Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Bioprom AIR PELLET 60 kW

- Page 1 AIR PELLET 60 kW FLARE PELLET BURNER Operation Manual СВ.060.00.00СК...

-

Page 2: Table Of Contents

Contents 1. BURNER DESCRIPTION AND OPERATION ................. 4 1.1. Purpose ........................... 4 1.2. Performance Data ........................5 1.3. Delivery Set..........................6 1.3.1. Screw Feeder ......................... 6 1.4. Operation Concept and Configuration ..................7 1.4.1. Burner Components ....................... 7 1.4.2. Operation Concept ......................9 1.4.3. - Page 3 Operation Manual. Individuals authorized to operate and take care of "AIR PELLET 60 kW" burner shall follow this Operation Manual. Due to continuous enhancement of the structure (construction) of Air Pellet flare...

-

Page 4: Burner Description And Operation

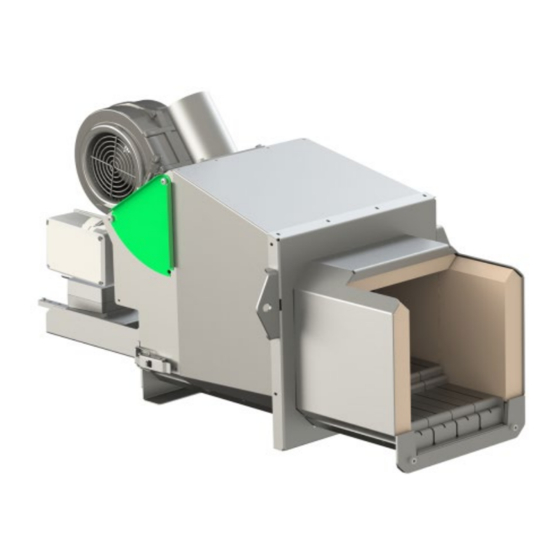

1. BURNER DESCRIPTION AND OPERATION 1.1. Purpose Burners of «AIR PELLET 60 KW» type (Picture 1) are intended for burning wood fuel pellets in water-heating boilers with a nominal heat output of up to 60 kW. Picture 1. Overall and mounting dimensions of the burner... -

Page 5: Performance Data

The design of the boiler on which the burner is installed shall meet the following requirements: – the boiler shall be adapted for burning biomass, and its internal flow channels shall have full capability to exchange heat and exhaust emissions; –... -

Page 6: Delivery Set

1.3. Delivery Set The standard delivery set for the burner is described in Table 2 Table 2. Burner as an assembly 1 ea. 1 set Burner control unit with sensor set and connecting wires Flexible heatproof tube for connecting feeder to the burner 2 ea. -

Page 7: Operation Concept And Configuration

Picture 3 – Screw feeder installation example CAUTION! Hose for hooking up the screw feeder and the burner shall correspond with UL 94-HB fire-resistance. 1.4. Operation Concept and Configuration 1.4.1. Burner Components The burner includes the following components: – burner housing; –... - Page 8 Picture 4 – Burner Design 1 – screw feeder driving gears; 2 – air supply fan; 3 – hole for pellets supply from the bunker; 4 – flange for attaching the burner; 5 – housing for mounting electrical part; 6 – driving gear system of movable grate bars;...

-

Page 9: Operation Concept

1.4.2. Operation Concept The fuel located in the bunker is supplied by screw feeders to the burner and further to the grate system, where it ignites as a result of contact with the elements of the ignition system. The air pumped by the fans goes further through the ejector openings of the grate directly to the supplied fuel, as a result of which a flame rises and is directed horizontally to the combustion chamber of the boiler. -

Page 10: Installation

The technical documentation of the burner is always inside the box, and a bill of lading is on the outer side. Products should be transported only in the original packaging, thus eliminating the possibility to damage the units. 2. INSTALLATION The burner is mounted in such a way to have the furnace in the combustion chamber and the burner is fastened with bolts using mounting holes located on the burner (Picture 6). -

Page 11: Preparation Of The Unit For Putting Into Operation

3.2. Preparation of the Unit for Putting into Operation Prior to the first commissioning of the burner it is required to: – verify proper installation and fastening of: the boiler, fuel tank, screw feeder and the burner; – check measuring devices for accurate installation; –... -

Page 12: Technical Maintenance

4.2. Safety Measures Basic principles and recommendations to follow while operating the boiler with the burner «AIR PELLET 60 KW»: – Individuals who got familiar with the Operation Manuals for the boiler, the burner, and the controller as well as with all possible threats can be allowed to operate this system. -

Page 13: Burner Maintenance Procedure

feeder). – The electrical system of the whole complex of the boiler with the screw feeder and the burner shall have an effective protection system ("grounding / zero"). Sockets of all used electrical connections must have a "zero" contact. – It is prohibited to store flammable and explosive materials and liquids in the immediate vicinity from the operating burner. -

Page 14: Periodic Technical Maintenance

– current elimination of minor operational problems on all the installed units (for instance, replacement of a safety fuse in the controller, cleanup of the screw feeder, fixing of a seal "burner – boiler", cleaning of the holes forcing the air into the burner); –... -

Page 15: Functionality Test

4.5. Functionality Test Burner functionality is checked with the help of the following sequence of actions: – visual review in order to make sure there are no any mechanical defects, impurities, then check fasteners and connecting wires for reliability; CAUTION! If required, replace damaged parts or send for repair, remove dust, impurities, screw attaching bolts as well as connecting ports. -

Page 16: Safety Measures

5.2. Safety Measures When carrying out repairs follow safety precautions described in Item 4.2 of this Manual, safety rules, as well as requirements to repair of boilers that also include requirements for the burner repair. 5.3. Potential Failures and Troubleshooting Practice Table 3 includes simple failures the user faces very often and the user is allowed to fix such failures by his own efforts. -

Page 17: Transportation And Storage

7. DISPOSAL Burners of «AIR PELLET 60 KW» type are safe for the environment and follow all the requirements of norms associated with cleanliness of exhaust as well as exhaust emission to the atmosphere. -

Page 18: Warranty

8. WARRANTY The item of warranty in this context is the pellet burner of «AIR PELLET 60 KW» type. The manufacturer guarantees failure-free operation of the burner for the period of 12 months starting from the date of the first startup (putting into operation), but not longer than 24 months from the date of manufacture and on conditions that the unit is operated properly and undergoes technical maintenance in a timely manner. -

Page 19: Warranty Ticket

For all issues relating to warranty and post-warranty service, please feel free to contact us at the address of: 126/1, Plekhanovskaya Str., Kharkov city, 61037, Ukraine. Telephone of Service Center: + 38 (095)654-67-19; + 38 (098)232-52-15. http://bioprom.ua/ Е-mail – no12service@bioprom.com.ua. - Page 20 Record on warranty repair Defect description: ______________________________________________________ Reason for failure: _______________________________________________________ ______________________________________________________________________ Repair work performed: ___________________________________________________ ______________________________________________________________________ Name of repair company: _________________________________________________ License # ____________ Expert ________________ Repair date _________________ stamp Record on warranty repair Defect description: ______________________________________________________ Reason for failure: _______________________________________________________ ______________________________________________________________________ Repair work performed: ___________________________________________________ ______________________________________________________________________...

-

Page 21: Ticket Of Putting Into Operation

TICKET OF PUTTING INTO OPERATION Burner Model ID # Date of Purchase Date of Installation User Details (Name, tel., e-mail) Detailed info of the company that performed installation... - Page 22 FOR NOTES...

- Page 23 FOR NOTES...

- Page 24 LTD «Bioprom Company Kharkov» 126/1, Plekhanovskaya Str. Kharkov Region Kharkov, Ukraine tel. +380 57 757-68-33 Email: info@bioprom.com.ua www.bioprom.ua www.bioprom.com.ua www.bioprom.kh.ua...

Need help?

Do you have a question about the AIR PELLET 60 kW and is the answer not in the manual?

Questions and answers