Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Vertical Express I-2

- Page 1 I-2 / I-3 Valve ® ®...

- Page 2 The material contained herein is subject to revision. Please report any problems with this manual to Vertical Express, P.O. Box 2019, Memphis, Tennessee 38101. Vertical Express • P.O. Box 2019 • Memphis, Tennessee 38101 ©...

-

Page 3: Table Of Contents

I-2 / I-3 Valve Contents Contents Safety Precautions ............3 Terms in This Manual. - Page 4 Contents I-2 / I-3 Valve This page intentionally left blank. ©Vertical Express...

-

Page 5: Safety Precautions

I-2 / I-3 Valve Contents Safety Precautions Read this page before any work is performed on elevator equipment. The pro- cedures contained in this manual are intended for the use of qualified elevator personnel. In the interest of your personal safety and the safety of others, do not attempt any procedure that you are not qualified to perform. -

Page 6: Mechanical Safety

Asbestos Compliance Vertical Express elevator personnel will no longer drill or modify any doors with asbestos containing materials (ACM) or possible asbestos containing materials (PACM). All elevator doors manufactured or installed 1980 and earlier will be treated as having ACM/PACM. -

Page 7: Static Protection Guidelines

I-2 / I-3 Valve Contents Static Protection Guidelines Read this page before working with electronic circuit boards. Elevator control systems use a number of electronic cards to control various functions of the elevator. These cards have components that are extremely sensitive to static electricity and are susceptible to damage by static discharge. - Page 8 Contents I-2 / I-3 Valve This page intentionally left blank. ©Vertical Express...

-

Page 9: Preliminary Settings

Changes in oil temperature cause changes in valve behavior. Relief Pressure Setting The I-2/I-3 Valve requires a minimum static system pressure of 90 PSI. 1. Ensure that the car is empty. 2. Turn OFF, Lockout, and Tagout the mainline disconnect. -

Page 10: Low Pressure Setting

Preliminary Settings I-2 / I-3 Valve Preliminary Settings (continued) Low Pressure Setting OUT = Counterclockwise (CCW), IN = Clockwise (CW) 1. Turn the low pressure adjustment screw OUT 1 " beyond the cover plate. See Figure 2. 2. Turn the low pressure adjustment screw IN by hand until it touches the regulator piston. -

Page 11: Lowering And Leveling Speed Setting

I-2 / I-3 Valve Preliminary Settings Lowering and Leveling Speed Setting To prevent damage to the piston face and seat, do not adjust the lowering and leveling screw unless the car is resting on the buffers or the car is in motion. -

Page 12: Preliminary Adjustments

Preliminary Adjustments I-2 / I-3 Valve Preliminary Adjustments When operating the elevator from the controller, follow all safety precautions. 1. Ensure that the car is empty and the manual lowering valve is closed. 2. Turn OFF, Lockout, and Tagout the mainline disconnect. -

Page 13: Relief Pressure Adjustment

I-2 / I-3 Valve Preliminary Adjustments Relief Pressure Adjustment Stop the power unit immediately if the pressure exceeds 625 PSI. 1. Close the line shut-off valve, and install a pressure gauge. 2. Place the controller on Inspection Operation. 3. Turn the power ON, start the motor, and read the pressure. -

Page 14: Up And Down Inspection Speed Adjustment

Preliminary Adjustments I-2 / I-3 Valve Up and Down Inspection Speed Adjustment 1. Turn the up slowdown adjustment screw OUT 10 turns to ensure that the car does not initially start up. See Figure 5. 2. Place the car on Inspection Operation, and start the car up. -

Page 15: Final Adjustments

The manufacturing presets of the valve adjustments are attached to the inside of the con- troller. These values ensure movement of the car and reduce final adjustment time. Adjustment of the I-2/I-3 Valve requires a minimum static system pressure of 90 PSI. -

Page 16: Valve-Down Section

Final Adjustments I-2 / I-3 Valve Valve-Up Section (continued) Up Stop and Up Start The up stop adjustment must be adjusted first because it affects the up start adjustment. 1. Adjust the up stop for a soft but positive stop. - Page 17 I-2 / I-3 Valve Final Adjustments Valve-Up Section (continued) Down Leveling Speed and Down Stop The down leveling speed and the down stop adjustment must be performed together since the down stop adjustment affects the down leveling speed. However, the down leveling speed does not affect the down stop adjustment.

-

Page 18: Performance Check With Full Load

Final Adjustments I-2 / I-3 Valve Valve-Up Section (continued) Down Slowdown The effect of the down slowdown adjustment is the opposite of the previous adjustments. Turning OUT on the down slowdown adjustment shortens the leveling zone. Turning IN on the down slowdown adjustment lengthens the leveling zone. Make this adjustment in small increments as soon as a change is observed in the leveling zone. -

Page 19: Final Relief Pressure With Full Load

I-2 / I-3 Valve Final Adjustments Final Relief Pressure with Full Load Stop the power unit immediately if the pressure exceeds 625 PSI. 1. Place the controller on Inspection Operation, and close the line shut-off valve. 2. Start the pump, and read the relief pressure. -

Page 20: Valve Tests

Valve Tests I-2 / I-3 Valve Valve Tests Relief Pressure Verification This test ensures that the pipe couplings and valve cannot be damaged if the elevator sys- tem’s oil flow or platform become restricted. Stop the power unit immediately if the pressure exceeds 625 PSI. -

Page 21: Low Pressure Adjustment

I-2 / I-3 Valve Valve Tests Low Pressure Adjustment When operating the elevator from the controller, follow all safety precautions. If the CPU Card is online when the low pressure adjustment is made, temporarily set the Z44 timer to 10 seconds, and run the motor less than 10 seconds at a time from Inspec- tion Operation. -

Page 22: Troubleshooting

Troubleshooting I-2 / I-3 Valve Troubleshooting Verify the following list before using the troubleshooting tables. See also: Troubleshooting Flowcharts on page 23. • No binding is present in the hoistway. • The proper voltage is supplied to the power unit. -

Page 23: Troubleshooting Table - Down Operation

I-2 / I-3 Valve Troubleshooting Troubleshooting Table - Down Operation Problem Solution 1. Check that the line shut-off valve is fully open. 2. Check the solenoids.* The car will not lower. 3. Turn OUT on the down start adjustment. 4. Turn IN on the down stop adjustment. -

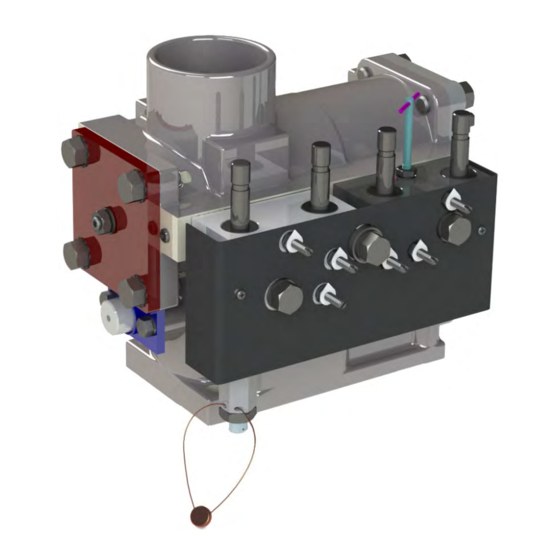

Page 24: Replacement Parts

ITEM PRINT NO. DESCRIPTION 114874 Valve Main Body Assembly, I-3, Down 148323 Valve Main Body Assembly, I-2, 125 GPM EP Units 137744 Valve Main Body Assembly, I-2, 120-215 GPM Units 137743 Valve Main Body Assembly, I-2, 30-100 GPM Units 189131... -

Page 25: Reference Material

I-2 / I-3 Valve Reference Material Reference Material The material included in this section was obtained from the previous publication. The Technical Publications Depart- ment does not update or maintain this information. Troubleshooting Flowcharts Start Is this a new job? - Page 26 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Will the car run in both directions? Turn over to construction crew. Adjust only thru initial adjustments. Turn over to construction crew. Flowchart 2 ©Vertical Express...

- Page 27 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Up Operation Down Operation Problem Direction Does the car settle (leak) down? Flowchart 18 Run car to lowest position. Flowchart 5 Is the oil level in the tank less than originally...

- Page 28 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Record amount car has settled (Y). After 15 minutes, record car Close down start record car location. location. Record amount car has settled (Z). Is Y more than 25 times X?

- Page 29 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Set up a down call Does the car lower at contract speed? Does the car lower at all? Flowchart 12 Does the car lower at less than contract speed? Is the line valve open? Flowchart 9 Adjust lowering speed.

- Page 30 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Does the car operate Verify proper performance. Does the car lower at all? Flowchart 7 Flowchart 5 Flowchart 6 ©Vertical Express...

- Page 31 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Turn off power. Close manual lowering valve. Record the number of turns that the start and stop adjustments are open. Was start open wider than stop? Are flats on leveling Put stop at original setting.

- Page 32 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Is stop more than two turns open? Turn stop to two turns open. Does car lower? Adjust to proper operation. Is start more than four turns open? Open start wider. Replace pilot body.

- Page 33 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Does car lower at leveling Open down start one turn. speed? Is the down fast solenoid energized? Does car Does car run faster than lower at less than leveling speed? leveling speed?

- Page 34 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Does the car lower at more than leveling speed? Run the car down on inspection. Replace valve. Is down stop abrupt? Adjust job. Turn out on down stop and Turn in on down stop.

- Page 35 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Is lowering speed OK? Is down start OK? Replace valve. Adjust job. Adjust down start. Does slowdown feel Adjust slowdown. Does empty car have 3” or 4” of leveling? Move slowdown signal to get 3”...

- Page 36 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Does the car stop Does the car reach properly at each floor? floor level at each floor? Does the car stop Does the car reach Flowchart 13 properly at any floor/...

- Page 37 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Does the car Does stop feel stop properly satisfactory? at any floor? Not a valve problem. Set all slowdown signals the same distance from the floor. Run the car down on Is stop too inspection.

- Page 38 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Run the car at full speed. Replace valve. Adjust job. Is start to hard? Is start too soft? Turn in on start adjustment. Turn out on start adjustment. Is start a double-start.

- Page 39 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Is slowdown too hard? Is down slow solenoid energized? Open manual lowering valve. Is slowdown too soft? Is there voltage on the coil? Turn out on slowdown adjustment? Replace coil. Does car lower? Turn in on slowdown adjustment.

- Page 40 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Install pressure gauge at bleed plug at jack. Record pressure as empty car runs up and down past a given point. Is difference in pressure more than 25 PSI? Run car from bottom to Remove and examine top.

- Page 41 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Does pressure at top and at bottom differ more than 20 PSI? Jack and rails are probably not aligned with each other. Verify and replumb jack and/ or realign jack and rails.

- Page 42 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Register an Up call. Does the car run Up OK at high speed? Does the car level Up Flowchart 19 Put car on inspection. Is Up slow solenoid Is Up inspection speed...

- Page 43 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Is stop more than one Does car move at all? turn open? Flowchart 23 Set stop at two turns open. Is motor running? Is the pump turning? Does car stand still?

- Page 44 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Was start open wider than stop? Replace valve. Set stop at original settings. Adjust job. Open start 3 turns wider than stop. Does car run Up? Adjust valve. Replace Up side strainer.

- Page 45 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Does car run Up? Adjust valve. Is start more than four turns open? Open start to more than four turns. Does car run Up? Adjust valve. Does relief adjustment have less than 5/8” out...

- Page 46 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Does car run Up? Adjust valve. Does pilot piston move freely? Is spring broken? Examine piston and spring. Is spring broken? Replace spring. Replace piston. Does car run Up? Adjust valve.

- Page 47 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Is Up slow energized? Should Up slow be energized? Is Up fast energized? Flowchart 26 Not a valve problem. Open Up start two full turns. Back off on low pressure while pump is running.

- Page 48 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Close start. Does car run at full speed? Does car stand still? Adjust valve. Replace up fast solenoid. Does relief have less than 5/8” outside main nut? Does car operate Turn in on relief.

- Page 49 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Examine piston and spring. Is spring broken? Replace piston. Replace spring. Does car run OK? Adjust valve. Replace valve. Adjust job. Flowchart 25 August 2019 - 89130 v.3.0...

- Page 50 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Put car on inspection. Does the car run faster than leveling speed? Is up fast energized? Is slowdown more than Not a valve problem. three turns open? Set slowdown two turns Close up start adjustment.

- Page 51 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Set up slowdown at ten turns open. Turn in on slowdown as pump runs. Does car run at leveling speed? Adjust valve. Take car off of inspection. Check leveling speed after full speed run.

- Page 52 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Does relief adjustment have less than 5/8” outside main nut? Turn in on relief until less than 5/8” sticks out main nut. Open slowdown to ten turns open. Turn in on slowdown adjustment as pump runs.

- Page 53 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Is strainer clean? Replace valve. Clean or replace strainer. Adjust job. Adjust valve. Flowchart 29 August 2019 - 89130 v.3.0...

- Page 54 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Does car stop properly at each floor? Run car on inspection. Does car stop properly at any floor? Does stop feel OK? Not a valve problem. Set all slowdown signals the same distance from the floor.

- Page 55 I-2 / I-3 Valve Reference Material Troubleshooting Flowcharts (continued) Does stop feel OK? Adjust stop. Does stop feel OK? Verify proper performance. Flowchart 22 Flowchart 31 August 2019 - 89130 v.3.0...

- Page 56 Reference Material I-2 / I-3 Valve Troubleshooting Flowcharts (continued) Is leveling speed Is start too slow? Is up side strainer Adjust leveling speed. Is start slower with five people on car? Was slowdown or leveling speed adjustment moved more than one...

-

Page 57: Sequence Of Events

I-2 / I-3 Valve Reference Material Sequence of Events Up Valve Section • Consists of an up leveling speed adjustment, a check valve piston, a regulator piston, and a relief valve. • Provides acceleration to full speed, slowdown to leveling speed, hydraulic stopping, and high-pressure relief for the car in the up cycle. - Page 58 Reference Material I-2 / I-3 Valve Sequence of Events (continued) Relief Pressure Adjustment Screw High-Pressure Relief Pilot MAIN FLOW Up Slow Solenoid (Closed) CONTROL FLOW TANK Regulator Piston Pressure Up Slowdown Adjustment Adjustment Pressure Control Piston Up Stop Adjustment Up Pilot Piston...

- Page 59 I-2 / I-3 Valve Reference Material Sequence of Events (continued) High-pressure Relief 1. The oil is transmitted to the high-pressure pilot. See Figure 8. 2. The movement allows the oil in back of the regulator piston and at the high-pressure adjustment to escape to the tank.

- Page 60 Reference Material I-2 / I-3 Valve Sequence of Events (continued) Up Slowdown and Leveling Speed 1. From slowdown to leveling speed, the up fast solenoid de-energizes, and the up slow solenoid energizes. See Figure 9. 2. The pressure on the spring end of the up pilot piston reduces, and the up pilot piston shifts to the up position.

- Page 61 I-2 / I-3 Valve Reference Material Sequence of Events (continued) Up Stop 1. The up slow solenoid de-energizes to stop the car. The pump runs slightly longer on a timed delay to provide a valve stop instead of a pump stop. See Figure 10.

- Page 62 Reference Material I-2 / I-3 Valve Sequence of Events (continued) Down Valve Section The down portion of the valve consists of a piston that seats and can be controlled in these positions: • Closed to stop the car • Partially open for slow speed •...

- Page 63 I-2 / I-3 Valve Reference Material Sequence of Events (continued) Down Slowdown and Leveling 1. To change to leveling speed, the down fast solenoid closes. The lowering piston starts in the full open position, and the piston skirt blocks the oil passage to the tank. See Figure 12.

- Page 64 Reference Material I-2 / I-3 Valve Sequence of Events (continued) Manual Lowering The manual lowering valve is parallel to the down slow solenoid and, when opened, lowers the car at leveling speed during emergencies. Down Stop 1. The down slow solenoid de-energizes, stopping all flow to the tank and stopping the car.

-

Page 65: Quick Reference

I-2 / I-3 Valve Reference Material Quick Reference Slowdown and Floor Approach This illustration explains the effects of slowdown point and rate adjustments on car stabilized leveling distances. These adjustments should be referenced as needed, specifically during final valve adjustments or subsequent service calls. - Page 66 Reference Material I-2 / I-3 Valve Quick Reference (continued) Complete Valve Setup Lower Lowering & FORBIDDEN Low Pressure Leveling Adjustment Speed Adjustment Adjustment Up Leveling Adjustment Down Slowdown Adjustment High Pressure REFERENCE INFORMATION Relief Adjustment The closer the on the Down Stop lowering &...

- Page 67 I-2 / I-3 Valve Reference Material Quick Reference (continued) Valve Adjustment Effects August 2019 - 89130 v.3.0...

- Page 68 Reference Material I-2 / I-3 Valve Quick Reference (continued) Final Adjustments Typical Performance Curve Adjustment 3 Adjustment 2 Fast Speed Starting Acceleration Adjustment 5 Deceleration to Leveling Speed Adjustment 1 Adjustment 5 Deceleration to Full Stop Leveling Zone Set at 3"-4"...

- Page 70 Tel: (866) 448-3789 (toll free) Fax: (901) 877-8099 www.verticalxpress.com All illustrations and specifications are based on information in effect at time of publication approval. Vertical Express reserves the right to change specifications or design and to discontinue items without prior notice or obligation. © 2019 Vertical Express...

Need help?

Do you have a question about the I-2 and is the answer not in the manual?

Questions and answers