Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for IML SLIDEFEEDER X80

- Page 1 LIDE EEDER X Original operating instructions With passion and precision...

- Page 2 - Blank page - SFx80_V1.1_210710_EN...

-

Page 3: Table Of Contents

Labels on the machine ......................10 3.11.1 Warning and information signs on the machine ..............10 3.11.2 Type plate .......................... 10 Structure and function ....................11 SlideFeeder x80 ........................11 Technical Data ........................12 4.2.1 Electrical and pneumatic specifications ................13 4.2.2 Temporal Specifications ..................... 13 4.2.3... - Page 4 9.4.2 Dispose of materials ......................21 10 Service ........................23 11 Record of changes ....................24 Appendix A: Declaration of conformity ............... 25 SFx80_V1.1_210710_EN...

-

Page 5: About This Operating Instructions

About this operating instructions About this operating instructions This documentation is primarily intended for the operator's operating personnel. For the purposes of these instructions, operating personnel is the group of people who are responsible for operation, maintenance including cleaning and troubleshooting. •... -

Page 6: Applicable Documents

Applicable Documents The applicable documents contain technical documents with further information. They are an integral part of the technical documentation. Upon delivery, IML GmbH provides the supplier documentation for assemblies that have only been further processed. Representational conventions Emphasis in the text To simplify readability and overview, various paragraphs/information are highlighted. -

Page 7: Product Information

Product name: SlideFeeder x80 Machine type: SFx80 Year of manufacture 2021 (see type plate) Manufacturer details Name: IML Instrumenta Mechanik Labor System GmbH Address: Parkstraße 33, 69168 Wiesloch, Deutschland E-Mail: info@iml.de Telephone: +49 (0) 6222 6797-0 Fax: +49 (0) 6222 6797-10... -

Page 8: Safety

Safety instructions DANGER Risk of fatal electric shock or serious injury when touching live parts. • Do not use the SlideFeeder x80 if the power cable, plug or other parts of the electrical equipment are damaged. • Check electrical equipment regularly. -

Page 9: Intended Use

Safety Intended use Purpose The machine is used exclusively to remove frames with customer-supplied slides from their magazines and place them on a customer-supplied microscope. The limits of the machine within the meaning of the Machinery Directive (2006/42/EC) and the products that can be processed are defined by the Technical Data (section 4.2). Foreseeable misuse Operating the machine with tools, parameters, materials equipments other than those spec- ified by the manufacturer is considered misuse. -

Page 10: Duties Of The Operator

Safety Duties of the operator Qualify personnel and deploy them according to qualification The operator must ensure the following: • The personnel is familiar with and instructed in the basic regulations on occupational safety and accident prevention. • Only qualified and instructed personnel may work on the machine. •... -

Page 11: Operating The Machine Safely

Safety Uncovering undetected risks The operator is obliged to cooperate in the detection of unrecognised risks. In particular, the operator must do the following: • Carry out a risk assessment on the basis of the Occupational Health and Safety Act, the Ordinance on Industrial Safety and Health or national regulations. -

Page 12: Transport, Installation

Safety Transport, installation CAUTION Risk of injury from slipping, tripping and falling. • Lay cables carefully. • Do not leave any tools or machine parts on the floor. • Wear personal protective equipment (PPE). CAUTION Risk of injury from carrying loads that are too heavy. •... -

Page 13: Personal Protective Equipment

Safety Personal protective equipment All persons working on the machine are recommended to wear the following personal pro- tective equipment: Pictogram Description Life phase Transport Foot protection must be worn Assembly Foot protection protects the feet from bruising, falling parts and slip- Commissioning ping on slippery surfaces. -

Page 14: Labels On The Machine

Safety 3.11 Labels on the machine 3.11.1 Warning and information signs on the machine Labels are attached to the machine to provide additional information and warn of hazards when handling the machine. The labels must be kept in legible condition throughout the machine's service life and replaced immediately if damaged. -

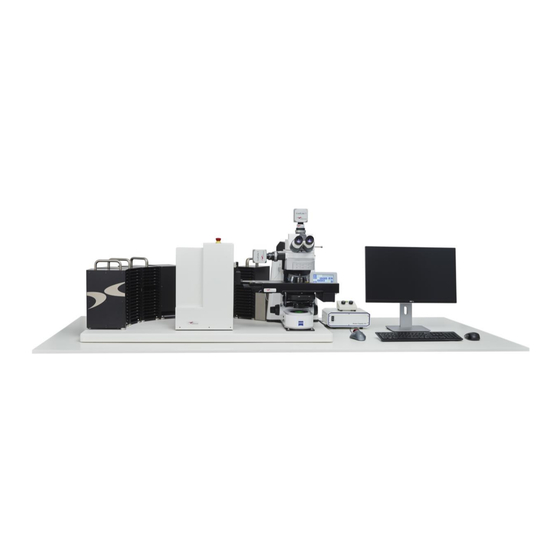

Page 15: Structure And Function

The machine consists of the feeder (2), the magazines (1) and the microscope base plate (3). Depending on the variant, the SlideFeeder x80 can be operated with 2, 7 or 11 maga- zines. In each magazine there are 16 slots for insert frames (4). -

Page 16: Technical Data

Structure and function Technical Data Parameter Unit Value Machine data Machine type SFx80 Year of manufacture 2021 AutoOiler Length (L) [mm] Breadth (B) [mm] Height (H) [mm] Weight [kg] 2.95 Base plate small Length (L) [mm] 1390 Breadth (B) [mm] Height (H) [mm] Weight... -

Page 17: Electrical And Pneumatic Specifications

Structure and function Parameter Unit Value Height (H) [mm] Weight [kg] 9.25 Machine contour plus 1 m around Spatial limits of the machine the machine (necessary clearance for operation and maintenance) Noise emission [db(A)] <72 4.2.1 Electrical and pneumatic specifications Parameter Value Electrical via cable with socket:... -

Page 18: Interfaces

Structure and function 4.2.4 Interfaces Parameter Description The electrical power supply is provided via the Lemo socket on the connection cable. Electrical power supply and data connection The on-site cable is connected to the external power supply and the PC (control). Operation as well as switching on and off are car- Operating ried out via the interface to the customer's control... -

Page 19: Transport

Transport Transport Symbols on the packaging NOTE Observe the symbols and notes on the packaging. If there are any ques- tions or uncertainties, do not carry out any work and contact the manu- facturer (see chapter 10). Incoming goods inspection The packages are packed according to requirements upon delivery. -

Page 20: Installation And Commissioning

Installation and commissioning Installation and commissioning Requirements for the installation site The machine may only be set up indoors on a level and sufficiently load-bearing surface. Parameter Unit Value Protective distances to adjacent in- stallations Permissible ambient temperature [°C] +15 °C to +40 °C Max. -

Page 21: Operating

Operating Operating The following sections describe the proper and safe operation of the machine. Checks before switching on the machine Before switching on the machine, it is essential to carry out the following checks: • Checking the safety devices for correct attachment and function. •... - Page 22 Operating CAUTION Risk of injury due to improper handling of hazardous substances. • Wear suitable personal protective equipment (safety goggles, gloves, protective clothing) when using hazardous substances. • Observe the instructions in the respective safety data sheets. For more information on operating the machine, see the control system documentation. SFx80_V1.1_210710_EN...

-

Page 23: Maintenance And Repair

Maintenance and repair Maintenance and repair The machine must be inspected and serviced at regular intervals. CAUTION Danger of crushing due to moving machine parts. • Before starting maintenance and repair work, safely switch off mov- ing parts of the machine and allow it to come to a complete standstill. •... -

Page 24: Decommissioning, Dismantling And Disposal

Decommissioning, dismantling and disposal Decommissioning, dismantling and disposal Laws and regulations Observe and comply with all laws and regulations on environmental protection and waste disposal applicable where the machine is used. Observe the instructions for disposal on the packaging. Pollutants Pollutants must not enter the drinking water, soil or sewage system. -

Page 25: Storage Conditions

Decommissioning, dismantling and disposal Storage conditions Designation Specifications Type of storage Store indoors in a dry place, protected from moisture and sun- light Storage period Max. 2 years Space requirement See chapter Technical data Instructions on disposal 9.4.1 Disassembly Disconnect from the mains. Dismantle the components. - Page 26 Decommissioning, dismantling and disposal Disposing of electrical waste E-waste (old electrical and electronic components) often contains chemical substances that can pollute the environment very badly. Therefore, e-waste must not be disposed of to- gether with normal waste. Electrical or electronic components are used in various devices for control or monitoring. Proper disposal of e-waste prevents hazardous substances from harming people and the environment.

-

Page 27: Service

Service Service If you have any questions or concerns, please contact customer service using the contact information below. IML Instrumenta Mechanik Labor System GmbH Parkstraße 33 69168 Wiesloch Germany Tel.: +49 (0) 6222 6797-0 Fax. +49 (0) 6222 6797-10 Web: www.iml.de... -

Page 28: Record Of Changes

Record of changes Record of changes Version Date Change July 2021 Initial version September 2021 Changes SFx80_V1.1_210710_EN... -

Page 29: Appendix A: Declaration Of Conformity

Declaration of conformity Appendix A: Declaration of conformity SFx80_V1.1_210710_EN... - Page 30 - Blank page -...

- Page 31 All rights reserved. All contents of these operating instructions, in particular texts, photographs and graphics, are protected by copyright. The copyright is held by IML Instrumenta Mechanik Labor System GmbH. No part of this manual may be reproduced, distributed or transmitted in any form or by any means, including photocopying,...

Need help?

Do you have a question about the SLIDEFEEDER X80 and is the answer not in the manual?

Questions and answers