Summary of Contents for Kobelt KP12

- Page 1 KP12 & KP14 Hydraulic Thrusters Owner's Manual December 2021 Kobelt Manufacturing Co. Ltd.

- Page 2 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd NOTES RECORD DATA BEFORE INSTALLATION FOR FUTURE REFERENCE Model #: Serial #: Date of purchase: Date of installation: Motor brand and part #: Rev A MNL-KP12X-H-TH 1 of 46...

-

Page 3: Table Of Contents

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd ABLE OF ONTENTS Introduction ......................3 Contact........................3 Safety ........................3 Product Description ....................5 Overview ........................5 Model Code Key ....................... 6 Technical Data ......................6 Parts ......................... 7 Installation and Location Selection ................8 Tunnel Thruster Location Selection and Installation .......... -

Page 4: Introduction

Kobelt reserves the right, without notice, to change the design, or construction, of any products and to discontinue or limit distribution of any products. Kobelt also reserves the right to change, or update, without notice, any technical information contained within this document. - Page 5 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd 1.2.2 Notice to Installer Disregarding the following safety measures can result in an accident causing severe injury to personnel and damage to material assets. • Only use the product as directed in this manual.

-

Page 6: Product Description

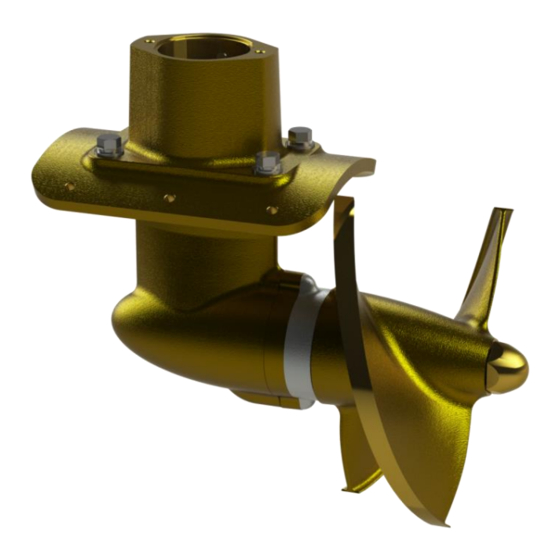

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd RODUCT ESCRIPTION VERVIEW The figure below shows a typical tunnel thruster with all of its major components identified. Thrusters are meant to assist in docking, station keeping and maneuvering in tight spaces and are usually installed to an athwartships tunnel that goes through the vessel’s hull (tunnel... -

Page 7: Model Code Key

ODEL ECHNICAL Your authorized Kobelt distributor typically will also sell you a hydraulic motor that is most compatible with your vessel’s existing hydraulic system. Given that there is no “standard” motor, pressure and flow requirements do not depend solely on the thruster model used and will vary from installation to installation. -

Page 8: Parts

• This manual Kobelt can supply fibreglass, steel and aluminum tubes for your thruster if needed. If supplying your own tube, be aware that the wall thickness must be correct for proper alignment of the thruster; you may be required to build up to the thruster saddle for thinner tubes. -

Page 9: Installation And Location Selection

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd NSTALLATION AND OCATION ELECTION This section has been prepared to assist the owner and the installer in understanding the installation of the thruster to the vessel. All work should be performed by a professional who is competent in marine mechanical installations. - Page 10 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Figure 2 – Thruster tunnel location parameters that affect performance Table 3 – Recommendations for thruster tunnel location. Dimension Recommendation Consequence if recommendation not met • • T ≥ D* Insufficient depth can cause air suction •...

- Page 11 Kobelt recommends consulting with a naval architect to design the protective grid as the optimum design will depend greatly on the shape and operating conditions of your vessel.

- Page 12 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd 3.1.3 Installation of Fibreglass Thruster Tubes This section has been prepared to assist the owner and installer in understanding the installation of fibreglass thruster tubes. All work should be done by a professional who is competent in marine mechanical installations.

- Page 13 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Figure 5 – Thruster tube fibreglassing example Rev A MNL-KP12X-H-TH 12 of 46...

- Page 14 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd 3.1.4 Installing the Thruster to the Tube This section has been prepared to assist the owner and installer in understanding the installation of the thruster to the tube. All work should be performed by a professional who is competent in marine mechanical installations.

- Page 15 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd At this point it is recommended to apply a marine barrier coat and antifouling paint to the thruster tunnel. The following sub-steps will guide you through that process: Obtain marine barrier epoxy and antifouling paint that is appropriate for the operating environment of the vessel.

-

Page 16: Transom Mounted Thruster Location And Installation

If you find it challenging to fit the standard tube offering to your vessel, please contact Kobelt Manufacturing and we will try to come up with a custom solution that will work for you. - Page 17 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd 3.2.2 Tube Preparation It is recommended to apply a marine barrier coat and antifouling paint to the tube before installing the thruster to the transom. The steps below will guide you through that process.

- Page 18 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Figure 7 – Backing plate for transom-mounted thrusters Figure 8 – Installation of transom-mounted thrusters to cored fibreglass hulls Rev A MNL-KP12X-H-TH 17 of 46...

- Page 19 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd 3.2.4 Installing the Thruster to the Transom This section has been prepared to assist the owner and installer in understanding the installation of transom-mounted thrusters. All work should be performed by a professional who is competent in marine mechanical installations.

-

Page 20: Lubricating Oil System

Figure 10 above should be replaced with a return line to the lube reservoir. Either of the remaining ports on the side of the saddle can be used to connect to the pressure source. Kobelt manufactures a pump (part number: KP426-B) specifically designed for this application that is available for purchase. Use SAE75W-90 synthetic gear oil. -

Page 21: Maintenance And Service

Please contact the nearest Kobelt authorized distributor for assistance. ECOMMENDED PARE ARTS As a minimum Kobelt recommends the following spare parts are on-hand: Table 4: Recommended Spares Description Quantity Part Number Repair kit... -

Page 22: Propeller Installation And Removal

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd ROPELLER NSTALLATION AND EMOVAL Remove the propeller by following the instructions in Figure 11 below. You will need a 1-3/4” wrench to remove the prop nut and a 3/16” hex key to loosen the set screw. -

Page 23: Transom Mount Thruster Tube Removal And Installation

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd RANSOM OUNT HRUSTER EMOVAL AND NSTALLATION The following steps describe how to remove the tube from the thruster assembly: Remove the propeller as described in section 4.3 on page 21. This step is applicable only if the thruster is already installed to the vessel. Remove the leg by removing the four hex bolts holding it to the saddle. - Page 24 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd To reinstall the tube: Replace the tube onto the saddle and loosely refasten in six places. The heads of the carriage should be on the inside of the tunnel (see Figure 12 below).

-

Page 25: Setting Coupling Distance

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd ETTING OUPLING ISTANCE The coupling connecting the motor output shaft and thruster input shaft are already set to the correct positions when you receive your thruster, however, if ever during the life of your thruster you must remove the coupling from either of the shafts you must reinstall the coupling correctly. -

Page 26: Oil Changes

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd HANGES Dispose of any old/excess oil in accordance with your local environmental regulations. 4.7.1 Header Tank Fill Method This step should be skipped for first-time thruster installation. Remove the bearing cap from the thruster (instructions are in section 4.6 on page 24) and allow the oil to drain. -

Page 27: Shaft Seal Replacement

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd HAFT EPLACEMENT Removing the shaft seal requires removing the bearing cap for which instructions can be found in section 4.6 on page 24. When replacing the shaft seals of the thruster you must orient them face-to-face and you must replace the spring on the outer shaft seal with a -022 O-ring (see Figure 15 below). -

Page 28: Hydraulics

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd YDRAULICS Observe the following precautions: • Wear safety goggles. • Exhaust all pressure prior to working on hydraulics. • Never run your hand along pressurized lines to look for a leak. - Page 29 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd After all residual pressure has left (gauge reads zero) start the second engine if applicable. After allowing a few minutes for the pressure to stabilize, confirm on the main system gauge that the pressure is within 25 psi (1/7 bar) of the reading found in step 7.

-

Page 30: Parts Lists

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd ARTS ISTS KP12 T UNNEL HRUSTERS Figure 16 – KP12 hydraulic tunnel thrusters’ parts list diagram Rev A MNL-KP12X-H-TH 29 of 46... - Page 31 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Table 5 – KP12 hydraulic tunnel thrusters’ parts list Quantities Notes Item Part Number Description (pg. 39) Motor 1, 6, 9 KP10-E-005-AN Propeller KP10-E-006 Propeller KP12A-LEG_ASSY Leg assembly 2, 3, 5, 9...

-

Page 32: Kp14 Tunnel Thrusters

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd KP14 T UNNEL HRUSTERS Figure 17 – KP14 hydraulic tunnel thrusters’ parts list diagram Rev A MNL-KP12X-H-TH 31 of 46... - Page 33 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Table 6 – KP14 hydraulic tunnel thrusters’ parts list Notes Item Part Number Description (pg. 39) Motor 1, 6, 9 KP10-F-007-AN Propeller KP10-F-008 Propeller KP14A-LEG_ASSY Leg assembly 2, 3, 5, 9...

-

Page 34: Kp12 Bolt-On Thrusters

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd KP12 B HRUSTERS Figure 18 – KP12 hydraulic bolt-on thrusters’ parts list diagram Rev A MNL-KP12X-H-TH 33 of 46... - Page 35 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Table 7 – KP12 hydraulic bolt-on thrusters’ parts list Notes Item Part Number Description (pg. 39) Motor 1, 6, 9 KP10-E-005-AN Propeller KP10-E-006 Propeller KP12A-LEG_ASSY Leg assembly 2, 3, 5, 9...

-

Page 36: Leg Subassembly

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd UBASSEMBLY Figure 19 – KP12 & KP14 leg subassemblies’ parts list diagram Rev A MNL-KP12X-H-TH 35 of 46... - Page 37 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Table 8 – KP12 & KP14 leg subassemblies’ parts lists Notes (page Item Part Number Description KP13-E-004 Pinion shaft KP13-E-005 Pinion shaft KP13-F-005 Pinion shaft KP13-S12-SUB Shaft sub. KP13-S14-SUB Shaft sub.

-

Page 38: Shaft Subassembly

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd HAFT UBASSEMBLY Figure 20 - Shaft subassembly parts list diagram Table 9 - Shaft subassembly parts list Notes Item Part # Description (p 39) KP14-G-004 Gear set KP14-G-005 Gear set KP13-G-007... -

Page 39: Accessories

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd CCESSORIES Figure 21 - Other KP thruster components Table 10 - Accessory parts Item Part # Description 1041-002030 Puller tool* KP-30114 Header tank KP-30117 Header tank mounting bracket KP-30123 Hose clamp *The puller tool is simply a 1-1/4”-7 UNC X 3”... -

Page 40: Parts Lists Notes

For the fasteners that mount the leg to the saddle, follow the instruction below that applies to your thruster: KP12 tunnel thrusters: Apply silicone sealant to the fasteners and torque them to 43 lbf·ft. KP12 bolt-on thrusters: Apply silicone sealant to the fasteners and torque them to 43 lbf·ft. - Page 41 20. Outer most shaft seal’s spring gets replaced by an O-ring (see section 4.8 on page 26 for detailed instructions). All are provided in the repair kit. 21. Part is included in repair kit that can be purchased from your authorized Kobelt distributor. Repair kit part number is KP12X-RK.

-

Page 42: Technical Drawings

KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd ECHNICAL RAWINGS UNNEL HRUSTERS Figure 22 – KP12 & KP12 HD tunnel thruster dimensions Rev A MNL-KP12X-H-TH 41 of 46... - Page 43 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Figure 23 – KP14 tunnel thruster dimensions Rev A MNL-KP12X-H-TH 42 of 46...

-

Page 44: Transom-Mounted Hydraulic Thrusters

Figure 24 - Transom mounted KP12 & KP12 HD thruster dimensions* *Note: Figure depicts standard tube offering. If it is incompatible with your vessel, please contact Kobelt Manufacturing and we can try to come up with a custom solution for you. Rev A... -

Page 45: Warranty

If any part is found to be defective, Kobelt will replace said part FOB the Kobelt factory provided that any such defective part is returned by the Buyer with freight and applicable forwarding charges prepaid by the Buyer. - Page 46 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Page Intentionally Left Blank Rev A MNL-KP12X-H-TH 45 of 46...

- Page 47 KP12 & KP14 Hydraulic Thrusters Kobelt Manufacturing Co. Ltd Page Intentionally Left Blank Rev A MNL-KP12X-H-TH 46 of 46 Heiko Digitally signed by Heiko Epkens Epkens Date: 2021.12.22 10:23:58 -08'00'...

- Page 48 Kobelt Manufacturing Co. Ltd. 8238 129th Street Surrey, British Columbia, Canada, V3W 0A6 Sales Tel: +1-604-572-3935 Fax: +1-604-590-8313 Email: sales@kobelt.com Website: www.kobelt.com Made in Canada / Printed in Canada...

Need help?

Do you have a question about the KP12 and is the answer not in the manual?

Questions and answers