Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Atlas Xenotest Beta+FD

- Page 2 Copyright This operating manual is protected by copyright. These rights, especially reprinting, photomechanical or digital further processing or reproduction even in part are only allowed with the written permission of Atlas Material Test- ing Technology GmbH. This condition does not cover the reproduction for internal use.

-

Page 3: Table Of Contents

Operating Manual Xenotest Beta+ FD Contents Page 1 Instructions for Safe Operation ......................... 6 Explanation of Symbols ........................8 General Safety Instructions ........................9 2 Delivery of the Instrument ........................11 Packaging ............................11 Scope of Delivery ..........................11 3 Requirements for the Installation Site ..................... 12 Room Climate ............................ 12 Room Ventilation .......................... - Page 4 Operating Manual Xenotest Beta+ FD Contents Page 10 Maintenance .............................. 50 10.1 Preventive Maintenance ........................50 10.2 Repair ..............................50 10.3 Maintenance ............................51 10.4 Cleaning ............................. 52 11 Technical Data ............................53 12 Accessories .............................. 54 13 Wearing Parts ............................56 14 Declaration of Conformity ........................

- Page 5 Operating Manual Xenotest Beta+ FD List of Figures Fig. 1 Instrument dimensions and space requirements Fig. 2 View from the front and right Fig. 3 View from rear and left Fig. 4 View of test chamber with bottle carousel Fig. 5 View of test chamber with packaging carousel Fig.

-

Page 6: Instructions For Safe Operation

Please note that the instrument may only be operated by authorized and qualified personnel. Qualified personnel are persons who: • have gained knowledge of instrument operation through an Atlas authorized technical training, • have been instructed in the operation and function of the Xenotest Beta+ FD on the basis of this operating ®... - Page 7 • Unauthorized modifications or conversions to the instrument are not permitted for safety reasons. Warranty: Atlas MTT GmbH guarantees the safety and functional capability of the instrument only on condition that: • only original spare parts or accessories approved by Atlas MTT are used, •...

-

Page 8: Explanation Of Symbols

Operating Manual Xenotest Beta+ FD Instructions for Safe Operation 1.1 Explanation of Symbols WARNING Failure to observe this warning may lead to severe or even fatal injury! CAUTION Failure to observe this may lead to moderate to minor injury or material damage. NOTE! Gives tips for use and useful information. Warning about dangerous solutions Warning about hot surfaces Warning about electric shock Symbols on the Instrument: WARNING AGAINST A DANGEROUS PLACE! Caution! See the operating manual. HOT SURFACE! Warning against burns. CE conformity mark REFERENCE TO DISPOSAL DIRECTIVE (WEEE)! The disposal of this product must comply with the EC Directive 2002/96/EG with regard to the used electrical and electronic equipment (WEEE). - 8 -... -

Page 9: General Safety Instructions

Operating Manual Xenotest Beta+ FD Instructions for Safe Operation 1.2 General Safety Instructions Use for the intended purpose • The Xenotest Beta+ FD is used for irradiance and weathering of material samples. • The instrument is suitable for continuous operation. • The Xenotest Beta+ FD is tested for electromagnetic compatibility and suitable for installation in an indus- trial environment. - Page 10 In this event a separate power supply cable with an adequate cross-section must be installed from the domestic use to the device. For additional information please contact the technical service of Atlas. Disposal: ObSERVE THE REGULATIONS FOR DISPOSAL! The manufacturer’s obligations to take back the equipment in accordance with the respective...

-

Page 11: Delivery Of The Instrument

Operating Manual Xenotest Beta+ FD 2 Delivery of the Instrument 2.1 Packaging The Xenotest Beta+ FD is delivered in a stable packaging crate. All packaging materials can be separated and are recyclable. • Packaging crate of chipboard • Steel screw for plywood together the crate and the crate lid •... -

Page 12: Requirements For The Installation Site

Operating Manual Xenotest Beta+ FD Requirements for the Installation Site 3.1 Room Climate Climatic requirements for the operating room: In continuous operation there may be a constant change in the room climate due to the emission of warm air from the lamp cooling. Therefore, the instrument may only be installed in adequately cooled, dust-free operating rooms. •... -

Page 13: Space Requirements

Operating Manual Xenotest Beta+ FD Requirements for the Installation Site 3.4 Space Requirements The instrument may only be transported by experienced personnel who have suitable tools. Position the instrument on a sufficiently stable, non-flammable floor and align horizontally. • Instrument weight: approx. 400 kg NOTE – ceiling load capacity If several instruments are installed in one place, the static load capacity of the installation site must be ensured. An access area of at least 1 m is needed around the machine to allow for operation, maintenance, and repair work (see Fig. 1): •... -

Page 14: Instrument Dimensions And Space Requirements

Operating Manual Xenotest Beta+ FD Requirements for the Installation Site 3.5 Instrument Dimensions and Space Requirements Fig. 1 A Front view B Side view C View from above D Space requirements service area All data in mm units - 14 -... -

Page 15: Description Of The Instrument

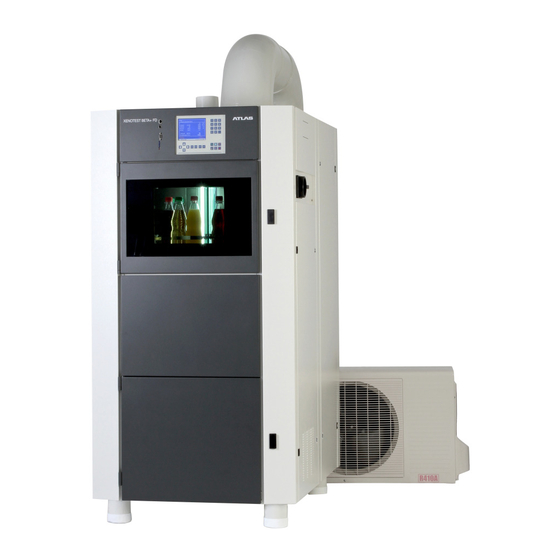

Operating Manual Xenotest Beta+ FD Description of the Instrument 4.1 View from the Front and Right Fig. 2 Fig. 2: View from the front: View from the right: Side door electrical supply unit Communication connections Operating panel with touch screen Side door electrical supply unit/heating system Test chamber with window Exhaust air nozzle circulating air channel Test chamber with sample rack carousel Master switch for turning the instrument on/off Door catch test chamber Radiation unit with filter system... -

Page 16: View From Rear And Left

Operating Manual Xenotest Beta+ FD Description of the Instrument 4.2 View from Rear and Left Fig. 3 View from rear, fig. 3: 1 Air inlet of the chilled chamber air 5 Side door electrical supply unit 2 Instrument rear panel 6 Air supply circulating air system 3 Incoming power supply cable to the instrument 7 Evaporator unit 4 Side door electrical supply unit/humidity system - 16 -... -

Page 17: View Of Test Chamber

Operating Manual Xenotest Beta+ FD Description of the Instrument 4.3 View of Test Chamber Fig. 4 View of test chamber with bottle rack, fig. 4 XENOSENSIV sensor for measuring the irradi- Sample rack holder of the sample rack ance and black standard temperature Door seal Filter system for generating specific light and xenon lamps for radiating material samples - 17 -... - Page 18 Operating Manual Xenotest Beta+ FD Description of the Instrument Fig. 5 View of test chamber with packaging carousel, fig. 5 XENOSENSIV sensor for checking irradiance and Sample rack holder of the sample racks Door seal Filter insert for generating specific light and xenon lamps for radiating material samples - 18 -...

-

Page 19: View Of Control Panel

Operating Manual Xenotest Beta+ FD Description of the Instrument 4.4 View of Control Panel Fig. 6 Control panel with touch screen, fig. 6: Display for showing the menu dialogs, status dis- Menu keys for activating the program modules Numeric block for entering the program parameters plays and program parameters Arrow keys for navigation in the menus and test values Function keys for activating the basic functions: • ENTER: Confirmation of the input values... -

Page 20: Functional Description

Operating Manual Xenotest Beta+ FD Functional Description 5.1 Program Control Fig. 7 Fig. 7: The Xenotest Beta+ FD is switched on with the main switch 2 and then operated by the program control 1 of the touch screen. The microprocessor-supported program control enables the initialization of user-specific tests. The parameter values required for the test are entered with the numeric block on the keyboard and initialized by the various function keys. -

Page 21: Filter Systems

Operating Manual Xenotest Beta+ FD Functional Description 5.2 Filter Systems 5.2.1 Overview of the Filter Systems Tab. 1 Filter system Filter assembly Outer cylinder „XENOCHROME 300, 11 pieces Daylight Special UV glass (identification II or 30) „XENOCHROME 320, 11 pieces Daylight behind window glass Special UV glass (identification III or 32) „XENOCHROME 300, 11 pieces StoreLight StoreLight... - Page 22 Operating Manual Xenotest Beta+ FD Functional description 5.2.2 Representation of the beam Path Fig. 8: The xenon lamps 3 radiate evenly in all directions. The parts of the UV and light radiation which hit the coated filters 2 pass the outer cylinder and radiate the samples 4. The IR radiation parts are partially reflected, passed to the black absorbers 1 , absorbed by these and fed out by the cooling air stream.

- Page 23 Operating Manual Xenotest Beta+ FD Functional Description Fig. 9 5.2.3 XENOCHROME Filter System Fig. 9: The filter systems consist of: • A filter assembly 2 with 3 absorbers offset at 120° 1, • the XENOCHROME filter discs 3 with specific filter properties: • XENOCHROME 300 (II) and •...

- Page 24 Operating Manual Xenotest Beta+ FD Functional Description 5.2.4 Spectral Power Distribution Fig. 10: The diagram represents the spectral power distribution in the wavelength range of 250 – 800 nm of the XENOCHROME filter system 300 with outer cylinder. The data of the table 1, page 24 corresponds to the CIE No.

- Page 25 Operating Manual Xenotest Beta+ FD Functional Description Fig. 11 Fig. 12 - 25 -...

- Page 26 Operating Manual Xenotest Beta+ FD Functional Description Application: The XENOCHROME filter systems can be used for the following tests: Outdoor daylight and daylight behind window glass (indoor). The relative spectral distribution of the XENO- CHROME filter system can be found in the tables Tab. 2 + Tab. 3. Tab. 2 XENOTEST Beta+ filter: XENOCHROME 300 RSP*...

-

Page 27: Ventilation System

Operating Manual Xenotest Beta+ FD Functional Description 5.3 Ventilation System Fig. 13: The Xenotest Beta+ FD is air-cooled. The cooling system is fed by two different air streams: • Lamp cooling 1 and • Test chamber cooling 2. Lamp cooling: A fan 3 pulls in the cooling air 1 for lamp cooling at the air vents 4 on the right hand side of the instrument. The air current flows along the module shaft and cool the electronic components first. -

Page 28: Measuring And Control Sensors

Operating Manual Xenotest Beta+ FD Functional Description 5.4 Measuring and Control Sensors A combined test chamber temperature and humidity sensor is built into the Xenotest Beta+ FD test chamber. The test chamber temperature and the relative humidity can be controlled with this sensor. The XENOSENSIV sensor 1 can be installed optionally. This sensor measures the BST at sample level (in the temperature range 20°... -

Page 29: Calibration Sensors

Operating Manual Xenotest Beta+ FD Functional Description Fig. 14 (page 28): XENOSENSIV sensor: The optionally installable system enables: • Display of the measured irradiance • Constant control of the irradiance • Display of the BST • Constant control of the BST NOTE – operation without sensor: If the Xenotest Beta+ FD is operated without the XENOSENSIV sensor, the lamp power is controlled constantly according to a default value (see sect. -

Page 30: Start Up

Operating Manual Xenotest Beta+ FD Start Up 6.1 First Start Up NOTE - first start up: The instrument may only be started for the first time by the Atlas technical service or authorized service repre- sentative. All the functioning components of the instrument are checked during first-time startup. 6.2 Checking the Instrument Components WARNING – electric shock! -

Page 31: Installing / Removing The Xenon Lamp

Operating Manual Xenotest Beta+ FD Start up 6.3 Installing / Removing the Xenon Lamp Fig. 15 WARNING – electric shock! Touching live parts can lead to life threaten- ing electric shocks. The instrument’s lamp ignition is under high voltage. Disconnect the instrument from the electrical power before installing/removing the xenon lamps! • Turn the instrument off at the ON/OFF switch. • Pull the electrical plug out of the receptacle and secure against reconnecting. • Check whether the instrument is voltage free. CAUTION – danger of burns! The components of the lamp unit get very hot and can cause burns when they come into contact with the skin. Let the components of the lamp unit cool down sufficiently before changing the xenon lamp! NOTE – handling the xenon lamp: Residue from finger marks can burn into the glass tubes of the xenon lamp and cause uneven light radiation. •... - Page 32 Operating Manual Xenotest Beta+ FD Start Up Installing the xenon lamp: Fig. 16 1. Fig. 16: Push the xenon lamps 7 through the flange tube 6 , place in the lamp socket and press in care- fully. 2. Set the lamp centering 8 between the xenon lamps. 3.

-

Page 33: Changing The Filter System

Operating Manual Xenotest Beta+ FD Start Up 6.4 Changing the Filter System Fig. 17 XENOCHROME filter system: The XENOCHROME filter system (300/320) consists of eleven filter glasses. The XENOCHROME filter assembly is required to accommodate the filters. Equipping the filter assembly: 1. Fig. 17: Clean the filters 1 with a soft cloth and commercially available alcohol or white spirit. -

Page 34: Loading The Sample Rack

Fig. 19 6.5 Loading the Sample Rack The sample holders are not included with the instrument. They can be ordered from the Atlas spare parts service. NOTE – loading the sample rack: All 16 sample holders must always be inserted into the sample rack to guarantee reproducible test conditions. - Page 35 Operating Manual Xenotest Beta+ FD Start Up Special sample holder with three sample positions: Fig. 21 To further differentiate test series with larger amounts of samples, special sample holder with divided viewing win- dows can be used which allow three samples to be placed in one sample rack. 1.

- Page 36 Operating Manual Xenotest Beta+ FD Start Up 1. Loading the sample rack with bottles: Fig. 23 The sample rack ‘D’ serves for exposure/photostability testing of drinks and bottles. Two different sample holders are available: a) For bottles up to maximum 0.75l b) For bottles from 0.75l to maximum 1.5l The sample holders can be mounted in sample rack ‘D’...

-

Page 37: Installation Of The Xenosensiv Sensor / Standard Sample Carousel

Operating Manual Xenotest Beta+ FD Start up Fig. 26 Fig. 26: A separate sample rack is available for plastic tin packagings 1 into which the packaging tins can be placed in from above. The underside of the packaging faces towards the lamp. Fig. 27 6.6 Installation of the XENOSENSIV Sensor / Standard Sample Carousel CAUTION – danger of burns! -

Page 38: Connecting The Lamp Cooling To The Exhaust Air System

Operating Manual Xenotest Beta+ FD Start Up Fig. 28 6.7 Connecting the Lamp Cooling to the Exhaust Air System NOTE – exhaust air lamp cooling The lamp cooling of the Xenotest Beta+ FD must be con- nected to an exhaust air system. The instrument exhaust air system can overheat if the maximum length of the exhaust air channel and the maximum permissible number of two 90°... -

Page 39: Setting Up The Interface

Operating Manual Xenotest Beta+ FD Start up 6.8 Setting up the Interface Fig. 29 Fig. 29: The instrument is equipped with four interfaces for exchanging data with external systems. Network connection 1: The test instrument can be integrated into a TCP-IP Eth- ernet network (see software documentation). Serial interface 2: The RS232 interface enables measured data to be output during an ongoing test program on a computer. -

Page 40: Operation

Operating Manual Xenotest Beta+ FD Operation 7.1 Menu Structure of the Instrument Fig. 31 Control An overview of the menu structure for the program mod- ules and the corresponding submenus can be found in the software documentation. 7.2 Operating the Touch Screen Function units: Fig. 31: The instrument control is operated with a touch screen: 2 Function keys for activating the basic functions and arrow keys 1 for navigation in the menus,... -

Page 41: 7.3 Switching On The Instrument

Operating Manual Xenotest Beta+ FD Operation basic functions: Fig. 32 Fig. 32: Function keys 2 for controlling the basic func- tions: Confirm entry Cancel action or return to previous menu Start program run Interrupt program run The arrow keys 1 serve to mark an entry in a dropdown menu: Move the cursor up Move the cursor down... -

Page 42: Starting The Test Program

1. The test input dialog window is shown in the display 1 after switching the instrument on. 2. Define configuration type 5 of the test. Select user- created or Atlas pre-programmed tests (customer test / standards). 3. Select test program 4: •... -

Page 43: Adjusting The Xenosensiv Sensor

Operating Manual Xenotest Beta+ FD Operation 7.5 Adjusting the XENOSENSIV Sensor In order to obtain reproducible test conditions, the XENOSENSIV sensor can be calibrated and adjusted using the instrument-independent sensors: • The XENOCAL BB 300-400 sensor (ID no. 55007863) is used for calibrating the irradiance in the wave- length range from 300 to 400 nm, •... - Page 44 8. Enter the irradiance value read out with the XenoCal sensor in the input box. The old adjustment factor and the newly calculated adjustment factor are then shown in the display. If the new factor is outside the range (below 0.8 or above 1.2) the XENOSENSIV should be sent to Atlas for recalibration.

-

Page 45: Regulation Without Sensors

8. Enter the black standard temperature value, read out from the XenoCal BST sensor in the input box. The old adjustment factor and the newly calculated adjustment factor are then shown in the display. If the new factor is outside the range (below 0.8 or above 1.2) the XENOSENSIV should be sent to Atlas for recalibration. -

Page 46: Temperature Fields

Operating Manual Xenotest Beta+ FD Operation 7.7 Temperature Fields The black standard temperature (BST) and the test chamber temperature (CHT) or the difference of both is very important for material testing: DT = bST-CHT The two diagrams show the temperature field DT depending on the irradiance for the different filter systems. The BST is regulated depending on the irradiance, test chamber temperature and selected filter system by the value of the fan speed. -

Page 47: Note On Implementation

Operating Manual Xenotest Beta+ FD Operation 7.8 Note on Implementation When working in accordance with quality management principles, test validation of the integration (implementa- tion) of the instrument into existing processes usually takes place first. NOTE - validation (see also ISO 4892-1) User validation tests with typical test materials for the selected test method are recommended. - 47 -... -

Page 48: Shut Down

Operating Manual Xenotest Beta+ FD Shut down 8.1 Switching Off the Instrument Fig. 36 The instrument can be switched off at the end of or inter- ruption of a test program. Switch off at the end of the test program: • Set the main switch to position “0” after the cool down time. Interrupt the test program, switch off the instrument: 1. -

Page 49: Troubleshooting

Operating Manual Xenotest Beta+ FD Troubleshooting 9.1 Error Message and Remedial Measures A detailed list of the error messages and remedial measures can be found in the software documentation for the Xenotest Beta+ FD. - 49 -... -

Page 50: Maintenance

Only original spare parts may be used to install or change instrument components. Atlas will accept no liability for instrument components or parts from third-party manufacturers. NOTE – service documents Atlas can provide a full list of spare parts and other repair documents to qualified technical personnel on de- mand. - 50 -... -

Page 51: Maintenance

Operating Manual Xenotest Beta+ FD Maintenance 10.3 Maintenance Fig. 37 WARNING – electric shock! Touching live parts can lead to life threatening electric shocks. Disconnect the instrument from the power supply before maintenance work! • Turn off the instrument at the main switch. • Pull the electrical plug out of the socket and secure against reconnecting. • Check whether the instrument is voltage free. Fig. 37: Removing and installing the lamp cooling air filter: 1. Open the right instrument door 1 and turn the closing screws with a screwdriver. 2. Pull the filter 2 up out of the holder. 3. -

Page 52: 10.4 Cleaning

Operating Manual Xenotest Beta+ FD Maintenance 10.4 Cleaning Cleaning the filters and glass parts: The special UV glass outer cylinder should be cleaned with a suitable laboratory glass cleaner and then rinsed with water. Wipe off the XENOCHROME filter set with a cloth moist- ened with a suitable laboratory glass cleaner. NOTE – handling the filter Residue from touching with fingers can burn into the filter plates and cause uneven irradiance. -

Page 53: Technical Data

Operating Manual Xenotest Beta+ FD Technical Data Interfaces: Incoming power: USB (only available with later software version) Incoming power connection: Ethernet (3P/N/PE) AC, CEE (32A, 5-pole, 6h) RS 232 Nominal voltage/frequency: 400 V ±10 %, 50/60 Hz Memory chip Nominal current: Nominal power: max. -

Page 54: Accessories

Operating Manual Xenotest Beta+ FD Accessories Accessory Xenotest beta+ FD Tab. 4 Order no. Designation Quantity Sample holder „Standard“ sample holder set 56076543 For samples up to 10 mm thick, size: 310 x 80 mm „Standard“ mask set 56076544 16 each with opening width 9, 18 and 27 mm „Special“... - Page 55 Operating Manual Xenotest Beta+ FD Accessories Accessory Xenotest beta+ FD Tab. 5 Order no. Designation Quantity Combi-sensor XenoCa BB 300-400 BST ® Calibrated broadband sensor for data retrieval, calibration and adjust- ment (via IBM-compatible PC) of irradiance (W/m²) and radiant expo- sure (kJ/m²) in the wavelength range of 300 – 400 nm (UV), combined with calibrated black standard sensor for data retrieval, calibration and adjustment of the black standard temperature (°C);...

-

Page 56: Wearing Parts

Operating Manual Xenotest Beta+ FD Wearing Parts Wearing parts Tab. 6 Order no. Designation Quantity Life (h) 56050886 Sealing ring 56050908 Ignition diode 56052340 Gasket 56055232 Battery CR 2032 3 (years) 56052871 Outer cylinder special UV glass 15 000 56052878 Filter glass, Xenochrome 300 25 000 56052879 Filter glass, Xenochrome 320 25 000... -

Page 57: Declaration Of Conformity

Operating Manual Xenotest Beta+ FD - 57 -... - Page 58 Operating Manual Xenotest Beta+ FD Notes Notes - 58 -...

- Page 59 Operating Manual Xenotest Beta+ FD Notes Notes - 59 -...

- Page 60 Atlas Material Testing Technology GmbH An AMETEK Company Vogelsbergstr. 22 63589 Linsengericht / Germany Phone: + 49 (0)6051 707-140 Fax: + 49 (0)6051 707-149 E-mail: info@atlasmtt.de www.atlas-mts.com ID-No.: 56352558 Edition: 11/11...

Need help?

Do you have a question about the Xenotest Beta+FD and is the answer not in the manual?

Questions and answers