Subscribe to Our Youtube Channel

Summary of Contents for Delachaux Conductix-Wampfler 1900 Series

- Page 1 dual hose reel series 1900 / 2400 P/n 962101 2008.10.24 rev. 2 iom 1900 / 2400 dual hose reel manual...

- Page 2 Conductix Incorporated The technical data and images which appear in this manual are for informational purposes only. no WarranTies, eXPress or imPlied, inCludinG WarranTies oF merChanTaBiliTY or FiTness For a ParTiCular PurPose, are CreaTed BY The desCriPTions and dePiCTions oF The ProduCTs shoWn in This manual.

- Page 3 Index 1.0 safety instructions 1.1 Pressure Warnings 1.2 Operational Warnings 1.3 Maintenance Warnings 1.4 Specifications and Listings 1.5 Pressure and Temperature Rating 1.6 Labels and Markings 2.0 installation 2.1 Application Types 2.2 Mounting 2.3 Guide Rails 2.4 Roller Guides 2.5 Ratchet 2.6 Hose Installation and Replacement 2.7 Spring Tension Adjustment 3.0 operation...

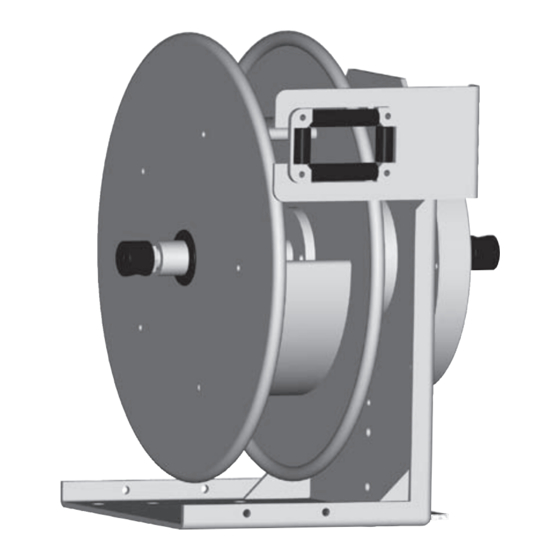

- Page 4 Basic Component Identification swivel reducer spring motor Frame spool shaft roller Guide reducer spool assembly swivel iom 1900 / 2400 dual hose reel manual P/n 962101 2008.10.24 rev. 2...

- Page 5 1.0 Safety 1.1 Pressure Warnings 1.1.1 This equipment should be properly installed before use in accordance with local codes and ordinances. 1.1.2 The pressure to the hose reel should be disconnected from the hose reel before any service functions are performed. 1.1.3 This hose reel must not be used for pressure greater than the rating listed on the label.

-

Page 6: Installation

2.0 Installation application Types 2.1.3 drag applications 2.1.1 stretch applications suPPorTed susPended 2.1.3.1 The reel is mounted on a stationary object and is required 2.1.1.1 The hose is suspended without any intermediate support. to drag the hose over the surface to the reel. The hose is Stretch reels generally require a line pull equal to two times the supported by the ground or some type of hose tray. - Page 7 2.0 Installation 2.2 mounting 2.2.1 standard mounting 2.2.1.1 The reel is mounted by bolting the base to any flat surface which is structurally sound enough to support it and the forces of winding and unwinding the hose. 2.2.1.2 The spool drum must rotate on a horizontal axis. Use a level to confirm this. 2.2.1.3 The reel should be oriented so that the hose extends perpendicular to the rotation of the spool.

-

Page 8: Guide Rails

2.0 Installation 2.3 Guide rails 2.3.1 The optional guide rails can be installed on any of the 1900 & 2400 Series Dual Hose Reels. 2.3.2 Guide Rails provide a barrier between the hose and rotating spool flange rim. They also act as a safety barrier for installations where human contact with the rotating spool flange is likely to occur. - Page 9 2.0 Installation 2.5 ratchet 2.5.1 The ratchet option allows the extended hose to be pulled out and held from retraction by spring tension; generally appropriate for operator attended applications. 2.5.2 The ratchet for the 1900 & 2400 Series Hose Reels is spring loaded. It is designed to function in all acceptable mounting configurations. 2.5.3 The ratchet option can be installed at the time of purchased or later added to reels that have already been introduced to service.

- Page 10 2.0 Installation 2.6 hose installation Warnings 2.6.1 hose installation Warnings 2.6.1.1 If an existing hose is being replaced, remove the old hose. Replacement hose should be the same size and length and pressure rating as the existing hose. Any variations to existing hose specifications should be pre-approved by the factory. 2.6.1.2 Variations in inner and outer hose diameters will significantly impact reel performance.

-

Page 11: Spring Tension Adjustment

2.0 Installation 2.7 spring Tension adjustment 2.7.1 spring Tension Warnings 2.7.1.1 The adjustment may require mechanical assistance in more demanding applications and installations. 2.7.1.2 WarninG: Do not allow hose to retract without restraining the retraction speed. Walk the hose back to the reel during the spring tension adjustment process. -

Page 12: Operation

3.0 Operation Do not exceed the pressure or temperature rating of the hose. Do not exceed the pressure or temperature rating of the reel. Pressure and temperature above the rated capacity could cause damage to equipment and personal injury could result. Operate the reel within the hose size, length and spring tension limits for which it was intended. - Page 13 4.0 Maintenance spring motor replacement 4.5.1 spring motor Warnings 4.5.1.1 CauTion: do not open the spring motor or personal injury may result. 4.5.1.2 The spring replacement process is determined by the spring configuration and cannot be performed in the field. The entire spring motor must be replaced as a unit.

-

Page 14: Troubleshooting

5.0 Troubleshooting Problem Possible Cause solution 1) Improper pretension. 1) See tension adjustment Section 2.7 2) Incorrect reel for application (lift vs. stretch). 2) Quantify application vs. reel selection. Reel will not retract hose but has some tension 3) Improper hose or hose length installed. 3) Install hose for which reel is intended. - Page 15 1900 / 2400 dual Hose Reel Parts View 3 a & B iom 1900 / 2400 dual hose reel manual P/n 962101 2008.10.24 rev. 2...

-

Page 16: Replacement Parts

6.0 Replacement Parts swivel Kit Frame assembly discriptive digit Assy swivel Reducer assy Bearing Housing Bearing 1/4” 43870 e614-.25 05918 42962 40220 E&F 3/8” 43871 e614-.375 05906 42963 40220 G, H, J, K, L & M 1/2” 43872 e614-.500 05917 Guide arm swivel Kit Catalog #... - Page 17 notes iom 1900 / 2400 dual hose reel manual P/n 962101 2008.10.24 rev. 2...

- Page 18 notes iom 1900 / 2400 dual hose reel manual P/n 962101 2008.10.24 rev. 2...

- Page 19 notes iom 1900 / 2400 dual hose reel manual P/n 962101 2008.10.24 rev. 2...

- Page 20 www.conductix.com Conductix-Wampfler 10102 F Street Omaha, NE 68127 Customer Support Phone: 800 521 4888 Fax: 800 780 8329 Phone: 402 339 9300 Fax: 402 339 9627 info.us@conductix.com www.conductix.com manual name P/n 962101 2008.10.24 rev. 2...

Need help?

Do you have a question about the Conductix-Wampfler 1900 Series and is the answer not in the manual?

Questions and answers