Summary of Contents for TEI TE260

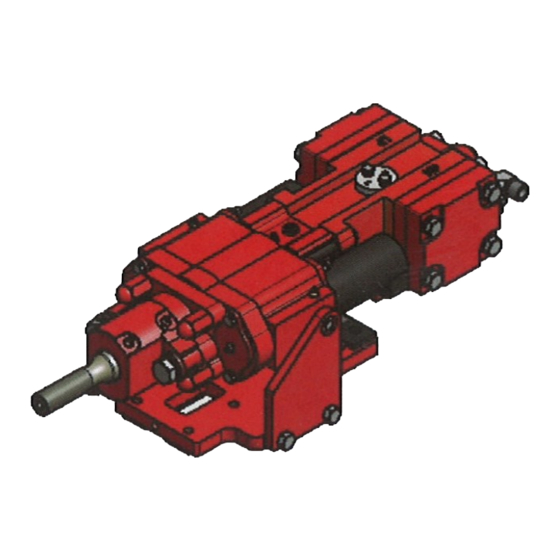

- Page 1 SERVICE AND MAINTENANCE MANUAL TE260 HYDRAULIC DRIFTER Blast hole and Foundation Drilling January 2015...

- Page 2 This manual contains instructions for the maintenance, troubleshooting, and field repair of the TEI ROCK DRILLS TE260. It is intended to help you maintain the drill and perform on-site repairs. Read and understand this manual before operating or servicing this machine.

- Page 3 ADDITIONAL MANUALS ARE AVAILABLE Additional copies of this manual are available for purchase from TEI ROCK DRILLS. To order please specify equipment model and serial number, quantity desired, type of manual, and remit $25 per manual with order.

-

Page 4: Table Of Contents

TE260 SERVICE AND MAINTENANCE MANUAL TABLE OF CONTENTS INTRODUCTION SECTION 1 Specifications 1-1 thru 1-2 PRECAUTIONARY NOTICES SECTION 2 Operator Warnings Equipment Cautions MAINTENANCE SECTION 3 General Maintenance Tips Maintenance Schedule 3-2 thru 3-5 Troubleshooting 3-6 thru 3-12 Nitrogen Charging Instructions... -

Page 5: Introduction

INTRODUCTION Section 1 Specifications 1-1 Thru 1-2 BEFORE ATTEMPTING MAINTENANCE OR REPAIR OF ANY COMPONENTS OF THIS MA- CHINE, READ THE WARNINGS AND CAUTIONS LISTED IN SECTION 2... - Page 6 Section 1 Page 1-1...

- Page 7 HYDRAULIC OIL SPECIFICATIONS Mobile Mobile Mobile DTE 24 DTE 25 DTE 26 Product Number 60262-3 60263-1 60264-9 Gravity, API 30.4 28.4 27.5 Specific Gravity 0.874 0.885...

- Page 8 PRECAUTIONARY NOTICES Section 2 Operator Warnings Equipment Cautions BEFORE ATTEMPTING MAINTENANCE OR REPAIR OF ANY COMPONENTS OF THIS MA- CHINE, READ THE WARNINGS AND CAUTIONS LISTED IN SECTION 2...

-

Page 9: Operator Warnings

OPERATOR WARNINGS Your first consideration, when servicing your TE260, must be your personal protection and that of others. Correct servicing is a matter of being completely familiar with your machine and the job it is intended to do. Carefully read and understand the warnings listed below, and most of all remember to apply good common sense at all times. -

Page 10: Equipment Cautions

3. PERIODICALLY INSPECT HOSE RETAINERS CLEAN THE EXTERIOR OF ALL PARTS AND AND HOSES FOR INDICATION OF WEAR, HOSE CONNECTIONS BEFORE REMOVING. LOOSENESS, CRACKING, OR FRAYING. DO NOT OPPERATE THE TE260 HYDRAULIC FREQUENTLY CHECK ALL NUTS, BOLTS, DRILL UNTIL ACCUMULATORS... -

Page 11: Maintenance

MAINTENANCE Section 3 General Maintenance Tips Maintenance Schedule 3-2 thru 3-5 Troubleshooting 3-6 thru 3-12 Parts Wear Tolerances 3-13 Nitrogen Charging 3-14 Instructions BEFORE ATTEMPTING MAINTENANCE OR REPAIR OF ANY COMPONENTS OF THIS MACHINE, READ THE WARNINGS AND CAUTIONS LISTED IN SECTION 2... - Page 12 2. Carefully examine all filters for evidence and is intended to help the servicemen in of metal or rubber particles. Replace the the field to service and repair the TE260. It filters as necessary. is not meant to imply that all such parts will fail in the described manner, or that 3.

- Page 13 6. Ensure that all waste is disposed of according to environmental regulations. DAILY MAINTENANCE Normal operation of the TE260 requires daily greasing of the front rotation housing every 2 percussion hours using a moly disulfide high temperature type grease. This is most important to prevent galling and failure of the rotation gears and bearings.

- Page 14 Every six months or 1,000 percussion hours, the drill must be inspected for hammer and bearing seal wear. Maintenance of hammer, bearings, accumulators, valve assembly or stroke control must be performed in a clean sheltered area. YEARLY INSPECTION AND OR COMPLETE REBUILD Send to TEI Factory or Authorized TEI Distributor Section 3 Page 3-3...

- Page 15 TE260 Recommended Spare Parts PART NUMBER DESCRIPTION TE26778 COMPLETE SEAL KIT TE30706SK GROUT/WATER SEAL TE30350 DIAPHRAGM 1050094 VALVE TE55183SX BOLT, GROUT SWIVEL TE35161 THRUST BLOCK TE357 CHUCK TE30835SK THRUST WASHER TE3549---- SHANK, SPECIFY THREAD ST16204 BUSHING, STEEL SB48528 BEARING, BRONZE...

- Page 16 HYDRAULIC OIL SPECIFICATIONS Mobile Mobile Mobile DTE 24 DTE 25 DTE 26 Product Number 60262-3 60263-1 60264-9 Gravity, API 30.4 28.4 27.5 Specific Gravity 0.874 0.885...

- Page 17 TE260 TROUBLESHOOTING PROBLEM PROBABLE CAUSES REMEDY A. Drilling rate falls off quickly, High pressure accumulator has lost Recharge or replace high pressure supply hoses pulsate pressure accumulator diaphragm or fill excessively, hoses heat up, valve drill vibrates excessively B. Drill bounces and vibrates...

- Page 18 TE260 TROUBLESHOOTING PROBLEM PROBABLES CAUSES REMEDY F. Drilling rate falls off quickly Hydraulic lines have been torn or Check hydraulic system crushed Severe hydraulic leakage Check and replace faulty part Shank failure Replace shank and check related parts for damage G.

- Page 19 TE260 TROUBLESHOOTING PROBLEM PROBABLE CAUSE REMEDY Drill rotates but won’t hammer Leaky oil hose Replace Broken hammer Replace complete cylinder and hammer assembly Lines are backwards Check supply and return lines Hose to drill collapsed or kinked Check and replace hose J.

- Page 20 TE260 TROUBLESHOOTING PROBLEM PROBABLE CAUSE REMEDY K. Rapid chuck driver bushing Worn and scored shank Replace wear Improper feed pressure Adjust Insufficient lubrication Grease chuck end more frequently Contamination in chuck end of Clean parts; check front seal and drill grout swivel seals, replace L.

- Page 21 TE260 TROUBLESHOOTING PROBLEM PROBABLE CAUSE REMEDY Q. Supply and return hoses are Accumulators not charged Charge accumulator diaphragm; shaking or bouncing properly see chart on page 3-13 excessively Accumulator diaphragm is Change accumulator diaphragm ruptured (oil will leak from charging valve when checking pressure) R.

- Page 22 Common Causes of Failure Drill Steel Surface damage caused by hammering or careless use of drill steels Off-line drilling Fatigue from surface irregularity, Corrosion originating in bore, Caused by excessive heat and Accelerated by high stress conditions welding action between coupling and steel Button Bits Outer gage wear:...

- Page 23 Common Causes of Failure Striking Bars Chipped rod end; damaged coupling Off-line drilling Too much rotation when pulling rods out of hole Worn chuck; heavy rotation loads Worn chuck-driver bushing Sever overfeeding Fatigue from water seal recess Couplings Scalding/bluing Improper chamfering of drill steel Steels not seating together in coupling Operating machine with coupling Touching centralizer...

- Page 24 Section 3 Page 3-13...

- Page 25 Section 3 Page 3-14...

-

Page 26: Parts Book

PARTS BOOK Section 4 TE260 Drill TE260 Percussion TE260 Parts List 4-3 thru 4-4 Shank Listing TE2689X Mtg. Slide JB779X Nitrogen Charge Kit 4-7 BEFORE ATTEMPTING MAINTENANCE OR REPAIR OF ANY COMPONENTS OF THIS MA- CHINE, READ THE WARNINGS AND CAUTIONS LISTED IN SECTION 2... - Page 27 Section 4 Page 4-1...

- Page 28 Section 4 Page 4-2...

- Page 29 TEI ROCK DRILLS ENGINEERING, MONTROSE, CO. PHONE (970)249-1515 FAX (970)249-1999 TE260 Hydraulic Rock Drill ( * ) Items for Grout Swivel Option Bill of Material Listed by Part Number Qty. Part Number Description 2 1050094 VALVE HIGH PRESSURE 4 CF793D...

- Page 30 TE260 Parts Listing Cont’d 1 TE25275 CHUCK DRIVER 1 TE25281 PLATE, FRONT 2 TE25360 BUSHING, DOWEL 1 TE2639 HOUSING, GEAR 1 TE25428 GASKET, HIGH TEMP 2 TE25557 PLATE, COVER 2 TE25722B ADAPTER, SHAFT 1 TE261A CYLINDER, HAMMER 1 TE2615A VALVE BODY...

- Page 31 TE260 Shank Listing TE3549R1GS Grout Swivel Shank, 1.0 Rope 40mm TE3549R32GS Grout Swivel Shank, 1.25 Rope 40mm TE3549R38GS Grout Swivel Shank, 1.50 Rope 40mm TE3549T38GS Grout Swivel Shank, T-38 40mm TE354932GS Grout Swivel Shank, Williams 32 40mm TE354938GS Grout Swivel Shank, Williams 38...

- Page 32 Section 4 Page 4-6...

- Page 33 Section 4 Page 4-7...

- Page 34 ROCK DRILLS’ limited warranty does not cover other manufacturers equipment. If you have to make a claim within the terms of TEI ROCK DRILLS’ Limited warranty, you must write to your TEI ROCK DRILLS supplier within 15 (fifteen) days from the date of defect or fault. You are to give TEI ROCK DRILLS’...

- Page 35 DISCLAIMER TEI ROCK DRILLS does not accept responsibility for any misprints in this booklet. Prices or numbers may change without written notice to anyone. This manual is not intended to create a contract.

Need help?

Do you have a question about the TE260 and is the answer not in the manual?

Questions and answers