Advertisement

Quick Links

CHAPTER 1. SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHAPTER 2. HARDWARE DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 3. NOTE FOR SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 4. DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 5. DIAGNOSTICS AND CHECK ITEMS . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 6. CIRCUIT DIAGRAM & PARTS LAYOUT . . . . . . . . . . . . . . . . . . . .

PARTS GUIDE

Parts marked with "!

" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

SERVICE MANUAL

CONTENTS

SHARP CORPORATION

CODE: 00ZHC4000SP/E

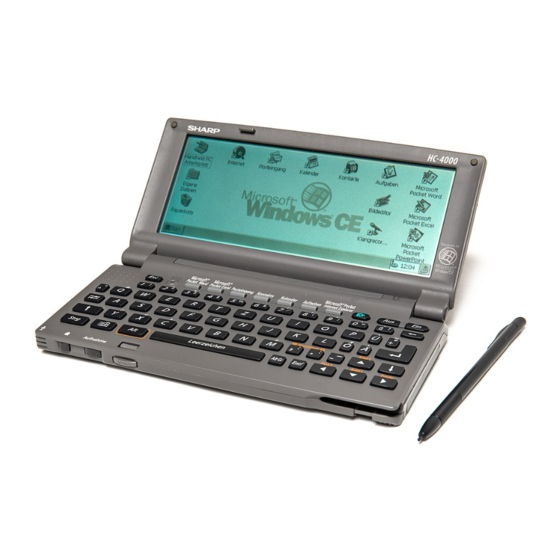

Handheld PC

HC-4000

MODEL

HC-4100

MODEL

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Advertisement

Need help?

Do you have a question about the HC-4000 and is the answer not in the manual?

Questions and answers