Table of Contents

Advertisement

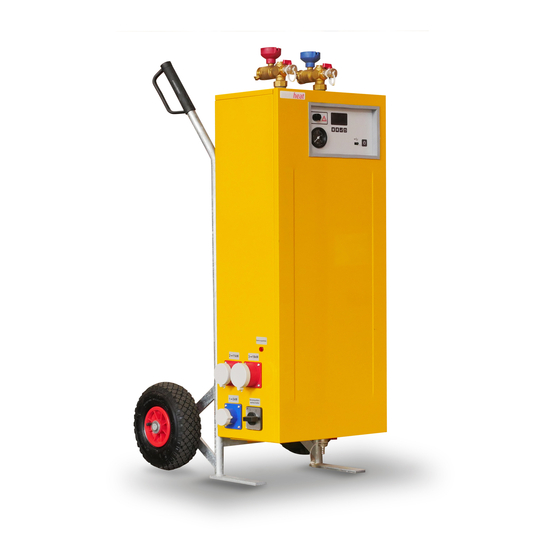

Electric mobile heating

units

English translation of original operating

instructions

For type MH19.2ME/Q1, MH20.2E, MH40.2ME/Q1

Two different control units are described in this manual. Please observe the appropriate

instructions for your device in the following sections

3.3.3 Settings for type MHRE control unit

3.3.4 Settings for type MHRE control unit

V18.4

Art. No: MH-BA-25

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for mobiheat MH19.2ME/Q1

- Page 1 English translation of original operating instructions For type MH19.2ME/Q1, MH20.2E, MH40.2ME/Q1 Two different control units are described in this manual. Please observe the appropriate instructions for your device in the following sections 3.3.3 Settings for type MHRE control unit 3.3.4 Settings for type MHRE control unit...

-

Page 2: Table Of Contents

Table of contents Section Important safety regulations Technical data 2.1 MH19.2ME/Q1 2.2 MH20.2E 2.3 MH40.2ME/Q1 2.4 Intended use Setup/commissioning 3.1 Transport 3.2 Setup 3.3 Commissioning 3.3.1 Connection 3.3.2 Filling and venting 3.3.3 Settings for type MHRE control unit 3.3.4 MHRQ1 type control setting 3.3.4.1 Menu overview... - Page 3 3.3.10 Dismantling Malfunctions: Causes and remedies 4.1 General information 4.2 Error code table for type MHRE 4.3 Error code table for type MHRQ1 4.4 Heating circuit pump Maintenance 5.1 Regular maintenance 5.2 Storage Accessories 6.1 Supplied accessories 6.2 Optional accessories Miscellaneous 7.1 Imprint / Hotline V18.4...

- Page 4 Symbols and terms used All safety and warning notices in this manual have been clearly highlighted. The following symbols and signal words have been used for warnings. Danger Warns you of dangers that could result in personal injury or considerable damage to property.

-

Page 5: Important Safety Regulations

1. Important safety regulations IMPORTANT SAFETY REGULATIONS FOR BOILERS READ THIS MANUAL CAREFULLY BEFORE CONNECTING THE BOILER TO THE HEATING CIRCUIT. Installation and connection may only be carried out by qualified personnel. Danger due to misuse! Use the device only for the purpose described in this manual. Otherwise you may endanger yourself or damage the device. -

Page 6: Technical Data

2. Technical data Please refer to the following tables for the respective technical data and connected loads for your model. 2.1 MH19.2ME/Q1 Dimensions (W x D x H): 600 mm 580 mm 1220 mm Weight (including transport approx. 58 kg trolley): Circulating pump: max. - Page 7 Heating mode: 20 – 80°C Heating capacity: 19 kW Electrical connection: CEE 32 A/400V/50Hz/3 V18.4 Art. No: MH-BA-25 Page 6...

-

Page 8: Mh40.2Me/Q1

Control unit: MHRE MHRQ1 Digital Digital and programmable Screed heating programs Screed heating programs: - Screed curing DIN 1264-4 - Screed curing DIN 1264-4 - Functional heating DIN 1264-4 - Functional heating DIN 1264-4 - OE standard B 3732 - OE standard B 2242-2 - Suissetec Cement - Suissetec Calcium Sulphate CaSO... -

Page 9: Setup/Commissioning

3. Setup/commissioning Transport Transport by forwarding agency • Never lift or lash the device by the fittings. • Store the device in a dry, frost-free and dust-protected place. • Disconnect the device from the power source for storage. • After use, store the device only in a completely empty condition. In this way you ensure that no damage occurs to the device during transport and storage. -

Page 10: Filling And Venting

3.3.2 Filling and venting • Attach a vent line to the flow pipe (Pos. 4, Fig. 2, Section 3.3.2). • Attach a water supply line to the fill and drain valve (Pos. 6, Fig. 2, Section 3.3.2). • Open the fill and drain valve for the water supply line and bleed line. •... -

Page 11: Settings For Type Mhre Control Unit

3.3.3 Settings for the type MHRE control unit • The heating circuit pump starts. • A rotating running light appears in the display (Fig. 3, Section 3.3.3). • The LED operating display flashes at position "0" (Fig. 3, Section 3.3.3). •... - Page 12 • Tap on the temperature selector switch (Fig. 6, Section 3.3.3) to display the target temperature and the remaining running time of the program. (Figure 6) • If one of the selected heating programs is manually interrupted, the program is stopped and starts from the beginning. •...

- Page 13 3.3.4 Setting the MHRQ1 type controller Installation and commissioning may only be carried out by qualified personnel Power button USB port Boiler temperature Outdoor temperature (only for units with outdoor temperature sensor) Number of active heating stages Heating circuit pump in operation Date Operating mode: Manual M or screed heating program...

-

Page 14: Menu Overview

3.3.4.1 Menu overview 1. Service menu Outdoor temperature sensor / weather-controlled Heating circuit pump run-on Stand-by temperature Min. boiler temperature Max. boiler temperature Switch-on delay for power levels Date / time Delete log data Reset counter Reset to factory settings 2. -

Page 15: Service Menu

Service menu Press the buttons (13 and 14) for at least 5 seconds to call up the service menu. Enter the PIN by pressing the following key combination 334112: 3.3.5 Service menu 3.3.5.1 Outdoor temperature sensor / weather controlled Setting the heating characteristic (only for devices with outdoor temperature sensor) Preset characteristic curves Outside temperature... -

Page 16: Heating Circuit Pump Run-On

• Underfloor heating ON → Heating characteristic 0.1 – 0.9 • Underfloor heating OFF → Heating characteristic 1 – 3 • Select the desired heating characteristic with the arrow keys (11 and 12) and confirm with the Enter key (13). •... -

Page 17: Reset Counter

3.3.5.8 Reset counter • You can reset the operating hours of the individual heating elements. The total operating time of the boiler cannot be reset. • Select the desired heating element or all heating elements with the arrow keys (11 and 12) and confirm with the Enter key (13). Select YES or NO with the arrow keys (11 and 12) and confirm with Enter. -

Page 18: Installing Your Own Programs

50°C 50°C Program terminated: 25°C 3.3.6.2 Installing your own programs Create program file • Download and install the Windows app MHLogs from www.mobiheat.de on your PC or notebook. • Start the MHLogsprogram. • In the main menu, click on •... -

Page 19: User Menu

• Create log. • Connect the USB stick to your PC or notebook. • Start the MHLogsprogram. • Click in the menu bar on • Select the folder with your recordings on the USB stick. • By double-clicking on the recording in the MHLogs program, you can view the recording as text and graphics. - Page 20 3.3.8 Setting the heating circuit pump - Heating circuit pump - Heating circuit pump MH19.2ME/Q1 MH40.2ME/Q1 - Heating circuit pump MH20.2E • If the rooms are not heated sufficiently, the speed of the pump may be too low. In this case, switching to a higher speed is necessary. If the pump is set to a speed that is too high, flow noises are generated in the pipes and especially at throttled thermostatic valves.

-

Page 21: Voltage Monitoring

3.3.9 Voltage monitoring • Voltage monitoring protects the device against undervoltage and overvoltage. If the power supply is faulty, the heater is switched off. Meaning Voltage OK Overvoltage Undervoltage Neutral conductor or phase missing, no voltage / ... -

Page 22: Malfunctions: Causes And Remedies

4. Malfunctions: Causes and remedies 4.1 General Malfunction Possible cause Remedy • • • No mains voltage Check on-site fuse Heating system cools down • Check supply line • Check earth-leakage circuit breaker and devices in the unit itself and in the distributor provided by the customer •... - Page 23 4.2 Error code table for MHRE control unit Troubleshooting may only be carried out by qualified personnel Error code on display Cause Remed • • • Short-circuit in Contact mobiheat temperature sensor • • • A system error has occurred Contact mobiheat •...

-

Page 24: Heating Circuit Pump

Check the residual current circuit breaker before each start-up. • Clean the dirt trap in the return line after each use. • Have the device serviced by mobiheat once a year Please observe the statutory inspection intervals V18.4 Art. No: MH-BA-25... -

Page 25: Storage

5.2 Storage • After use, store the device only in a completely empty condition. • Turn all ball valves to 45° position. This is to ensure that storage does not cause any damage to the device. 6. Accessories 6.1 Supplied accessories (included with rental equipment / optional for purchased equipment) •... -

Page 26: Miscellaneous

7. Miscellaneous 7.1 Imprint / Service Hotline OPERATING INSTRUCTIONS mobiheat GmbH Winterbruckenweg 58 D-86316 Friedberg - Derching Managing Directors: Andreas Lutzenberger ; Helmut Schäffer ; Marc-Oliver Pehlke Registered Court Augsburg HRB 21803 VAT ID: DE- 248 162 ALL RIGHTS RESERVED... - Page 27 Notes V18.4 Art. No: MH-BA-25 Page 25...

- Page 28 V18.4 Art. No: MH-BA-25 Page 26...

Need help?

Do you have a question about the MH19.2ME/Q1 and is the answer not in the manual?

Questions and answers