardware Connection Examples of how to connect external devices to the TReX input/output pins. Inputs Page 264 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 265: Outputs

TReX. VDD is voltage source externally provided between 5 and 24VDC depending on the control application. Page 265 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 266: Serial Connections

TReX User Manual v15.30 Firmware Serial Connections RS-232 Illustration 1: TReX RS-232 DB9 Connector as DTE Illustration 2: TReX RS-232 DB9 Connector as DCE Page 266 of 302 © WTE Limited, 2022 – Christchurch New Zealand... - Page 267 The TReX satisfies the requirements for both 4 and 2 wire RS-485 communications. The TReX will also be able to operate on a RS-422 bus. Page 267 of 302 © WTE Limited, 2022 – Christchurch New Zealand...

-

Page 268: Point To Point Connection

Illustration 4: TReX RS-485/RS-422 Multi-Point Note: this configuration only applies if driving less than 10 listeners/receivers when using RS- 422 devices or less than 32 devices for RS-485 devices. Page 268 of 302 © WTE Limited, 2022 – Christchurch New Zealand... -

Page 269: Wire Connection