Summary of Contents for Cardinal Health Alaris 8300 Series

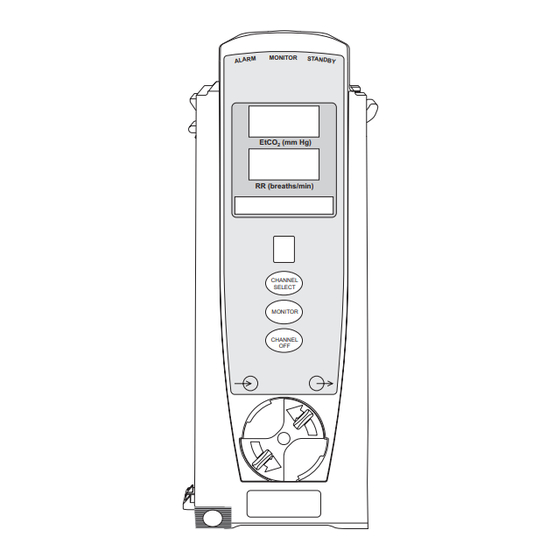

- Page 1 Technical Service Manual Alaris ® EtCO Module, 8300 Series Supports: Guardrails ® Suite (v7 or later) January 2006 EtCO (mm Hg) RR (breaths/min) CHANNEL SELECT MONITOR CHANNEL Alaris ® Products...

- Page 2 General Contact Information Cardinal Health Alaris ® Products 10221 Wateridge Circle San Diego, California 92121 http://www.cardinal.com/alaris Customer Advocacy - North America Clinical and technical feedback. Phone: 800.854.7128, Ext. 7812 E-Mail: CustomerFeedback@cardinal.com Technical Support - North America Maintenance and service information support; troubleshooting.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Chapter 1 - General Information Introduction ................... . Precaution Definitions . - Page 4 TABLE OF CONTENTS Chapter 5 - Corrective Maintenance Introduction ................... . Disassembly/Reassembly .

- Page 5 TABLE OF CONTENTS List of Tables Record of Configured Instruments ..............Required Materials, Supplies and Tools .

-

Page 6: Table Of Contents

TABLE OF CONTENTS T H I S PA G E I N T E N T I O N A L LY L E F T B L A N K Alaris ® EtCO Module (8300 Series) Technical Service Manual... -

Page 9: Chapter 1 - General Information

CAUTION experienced in analysis, troubleshooting, Any attempt to service this product by anyone and repair of analog/digital microprocessor- other than an authorized Cardinal Health Service based medical equipment. Representative while the product is under warranty may invalidate the warranty. The EtCO... -

Page 10: Precaution Definitions

GENERAL INFORMATION PRECAUTION DEFINITIONS ALARMS, ERRORS, MESSAGES Refer to the Alaris ® System The scrolling Channel Message Display bar shows alarms and other messages. Refer SPECIFICATIONS to the product-specific (EtCO Module) section of the Alaris ® System Refer to the product-specific (EtCO detailed information. -

Page 13: Chapter 2 - Checkout And Configuration

Contact Cardinal Health authorized service personnel if the instrument has physical damage, fails to satisfactorily pass the startup sequence, fails a self test, or continues to alarm. -

Page 14: Configuration Options And Defaults

CHECKOUT AND CONFIGURATION CONFIGURATION OPTIONS AND EtCO Module settings (including limit DEFAULTS mode, high and low respiratory rate alarm limit, high and low EtCO alarm limit, no NOTES: breath alarm setting, and high FiCO alarm • Changes to the factory default values are limit). -

Page 15: Configuration Setup - Etco 2

CHECKOUT AND CONFIGURATION CONFIGURATION SETUP 2.4.1 Alarm Limits NOTE: The following examples show adult To access System Configuration options: alarm limits for illustration. Follow the same steps for neonatal alarm limits. NOTE: Refer to EtCO Module DFU for alarm settings. If profiles are enabled, those settings are set by the profile. -

Page 16: Limit Mode

CHECKOUT AND CONFIGURATION CONFIGURATION SETUP (Continued) 5. To change another alarm limit, press the soft key for that parameter and enter a 2.4.1 Alarm Limits (Continued) new value. 6. Once all changes are complete, press the CONFIRM soft key. 2.4.2 Limit Mode NOTES: •... -

Page 17: Waveform Height

CHECKOUT AND CONFIGURATION CONFIGURATION SETUP (Continued) Every key press toggles the value between 60 and 99 mmHg. 2.4.2 Limit Mode (Continued) 3. To use the soft key: From the System Config - EtCO display, press the Waveform height soft key. 4. - Page 18 CHECKOUT AND CONFIGURATION CONFIGURATION SETUP (Continued) 2.4.4 Waveform Time Scale (Continued) 2. To toggle the value: From the System Config - EtCO display, press the soft key for the Waveform Time Scale value. Every key press toggles the value between 5 and 10 sec. 3.

- Page 19 CHECKOUT AND CONFIGURATION Table 2-1. Record of Configured Instruments Instrument ID/Serial # EtCO Alarm Limit, High EtCO Alarm Limit, Low FiCO Alarm Limit, High Limit Mode No Breath Alarm Respiratory Rate Alarm Limit, High Respiratory Rate Alarm Limit, Low Waveform Height Waveform Time Scale NOTE: If profiles are enabled, alarm limits are set by the profile.

- Page 20 CHECKOUT AND CONFIGURATION T H I S PA G E I N T E N T I O N A L LY L E F T B L A N K Alaris ® EtCO Module (8300 Series) Technical Service Manual...

-

Page 23: Chapter 3 - Preventive Maintenance

CALIBRATION Use the Maintenance Software (version 7 or later) to perform calibration and preventive maintenance. Contact Cardinal Health Technical Support if you need help obtaining or using the Maintenance Software. CLEANING Refer to the PC Unit section of the Alaris ®... - Page 24 PREVENTIVE MAINTENANCE T H I S PA G E I N T E N T I O N A L LY L E F T B L A N K Alaris ® EtCO Module (8300 Series) Technical Service Manual...

-

Page 27: Chapter 4 - Principles Of Operation

Chapter 4 — PRINCIPLES OF OPERATION INTRODUCTION This chapter describes the principles of operation for the EtCO Module and its major subsystems. Refer to the PC Unit/Pump Module Technical Service Manual for Point-of-Care Unit information. GENERAL INFORMATION The EtCO Module uses Oridion’s patented Microstream ®... - Page 28 PRINCIPLES OF OPERATION ® GENERAL INFORMATION (Continued) Microstream Disposables are single-use, disposable devices which must be changed approximately 190 ms and accurate CO with each use. The manufacturer’s sample readings, even at high respiration rates. flow, 50 mL/minute, does not affect the disposable’s life;...

-

Page 31: Chapter 5 - Corrective Maintenance

If the “Illustrated Parts Breakdown” chapter. there are any questions, look for Service Bulletins related to this chapter or contact Cardinal Health Following any level of maintenance, perform Technical Support. the applicable tests (refer to “Level of Testing Guidelines”... -

Page 32: Disassembly/Reassembly

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY Follow these procedures in order for the Before adhering gaskets and labels to the most efficient disassembly of EtCO Module instrument, clean the surface with a cotton swab or soft cloth lightly dampened with subassemblies. To reassemble the EtCO Isopropyl Alcohol. -

Page 33: Latch Assembly And Feet

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.1 Latch Assembly and Feet During Reassembly: When reinstalling the Latch Assembly, press 1. Remove two ( ) screws attaching Latch toward outer edge of the module and screw Assembly to bottom of Rear Case and into position. - Page 34 CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.2 IUI Connectors During Reassembly: • Ensure ground clips are still installed on Remove two ( ) screws attaching each both IUI connectors. (left and right) to module. • To install IUI Connector Gasket, remove protective backing and adhere to IUI Connector.

-

Page 35: Rear Case

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.3 Rear Case During Reassembly: Ensure that Silicone Tubing gasket in Rear 1. Remove two ( ) screws (and associated Case is in place and undamaged. washers) attaching Rear Case to chassis assembly. 2. Pull Rear Case away from chassis assembly. -

Page 36: Frame Assembly

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.4 Frame Assembly CAUTION When using cutters to remove snap rivet, take care not to cut the rivet. 1. Remove six (6) screws attaching Frame Assembly to Front Case. 2. Use small diagonal cutters to remove Snap upper snap rivet attaching Power Board Frame... -

Page 37: Logic Board

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.5 Logic Board During Reassembly: • Seat the holes in the Logic Board over CAUTION the standoffs on the IUI Bracket. When using cutters to remove snap • Reinstall the snap rivet and its locking pin rivet, take care not to cut the rivet. -

Page 38: Power Board/Oridion Module

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.6 Power Board/Oridion Module 4. Disconnect electrical harness between Power Board and Oridion Module. CAUTION 5. Separate Power Board and Oridion When using cutters to remove snap Module: rivet, take care not to cut the rivet. •... -

Page 39: Iui Bracket

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.7 IUI Bracket Flex IUI Bracket away from key pins and remove bracket and Ground Strap from Frame Assembly. During Reassembly: Position IUI Bracket over key pins on Frame Assembly IUI Bracket Ground Strap Frame Assembly Key pin Alaris ®... -

Page 40: Gas Inlet/Outlet Door

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.8 Gas Inlet/Outlet Door During Reassembly: 1. Place Torsion Spring on Door shaft with NOTE: To hold Torsion Spring in place long end facing up. during removal, hold Spring Retainer firmly when removing Cotter Pin. 2. Align Spring Retainer with shaft, push Torsion Spring down, insert Cotter Pin 1. -

Page 41: Luer Assembly

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.9 Luer Assembly During Reassembly: • Ensure that O-ring is correctly positioned 1. Remove three ( ) screws attaching Luer on Luer Assembly, then apply a small Retainer to Front Case. bead of water around the O-ring: this 2. -

Page 42: Display Board

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.10 Display Board During Reassembly: • When reinstalling Display Board, slide 1. Remove screw attaching ground wire to LEDs under Status Indicator Lens. Display Board. • Reinstall screws attaching Display Board 2. Cut cable tie, then disconnect Keypad to Front Case. -

Page 43: Status Indicator Lens

CORRECTIVE MAINTENANCE DISASSEMBLY/REASSEMBLY (Continued) 5.2.11 Status Indicator Lens 1. Remove two (2) screws attaching Status Indicator Lens and Gasket to Front Case. 2. Remove Status Indicator Lens. Status Indicator Lens Gasket Front Case Screws (x2) 5-13 Alaris ® EtCO Module (8300 Series) Technical Service Manual... -

Page 44: Torque Values

CORRECTIVE MAINTENANCE Table 5-2. Torque Values Functional Application Item Description Torque Value FINAL ASSEMBLY IUI Connectors 6-32 x 12 in/lb Latch Assembly 4-40 x Torx Security 6 in/lb Rear Case - Internal Frame 6-32 x 12 in/lb FRONT CASE ASSEMBLY Display Board 4-40 x 6 in/lb... - Page 45 CORRECTIVE MAINTENANCE Table 5-3. Level of Testing Guidelines Tests to Perform = Required X = If verification fails. Blank = Not Applicable Repair/Replacement of: Display Board Frame Assembly Front Case Gas Inlet/Outlet Door IUI Bracket IUI Connectors Latch Assembly and Feet Logic Board Luer Assembly Power Board/Oridion Module...

- Page 46 CORRECTIVE MAINTENANCE T H I S PA G E I N T E N T I O N A L LY L E F T B L A N K 5-16 Alaris ® EtCO Module (8300 Series) Technical Service Manual...

-

Page 49: Chapter 6 - Troubleshooting

Chapter 6 — TROUBLESHOOTING INTRODUCTION WARNING Use extreme caution in servicing the This chapter describes possible technical instrument when connected to AC power. problems and operating errors that may Hazardous voltages are present when AC occur while using the EtCO Module. -

Page 50: Technical Troubleshooting Guide

TROUBLESHOOTING Table 6-1. Technical Troubleshooting Guide Follow the steps in the order they are listed until the problem/fault is corrected. Before making a final diagnosis, visually inspect the instrument for damage and pay particular attention to the power cord and plug. Following repair/replacement, use Maintenance Software to perform the required tests (see Chapter . -

Page 51: Malfunction Codes

TROUBLESHOOTING Table 6-2. Malfunction Codes Refer to the PC Unit / Pump Module Technical Service Manual for information on viewing the Malfunction Log. Malfunction Code Subsystem Explanation Remedy Main Logic Board See NOTE See NOTE Keypad Decoder See NOTE See NOTE Keypad Decoder Comm Error See NOTE See NOTE... - Page 52 TROUBLESHOOTING T H I S PA G E I N T E N T I O N A L LY L E F T B L A N K Alaris ® EtCO Module (8300 Series) Technical Service Manual...

-

Page 55: Chapter 7 - Illustrated Parts Breakdown

NOTE: Due to product changes over time, illustrations in this chapter can differ from the instrument under service. See applicable Service Bulletins or contact Cardinal Health Technical Support for more information. PARTS LIST The parts lists include the following information for replaceable parts : •... -

Page 56: Ordering Parts

System for directions on how Parts can be ordered by writing or calling to view software version. Cardinal Health Customer Service (refer to • Part number. "General Contract Information" page at beginning of this manual). When requesting • Part description, as provided in parts list. - Page 57 ILLUSTRATED PARTS BREAKDOWN Table 7-1. Parts List (Continued) Item Part Number Description Assembly, EtCO Cable 148249-100 TC10003899 Board Assembly, Logic 146992-001 Strap, Ground, IUI Bracket Silicone Grease, Molykote Medium or equivalent As required 142794-000 Foot, Rubber 320763 Tubing, Medium Silicone, 0.030 x 0.065 x 0.18 10013667 Assembly, Rear Case (Assembled parts: Rear Case, Nameplate Label, items...

- Page 58 PNH PHH 300928 Nut, Hex, 4-40 STL PL 300345 Screw, Machine, 4-40 x PHL PNH ZNC PLT STL 305121 Screw, Machine, PNH Directions for Use, EtCO 10011281 Not sold by Cardinal Health. Alaris ® EtCO Module (8300 Series) Technical Service Manual...

- Page 59 ILLUSTRATED PARTS BREAKDOWN Figure 7-1. Housing Assembly 4 PL 2 PL 2 PL Alaris ® EtCO Module (8300 Series) Technical Service Manual...

- Page 60 ILLUSTRATED PARTS BREAKDOWN Figure 7-2. Frame/Front Case Assembly 6 PL 830 3 PL Alaris ® EtCO Module (8300 Series) Technical Service Manual...

- Page 61 ILLUSTRATED PARTS BREAKDOWN Figure 7-3. IUI Bracket/Frame Assembly Alaris ® EtCO Module (8300 Series) Technical Service Manual...

- Page 62 ILLUSTRATED PARTS BREAKDOWN Figure 7-4. Oridion Module/Power Supply Board 3 PL 6 PL 8 PL Alaris ® EtCO Module (8300 Series) Technical Service Manual...

-

Page 63: Front Case Assembly

ILLUSTRATED PARTS BREAKDOWN Figure 7-5. Front Case Assembly 841 2 PL 842 3 PL 841 3 PL Alaris ® EtCO Module (8300 Series) Technical Service Manual... -

Page 64: Rear Case Assembly/Latch Kit

ILLUSTRATED PARTS BREAKDOWN Figure 7-6. Rear Case Assembly/Latch Kit Labels (items ) are provided as separate items and as part of Rear 603 and 620 Case Assembly Kit. Reference Table , item for a list of parts included in Rear Case Assembly Kit. Nameplate Label is available only as part of Rear Case Assembly Kit. - Page 65 ILLUSTRATED PARTS BREAKDOWN Figure 7-7. EtCO Cable Assembly 7-11 Alaris ® EtCO Module (8300 Series) Technical Service Manual...

- Page 66 ILLUSTRATED PARTS BREAKDOWN T H I S PA G E I N T E N T I O N A L LY L E F T B L A N K 7-12 Alaris ® EtCO Module (8300 Series) Technical Service Manual...

- Page 68 Alaris ® and Guardrails ® are registered trademarks of Cardinal Health, Inc. or one of its subsidiaries. Microstream ® is a registered trademark of Oridion Medical 1987 Ltd. All other trademarks belong to their respective owners. Part Number 10011051 ©2005, 2006 Cardinal Health, Inc. or one of its subsidiaries. All rights reserved.

Need help?

Do you have a question about the Alaris 8300 Series and is the answer not in the manual?

Questions and answers