Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Trebor MAGNUM 610R

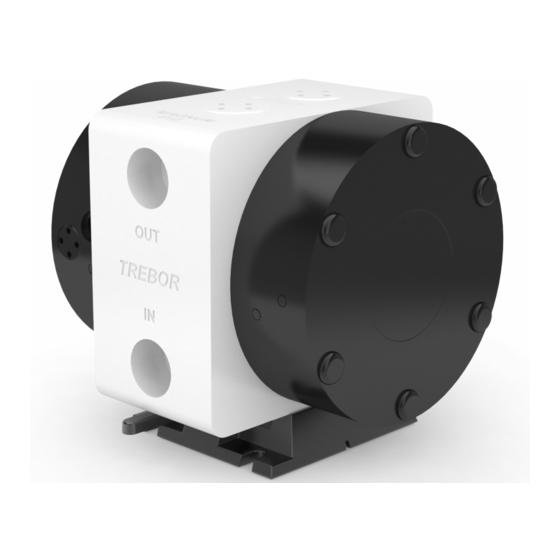

- Page 1 Phone: 800-669-1303 or 801-561-0303 Fax: 801-255-2312 e-mail: treborservice@idexcorp.com MAGNUM 610R PUMP Operation / Maintenance Manual SERIAL NUMBER (located on top of product): 1/29/2014 – M610R-B PATENTS: U.S. 09642426, U.S. 06106246, U.S. 05971402, U.S. 05370507...

-

Page 2: Table Of Contents

Dry Pump ..................... 20 4.9.c Dry Suction ..................20 TROUBLESHOOTING ....................21 WARRANTY ....................... 23 CONTACT INFORMATION ..................24 GENERAL CONTACT INFORMATION ............24 TECHNICAL SUPPORT ................... 24 REGIONAL REPRESENTATIVES ..............24 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL CONTENTS... -

Page 3: Installation

The tie bolts on the pump are tightened before leaving the factory. However, relaxation may occur due to handling, material creep, or other unforeseen events. Trebor recommends that all eight tie bolts be re-tightened upon pump install. The following procedure should be used. - Page 4 ATTENTION: The pump should be operated with clean, dry air or nitrogen. Particulate, water and oils in the air supply can damage the pump. NOTE: 1. It is recommended that a filter be placed on the discharge side of the pump. PAGE 4 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL...

-

Page 5: See Section 4.1 Preventative Maintenance Schedule For Additional Requirements For High Temperature Applications

NOTE: Air consumption during “Dead Cycling” is very little since the pump diaphragms are displacing only internal bypass. “Dead Cycling” should be considered as a normal standby idle mode. MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 5... - Page 6 Turn adjustment screw clockwise (CW) to increase backpressure. Turn adjustment screw counter-clockwise (CCW) to decrease backpressure. NOTE: Loosen locking nut prior to making adjustment, then re-tighten nut to maintain adjustment. PAGE 6 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL...

-

Page 7: Options

FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP Surge Suppressor Assembled Height: IN (CM) SS75 12.29 (31.21) SS85 14.82 (37.65) SS40 12.37 (31.43) Figure 2-2 NOTE: See Surge Suppressor Operation Manual for detailed installation instructions. MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 7... -

Page 8: Start-Up

Pressure Fluid Used Pressure Minute Cycle (PSIG) (PSIG) (SCFM) 10.4 10.5 10.5 10.5 10.2 10.6 Table 1: Consumption / Efficiency NOTE: Specification to be used to size regulators and control valves. PAGE 8 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL... - Page 9 Figure 3-1: Pressure & Capacity Chart NOTE: Test information is based on specific conditions and limited sampling. Use for general reference only. MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 9...

-

Page 10: Maintenance

If the pump has exceeded its useful life and cannot be rebuilt, the customer may elect to purchase a new Trebor pump. If the customer chooses not to rebuild or replace the pump, a $150.00 evaluation charge will be required. - Page 11 *Extreme operating conditions are applications requiring high suction or the fluid is HF, ACT 935, or TMAH (strong etchants) **Required if operating temperature exceeds 60°C or thermal cycling occurs ***Required if fluid is ACT 935 or TMAH MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 11...

-

Page 12: Preventive Maintenance Record

Notes: ________________________________________ ________________________________________ Date: ________ Tech: _____ Notes: ________________________________________ ________________________________________ Date: ________ Tech: _____ Notes: ________________________________________ ________________________________________ Date: ________ Tech: _____ Notes: ________________________________________ ________________________________________ Date: ________ Tech: _____ Notes: ________________________________________ ________________________________________ PAGE 12 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL... -

Page 13: Recommended Spare Parts

98003305 Drive Handle T000B0014 Check Sleeve Removal Tool T000B0020 Check Sleeve Insertion Tool T0123 Shuttle Sleeve Tool 3/4” Pin Tool T0146 1/2” Pin Tool T0148 T16002104 Shaft Bullet T0144 Cleaning Tool MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 13... -

Page 14: Parts Illustration

PARTS ILLUSTRATION PAGE 14 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL... -

Page 15: Parts List

Thoroughly clean / flush the pump using DI water (Refer to Section 4.6 Clean Up). Unlock pump from quick release base by pulling out locking lever on front of base. Then slide pump forward until it stops. Lift pump off base. MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 15... -

Page 16: Body Disassembly

Remove the pilot valves from the master and slave heads, with 1/2” nut driver. PAGE 16 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL... -

Page 17: Assembly

Body must be upside down with check port extending over a table edge so that parts remain assembled during insertion of sleeves. (See Figure 4-2.) MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 17... - Page 18 Additionally apply a ¼” turn to ensure proper installation. Insert shaft through shaft bore using shaft bullet as shown (This prevents damage to the TFE shaft seals and prevents dislodgement of shaft seals). PAGE 18 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL...

-

Page 19: Final Assembly

42 in-lbs. Install tie bolt caps and check muffler assembly. Install pump onto base and slide back. Use locking lever to secure. MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 19... -

Page 20: Testing

Turn off Air Supply and allow the pump to purge for 5 minutes. 4.9.c Dry Suction 20 psig Supply Pressure Target Record Suction Value Target = 8 in-Hg. PAGE 20 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL... -

Page 21: Troubleshooting

Check bore cap. Replace diaphragms, and any parts that may have been Ruptured diaphragm(s) can result in fluid leaks through air exhaust port and damaged by fluid exposure. shuttle valve. MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL PAGE 21... - Page 22 Additional TFE thread tape on pilot valve threads. Check diaphragm hole alignment. Replace O-ring seals. Pilot valve transfer O-rings leaking. Replace check balls and O-rings. Check ball(s) not seating. PAGE 22 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL...

-

Page 23: Warranty

Operation/Maintenance Manual. TREBOR’s obligation under this warranty is limited to repairing or replacing, at TREBOR’s option and at the TREBOR factory, any part or parts thereof which shall, within 1 year after delivery thereof to the original purchaser, be demonstrated to TREBOR’s satisfaction to have been defective. -

Page 24: Contact Information

Fax Number: (801) 255-2312 Email: treborinfo@idexcorp.com treborsales@idexcorp.com Address: Trebor International 8100 South 1300 West West Jordan, Utah 84088 U.S.A. TECHNICAL SUPPORT Email: treborservice@idexcorp.com Phone Number: (801) 244-6156 REGIONAL REPRESENTATIVES Web: http://www.treborintl.com/about_contact_us.asp# PAGE 24 MAGNUM 610R PUMP OPERATION / MAINTENANCE MANUAL...

Need help?

Do you have a question about the MAGNUM 610R and is the answer not in the manual?

Questions and answers