Table of Contents

Advertisement

Quick Links

Department

TB

Rev. Index

B

Date

01.01.09

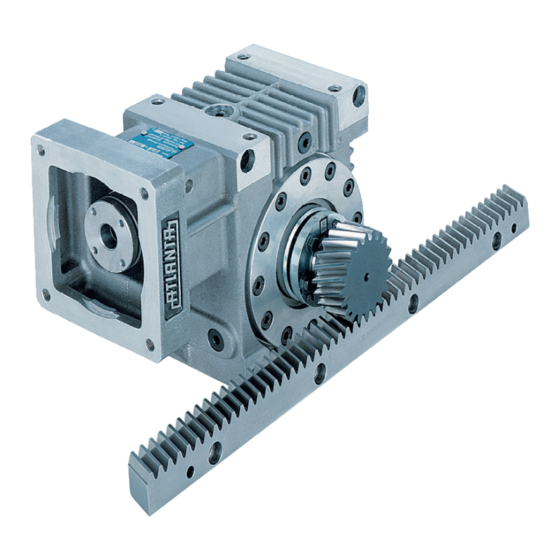

Rack and Pinion Drives

www.tekmatic.com 815.282.1775 insidesales@tekmatic.com

Handling, Installation, Operation &

Maintenance Instructions

Rack & Pinion Drives

Drive Systems

Operating Manual

© 2009 Atlanta Drive Systems Inc.

MPZ 001e

4100-001-06.05

Page

1

24

Name

01.06.05

Schell

Released

01.06.05

Lorch

Advertisement

Table of Contents

Summary of Contents for Atlanta MPZ 001e

- Page 1 Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Drive Systems Rack and Pinion Drives Operating Manual © 2009 Atlanta Drive Systems Inc. www.tekmatic.com 815.282.1775 insidesales@tekmatic.com...

-

Page 2: Table Of Contents

Lorch CAUTION! This operating manual is meant for all persons involved in the installation, operation and maintenance of ATLANTA Rack & Pinion Drives. To prevent damages and injuries, all instructions in this manual must be read and understood before any work is performed. -

Page 3: Company Address

Who Should Study These Instructions? These instructions are addressed to all persons handling, installing, operating or maintaining the ATLANTA Rack & Pinion Drives. You must not use these drives before having read and understood all of these instructions. These instructions should be given to all applicable personnel and kept for future reference. -

Page 4: General

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch General Safety Instructions: The Rack & Pinion Drives incorporate the latest technological development at the time of delivery and can be principally regarded as safe to operate, but below instructions should be observed. -

Page 5: Exclusion Of Liability

EC directive, the Rack & Pinion Drives must not be operated unless the machine into which this product is installed fulfills the requirements of the directive. Technical Changes: ATLANTA Drive Systems Inc. reserves the right to make technical changes to improve the product without notice. Intended Use: Rack &... -

Page 6: Improper Use

☞ The machine design must be made strictly in accordance with our instructions. Any deviation requires written approval by ATLANTA, otherwise this will be considered improper use and is prohibited. ☞ Wrong alignment (see section “Final Inspection“ on page 19) of the pinion with relation to the rack shall be considered improper use and is therefore prohibited. -

Page 7: Rack Handling Safety

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Rack Handling Safety: The racks must be assembled and installed only by skilled personnel having the necessary knowhow and experience. -

Page 8: Transport And Handling

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Always wear gloves when handling racks, because racks (especially those with helical teeth) have sharp edges. -

Page 9: Short Description

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Short Description: Rack and Pinion Drives convert rotary motion and torque of a gear into the power- transmitting linear motion of a gear rack. -

Page 10: Storage

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Storage: If the rack is not going to be installed immediately after delivery, the following measures should be taken: ☞... -

Page 11: Mounting Instructions

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Mounting Instructions: ☞ Please observe the instructions in the sections “General Safety Instructions” and “Rack Handling Safety”... - Page 12 MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch ☺ Mounting example on the machine bed 3. Remove the mating companion rack and the suitable clamping surface.

- Page 13 MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch 6. Plug the adjustment tool into the dowel holes at the joint of the two racks. One measuring pin is laid into the tooth gap at the joint and the other two in a tooth gap left and right of the joint.

- Page 14 MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch 8. Slightly tighten the socket head cap screws on the not yet fully fixed rack. Then loosen the screw on the adjustment tool and remove it from the dowel holes of the racks.

-

Page 15: Rack Mounting To Contact And Supporting Surfaces

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch ☺ In the case of racks of 1 meter length or more, the dowel pins are only needed for fixing, i.e. - Page 16 MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch ☺ The following is a mounting example on the machine bed Steps 4 to 10 are the same as with the mounting instructions with the contact surface only.

-

Page 17: Mounting The Reducer

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Mounting the Reducer: Before mounting the reducer on the machine table, the pinion shaft and lubricator (see separate instructions) should be mounted. -

Page 18: Engaging The Reducer To The Rack

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Engaging the Reducer to the Rack: ☞ Please observe the instructions in the section “General Safety Instructions”... -

Page 19: Final Inspection

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Final Inspection: ☞ Remove the grease from the rack and pinion tooth flanks. ☞ Coat the tooth flanks with marking/bluing compound. -

Page 20: Starting Automatic Lubrication System

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Starting Automatic Lubrication System: ☺ The automatic lubrication system consists of a mounting bracket, an electronically-controlled lubricator, a connecting hose, a mounting shaft, and a felt gear. -

Page 21: Maintenance

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Maintenance: Taking Out of Operation, Preparations ☞ Please observe the instructions in the sections “General Safety Instructions” and “Rack Handling Safety”... -

Page 22: Restarting Operation After Maintenance

MPZ 001e Handling, Installation, Operation & 4100-001-06.05 Maintenance Instructions Department Page Rack & Pinion Drives Rev. Index Name 01.06.05 Schell Date 01.01.09 Released 01.06.05 Lorch Please also observe the operating and maintenance instructions BKI 101; BKI 102; BKI 103; BKI 104; BKI 105, and BKI 106 for the lubricator. -

Page 23: Disassembly

Lubrication of Rack and Pinion Drives: For the continuous lubrication of Rack & Pinion Drives, we recommend to using ATLANTA electronically-controlled lubricators together with felt gear or the sliding brush applicators. Item numbers and descriptions are contained in our servo catalog or on our website. -

Page 24: Disposal

Felt Gears ☞ Felt gears can be disposed of as residual waste. ATLANTA will not assume any liability for damage or injuries resulting from improper use or handling of the Rack & Pinion Drives. Buyer assumes all risk and liability for loss, damage or injury to persons or property of buyer or others arising out of use or possession of any product sold hereunder.

Need help?

Do you have a question about the MPZ 001e and is the answer not in the manual?

Questions and answers