Advertisement

Quick Links

GENERAL DESCRIPTION

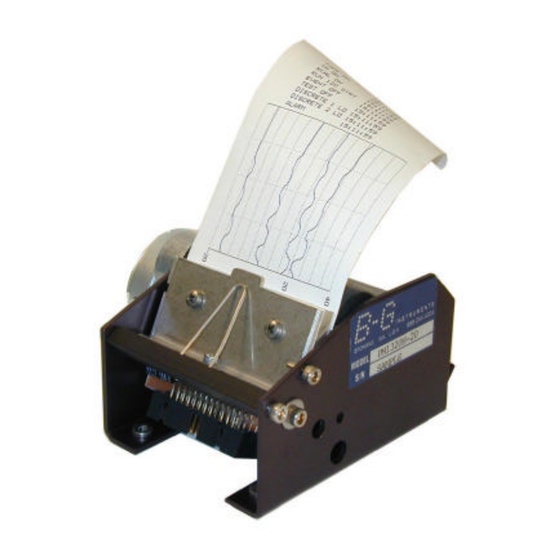

The DataPlot model PM1320 Print Mechanism incorporates a

fixed-dot thermal printhead with 320 heat element dots

arrayed in a single line across the width of the paper. The

mechanism holds a supply roll of thermal paper and causes

that paper to move past the printhead in steps of

approximately .005 inch. When driven by the DataPlot

CB1320 Printer Control Board, the print mechanism steps the

paper forward, pausing after each step to heat selected dots. In

this manner, a dot matrix representation of alphanumeric

and/or graphic data can be printed.

RESOLUTION

The 320 thermal dot elements are uniformly spaced 150 dots

per inch, or approximately .0067 inches apart. The total print

width is 2.13 inches, centered on the paper. The dot matrix

has a pitch, therefore, of .0067" across the width of the

paper by .005" along its length.

Technical Data and Instructions

DataPlot Print Mechanism

Model PM1320

CONTROL BOARD CONNECTION

This print mechanism is designed to operate properly and

reliably when driven by the B-G Instruments' DataPlot model

CB1320 Control Board or another board specifically

approved by B -G Instruments for that purpose. Attempting to

operate this print mechanism in any other way may cause

permanent damage to its components that would not be

covered by warranty. With all system power off, attach the

supplied ribbon cable between the 26-pin printhead connector

and connector J4 on the control board, being sure to observe

correct polarity by aligning the red dots on the connectors

with those on the cable cads. Also connect the 8-pin stepper

motor cable to connector J 1 on the control board. This

connector is keyed to facilitate correct polarity assembly.

Refer to the CB1320 data sheet for instructions for applying

power and operating the printer.

MOUNTING

The DataPlot model PM1320 print mechanism is designed to

be mounted to a horizontal support platform, as shown

here, using 6-32 screws.

Mating PEM nuts are set

into the print mechanism

chassis. (See the drawing

on the reverse side of this

sheet for mounting

dimensions.) Usually a

housing cover is provided

for appearance and to

protect the mechanism.

Such a cover must include a slot, positioned to permit the

paper to exit freely. Many cabinet designers also provide a

transparent tear-off bar to facilitate tearing the paper a short

distance away from the platen. This makes it easy to lift the

paper from the platen when printing resumes.

PAPER OUT, PAPER LOADING

A paper sensor in the PM1320 provides signals that are used

by the CB1320 Control Board to stop printing when the paper

runs out and to "autoload" a new paper roll. To load the

printer, be sure the power is on and insert the paper end into

the paper feed slot beneath the platen from the rear. Be sure

the sensitive side (outside on roll) is away from the platen.

When the paper is fully inserted, the platen will run, pulling

about 2 inches of paper through.

Page 1 of 2

Release A, March 15, 2000

Advertisement

Summary of Contents for B-G Instruments PM1320

- Page 1 PAPER OUT, PAPER LOADING A paper sensor in the PM1320 provides signals that are used by the CB1320 Control Board to stop printing when the paper runs out and to “autoload” a new paper roll. To load the printer, be sure the power is on and insert the paper end into the paper feed slot beneath the platen from the rear.

- Page 2 PM1320 been modified in any way not specifically authorized by printer. It is available from B-G Instruments in cartons of 36 B-G Instruments, Inc., and rolls, or in larger quantities.

Need help?

Do you have a question about the PM1320 and is the answer not in the manual?

Questions and answers