Summary of Contents for COSMO Bully SGM Series

- Page 1 FINISHING MOWERS SGM- SERIES SGM 60-72-84 OPERATOR'S AND PARTS’ MANUAL Tirth Agro Technology Pvt. Ltd. ISO 9001:2015 & CE Certified Company Manual P/N: OM2812-21EN-000_19...

- Page 2 Congratulation for purchasing your new Cosmo Bully Finishing Mower! This mower has been designed and manufactured following all safety and quality requirements needed for a safe and satisfactory use over time. A careful reading of this manual will permit you to familiarize with your new equipment, and will pro- vide you all the tools needed to use it safely.

- Page 3 RIGHT-HAND AND LEFT-HAND sides are determined by watching from the tractor side. Sometime in the future your Finishing mower may need new parts to replace those are worn or broken. If so, go to nearest COSMO BULLY dealer and provide him the model and part number.

-

Page 4: Table Of Contents

Index 1. ABOUT THIS MANUAL ......................1 2. INTRODUCTION ......................... 1 2.1. IDENTIFICATION ............................1 2.2. INTENDED USE ............................2 2.3. MAIN PARTS DESCRIPTION ........................3 2.4. SPECIFICATIONS ............................4 3. SAFETY ..........................5 3.1. GENERAL SAFETY INSTRUCTION ......................5 3.2. -

Page 5: About This Manual

1. ABOUT THIS MANUAL The operator must read the manual for a correct understanding of the hazards that may present when operating the mower, as well as for obtain optimum performance from the machine. The manual is part of the machine, it must be kept in good condition and remain with the machine even in case of resale, until its demolition. -

Page 6: Intended Use

2.2. INTENDED USE The SGM-series Finishing mowers are specifically designed for lawn and grass professional mowing and maintenance of areas like private lawns, parks, airports, hospital grounds, schools, highways, golf courses etc. The SGM mowers are NOT designed for rough conditions or heavy weed mowing. The SGM mowers can be either tractor front or rear mounted on universal three-point hitch, and are driven by the tractor power through a PTO driveshaft connected to a speed multiplier gearbox. -

Page 7: Main Parts Description

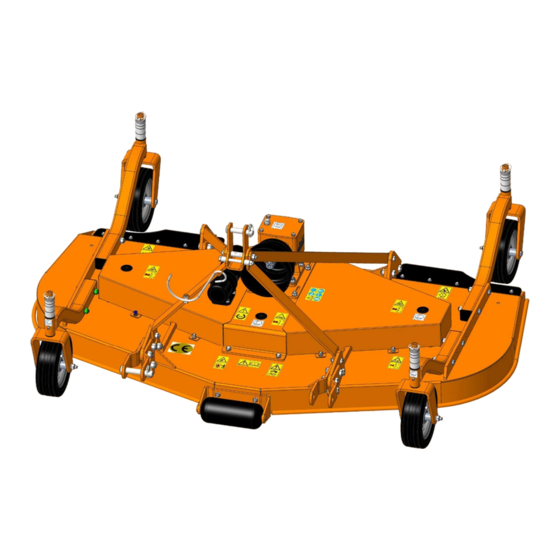

2.3. MAIN PARTS DESCRIPTION Mower deck 11. Driven pulley Top hitch support 12. Blade Top hitch arm 13. Transmission belt Top hitch link 14. Belt cover Lower hitch pin 15. Belt tensioner screw Upper hitch pin 16. Wheel arm PTO shield 17. -

Page 8: Specifications

some components (e.g. belt cover). 2.4. SPECIFICATIONS SGM 48^ SGM 60 SGM 72 SGM 84 MODEL (1.2M) (1.5M) (1.8M) (2.1M) Overall dimensions 136x134x75 163x147x75 192x152x75 225x173x75 Cutting width inches 48'' 60'' 72'' 84'' Tractor power 20-50 3-point Hitch type Category 1 (ISO 730 standard) PTO Input speed 19 - 110 Cutting height... -

Page 9: Safety

3. SAFETY Proper use of the equipment, a strict observance of the safety messages listed below and application of all reasonable practices to avoid any risks, prevents accidents or injury, allows the machine working better and longer, and minimize the failures. The manufacturer assumes no liability for any damage resulting from not applying the behavioral rules indicated into the manual. -

Page 10: Equipment Safety Instructions

CAUTION If the use of the machine is required at night or in conditions of reduced visibility, use the lighting system of the tractor and possibly an auxiliary lighting system. 3.2. EQUIPMENT SAFETY INSTRUCTIONS WARNING Use the mower for its intended purpose only. Improper use can damage the implement and cause seri- ous injury to persons, animals, or death. -

Page 11: Operating Safety Instruction

3.3. OPERATING SAFETY INSTRUCTION WARNING Before using the machine, be sure to have cleared the operating area from obstacles (stones, branches, debris, etc...). Mark all the obstacles that cannot be eliminated (e.g. by means flags). DANGER Never engage the tractor PTO in the presence of people close to the driveshaft. The body, hair or cloth- ing of a person can get caught in rotating parts, causing serious injury or death. -

Page 12: Transporting Safety Instructions

Stop operating immediately if blades strike a foreign object. Repair all damage and make certain spin- dles and blades are in good condition before restarting operation. WARNING Always disengage the tractor PTO when the driveshaft exceeds an angle of 10 degrees up or down while operating. -

Page 13: Maintenance Safety Instruction

3.5. MAINTENANCE SAFETY INSTRUCTION WARNING All maintenance and repairing operations must be performed by qualified and trained operators, with the tractor engine off, the PTO disengaged, the mower lowered to the ground or on security stands, the parking brake and the set ignition key off. Secure blocking prevents equipment from dropping due to hydraulic leak down, hydraulic system failures, or mechanical component failures. -

Page 14: Safety Labels

3.7. SAFETY LABELS The safety labels applied on the machine give fundamental information for using the machine safely. Make sure safety labels are in good conditions. If pictograms are worn, they must be replaced with oth- ers obtained from the Manufacturer and placed in the position indicated by this manual. Make sure the safety labels are legible. - Page 15 Disengage the PTO, turn off the trac- tor engine, remove the key and en- sure that all rotating parts have D1038 stopped before approaching the im- plement. Read the operator's manual before performing any maintenance operation. Thrown or flying object hazard. Keep D1095 a safe distance from the machine.

- Page 16 Crushing hazard. stay clear of draft D1097 link lifting range while in operation. Implement input driveline: body en- tanglement hazard. Do not open or D1098 remove safety shields while engine is running. Before engaging the tractor PTO, check that rpm rate and sense of ro- D1099 tation are those prescribed for the implement.

-

Page 17: Set Up

D1108 CE LOGO ROTATING DRIVELINE (COVER) D1123 D1124 ROTATING DRIVELINE (TUBE) 4. SET UP The mower is delivered equipped with a driveshaft and related operating manual. When the machine is delivered, check that there is no damage to the mower or driveshaft. In case of damage or missing parts immediately notify the Manufacturer or your Dealer. - Page 18 To connect the mower to the tractor the operator must do the following: drive the tractor in reverse up to the mower, in order to slip the tractor hitch arms over the hitch pins of the mower (see picture below); ...

-

Page 19: Driveline Installation

4.2. DRIVELINE INSTALLATION Before installing the driveshaft, the operator must read the manuals of the tractor and driveshaft, check- ing in particular that rpm and direction of rotation of the PTO tractor match those of the mower. If the direction of rotation of the PTO tractor does not match that of the mower, contact the Manufacturer or your Dealer. -

Page 20: Tractor-Mower Stability

A driveshaft too long may cause structural damages to the tractor and machine. If the driveshaft is too long, it may be adapted by removing it and shortening the tubes according to the instructions provided by the Manufacturer in its use and maintenance manual. A driveshaft too short can cause disengage of the tubes during operation, with severe hazard for the operator and structural damage to the tractor and machine. -

Page 21: Operating

Tractor wheelbase (cm) Distance between front axle and ballast center of mass (cm) Weight of tractor + operator (75 kg) Ballast weight (kg) Implement weight (kg) s1 = Distance between rear axle and lower hitch points (cm) s2 = Distance between lower hitch points and implement center of mass: 51 cm (SGM 48) - 55 cm (SGM 60) - 60 cm (SGM 72) - 68 cm (SGM 84) CAUTION The weight of the implement modifies the stability of the system tractor-mower, resulting in loss of... - Page 22 check that all guards and safety devices have no damages and are properly positioned. Repair and / or replace the damaged shielding, restore the correct position; verify that the PTO driveshaft is properly installed (see section: Connection of the driveshaft); ...

-

Page 23: Operating Instructions

the mower in the down position and resting on the ground, reduce engine speed and disengage PTO, set the parking brake, stop engine and remove the ignition key. 5.2. OPERATING INSTRUCTIONS The SGM-series Finishing mowers have been designed to cut grass with heights up to 8”. It is recom- mended to avoid cutting grass taller than 10”. - Page 24 if the blades strike a foreign object, stop operating immediately, idle the engine speed and disengage the PTO. Wait for stopping of all rotating parts, then raise the implement and proceed to removing possible objects or debris, after stopped the tractor, set the parking brake, stopped engine and re- moved the ignition key.

-

Page 25: Adjustments

5.3. ADJUSTMENTS WARNING All adjustment operations must be performed with the tractor engine off, the PTO disengaged, the mower lowered to the ground or on security stands, the parking brake set and the ignition key off. Se- cure blocking prevents equipment from dropping due to hydraulic leak down, hydraulic system failures, or mechanical component failures. - Page 26 IMPORTANT: Very low cutting heights should be avoided. Damaging shock loads occur when the blades strike the ground. This can cause damage to the mower and drive. WHEEL ARM ADJUSTMENT The front wheel arms of the SGM60-72-84 mowers (*) can be set in two different configurations: ...

- Page 27 (*) NOTE: SGM48 front wheel arms are fixed and cannot be changed. LOWER HITCHES ADJUSTMENT The lower hitched of the SGM mowers can be set in two different configurations: fixed position (see picture below - left side); floating position (see picture below - right side), that allows the mower to float and follow contour over hilly and uneven terrain.

- Page 28 To maximize the floating effect, providing at the same time the most clearance for interference with trac- tor tires, the lower hitches can be moved ahead (see picture): UPPER HITCHES ADJUSTMENT The upper hitched of the SGM mowers can be set in two different configurations: ...

-

Page 29: Stopping And Disconnection

To change from fixed to floating position, of 3 – point hitching bracket, remove hex bolt (A), two bush (B) & nut (c) from bracket. 5.4. STOPPING AND DISCONNECTION To stop the mower at the end of a working session: ... -

Page 30: Transport

Before a long term storage (e.g. at seasonal end), do cleaning and maintenance operations as specified in sections Maintenance and Storage. 5.5. TRANSPORT To set the mower for transportation, perform the following steps: idle tractor engine, disengage tractor PTO, and wait for stopping of all rotating parts; ... -

Page 31: Maintenance

6. MAINTENANCE Proper and regular maintenance ensures a long life of your implement, avoids failures and saves time and repair costs. Periodic inspections and maintenance operations described in this section must be performed by oper- ator in the times and terms prescribed. Failure to comply with maintenance prescriptions can compro- mise the functioning and duration of the machine, and consequently invalidate the warranty. - Page 32 To adjust belts tension (see picture below): remove belt cover (A). Clean debris and foreign material from the mower deck and belt area; loosen the four nuts (B) holding the gearbox support plate (C) to the gearbox support (D); ...

-

Page 33: Belts Replacement

6.2. BELTS REPLACEMENT Belts replacements is required if belts are stretched or damaged to the point that the proper tension cannot be obtained. To replace belts, do the following (see picture above): remove belt covers (A). Clean foreign material from the mower deck and belt area; ... - Page 34 reinstall the conical spring and the nylock nut (A). Tighten the nylock nut (A), blocking the blade shaft by fitting a wrench in special spacer. IMPORTANT After replacement, always make sure that the blade installed has the cutting edge facing direction of rotation.

-

Page 35: Gearbox Lubrication

WARNING Unbalanced blades cause excessive vibration that can result in damages to blade spindle bearings, mower components and/or personal injury. Always sharpen both ends of the blade equally or until the blade is balanced. Always keep all three mower blades sharpened equally in order to maintain balance. WARNING Always wear eye protection and gloves when sharpening a blade. -

Page 36: Spindle Shafts Lubrication

6.5. SPINDLE SHAFTS LUBRICATION Lubricant: SAE MULTI – PURPOSE lithium -type grease (or equivalent). The blades spindles shafts are supported by two bearings that require regular lubrication. Grease fittings points (A) are placed on the top of the three spindle shafts, protected by special rubber caps (see picture below). -

Page 37: Driveshaft Maintenance

6.7. DRIVESHAFT MAINTENANCE Lubricant: SAE multi-purpose lithium-type grease Grease crosses, sliding parts of protective shielding and driveshaft transmission tubes (see picture be- low) every 8 working hours. IMPORTANT For details about maintenance and lubrication of the driveshaft, refer to the user manual of the driveshaft Manufacturer. -

Page 38: Troubleshooting

9. TROUBLESHOOTING PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION Excessive vibration Breakage or excessive wear of Replace the worn or cracked blades blades Spindle shaft bearings worn Replace bearings Uneven cutting Blades assembled incorrectly Check spindle assembly and re- on spindle shafts store correct position of the parts (blade, spacer and washer) -

Page 39: Torque Values Table

Rear discharge area Grass too high Raise cutting height of mower plugged and cut grass in two pass. Shift transmission to a lower gear. Tractor rpm too slow Mow at full throttle (540 PTO rpm), check PTO speed and trac- tor engine Overheating of belts Incorrect tension of belts... -

Page 40: Warranty

11. WARRANTY Tirth Agro Technology Pvt. Ltd. offers the following warranty to the purchaser of COSMO BULLY ROTARY HOE mentioned herein above subject to the conditions set out herein after provided the COSMO BULLY ROTARY HOE shall be in the possession of and used by such purchaser as from the date of delivery. - Page 41 The warranty card has not been returned within 30 days of the date of purchase. The COSMO BULLY ROTARY HOE parts thereof are subjected to neglect, fire, flood or other acts of God or if in the company’s opinion any damage has caused to the COSMO BULLY ROTARY HOE in transportation.

-

Page 42: Spare Parts

All repairs and replacements on the machine must be performed only by using original spare parts, which must be obtained from the Manufacturer or your Dealer. This section contains the information needed to identify the parts of SGM series mowers that may be ordered to Manufacturer. -

Page 43: Ec " Declaration Of Conformity

Dist.: Rajkot - 360311 Gujarat - INDIA. CIN: U72900GJ2000PTC 038435 hereby declares that the machine: Type: COSMO BULLY Finishing Mower Model: SGM-Series satisfies the basic safety and health requirements established by European Directive 2006/42/EC. Harmonized standards used: EN ISO 12100:2010... - Page 44 Distributed by: Manufactured by: Farm Implements Pty Ltd. Tirth Agro Technology Pvt. Ltd. 12 Tarmac Way “COSMO BULLY”, Survey No.-108/1 Pakenham Victoria Plot No. B,NH-27, Nr. Bharudi Toll Plaza Australia 3810 Bhunava (Village), Taluka: Gondal Phone: +61 3 9706 5166 Dist.: Rajkot - 360311 State: Gujarat- INDIA E-mail: sales@farmimplements.com.au...

Need help?

Do you have a question about the SGM Series and is the answer not in the manual?

Questions and answers