Table of Contents

Advertisement

Quick Links

Waste Big Bag

Customer Product Manual

Part 7093466

Issued 04/21

For parts and technical support, call the Industrial Coating

Systems Customer Support Center at (800) 433‐9319 or

contact your local Nordson representative.

This document is subject to change without notice.

Check http://emanuals.nordson.com for the latest version.

NORDSON DEUTSCHLAND GMBH

Advertisement

Table of Contents

Summary of Contents for Nordson Waste Big Bag

- Page 1 Issued 04/21 For parts and technical support, call the Industrial Coating Systems Customer Support Center at (800) 433‐9319 or contact your local Nordson representative. This document is subject to change without notice. Check http://emanuals.nordson.com for the latest version. NORDSON DEUTSCHLAND GMBH...

- Page 2 Contact Us Notice This is a Nordson Corporation publication which is protected by copyright. Nordson Corporation welcomes requests for information, comments, and Original copyright date 2021. No part of this document may be inquiries about its products. General information about Nordson can be...

- Page 3 Change Record Change Record Revision Date Change Part E 2021 Nordson Corporation 7093466...

- Page 4 CE label. Provided the product is installed and operated in line with the Nordson manuals, its operation is safe. Name and address of the responsible person authorized to compile the technical file Kai Flockenhaus Manager Procurement &...

-

Page 5: Table Of Contents

TABLE OF CONTENTS Waste Big Bag ......... . -

Page 6: Waste Big Bag

Intended Use CAUTION: Use of Nordson equipment in ways other than those described in the documentation supplied with the equipment may result in injury to persons or damage to property. -

Page 7: Personal Safety

Clean, maintain, test, and repair equipment according to the instructions in your equipment documentation. Use only replacement parts that are designed for use with original equipment. Contact your Nordson representative for parts information and advice. E 2021 Nordson Corporation Part... -

Page 8: Grounding

Waste Big Bag Grounding WARNING: Operating faulty electrostatic equipment is hazardous and can cause electrocution, fire, or explosion. Make resistance checks part of your periodic maintenance program. If you receive even a slight electrical shock or notice static sparking or arcing, shut down all electrical or electrostatic equipment immediately. -

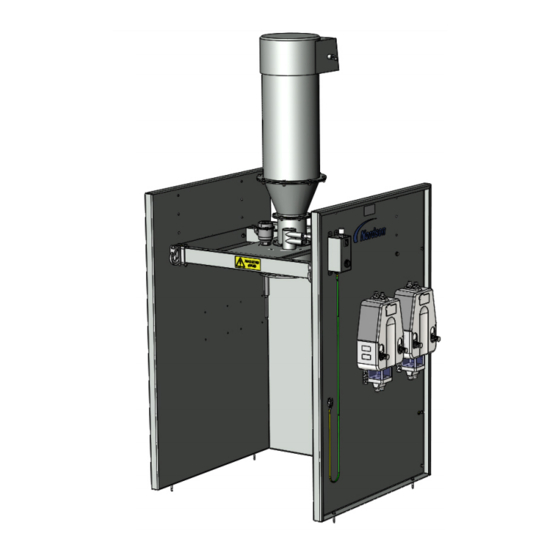

Page 9: Description

Afterfilter, the Stand Alone version, fitted with it’s own venting extract and pulse cleaning cartridge filter, is an ideal solution. The Waste Big Bag must only be operated in a way of proper and conforming use. Conforming use also means strict observance of all operating and maintenance instructions stipulated by the manufacturer or supplier of your equipment. -

Page 10: Powder Flow Process Diagram & Description

Waste powder Waste powder path from the Afterfilter to the Waste Big Bag Prodigy HDLV Transfer Draws powder from the Afterfilter and transfers it to the Waste Big Bag Pump Excess air Excess air from the bag is extracted correctly and safely... -

Page 11: Installation

Nordson representative or a suitably qualified person. 1. Choose a level site on which to install the Waste Big Bag station. If part of a complete system, see the general layout drawings for location. -

Page 12: Atex Zoning

Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Ì Figure 4 Atex Zoning of Waste Big Bag ATEX Zoning suggested by Nordson Part E 2021 Nordson Corporation... -

Page 13: Daily Operation And Start Up

Daily Operation and Start Up The Waste Big Bag is active when the main system is in operation. Check the system is correctly grounded, vent hoses are fitted (if a vented system) and the big bag is securely and safely loaded with pallet underneath as shown on the following page. -

Page 14: Bag Installation Procedure

Figure 6 Position a suitable and strong pallet inside the Waste Big Bag station and place the new empty bag on top. Figure 7 Starting with the 2 at the rear of the bag, attach all 4 support straps of the bag, to the support hooks on the frame and ensure the latch is closed. - Page 15 Waste Big Bag Figure 8 Attach the opening of the bag to the vent cylinder and secure using the belt. Figure 9 Connect the grounding wire clamp. Double check that everything is correctly fitted and secure before starting production. Bag Removal − Switch off the system to avoid powder retuning to the bag. Disconnect the grounding wire.

-

Page 16: Maintenance

Waste Big Bag Maintenance WARNING: Breathing in certain airborne dusts (including finishing powders) may be hazardous to health. Ask the powder manufacturer for a Material Safety Data Sheet (MSDS) for information. Use appropriate respiratory protection. CAUTION: It is important to follow the specific maintenance instructions of each product. - Page 17 Waste Big Bag 4000 Body Inspect the Big Check for damages, strength, welding cracks and cor- Bag station and rosion its support 4000 Electrical Inspect all Resistance < 1 Ohm grounding* equipment ground connections 8000 Level Sensor Calibrate level Calibrate the level sensors for correct measuring...

-

Page 18: Troubleshooting

Obvious causes of malfunction such as broken wires, missing fasteners etc., should be noted during visual inspections and corrected immediately. These troubleshooting procedures cover only the most common problems. If you cannot solve a problem, contact your Nordson representative. Problem... -

Page 19: Parts

Waste Big Bag Parts To order parts, call the Nordson Industrial Coating Systems Customer Support Center at (800) 433-9319 or contact your local Nordson representative. Item Part Description Quantity Note 7035479 SENSOR,LEVEL,WASTE BIG BAG 7035481 FILTER, CARTRIDGE, WASTE BIG BAG... - Page 20 BELT, WASTE BIG BAG 768178 TUBING,PWDR,ANTISTATIC 12.7MM (.5 IN) ID NOTE A: Optional B: Pumps will be mounted on Waste Big Bag frame or Afterfilter legs AR: As Required NS: Not Shown Figure 11 Spare Parts Identification Images - Vented...

-

Page 21: Specifications

Waste Big Bag Specifications Refer to the Services drawing supplied with the system for exact specifications. Below, you can see the typical values. Description Values Factory ambient temperature 5°C - 35°C 24vdc Electrical connection 10mm for pumps − supplied from Afterfilter... - Page 22 Waste Big Bag Part E 2021 Nordson Corporation 7093466...

Need help?

Do you have a question about the Waste Big Bag and is the answer not in the manual?

Questions and answers