Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for VWR VWR B2 Series

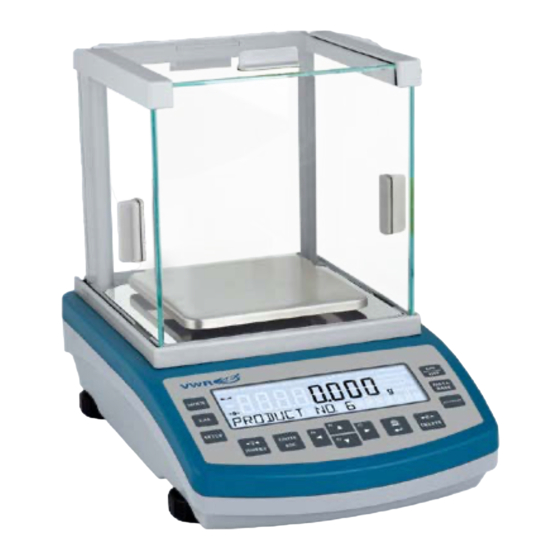

- Page 1 User Manual VWR B2 SERIES BALANCES Rev B2-05...

-

Page 2: Table Of Contents

TABLE OF CONTENTS General Information ..................4 1.1. INTENDED USE ..................4 1.2. INAPPROPRIATE USE ................4 1.3. WARRANTY .................... 4 UNPACKING AND INSTALLATION ..............4 2.1. STANDARD DELIVERY COMPONETS LIST ........... 4 2.2. UNPACKING ................... 4 2.3. PLACE OF USE AND ASSEMBLY ..............5 2.4. - Page 3 WEIGHING ....................24 8.1. UNDER-PAN WEIGHING ................ 25 PARTS COUNTING ..................26 9.1. SETTING REFERENCE MASS: MASS DETERMINATION FOR THE SAMPLE OF KNOWN QUANTITY ..................26 9.2. SETTING REFERENCE MASS: ENTERING MASS VALUE ....... 27 10. DEVIATIONS ..................... 28 10.1. SETTING THE REFERENCE MASS: WEIGHING REFERENCE SAMPLE ..... 28 10.2.

-

Page 4: General Information

1. GENERAL INFORMATION 1.1. INTENDED USE B2 series balances are designed to provide accurate measurement of weighed loads, performed under laboratory conditions. It is intended for application as a non-automatic weighing instrument only, i.e. the material to be weighed is manually and carefully placed in the center of the weighing pan. -

Page 5: Place Of Use And Assembly

The original packaging protects the equipment against potential damage during transportation. 2.4. BALANCE ASSEMBLY Model: VWR-64B2, VWR-124B2, VWR-214B2 Components- Installation- 1) Remove the transport lock– gently press the transport lock and turn it accordingly to <OPEN>, keep the transport lock should your balance be transported in the future. - Page 6 3) Install components following diagram below: i. Bottom insert ii. Centering ring [embossment side up] iii. Weighing pan Model: VWR-203B2, VWR-403B2, VWR-503B2 Components: Installation: 1) Check that the grounding spring is in the correct location, the spring juts slightly out of the hole.

- Page 7 2) Install components following the diagram below: i. Bottom Insert ii. Rubber feet (grounding foot can be in any location on the balance) iii. Weighing pan Model: VWR-4002B2, VWR-5002B2 Components: Installation: 1) Install components following the diagram below: i. Draft Shield ii.

-

Page 8: Balance Leveling

2.5. BALANCE LEVELING It is necessary to level the balance prior to plugging it in. To level the balance, turn its feet until the air bubble is in the center position. The balance should firmly rest on a surface, each of the feet must be supported. 2.6. -

Page 9: Keyboard - Button Functions

3. KEYBOARD – BUTTON FUNCTIONS Press to switch the balance ON/OFF. If switched off, balance components other than the display are powered, and balance is in stand-by mode. Press to access data stored in a database: user, product, tare. Press to enter directly the active working mode settings. Press to select working mode. -

Page 10: Start-Up

4. START-UP When plugged to mains, the balance displays program name and number, next it proceeds to the weighing mode. 4.1. TEMPERATURE STABILIZATION PERIOD Before start of measuring processes, it is necessary to wait until the balance reaches thermal stabilization. For balances that were stored in much lower temperatures before plugging to mains (e.g. - Page 11 P5 PRINTOUT CAL. REPORT [contents of the adjustment report] P5.1 HEADER [contents of the header printout] P5.2 GLP PRNT. [contents of the weighing result prnt.] P5.3 FOOTER [contents of the footer printout] P5.4 P5.5 NSD.PRN.1 [project of non-standard printout 1] NSD.PRN.2 [project of non-standard printout 2] P5.6...

-

Page 12: Balance Operation - General Information

5. BALANCE OPERATION – GENERAL INFORMATION 5.1. BALANCE ZEROING Zeroing is a function allowing to zero the mass on the indication. To perform this function, press button. Mass indication of zero value shall be displayed together with precise zero stability markers The zeroing process is an equivalent for determining new zero point, recognized by the balance as precise zero. -

Page 13: Units

5.3. UNITS UNITS parameter group enables the user to change availability of mass units (the change can be performed in-course of balance operation), and to define two custom units, thus positively effecting comfort and speed of operation. It is possible to change unit to other than unit [g] during weighing process or during operation of other modes. -

Page 14: Custom Unit

5.7. CUSTOM UNIT You can declare two custom units. The custom unit is a result of indication multiplied by a specified coefficient. The units are displayed as [u1] – user unit 1, and [u2] – user unit 2. Procedure: 6. WORKING MODES- GENERAL INFORMATION The balance features the following working modes: Weighing Means of operation: weight of a load is determined through an indirect measurement. -

Page 15: Running Working Mode

6.1. RUNNING WORKING MODE In order to run a particular mode press button, and select the mode from the list. Procedure: CAUTION! Upon restart, the balance is launched with the most recently operated working mode. For settings of this function read later sections of this user manual. 6.2. -

Page 16: Working Mode Settings- Reading

Caution: You can modify all settings of User profile. Settings of other profiles (Fast, Fast dosing and Precision) can be modified only to a limited extend. Name of currently selected profile is displayed in the bottom line. The profile can be selected individually for working mode. -

Page 17: Value Release

6.4.2. VALUE RELEASE Value release setting (function unavailable for the following profiles: Fast, Fast dosing, Precision) Since ambient conditions at a workplace vary, it is necessary to determine the value release parameter that are best for your working environment, parameter options are: <FAST.+REL.>, <FAST>... -

Page 18: Last Digit Display

6.4.4. LAST DIGIT DISPLAY Function enables displaying the last digit of decimal place for a weighing result. There are three available options: • <ALWAYS> all digits visible • <NEVER> last digit is not displayed • <WHEN STB> last digit is displayed only for a stable weighing result Procedure: 6.4.5. -

Page 19: Working Mode Settings- Print Mode

• The balance removes the tare value (packaging weight recorded during the first step of the operating process) after the gross weight value (set in <AUTO THRES> parameter) has been exceeded. • Place packaging of the next product on the weighing pan, automatic taring of the packaging weight proceeds after measurement stabilization (Net marker appears in the top section of the display);... - Page 20 • <AUTO> - select this option to enable automatic printing of measurements. If this option has been selected, remember to set <AUTO THRES> parameter to suit your needs. • <AUTO+INT.> select this option to start automatic printout and record of indications in Weighings database and Alibi database, carried out in a cyclic manner in a specified time interval.

-

Page 21: Working Mode Settings- Information

<BARGRAPH> option presents amount of used weighing capacity in a graphic form, it covers 0 – MAX range. Example of a VWR-1003AC balance display with bar graph option on: 500 g heavy load placed on a weighing pan means that 50% of max capacity has been used (half-filled bar graph bottom line). -

Page 22: Working Mode Settings- F Shortcut Keys

If you want the declared non-standard information is to be visible, set parameter P2.1.2 to < NSTD. INF. > option. 6.9. WORKING MODE SETTINGS- F SHORTCUT KEYS Function enables assigning quick access for weighing functions which are to be accessible by pressing F1, F2, F3 or F4 keys. -

Page 23: Calibration

30% of Max range. 7.2. EXTERNAL CALIBRATION 7.2.1. EXTERNAL CALIBRATION The external calibration for VWR B2-series balances should be carried out with an external mass standard of class F Run an external calibration process, the balance displays a command ordering to unload the weighing pan, <REMOVE MASS>... -

Page 24: Calibration Report Printout

Once the mass of the weight is entered and confirmed, the message prompting the user to remove the weight from the pan is displayed: <REMOVE MASS> (the weighing pan must be empty). Unload the pan and press button, the balance determines the weight of an unloaded pan, message <CALIBRATION>... -

Page 25: Under-Pan Weighing

The balance requires calibration before weighing process start or in case of drastic change of ambient conditions at a workstation. • Before the start of weighing procedure, it is recommended to load the weighing pan a few times with mass close to balance max capacity •... -

Page 26: Parts Counting

Mass of all additional elements of under pan weighing kit, like the hook, weighing pan, string, etc. should be zeroed by pressing 9. PARTS COUNTING Parts counting is a working mode which enables determination of quantity of small parts with equal weight. -

Page 27: Setting Reference Mass: Entering Mass Value

CAUTION! Remember that: • The total mass of all the pieces put on the weighing pan must not be greater than the balance maximum weighing range. • The mass of a single piece cannot be lower than 0.1 reading unit of the balance. If this condition is not met, the balance displays message: <Single part mass too low>. -

Page 28: Deviations

10. DEVIATIONS Deviations is a working mode for comparison of a measured sample with the reference mass. The result is expressed in [%]. 10.1. SETTING THE REFERENCE MASS: WEIGHING REFERENCE SAMPLE Procedure: • Press F button to which function <DETERMINE SAMPLE> is assigned, <PUT 100%> editing window is displayed. -

Page 29: Density Of Solids

11. DENSITY OF SOLIDS Solids density is a working mode enabling determination of density of a representative sample material. In order to operate this mode, an optional Density Determination Kit is available for purchase. For the measurement, an appropriate model of the kit is used for the balance depending on pan configuration. - Page 30 10. First, place a mass sample on the top weighing pan of the kit (weighing in the air), and confirm the indication when stable. 11. Next, place a mass sample on the bottom pan of the kit (mass determination in the liquid), and confirm the indication when stable.

-

Page 31: Density Of Liquids

12. DENSITY OF LIQUIDS Liquids density is a working mode enabling determination of density of liquid with use of representative sample of a given liquid. To operate this mode, an optional Density Determination Kit is available for purchase. For the measurement, an appropriate model of the kit is used for the balance depending on pan configuration. -

Page 32: Animal Weighing

Next, take the sinker out of the hook, put the beaker with liquid on the beaker’s basis (the beaker cannot touch the hook), gently hang the sinker on the hook providing that it is totally immersed in the tested liquid (sample mass determination in liquid) – and confirm the indication when stable 10. -

Page 33: Running The Process Manually

• AUTOSTART - Determines start criterion for measurements: whether they are to be initiated manually, on pressing a button or selecting <START>, or automatically. When the parameter is set to <YES> option, the measurement starts automatically if an indication on a balance display exceeds the set threshold value. -

Page 34: Running The Process Automatically

13.2. RUNNING THE PROCESS AUTOMATICALLY To start the process of weighing automatically, enter the mode settings, select an <AUTOSTART> parameter and set <YES> value, follow description form the previous paragraph. Additionally, set parameters <AVERAGING TIME> and <THRESHOLD>. In order to carry out the measurement in a container (TARE) for this mode, select the option <ENTER TARE>, for the option overview to be found in weighing mode options description. - Page 35 Backlight turn-off time Parameter <P6.4 STAND-BY MODE> enables use of function responsible for activation of the display stand-by mode when weighing process is not being performed (stable indication is a necessary condition for activation of the stand-by mode). NONE – backlit turn-off time not activated 0.5;...

-

Page 36: Determinig Printout Content

Time format Time form. parameter enables specifying time format for a printout [12h / 24h]. For [12h] option selected, <A> or <P> letter is displayed next to presented time value, where: A stands for hours before noon; P stands for hours after noon. 15. -

Page 37: Header, Footer, Glp Printouts

15.2. HEADER, FOOTER, GLP PRINTOUTS HEADER group of parameters enabling to declare data that is to be printed on a header printout. GLP PRINTOUT group of parameters enabling to declare data that is to be printed on a measurement result printout FOOTER group of parameters enabling to declare data that is to be printed on a footer printout... -

Page 38: Non-Standard Printouts

STANDARD PRNT. Option enables printing out one of standard Header printouts on the footer printout. GLP printout Footer For the parameters described above, one of these values must be selected: NO - do not print; YES – print 15.3. NON-STANDARD PRINTOUTS The balance software enables entering 4 non-standard printouts. -

Page 39: Variables

Example 1: “AAAAAA” DATE: <current measurement date> TIME: <current measurement time> PRODUCT MASS: <current mass indication> *****SIGNATURE:..<current working mode> Enter printout content settings and design the printout using respective data variables and characters for text format. The way of inserting texts: •... -

Page 40: Communication

16. COMMUNICATION 16.1. RS 232 PORT SETTING (COM) Procedure: • Select communication port <COM 1>, • Set respective values The RS 232 ports enable the following setting of transmission parameters: • Baud rate – 2400, 4800, 9600, 19200, 38400, 57600, 115200 bit/s •... -

Page 41: Printer

Procedure: press button enter <P4 DEVICES> menu enter menu group: <P4.1 COMPUTER> select port to which a computer is to be connected, COM 1– RS 232 port, to which the computer is connected Continuous Transmission Continuous transmission parameter enables turning on/off continuous transmission... -

Page 42: Cooperation With Devices

(this possibility is available only for printers with such option – see a user manual of the printer). CAUTION! CODES MUST BE ENTERED IN A HEXADECIMAL FORM! Example balance settings for correct cooperation with VWR Dot Matrix Printer (10799-132) connected to RS232 port Communication parameters for port to which the printer is connected: •... -

Page 43: Transferred Data Format

• Baud rate - 4800 ÷ 115200 bit / s • Parity control - NONE, ODD, EVEN Value indicated on a display can be sent via RS232 port to a peripheral device in one of four accessible ways: • manually - on pressing button •... -

Page 44: Communication Protocol

next: 1 – 3 8 – 16 18 - 20 Command 1-3 characters Stability marker [space] if stable [?] if unstable [^] if high limit is out of range [v] if low limit is out of range Character [space] for positive values [-] for negative values Mass 9 characters with decimal point and right justification... - Page 45 Give current working mode Give accessible units Set unit Give current unit Activate sound signal Send all implemented commands Give balance type Give Max capacity Give program version Set autozero function Set ambient conditions state Set filter Set value release Set last digit CAUTION! Each command must end with CR LF characters;...

- Page 46 Give tare value Format: OT CR LF Response: OT_TARE CR LF - command carried out Response format: 4-12 space tare space unit space Tare - 9 characters with right justification Unit - 3 characters with left justification CAUTION! Tare value is always given in calibration unit. Set tare Format: UT_TARE CR LF, where TARE –...

- Page 47 Format: SU CR LF Response options: SU_A CR LF - command understood and in progress SU_E CR LF - time limit exceeded while waiting for a stable measurement result SU_I CR LF - command understood but not accessible at this moment MASS FRAME - response: mass value in a current measuring unit Response format:...

- Page 48 Response format: 7-15 stability space character mass space unit marker Switch off continuous transmission in a current measuring unit Format: CU0 CR LF Response options: CU0_I CR LF - command understood but not accessible at this moment CU0_A CR LF - command understood and carried out Set mass value of a single item (only for PARTS COUNTING) Format:...

- Page 49 Response options: OMI <CR><LF> n_”Nazwa modu” <CR><LF>: – command carried out, response: accessible working modes n_”Nazwa modu” <CR><LF> OK <CR><LF> OMI_I <CR><LF> – command understood but not accessible at this moment Mode name – parameter, working mode name, inserted in between inverted comas. The name takes form given on a particular balance display, it is provided in a currently selected language.

- Page 50 Give accessible units Command overview: Command returns units available for a particular device and for a current working mode. Format: UI <CR><LF> Response options: UI_”x , … x ”_OK<CR><LF> – command carried out, returns accessible units UI_I <CR><LF> – command understood but not accessible at this moment x –...

- Page 51 An example: Command: BN <CR><LF> – return balance type Response: BN_A_”VWR” – balance type: ”VWR” Give max capacity Format: FS <CR><LF> Response options: FS_A_”x” <CR><LF> - command understood, response: Max capacity FS_I <CR><LF> - command understood but not accessible at this moment x –...

- Page 52 1 – stable ambient conditions CAUTION! Command changes settings for a current working mode. An example: Command: EV_1<CR><LF> – set value ‘stable’ for ambient conditions option Response: EV_OK<CR><LF> – ambient conditions option set to value ‘stable’ <AMBIENT CONDITIONS> parameter is set to value <STABLE> until command EV 0 swaps it to value <UNSTABLE>.

-

Page 53: Appendix

The command changes settings for a current working mode if, for a particular balance type, last digit settings are assigned to the working mode. An example: Command: LDS_1<CR><LF> – set last digit option to value ‘always’ Response: LDS_OK<CR><LF> – ‘always’ value set 20. -

Page 54: Connection Cables - Diagrams

20.3. CONNECTION CABLES - DIAGRAMS Scale – computer cable (RS232) Scale – printer cable (CITIZEN, EPSON) 20.4. MAINTENANCE ACTIVITIES 1. Disassemble a weighing pan and other detachable components (the components differ depending on a balance type – see Unpacking section). Be careful while detaching the components so as not to cause any damages to the balance mechanism. - Page 55 Remove the back pane. Remove side panes. Side panes shall not be swapped therefore it is necessary to remember which one is right, and which one is left in order to install them back properly. CAUTION! Do not remove the front pane! Remove a weighing pan, a draft shield, a bottom insert.

-

Page 56: Error Messages

21. ERROR MESSAGES Error Message Cause Solution -Err2- Value beyond zero range *Only Zero balance with weighing pan empty *Wait until stability marker appears to press the Zero button -Err3- Value beyond tare range *Only Tare balance with load on the weighing pan *Wait until stability marker appears to press the Tare button...

Need help?

Do you have a question about the VWR B2 Series and is the answer not in the manual?

Questions and answers

What are accuracy / tolerance specifications for B2-T balance