Table of Contents

Advertisement

Quick Links

M

LFMR6

ODEL

P

M

-R

L

ORTABLE

ID

ISE

IFT

(6,000 lb Capacity)

I

, O

NSTALLATION

PERATION AND

M

M

AINTENANCE

ANUAL

IMPORTANT!!!

READ THIS MANUAL COMPLETELY BEFORE INSTALLING OR

OPERATING THE LIFT

200 CABEL STREET, P.O. BOX 3944

LOUISVILLE, KENTUCKY 40201-3944

E-Mail - sales@challengerlifts.com

Web Site - www.challengerlifts.com

OFFICE (502) 625-0700

FAX (502) 587-1933

Advertisement

Table of Contents

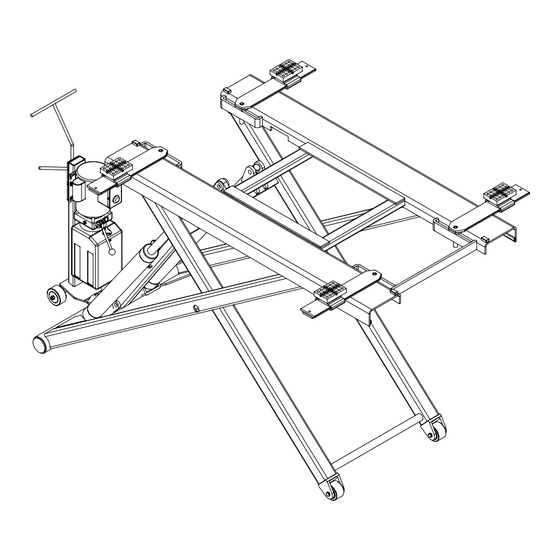

Summary of Contents for MAC TOOLS LFMR6

- Page 1 LFMR6 ODEL ORTABLE (6,000 lb Capacity) NSTALLATION PERATION AND AINTENANCE ANUAL IMPORTANT!!! READ THIS MANUAL COMPLETELY BEFORE INSTALLING OR OPERATING THE LIFT 200 CABEL STREET, P.O. BOX 3944 LOUISVILLE, KENTUCKY 40201-3944 E-Mail - sales@challengerlifts.com Web Site - www.challengerlifts.com OFFICE (502) 625-0700...

-

Page 2: General Specifications

Model LFMR6 Installation, Operation, and Maintenance GENERAL SPECIFICATIONS Maximum Capacity..................6,000 lbs Minimum Table Height ................5 1/2 inches Maximum Table Height ................53 1/4 inches Electrical Requirements ............115V, 50/60 Hz, 1 phase Lifting Time....................45 seconds Safety Lock ………………………………………………System Mechanical Safety Lock File: LFMR6-IOM.doc... -

Page 3: Safety Notices And Decals

Model LFMR6 Installation, Operation, and Maintenance Before You Begin Safety decals similar to those shown here are found on a properly installed lift. Be Safety Notices and Decals sure that all safety decals have been correctly installed on the lift. Verify that all... -

Page 4: Installation

Model LFMR6 Installation, Operation, and Maintenance Electrical Requirements Receiving For lift installation and operation, it is necessary to The shipment should be thoroughly inspected as have a dedicated 115V single-phase 60-cycle soon as it is received. The signed bill of lading is... -

Page 5: Owner/Operator Checklist

Model LFMR6 Installation, Operation, and Maintenance CAUTION The power unit operates at high the lift manufacturer’s instructions or ANSI/ALOIM- pressure. 2000, American National Standard for Automotive Lifts-Safety Requirements Operation, Raise and lower lift a few times and check hose Inspection and Maintenance; and the employer and fittings for leaks and tighten if required. - Page 6 Model LFMR6 Installation, Operation, and Maintenance Operating Instructions NOTE: After reviewing these instructions and all decals, get familiar with lift controls by running the lift through a few cycles before loading vehicle on lift. Loading Vehicle Ladder 1. Be sure lift is fully lowered and service bay is clear of all personnel before the vehicle is driven on to lift.

-

Page 7: Lowering Vehicle

Model LFMR6 Installation, Operation, and Maintenance CAUTION Most specialty or modified vehicles Raising Vehicle cannot be raised on a frame engaging or pad lift. Contact vehicle manufacturer for raising 4. To raise lift: or jacking details. Actuate RAISE switch on electric power unit. -

Page 8: Maintenance

Model LFMR6 Installation, Operation, and Maintenance MAINTENANCE NOTE: To avoid personal injury, permit only qualified personnel to perform maintenance on this lift. See repair parts breakdown for replacement parts. ALWAYS: Keep all bolts tight. Check periodically. ALWAYS: Keep lift clean. Raise lift when cleaning floor area. -

Page 9: Parts Breakdown

Model LFMR6 Installation, Operation, and Maintenance ARTS REAKDOWN Description Part # Description Part # Scissor Outside Safety Locking Pin (Bottom) GTYJ3-01-00 TYJ3-08 Scissor Inside Safety Locking Pin (Top) GTYJ3-03-00 TYJ3-10 Platform Locking Nut, M18 GTYJ3-02-00 SR-0114 Cylinder Assy. Cylinder Pin... - Page 10 Model LFMR6 Installation, Operation, and Maintenance AFETY SSEMBLY Qty. Description Part # Lock Sheath GTYJ3-07-02 Lock Pole GTYJ3-07-01 Base TYJ3-07-05 Bolt, M8 S251397 Washer, M8 SR-0112 Pulley Assy. TYJ3-07-04 Spring TYJ3-07-06 Lock Block TYJ3-07-03 GB879-86 File: LFMR6-IOM.doc Rev: 2/22/08...

- Page 11 Model LFMR6 Installation, Operation, and Maintenance OWER TAND OLLY SSEMBLY NSTRUCTIONS Part # Qty. Description Part # Qty. Description TYJ3-00-01-1 Handle ZVS1882 Lock Washer, M8 TYJ3-00-01-2-1 Stand S251401 Bolt, M8x25 TYJ3-00-01-2 Base SR-0112 Washer, M8 AB-1653-B Electric/Hyd. Unit X10-040 Nut, M8...

- Page 12 Model LFMR6 Installation, Operation, and Maintenance YDRAULIC ELEASE REAKDOWN Part # Qty. Description TYJ3-25 Hydraulic Hose Short TYJ3-31 Lock Release Cable TYJ3-26 Hydraulic Hose Long 16167 Hyd. Elbow; 9/16-18 O-Ring x 37 deg Male 66020 ¼ NPTM x #6 JIC 37 deg Female File: LFMR6-IOM.doc...

Need help?

Do you have a question about the LFMR6 and is the answer not in the manual?

Questions and answers