Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for THORLABS vytran GPX3800

- Page 1 GPX3800 and GPX3850 Glass Processors User Guide...

-

Page 2: Table Of Contents

GPX3800 and GPX3850 Glass Processors Table of Contents Chapter 1 Warning Symbol Definitions .................... 1 Chapter 2 Safety ............................ 2 Chapter 3 Description ........................... 3 3.1. Introduction ........................3 3.2. Features ........................... 4 3.2.1. GPX3800 ..........................4 3.2.2. GPX3850 ..........................4 ... - Page 3 GPX3800 and GPX3850 Glass Processors 5.7.2. Manual Alignment ....................... 34 5.7.3. Drawing Tapers ........................34 5.7.4. Taper Properties ......................... 34 5.7.5. Tension Monitor ........................37 5.7.6. Filament Ramp and System Configuration ................. 38 ...

- Page 4 8.3. Fiber Holder Insert Size Selection Guide ..............70 Chapter 9 Specifications ........................72 9.1. Electrical Power ......................73 9.2. Gas Supply ........................73 9.2.1. Gas Supply Specifications ....................74 Chapter 10 Regulatory ...........................75 Chapter 11 Thorlabs Worldwide Contacts ..................76 ...

-

Page 5: Chapter 1 Warning Symbol Definitions

GPX3800 and GPX3850 Glass Processors Chapter 1: Warning Symbol Definitions Chapter 1 Warning Symbol Definitions Below is a list of warning symbols you may encounter in this manual or on your device. Symbol Description Direct Current Alternating Current Both Direct and Alternating Current Earth Ground Terminal Protective Conductor Terminal Frame or Chassis Terminal... -

Page 6: Chapter 2 Safety

GPX3800 and GPX3850 Glass Processors Chapter 2: Safety Chapter 2 Safety WARNING The filament in the glass processor furnace generates intense light when it is in operation. It is strongly advised that the user does NOT look directly at it during splicing or tapering operations. CAUTION: HOT SURFACE The furnace gets extremely hot when the filament is turned on. -

Page 7: Chapter 3 Description

GPX3800 and GPX3850 Glass Processors Chapter 3: Description Chapter 3 Description 3.1. Introduction ® Thank you for purchasing a Vytran Glass Processor. This manual is intended to convey the basic instructions necessary for operating the glass processor. The Vytran Glass Processors are a versatile glass processing platform for the fabrication of splices, tapers, terminations, couplers and combiners. -

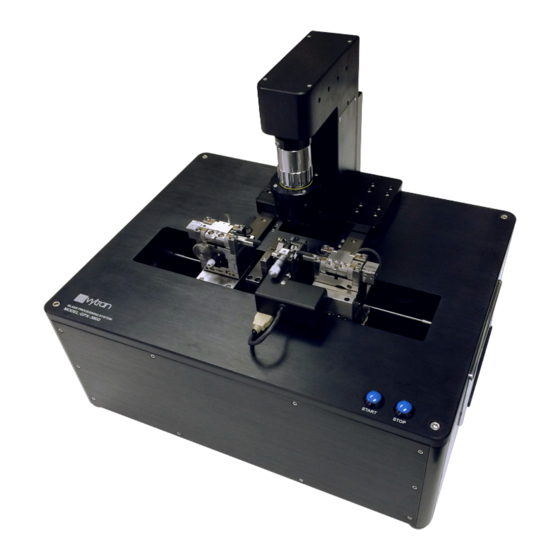

Page 8: Features

GPX3800 and GPX3850 Glass Processors Chapter 3: Description 3.2. Features 3.2.1. GPX3800 Standard Features Fiber Splicing and Tapering up to Ø1.25 mm Cladding Automated Splice Head XY Alignment Blocks with Rotary Capability Camera Tower with Ring Illuminator Tension Monitoring and Control System Optional Features Liquid Cooling System (Item # GPXWCS) Fused Taper Software Enhancement (Item # GPXFBT-SFT) -

Page 9: Accessories Gpx3800 And Gpx3850

GPX3800 and GPX3850 Glass Processors Chapter 3: Description 3.3. Accessories GPX3800 and GPX3850 Component Description Workstation GPX3800 or GPX3850 Glass Processor Workstation Computer, including Monitor, Keyboard and Mouse Vacuum Pump for Vacuum V-Grooves Vacuum Pump (Alternative Model Supplied for 230 V Markets) Power Supply Dual Voltage Power Supply and Cable Gas Tank Regulator... -

Page 10: External Workstation Connections

GPX3800 and GPX3850 Glass Processors Chapter 3: Description 3.4.1. External Workstation Connections The splicer workstation is the main component of the glass processor. The PC and gas supply, as well as peripheral components, are connected to its back panel as illustrated in Figure 2. Figure 2 GPX3800 Back Panel Connections Power... -

Page 11: Fiber Holding Blocks

Different sized bottom V-grooves and top inserts are available for various coating fiber diameters. For available insert sizes, please see the selection chart in Chapter 8. In addition to the standard sizes, custom inserts may be specially designed for various applications. Contact Thorlabs for more information. Figure 3... -

Page 12: Splice Head

GPX3800 and GPX3850 Glass Processors Chapter 3: Description Fiber Handler Transfer Inserts The fiber handler transfer insert used on the glass processors make splicing faster and easier because it facilitates repeatable fiber positioning when used in conjunction with a LDC400 Large-Diameter Fiber Cleaver. For example, if the operator uses transfer inserts to hold fibers during cleaving, the operator can then transfer each of those cleaved fibers a glass processor in the same insert that held them during cleaving and ensure that the ends of the fibers will fall exactly in the same place every time. - Page 13 Filament Tower Filaments The filaments are omega-shaped resistive heaters. Thorlabs offers these filaments preassembled in a variety of sizes as well as different materials that could be more appropriate to a particular splicing application. Graphite filaments are capable of achieving the high temperature required for splicing large-diameter silica fibers.

- Page 14 Chapter 3: Description Filament Assembly Thorlabs supplies filaments pre-assembled in a filament body as shown in the Figure 6. This is called a filament assembly. Different filament bodies are used with different filaments, and are distinguished by a version number engraved on the front of the housing.

-

Page 15: Mirror Tower

GPX3800 and GPX3850 Glass Processors Chapter 3: Description 3.4.4. Mirror Tower The mirror tower has two sets of mirrors and an LED. The first set of mirrors makes it possible to view the sides of the fiber. They provide the “Front View” and “Back View”. The second set of mirrors makes it possible to view the ends of the fibers. -

Page 16: Chapter 4 Setup

GPX3800 and GPX3850 Glass Processors Chapter 4: Setup Chapter 4 Setup 1. Unpack PC, monitor and peripherals. Set-up the computer using the included instructions from the computer manufacturer. 2. Unpack the glass processor workstation and place it on a workbench. Make sure not to damage any components of the glass processor during handling of the workstation. - Page 17 GPX3800 and GPX3850 Glass Processors Chapter 4: Setup 8. Clean the outlet of the gas tank thoroughly to remove any debris or deposits, and then install the supplied CGA-580 or DIN 477 Number 6 gas regulator to the gas tank, using the manufacturer-supplied operating and safety instructions Argon Gas Regulator 9.

-

Page 18: Chapter 5 Operation

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation Chapter 5 Operation 5.1. Software Interface The software interface involves a graphical user interface, or GUI, and an SQL database. Here is a detailed explanation for the control of the machine. 5.2. Graphical User Interface The GUI is the main window when working on the glass processor workstation. -

Page 19: Menu Bar

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.2.1. Menu Bar a. File The File menu is structured in the same way as shown. Open: Open a new splice data file. Open Recent: Shows the files opened recently. Save: Save the current settings to the current splice data file. - Page 20 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation c. Configuration The Configuration Menu allows the user to edit the property of the user interface and also set up the machine parameters. Four tool bars on the interface can be modified through Toolbars window. Through the Edit Processes Bar, the user can define which process will be shown in the user interface...

- Page 21 Home to View Distance sets the distance between the splice home and the actual viewing position of the splice head. Time Delays are preset by Thorlabs. Rev B, July 24, 2018 Page 17...

- Page 22 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation Load Fibers This window sets the fiber holding block’s position when it is ready for loading the fiber to perform the splice. Argon flow has three rates. The purge and background settings are controlled in this window, and argon flow rate for the splice is set in the splice property window.

- Page 23 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation d. Splice The different splice processes and parameters can be set through this window. The detail information will be discussed in Section 5.5.1 e. Reset The Reset Menu allows the user to initialize, stop, and reset the GPX window.

-

Page 24: Command Bar

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.2.2. Command Bar The transmission and receive command bar allows the user to directly enter a command to perform motion control of the motors. In the example above, the motor 3 (lens position) is moved forward by 200 steps. Commands are entered into the white window. -

Page 25: Process Bar

Macro Bar. Note that it is possible to make buttons for one-or-two line commands in the macro bar as well as buttons for entire macros. Please contact Thorlabs for more assistance. 5.2.6. Quick Open File Bar This toolbar allows the user to easily access the most common used files. -

Page 26: Main Toolbar

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.2.7. Main Toolbar The illustrated buttons on the toolbar right above the image window execute processes critical to splicing and data management. Open: opens a splice data file. This means it loads an XML file containing predefined parameters in preparation for a splice or a taper. -

Page 27: Splice Process List

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation Stop: This button stops whatever process is being executed. The blue button labeled “STOP” on the right front corner of the GPX has the same function. Reset: This button resets the parameters of the GPX to the default values. Initialize : This button initializes the unit. -

Page 28: Movement Control Bar

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.2.10. Movement Control Bar The seven boxes in the Movement Control Bar permit the user to move the fiber handlers and splice head at will, by clicking on the forward and back arrows. The radio buttons labeled “Fine”, “Medium” and “Coarse” allow the user to decide how much motion should occur with every click of an arrow. - Page 29 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation The “Right Rotation” box enables the user to rotate the right barrel, for the same reasons one would employ left rotation. The “Right Pivot” box enables the user to pivot the right fiber handler for alignment in the front view.

-

Page 30: Status Bar

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.2.11. Status Bar This window indicates the status of the unit. When the bottom bar is green and the window reads “Ready,” the unit is ready to execute new commands. When the top bar is red, the unit is not responding, and is either busy or needs to be initialized. -

Page 31: Storage And Transportation

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.4. Storage and Transportation When packing the glass processor workstation for storage or transportation, the following precautions are necessary: Ensure that the camera assembly is at the home position. Attach the transport blocks to secure the camera assembly in its home position. This is important to ensure that the camera assembly does not move during transport. - Page 32 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation Splice Power This is the amount of power the filament will deliver during the splice. Check the filament power displayed in the Splice Menu. To change the splice power value, select the power window and enter the desired splice power in watts.

-

Page 33: Filament Normalization

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.5.2. Filament Normalization Before using a new filament, when starting the equipment, or after a long period of inactivity, it is necessary to perform the filament normalization process. Doing so will adjust some parameters to ensure a high quality splice. Two key control parameters are the “view to splice distance”... -

Page 34: Active Xy Alignment

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.5.4. Active XY Alignment The active alignment method should be used for fibers which have a high core eccentricity. In such a case, and the edge alignment method cannot ensure proper alignment of fiber cores. Active alignment is a core-to-core alignment which uses output from an optical power meter to maximize the power transmission. -

Page 35: Multiple-Stage And Multiple File Splicing

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation Fiber Type Parameter 1 (P1) Parameter 2 (P2) OD Ratio Generic Panda Core Center to Stress Rod Stress Rod Diameter Center, (Pixels). (Pixels) Elliptical Core Core Center to edge of ellipse, Core Center to edge of ellipse, Minor diameter (Pixels). -

Page 36: Steps Of A Basic Splice With One Button Process

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.6. Steps of a Basic Splice with One Button Process The section will discuss the use of the One Button Splice process. The idea of the One Button Splice is to run all the steps necessary to complete a splice once the fibers are loaded and the filament has been centered (Section 7.4.2) and normalized (Section 5.5.2). -

Page 37: Modifiying The Splice Routine

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.6.2. Modifiying the Splice Routine The user has the abilitly to modify the splice routine of the “One Buttton” process by right clicking on the One Button Process button. The Process List in Figure 13 shows the current splice routine as well as the available processes and commands that can be added to the routine. -

Page 38: Manual Alignment

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.7.2. Manual Alignment The GPX3800 and GPX3850 workstations offer the operator the ability to perform manual splices where the alignment is carried out by the operator viewing the fibers on the screen and making the appropriate motor movements, or via a semi-automatic process where operator selects individual processes from the tool bar. - Page 39 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation This tapering process is in fact similar to a fiber drawing process, where the pre-form enters the furnace at a slow velocity and is pulled at a higher rate, inducing the smaller diameter fiber. The control of the diameters is achieved by a precise control of both feed and pull velocities along the process.

- Page 40 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation The final tab within the Taper Properties window, shown in Figure 17 is entitled “Taper Load Positions.” This tab allows the user to specify the starting positions of the fiber holding blocks and the furnace before the tapering process begins.

-

Page 41: Tension Monitor

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.7.5. Tension Monitor The Tension Monitoring System is series included with all Vytran glass processors to provide feedback on the taper process. At system turn on, the tension monitor (shown in Figure 18) needs to be zeroed to ensure proper reading of tension being applied to the fiber. -

Page 42: Filament Ramp And System Configuration

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.7.6. Filament Ramp and System Configuration All configurations take place on the Filament Ramp tab of the splice properties and taper properties pages. Access this page by clicking on the Splice menu. Splice Menu Select Splice Properties or Taper Properties from the pull down menu. - Page 43 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation If using the GPX3800 glass processor then you must select the 3300/3400 radio button. Doing so tells GUI software that it must issue lens home commands prior to the start of a taper or splice. This is essential for a GPX3800 system to avoid heat damage to the lens.

-

Page 44: Thermal Core Expansion

Users are advised to contact Thorlabs for assistance in these matters. 5.7.9. Mode Adaptors Fiber laser systems typically employ large-mode-area, double-clad gain fibers that must be coupled to a wide variety of dissimilar fibers. -

Page 45: Gpxfbt-Sft Fused Biconic Taper (Fbt) Processing Add-On Software

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.7.11. GPXFBT-SFT Fused Biconic Taper (FBT) Processing Add-On Software The Fused Biconic Taper (FBT) Processing Add-On Software allows the user to perform biconic tapers, meaning stretching the fiber by pulling outward on both fiber holding blocks while the furnace is applying heat to the fiber. This software add-on allows the user to have control on the power distribution along the process as well as shutoff process control. - Page 46 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation Analog Setup Defines the tension monitor channel (left or right), the analog power detectors used, and the ratio of filtering (smoothing data collection) as well as the power units to be used for the process. Stage Properties Defines the parameters for each process stage (up to a maximum of 5 stages).

-

Page 47: Taper Tension Process

GPX3800 and GPX3850 Glass Processors Chapter 5: Operation 5.7.12. Taper Tension Process Using the software add-on, a user can automatically apply a predefined tension on a fiber (or pair of fibers) loaded on a glass processor. This process (shown in Figure 23) requires the user to input the target tension in grams as well as the tension tolerance (typically a value from 1 g to 2 g). - Page 48 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation The software allows the user to define up to five stages to run the full taper process. At each stage the user can control the filament power, the duration or elongation of the stage, scan width, pulling velocity, and argon gas flow rate.

- Page 49 GPX3800 and GPX3850 Glass Processors Chapter 5: Operation Argon Flow The argon flow rate will depend on the filament used and the power delivered to the filament. Use a constant argon flow rate during all stages. Defining Overall Elongation - Stages To determine the amount of elongation required to achieve a desired fiber diameter for the taper, use the “Biconic Taper Diameter Estimator”...

-

Page 50: Chapter 6 Added Capabilities Of Gpx3800 / Gpx3850

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 Chapter 6 Added Capabilities of GPX3800 / GPX3850 The GPX Cleave Module controls the integrated cleaver on the GPX3800 and GPX3850 Glass Processors. Additional processes are provided to enable the imaging system and cleaver to be automated using the One Button Process function. - Page 51 GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 Cleave Tension (g): This parameter is the load, in grams, applied axially to the fiber prior to initiating the scribe process. The configuration menu provides both manual and auto-set options for setting the cleave tension. The optimal cleave tension depends on the cross-sectional area of the fiber and its material properties.

- Page 52 GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 The cleave properties page allows user access to cleave setup parameters. In addition, fiber holding block and cleaver (furnace) z-axis offset values can be entered. A negative value produces an offset to the left and a positive value an offset to the right.

-

Page 53: Gpx Cleaver View

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 Figure 26 Sub-Critical Cleave Parameters Re-Tension Level (g): This parameter is the load, in grams, applied axially to the fiber after the post-scribe pause. The optimal re-tension level is dependent upon the effective cross sectional area, material properties and type of fiber as well as scribe size. -

Page 54: Gpx Cleave Exposure

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 FHB Offset (mm): The position offset applied to both fiber holding blocks when in Cleave View. A negative offset will move both fiber holding blocks to the left, a positive offset will move both fiber holding blocks to the right. Together with the furnace motor position, this makes it possible to view the cleave operation through the imaging system. -

Page 55: Gpx Cleave Home

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 6.1.5. GPX Cleave Home GpxCleaveHome is an XSLT-based process that compiles and executes the homing process via an opto-sensor to establish the starting point of the cleave blade. 6.1.6. -

Page 56: Gpx Cleave Backstop Adjust

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 6.1.8. GPX Cleave Backstop Adjust GpxCleaveBackstopAdjust provides a visual assist to backstop adjustment. At the start of the process, both left and right fiber positions in the Y axis are captured. As the backstop is adjusted, the process window displays the measured deflection of each fiber. -

Page 57: Typical Process List For Gpx Cleave

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 6.1.10. Typical Process List for GPX Cleave Figure 33 shows a sample process list for a splice then cleave using the GPX Cleave. It includes the views, focus, and adjustment need to complete the process with the “one button”... - Page 58 GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 Figure 35 Hot View Filters When Hot View is On, the lens tower will not automatically go to the Home position before the splice. The ideal position is for the lens to be in Center View, thus looking directly down at the fibers during Hot View. A prompt message is inserted into the Process List to instruct the user to put the filter in place and to remove the filter after the splice.

-

Page 59: End View Quality Tool

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 6.3. End View Quality Tool The End View Quality Tool provides a (software) magnified view of a fiber end face together with a small collection of measurement tools to assist in verifying fiber quality and measuring fiber artifacts. 6.3.1. -

Page 60: Rectangle Tool

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 6.3.2. Rectangle Tool The Rectangle Tool allows the user to construct a bounding rectangle over the image. The width, height and diagonal measurements are displayed in microns in the overlay. Figure 39 Rectangle Tool Button Figure 40... -

Page 61: Circle / Ellipse Tool

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 6.3.3. Circle / Ellipse Tool The Circle/Ellipse Tool allows the user to construct a bounding circle or ellipse over the image. The width and height measurements are displayed in microns in the overlay. Figure 41 Circle / Ellipse Tool Button Figure 42... -

Page 62: Autolocate Tool

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 6.3.4. AutoLocate Tool The AutoLocate Tool automatically determines the diameter and position of a circular fiber. Figure 43 AutoLocate Tool Button Figure 44 AutoLocate Tool Page 58 TTN047534-D02... -

Page 63: Centroid Tool

GPX3800 and GPX3850 Glass Processors Chapter 6: Added Capabilities of GPX3800 / GPX3850 6.3.5. Centroid Tool The centroid tool automatically determines the centroid of a fiber using the Center Of Area method. This will work with any fiber geometry. Figure 45 AutoLocate Tool Button Figure 46 Centroid Tool... -

Page 64: Chapter 7 Maintenence

GPX3800 and GPX3850 Glass Processors Chapter 7: Maintenence Chapter 7 Maintenence 7.1. General Care The simple procedures and safeguards outlined in this section will help maintain the glass processor workstation in working condition. 7.2. Keep the System Clean The system should be kept clean at all times; dirt particles trapped in the furnace and fiber holder blocks can cause problems during operation. -

Page 65: Cleaning The Fiber Holding Block Insert

GPX3800 and GPX3850 Glass Processors Chapter 7: Maintenence 7.3.2. Cleaning the Fiber Holding Block Insert Debris in the fiber holding block v-grooves may interfere with fiber positioning. The v-grooves should therefore be cleaned carefully, using a soft brush moistened with acetone. 7.3.3. -

Page 66: Filament Replacement Procedure

GPX3800 and GPX3850 Glass Processors Chapter 7: Maintenence 7.4. Filament Replacement Procedure 7.4.1. Changing the Filament 1. Switch the glass processor on and initialize. 2. Home the lens by clicking on the “Lens Home” macro button. 3. Home the fiber holding blocks by clicking on “FHB Home” macro button. 4. - Page 67 GPX3800 and GPX3850 Glass Processors Chapter 7: Maintenence 7. Remove the 2 screws that secure the filament to the furnace body using a 5/64" hex key or balldriver (See Figure 51). Figure 51 Remove filament body screws using a 5/64" hex key or balldriver. 8.

-

Page 68: Filament Centering Procedure

GPX3800 and GPX3850 Glass Processors Chapter 7: Maintenence 7.4.2. Filament Centering Procedure Switch the on and home all motors. Press Load Fibers button to bring the fiber holding blocks to the load position. Load a fiber into to the left and right fiber holding blocks. Move the lens to Back View Gap and align the fibers in both Back View and Front View. -

Page 69: Cleaning The Mirror

GPX3800 and GPX3850 Glass Processors Chapter 7: Maintenence 7.5. Cleaning the Mirror The fiber image is distorted by debris that accumulates on the mirror surfaces. This debris may be dust from the atmosphere, small pieces of fiber coating, finger prints, etc. Care must be taken when cleaning the mirror surfaces, as they are all silver-coated on the front surface. -

Page 70: Installing The Gpx Cleaver

GPX3800 and GPX3850 Glass Processors Chapter 7: Maintenence 7.6. Installing the GPX Cleaver To install the GPX Cleaver; simply place the cleave assembly onto the adapter plate in which the location is controlled by 2 locating pins. The cleaver is secured by 3 screws. The location of the 3 screws is shown by the red arrows below. With the power of the GPX OFF, plug the USB end into the socket. -

Page 71: Adjusting The Cleave Blade Height

GPX3800 and GPX3850 Glass Processors Chapter 7: Maintenence Upon re-installing the GPX Cleaver, you may need to adjust the “Machine Specific Blade Compensation” value under the GPX Cleave Blade Service process. 7.7. Adjusting the Cleave Blade Height Only a small portion of the cleave blade edge is used to scribe the fiber. If this local portion of the edge gets damaged, the blade can be re-positioned to a new “un-used”... -

Page 72: Measuring The Argon Flow Rates

Image of Argon Gas Port (Left). Flow Meter in Vertical Position (Right) 7.9. RMA Process Contact Thorlabs for information on requesting an RMA for a purchased GPX3800 or GPX3850 glass processor. ATTENTION When returning the product to Thorlabs, please use the original packaging and pink anti-static bag that the unit came in. -

Page 73: Chapter 8 Appendix

GPX3800 and GPX3850 Glass Processors Chapter 8: Appendix Chapter 8 Appendix 8.1. Top Inserts The GPX3800 and GPX3850 Glass Processors require fiber holder inserts to be placed in the fiber holding blocks in order to clamp the fibers during the splicing process. Fiber holder top inserts sit in the lid of the fiber holding blocks and come in a variety of groove sizes. -

Page 74: Fiber Holder Insert Size Selection Guide

GPX3800 and GPX3850 Glass Processors Chapter 8: Appendix Fiber Holder Bottom Inserts for larger cladding or buffer diameters (indicated with Item #'s starting with VHE) come in single-sided and double-sided versions; the specified fiber diameter (in µm) is engraved on the part. These bottom inserts can also be used in the FPS300 Fiber Preparation Station, LDC Series of Fiber Cleavers, and LFS4100 Fusion Splicer. - Page 75 GPX3800 and GPX3850 Glass Processors Chapter 8: Appendix VHA00 VHA05 Top Insert Item # VHA00 VHA10 VHA15 VHA20 VHA25 VHA30 VHB00 VHB05 Accepted Diameter ≤320 µm 400 µm 500 µm 750 µm 1000 µm 1250 µm 1500 µm 1750 µm 2000 µm 2250 µm 2500 µm 3000 µm (Nominal) Bottom Accepted...

-

Page 76: Chapter 9 Specifications

GPX3800 and GPX3850 Glass Processors Chapter 9: Specifications Chapter 9 Specifications Item # GPX3800 GPX3850 Splicing Specifications Single Mode, Multimode, Photonic Crystal, Large Mode Area, Fiber Types (Non PM) Non-Circular Fiber Types (PM) Panda, Elliptical, Bow-Tie Fiber Cladding Diameter Up to 1.25 mm (Max) Up to 1.7 mm (Max) Filament Fusion Fusion Method... -

Page 77: Electrical Power

Thorlabs supplies a high purity PTFE gas line and a large gas regulator with the GPX. These are for use with a large gas tank (not available from Thorlabs) which has a CGA-580 output port; a DIN 477 Number 6 output port connector is also included. -

Page 78: Gas Supply Specifications

Use only the included gas line to interconnect the regulator to the splicing system. If an extended length gas line is required between the regulator and the splicer, please contact Thorlabs for purity requirements and line specifications. Page 74... -

Page 79: Chapter 10 Regulatory

Waste Treatment is Your Own Responsibility If you do not return an “end of life” unit to Thorlabs, you must hand it to a company specialized in waste recovery. Do not dispose of the unit in a litter bin or at a public waste disposal site. -

Page 80: Chapter 11 Thorlabs Worldwide Contacts

GPX3800 and GPX3850 Glass Processors Chapter 11: Thorlabs Worldwide Contacts Chapter 11 Thorlabs Worldwide Contacts For technical support or sales inquiries, please visit us at www.thorlabs.com/contact for our most up-to- date contact information. USA, Canada, and South America UK and Ireland Thorlabs, Inc. - Page 81 www.thorlabs.com...

Need help?

Do you have a question about the vytran GPX3800 and is the answer not in the manual?

Questions and answers